Cosmetic applicator and process for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

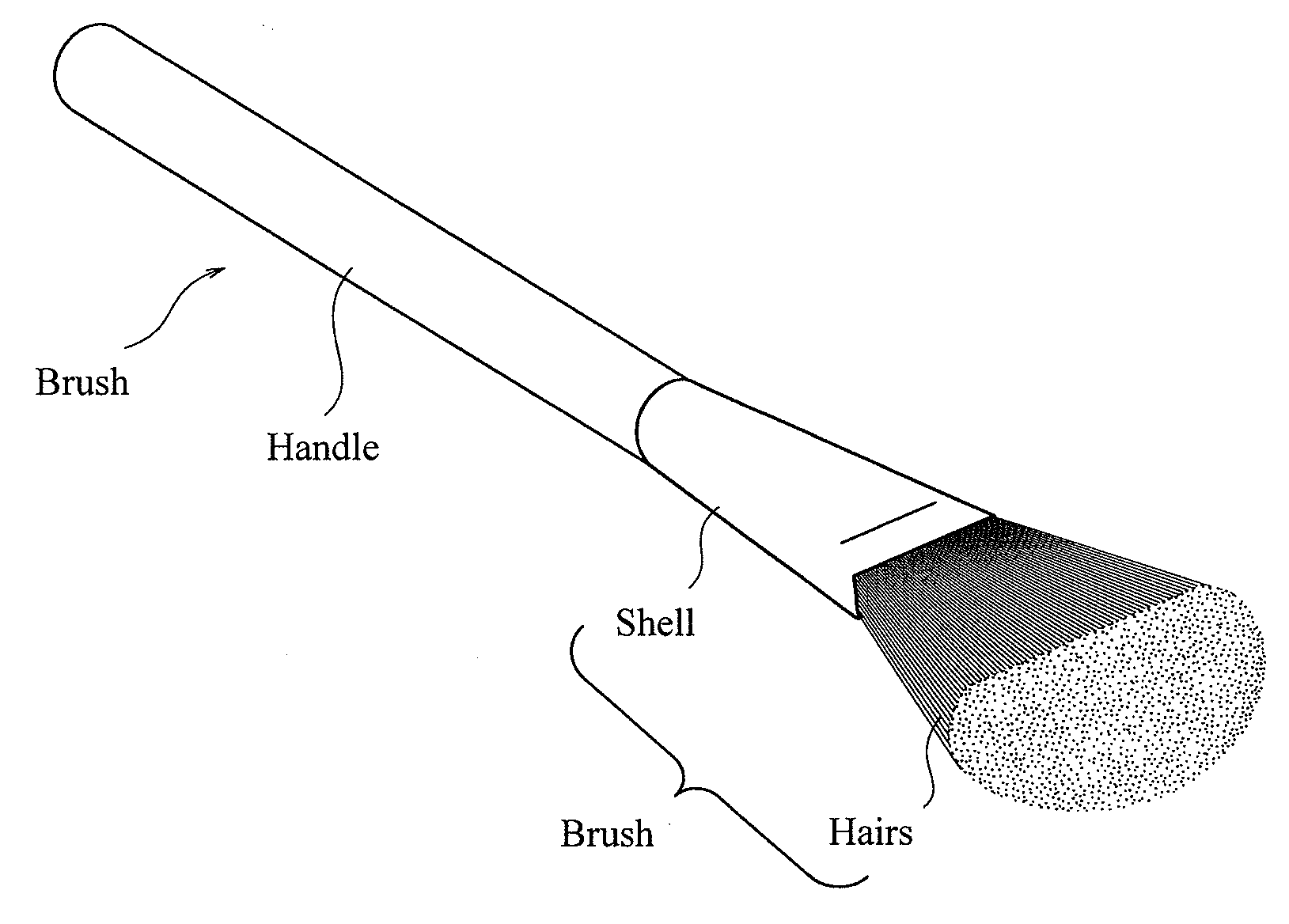

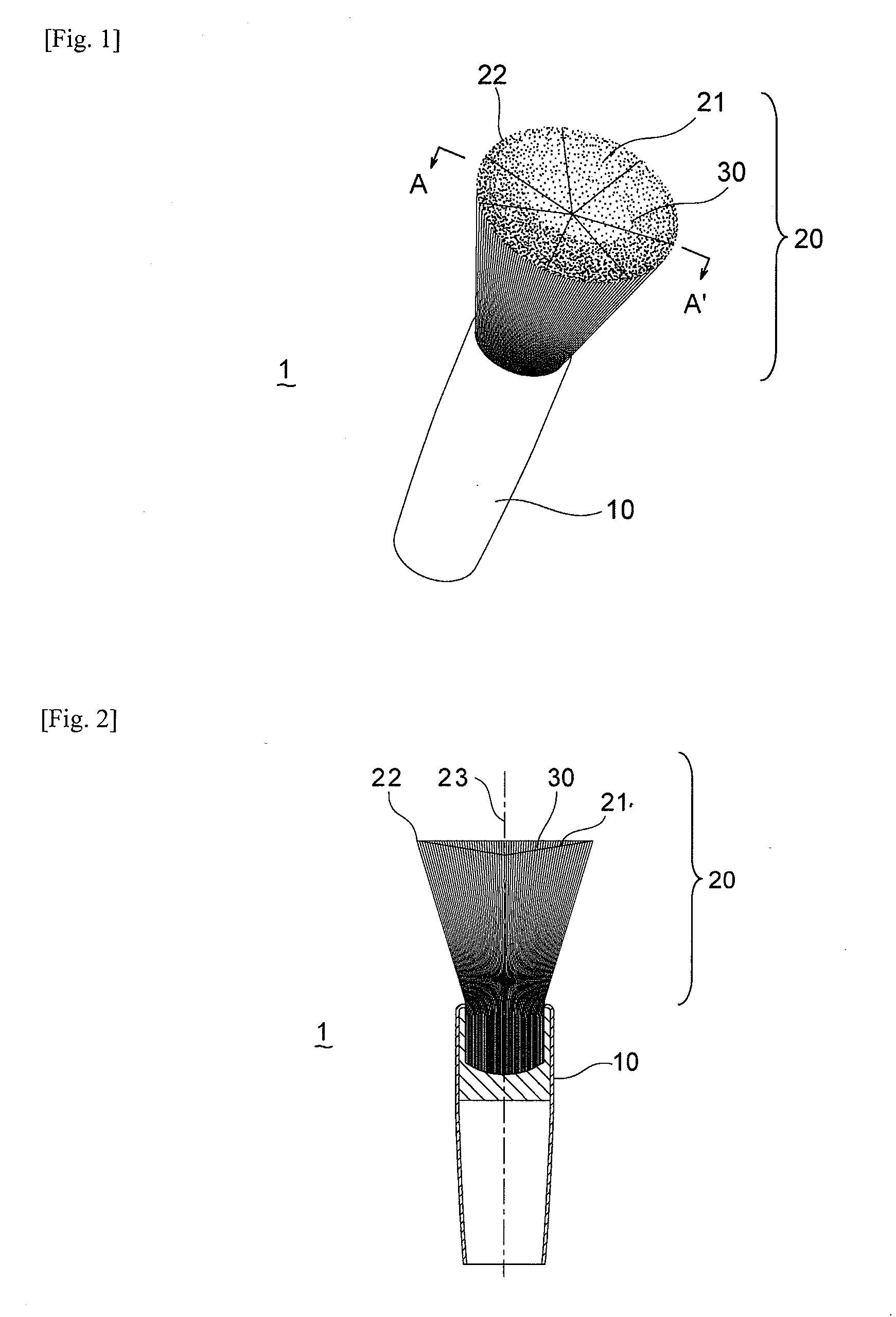

[0033]FIG. 1 is an oblique view showing the first embodiment of a cosmetic applicator 1 conforming to the present invention.

FIG. 2 is a section view that cuts FIG. 1 showing the cosmetic applicator 1 described in the first embodiment along the A-A′ plane.

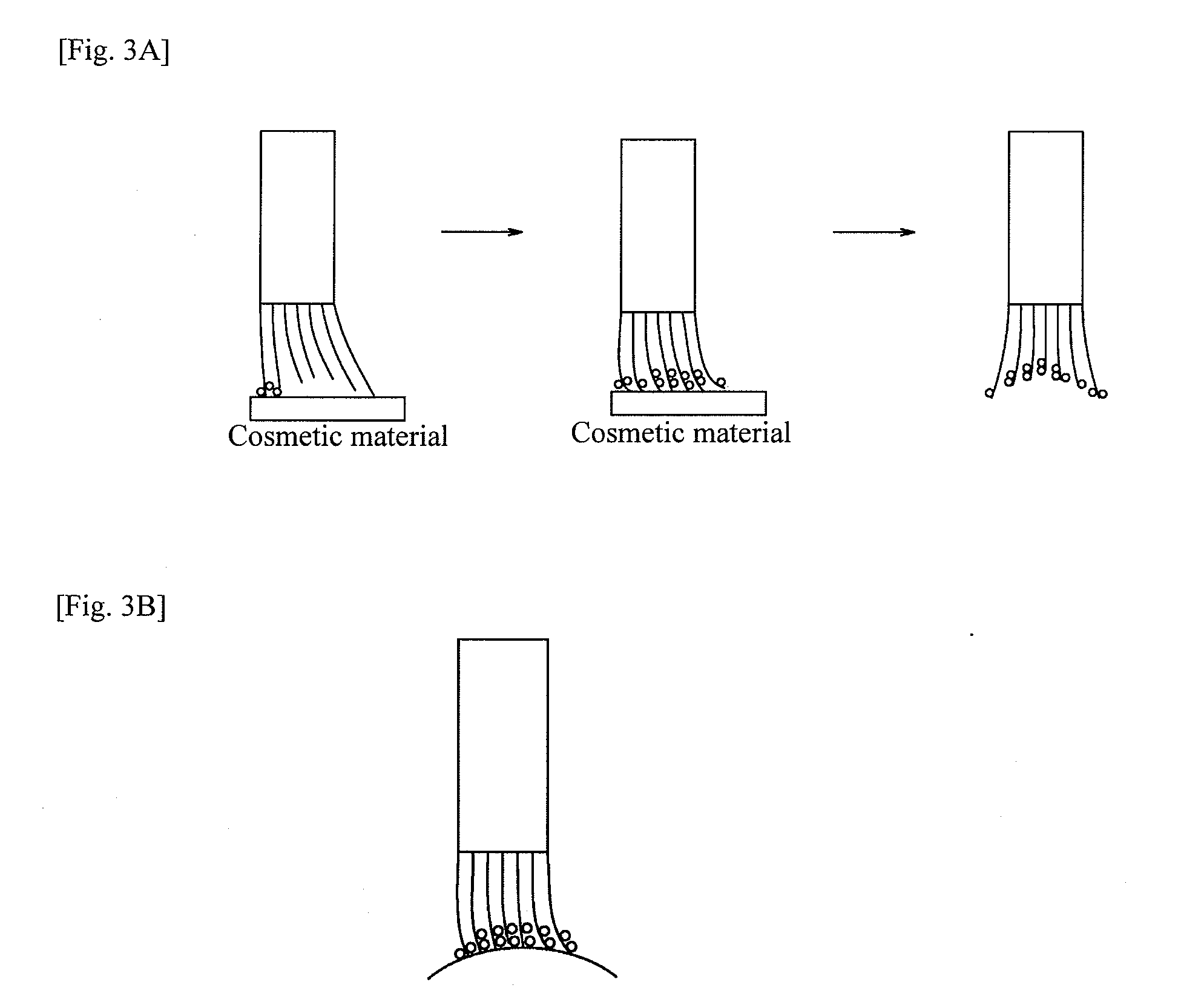

[0034]As shown in FIGS. 1 and 2, the cosmetic applicator 1 described in the present embodiment is a cosmetic applicator for applying cosmetic material, equipped with a handle part 10 having roughly a cylindrical shape and also with a brush part 20.

The tip of the aforementioned handle part 10 forms a surface which is cut vertically with respect to the center axis 23 of the handle part 10, and hairs are implanted onto this surface to form the brush part 20. The hairs expand from the tip of the aforementioned handle part 10 in the shape of a reverse cone.

[0035]With the cosmetic applicator 1 conforming to the present invention, the aforementioned handle part 10 is not limited to one having roughly a cylindrical shape and a handle part o...

second embodiment

[0045]FIG. 4 is an oblique view showing the second embodiment of a cosmetic applicator 1 conforming to the present invention.

FIG. 5 is a section view that cuts FIG. 4 showing the cosmetic applicator 1 described in the second embodiment along the A-A′ plane.

The cosmetic applicator 1 described in the second embodiment is different from the cosmetic applicator 1 described in the aforementioned first embodiment mentioned only in that the gradually concaving shape of the applicator in the second embodiment forms a curved surface 31. However, all other aspects of the second embodiment conform to the same constitution of the cosmetic applicator 1 in the aforementioned first embodiment mentioned.

Since the gradually concaving shape is a curved surface 31, more cosmetic material is transferred onto the tip of hairs and overall the amount of cosmetic material transferred onto the apical surface of brush 21 can be kept constant.

[0046]Also because the apical surface of brush 21 is a curved surfa...

third embodiment

[0047]FIG. 6 is an oblique view showing the third embodiment of a cosmetic applicator 1 conforming to the present invention.

FIG. 7 is a section view that cuts FIG. 6 showing the cosmetic applicator 1 described in the third embodiment along the A-A′ plane.

The cosmetic applicator 1 described in the third embodiment is different from the cosmetic applicator 1 described in the aforementioned first embodiment mentioned only in that the gradually concaving shape of the applicator in the third embodiment is steps 32. However, all other aspects of the third embodiment conform to the same constitution of the cosmetic applicator 1 in the aforementioned first embodiment mentioned.

[0048]The cosmetic applicator 1 in the third embodiment has its apical surface of brush 21 formed in a shape gradually concaving in a stepwise manner from the outer periphery 22 of the brush toward the center axis 23 (a shape concaving by drawing concentric circles). The number of steps to be provided can be adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com