Production method of bamboo louvre blade

A manufacturing method and technology of venetian blinds, applied in the field of bamboo chip manufacturing, can solve problems such as unsmooth operation, affecting product life, environmental damage, etc., and achieve the effect of increasing its use efficiency, improving service life, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

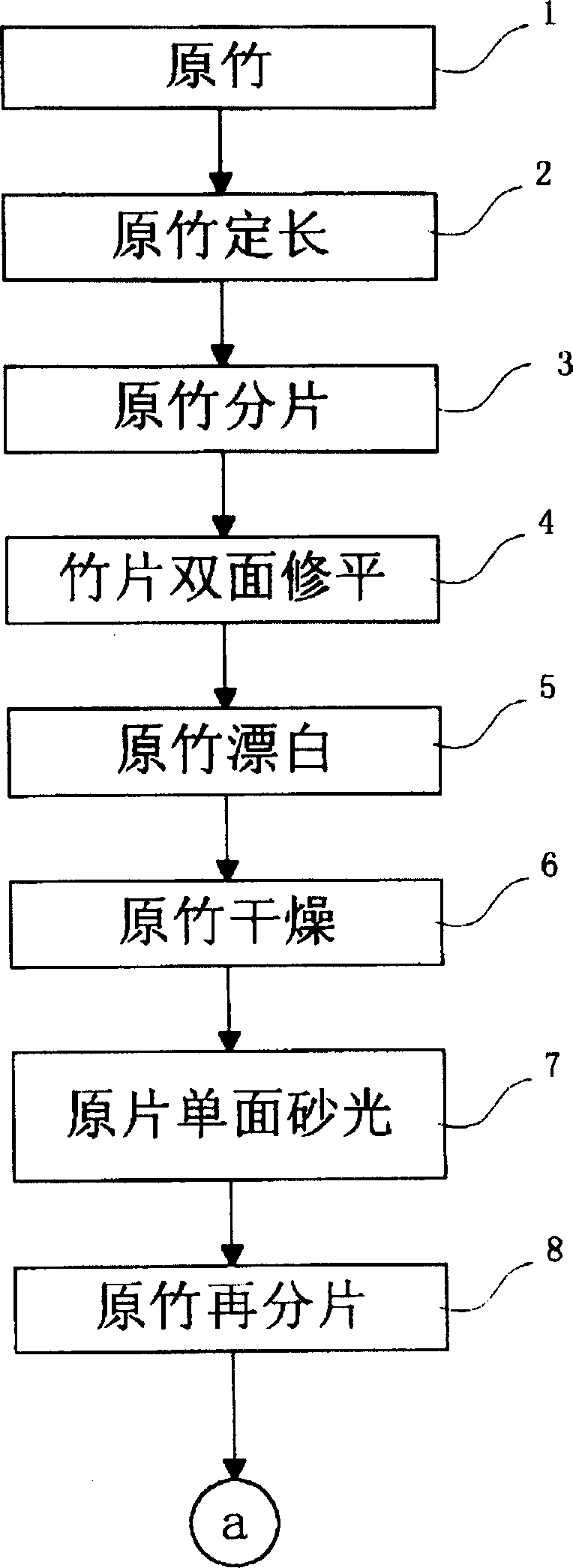

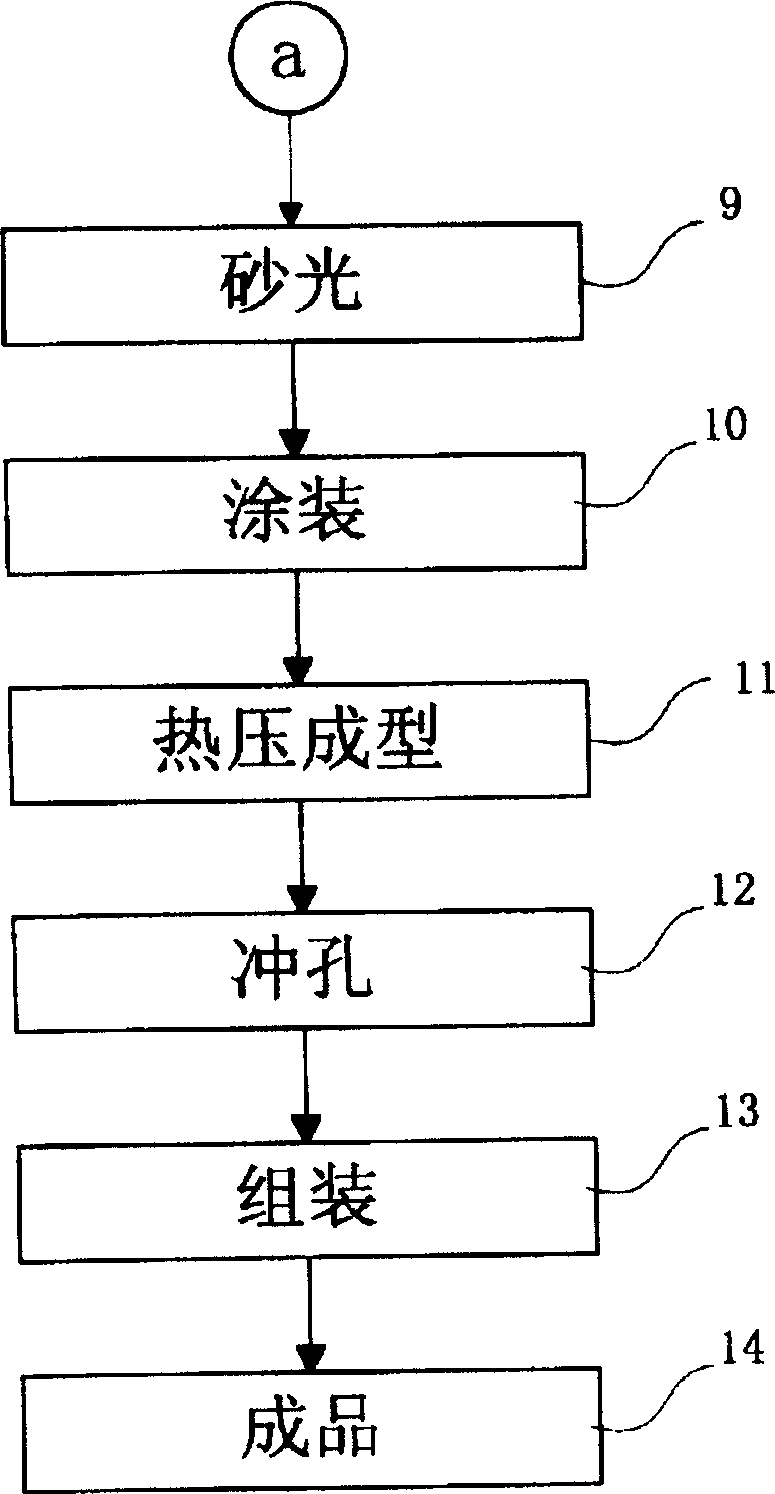

[0034] see figure 1 and figure 2 , as shown in the figure, the present invention is a manufacturing procedure for bamboo venetian blind blades, which is divided as follows according to the processing steps:

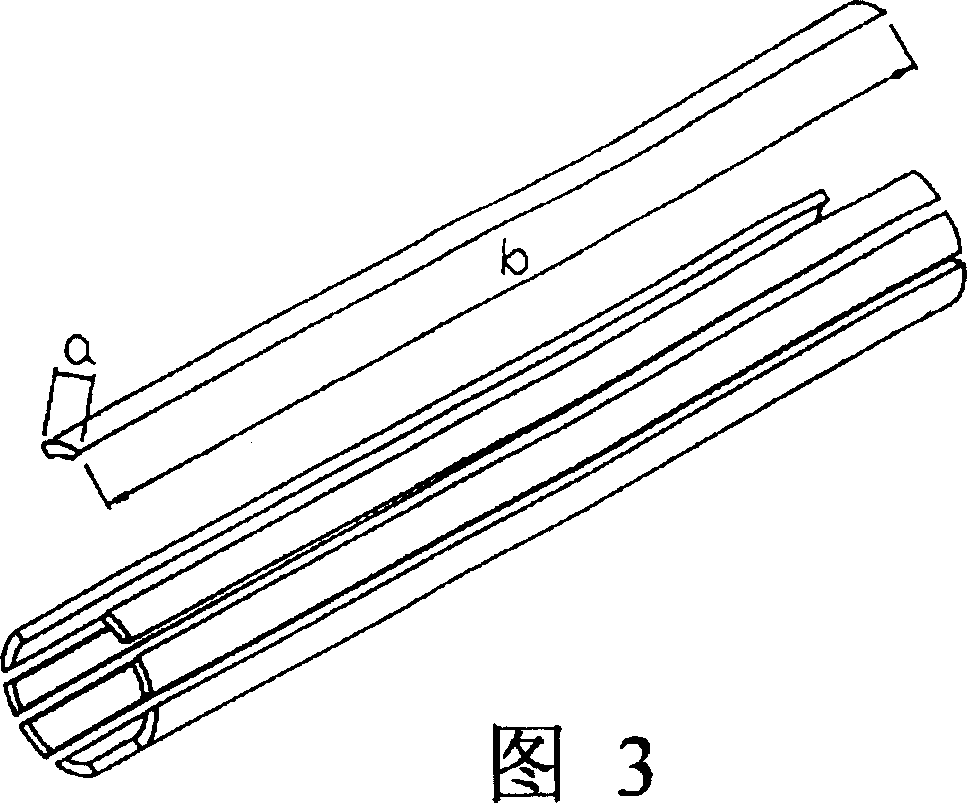

[0035] (1) at first select suitable original bamboo 1, bamboo material is mainly with bamboo and hemp bamboo, and this original bamboo 1 is four to five years with growth period, and the diameter of raw bamboo is more than 9 ", and thickness is 10mm. And bamboo The root is mainly more than 10cm, and try to choose the original bamboo 1 with less curvature, which is easier to process; and the original bamboo is fixed to the length 2, that is, cut to the required length b, and the length is required for the production size ; The former bamboo sub-sheet 3 is made to make its width a be a bamboo strip of 28mm (as shown in Fig. 3 and Figure 4 shown).

[0036] (2) The two sides of the bamboo slice 100 are flattened 4, and the part of the inner bamboo joint and the outer bam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com