Mechanical maze puzzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

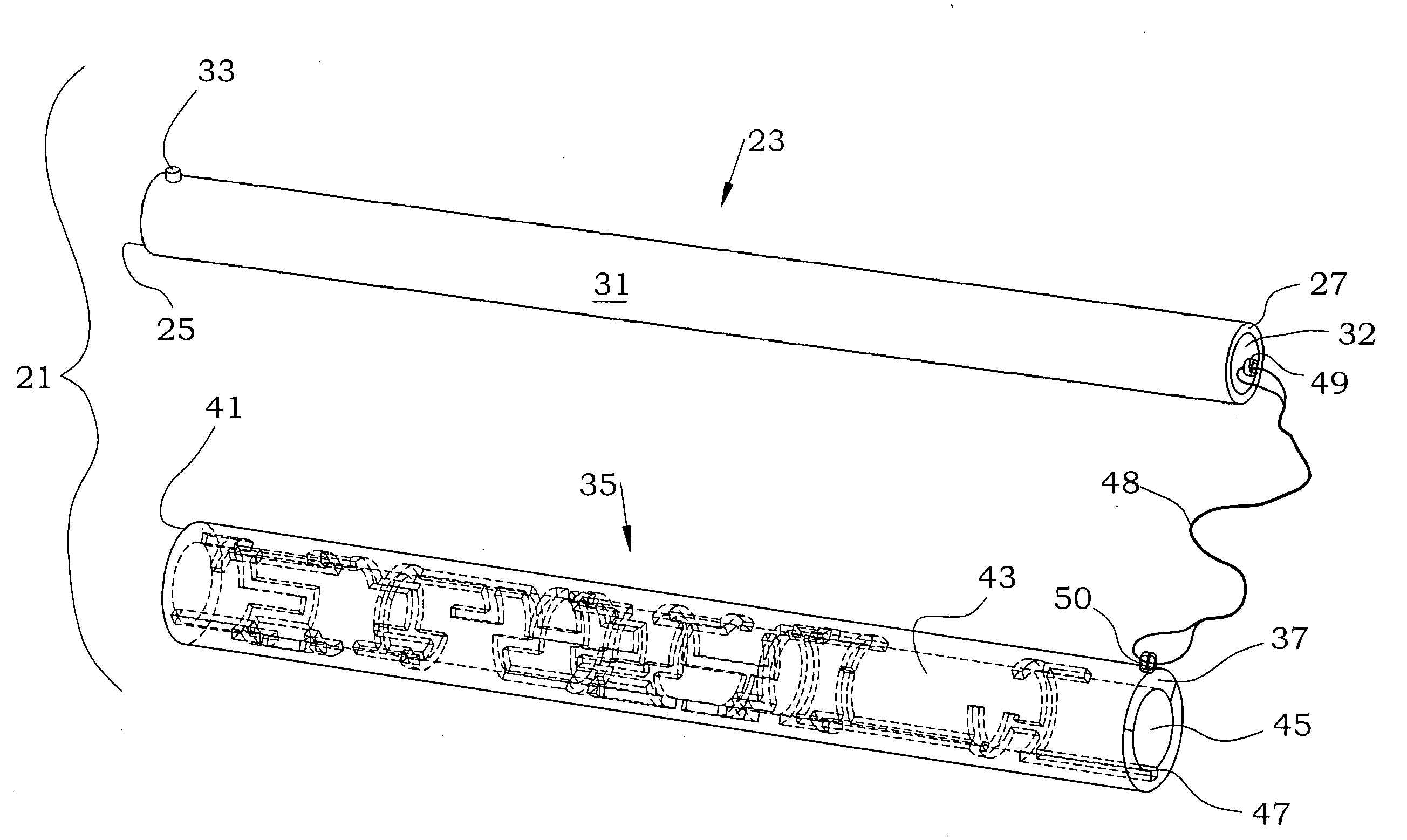

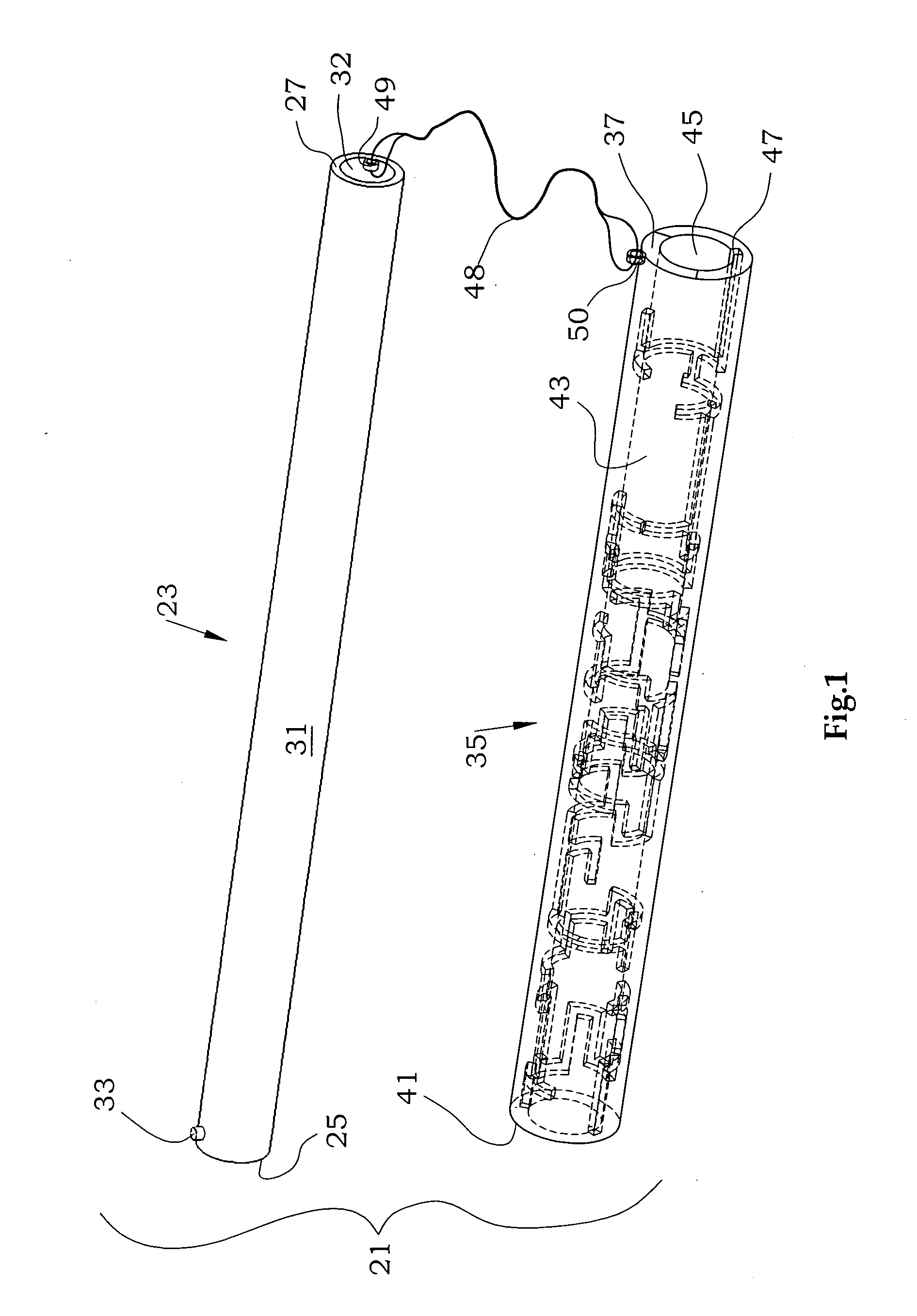

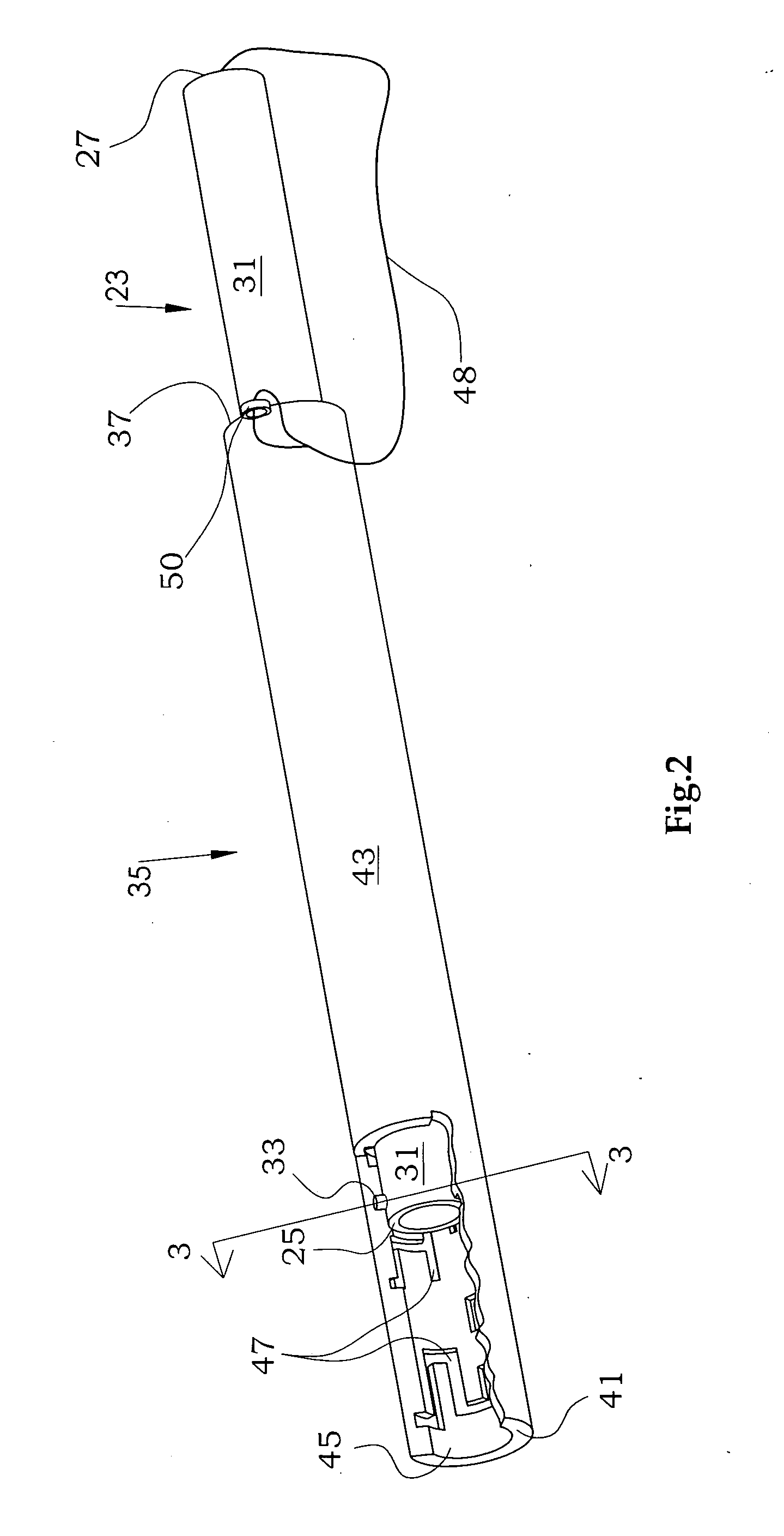

[0034]The description and operation of the invention will be best initiated with reference to FIG. 1, which is an exploded perspective view of the invention seen as puzzle 21 of the present invention.FIG. 1 illustrates a first cylinder 23 having a first end 25, a second end 27, an outer surface 31, an inner surface 32, and a pin 33 projecting from outer surface 31 near first end 25. Although pin 33 may be any size, it may preferably be about ⅛ of an inch in diameter and may project about ⅜ of an inch away from outer surface 31. Pin 33 may be formed integrally with the first cylinder 23, may be formed and inserted in a bore formed in first cylinder 23, or may be attached to first cylinder 23 in any other manner.

[0035]FIG. 1 illustrates a second cylinder 35 having a first end 37, a second end 41, an outer surface 43 and an inner surface 45 into which a groove 47 is cut to form a maze pattern. Groove 47 may be formed by cutting, routing, pressure impression, or other manufacturing tech...

second embodiment

[0048]FIG. 5 is a cutaway perspective view of the invention seen as puzzle 55, which is similar to puzzle 21 of FIGS. 1 and 2 except for modifications to second cylinder 35, described as follows. In FIG. 5, second cylinder 35 is closed at second end 41 by end piece 57. End piece57 may be formed simultaneously with second cylinder 35 or may be formed separately as a cap or plug type closure. End piece 57 is adjacent a spring 61 which extends into an accommodation space 63 adjacent second end 41 of second cylinder 35. Groove 47 (not shown in FIG. 5) may or may not extend the full length of inner surface 45 of second cylinder 35.

[0049]A canister 65 may fit into accommodation space 63 such that when first cylinder 23 is advanced toward canister 65, first end 25 of first cylinder 23 exerts force on canister 65, which compresses spring 61 in turn. Groove 47 may preferably be designed so that moving pin 33 into a blind passage of groove 47 causes canister 65 to be trapped by first cylinder...

third embodiment

[0052]FIG. 6 is a cutaway perspective view of the invention seen as puzzle 71, which is similar to puzzle 21 of FIGS. 1 and 2 except for a added features as follows. Second end 27 of first cylinder 23 may include a large-diameter handle 73, and second end 41 of second cylinder 35 may similarly include a large-diameter handle 75. Second cylinder 35 may also include a pin 77 projection from outer surface 43 adjacent first end 37. Handles 73 and 75 may preferably be approximately 2 inches in length, potentially increasing the overall length of first and second cylinders 23 and 35 by about 2 inches each.

[0053]Puzzle 71 may further include a third cylinder 81 having a first end 83, a second end 85, an outer surface 87, and an inner surface 91. The length of cylinder 81 may preferably be about 12 inches to match the preferred length of the main portion of first and second cylinders 23 and 35. Third cylinder 81 may include a groove 93 on its inner surface 91 and may have a diameter larger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com