Wear-resistant zirconium-aluminum composite ball and preparation method thereof

A technology of wear-resistant zirconium-aluminum and composite balls, which is applied in the field of ceramic balls, can solve the problems of difficult marketing, high raw material costs, and high costs, and achieve optimal reuse, good mechanical properties, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

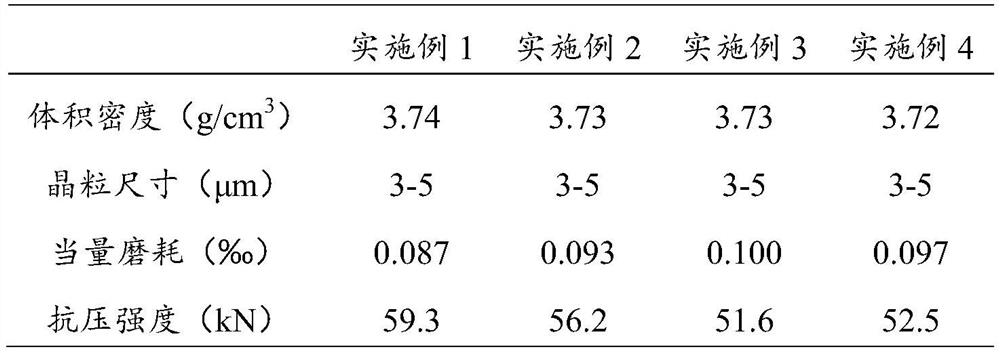

Examples

preparation example Construction

[0048] Correspondingly, the preparation method of the wear-resistant zirconium-aluminum composite ball includes the following steps:

[0049] S1. Preform ball milling: Add the raw materials of wear-resistant zirconium-aluminum composite balls into the ball mill according to the proportion, add the dispersion solution and mix evenly to obtain the slurry;

[0050] S2. Drying and granulating: granulating the slurry to obtain dry powder;

[0051] S3. Forming and drying: dry the powder after cold isostatic pressing or pellet forming to make green balls;

[0052] S4. Sintering: the green balls are sintered in a kiln, and taken out after the kiln is cooled to obtain wear-resistant zirconium-aluminum composite balls.

[0053] The preparation method of the wear-resistant zirconium-aluminum composite ball provided by the present invention has a simple process, uses a variety of solid wastes as raw materials, and can realize the comprehensive utilization of solid wastes. The following i...

Embodiment 1

[0072] Wear-resistant zirconium-aluminum composite ball and preparation method thereof,

[0073] The raw material formula is (by mass fraction): 68% of industrial alumina powder, 25% of waste zirconium corundum powder, 1% of talc, 5% of dolomite, and 1% of bentonite.

[0074] The chemical composition is calculated by mass fraction: Al 2 o 3 81.6%, ZrO 2 7.6%, SiO 2 5.2%, CaO 1.7%, MgO 1.4%, K 2 O 0.5%, Na 2 O 0.7%.

[0075] The preparation method of the wear-resistant zirconium-aluminum composite ball comprises the following steps:

[0076] S1. Preform ball milling: Weigh the raw materials into the ball mill according to the proportion, add water, polyacrylamide and polyvinyl alcohol PVA, wherein the amount of polyacrylamine added is 0.2%, and the amount of polyvinyl alcohol added is 0.2%. 0.4%, the rest is water. Ball mill for several hours to make the slurry particle size D90≤6μm.

[0077] S2. Drying and granulation: sending the slurry into a spray granulation to...

Embodiment 2

[0081] The raw material formula is (by mass fraction): 74% of industrial alumina powder, 20% of waste zirconium corundum powder, 5% of dolomite, and 1% of bentonite.

[0082] The chemical composition is calculated by mass fraction: Al 2 o 3 85.2%, ZrO 2 6.1%, SiO 2 4.9%, CaO 1.6%, MgO 1.7%, K 2 O 0.5%, Na 2 O 0.7%.

[0083] The preparation method of the wear-resistant zirconium-aluminum composite ball includes the following steps:

[0084] S1. Ingredients ball mill: Weigh the raw materials into the ball mill according to the proportion, add water, polyacrylamide and polyvinyl alcohol PVA, wherein the addition amount of polyacrylamine is 0.2% and the amount of polyvinyl alcohol is 0.4% in terms of mass fraction , and the rest is water. Ball mill for several hours to make the slurry particle size D90≤5μm.

[0085] S2. Drying and granulation: sending the slurry into a spray granulation tower for granulation to obtain dry powder.

[0086] S3. Forming and sintering: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com