Method and System for Building Modular Structures from Which Oil and Gas Wells are Drilled

a technology of modular structure and well, which is applied in the direction of drilling rods, drilling pipes, artificial islands, etc., can solve the problems of affecting wildlife breeding areas and/or migration paths, damage to terrain, and general soft ground for trucks and other heavy equipment, so as to minimize the environmental impact of associated drilling and improve the overall efficiency of drilling platform disposed, efficient equipment disposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

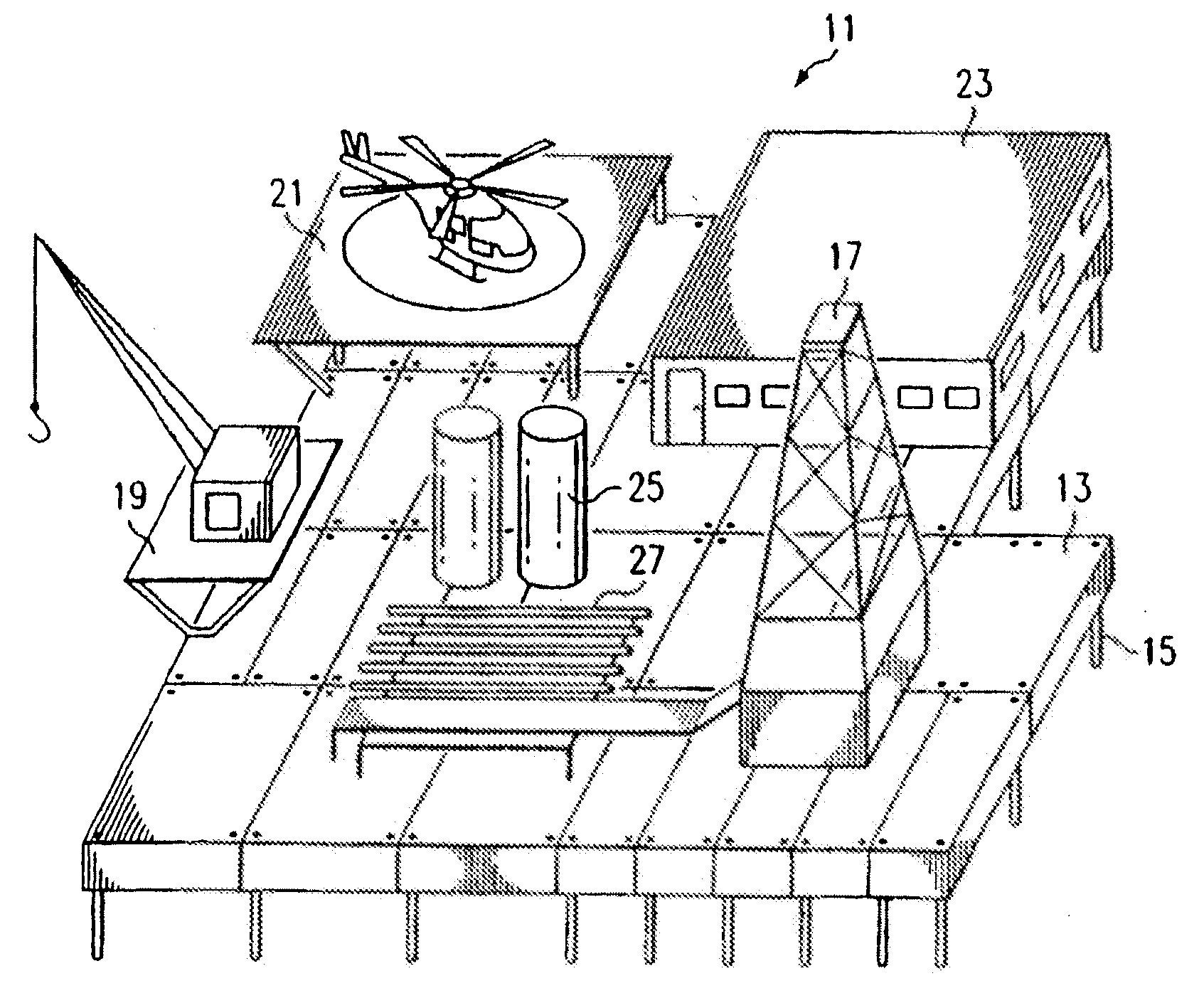

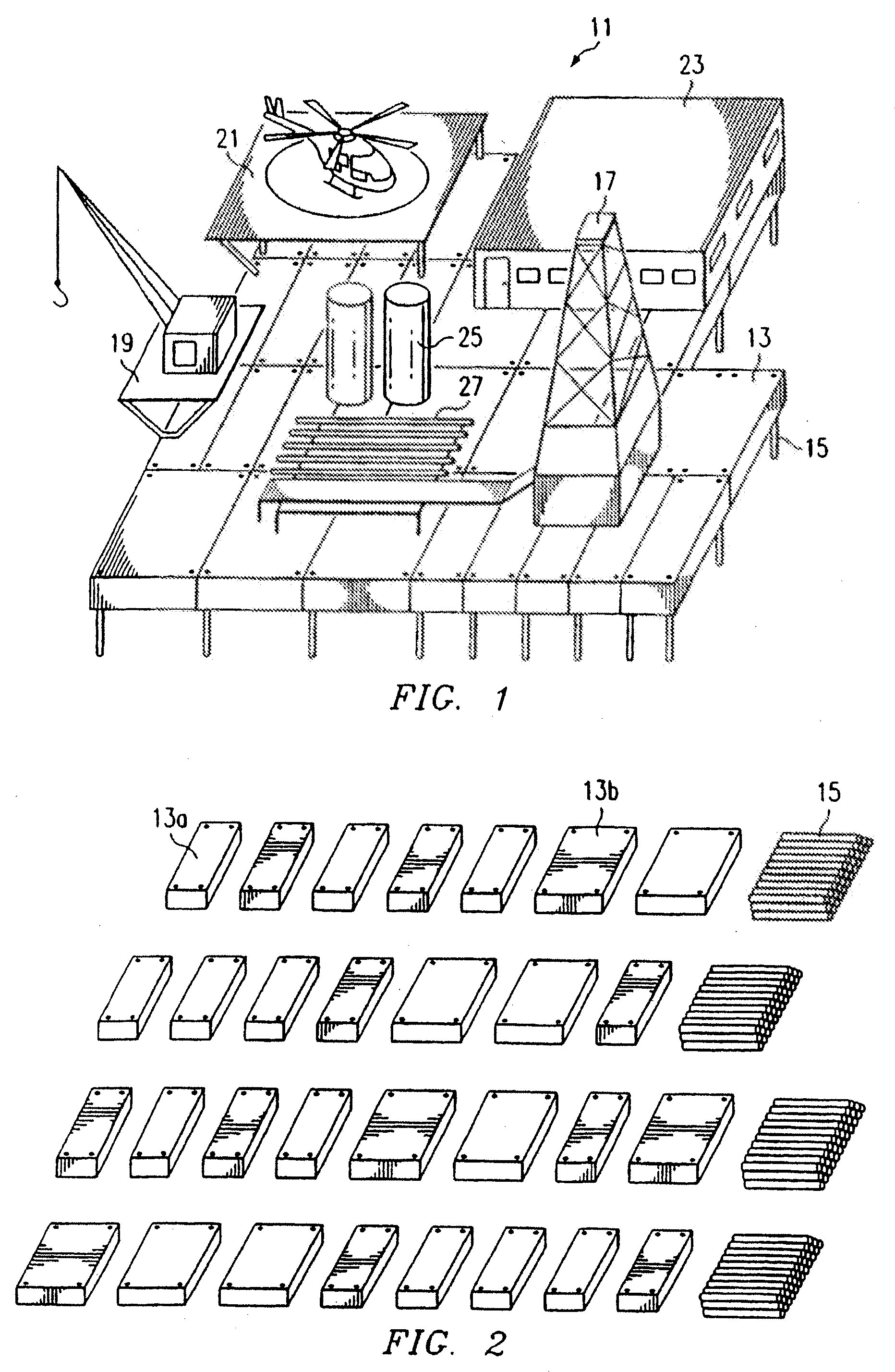

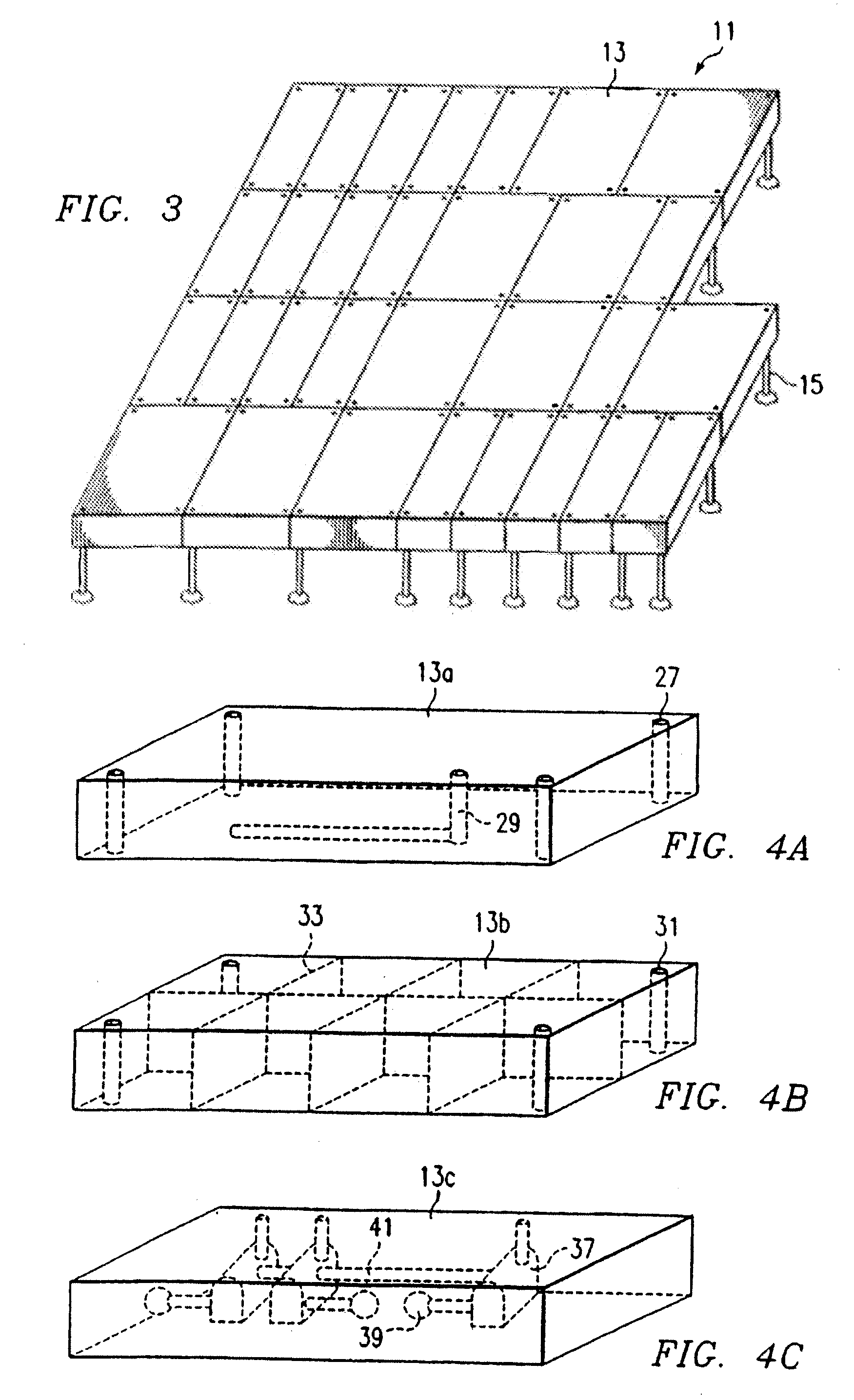

[0041]Referring now to the example embodiment shown in FIG. 1, a drilling platform 11 is illustrated comprising a plurality of interconnected platform modules 13 elevated above the ground on a plurality of legs 15. According to a further embodiment of the invention, platform 11 is adapted to support various types of equipment and facilities used in oil and gas drilling or production operations, for example, a derrick 17, a crane 19, a helicopter pad 21, a drilling fluid handling enclosure 23, bulk storage tanks 25, and oilfield tubular goods 27. The equipment and facilities illustrated in FIG. 1 are non-limiting, and those of ordinary skill in the art will appreciate that many other types of facilities and equipment may be included on platform 11 without departing from the scope or spirit of the present invention.

[0042]According to a further example embodiment, drilling platform 11 is constructed by transporting a plurality of interconnectible platform modules 13 and a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com