Liquid carbon dioxide absorbent and methods of using the same

a liquid carbon dioxide and absorbent technology, applied in the direction of emission prevention, other chemical processes, separation processes, etc., can solve the problems of unable to vary independently, amine-based systems are not designed for processing large volumes of flue, and the overall cost of electricity for pc plants is 83% higher than the average, so as to achieve low cost, high thermal stability, and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-12

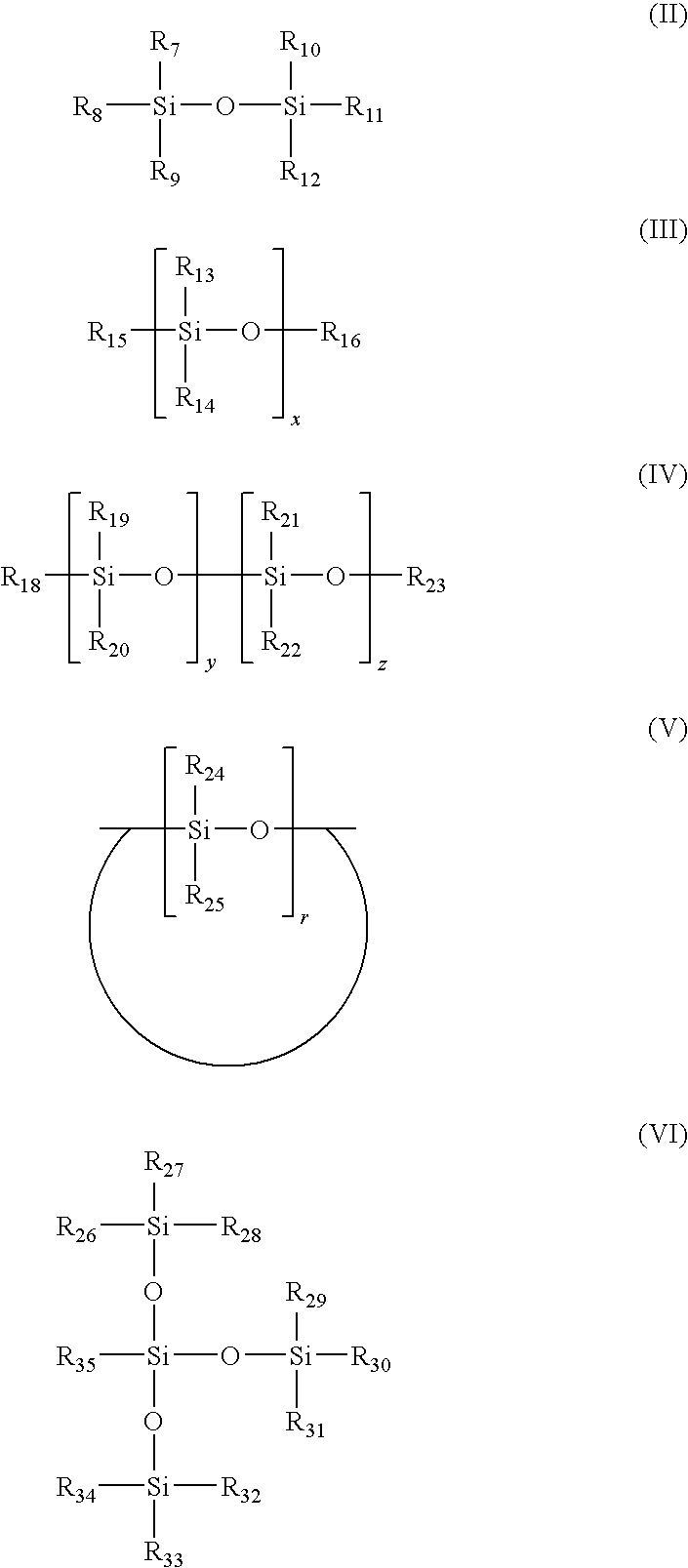

[0035]Reaction of silicon-based materials with CO2 in the presence of a hydroxy-containing co-solvent.

[0036]To illustrate the ability of the hydroxy-containing co-solvent triethylene glycol to enhance the CO2 absorption of various silicon-based materials as well as provide a liquid medium, the following Examples 1-12 were conducted. The silicon-based materials were exposed to 1 atmosphere of CO2 in the presence of, or not in the presence of, the hydroxyl-containing co-solvent triethylene glycol (at 50 wt %, with the exception of example 4 at 75 wt %) at 40° C. for 2 hours (h) with mechanical stirring.

example 2

[0038]2.0194 g of 1,3-Bis(3-aminopropyl)tetramethyldisiloxane and 2.0174 g of triethylene glycol were charged into a flask and allowed to react with CO2 according to the procedure described in Example 1. The total weight gain was 0.4089 g. This corresponded to 114% of the theoretical amount of weight that should have been gained if all the amine groups had reacted with a stoichiometric amount of CO2. The reaction product was a liquid.

example 4

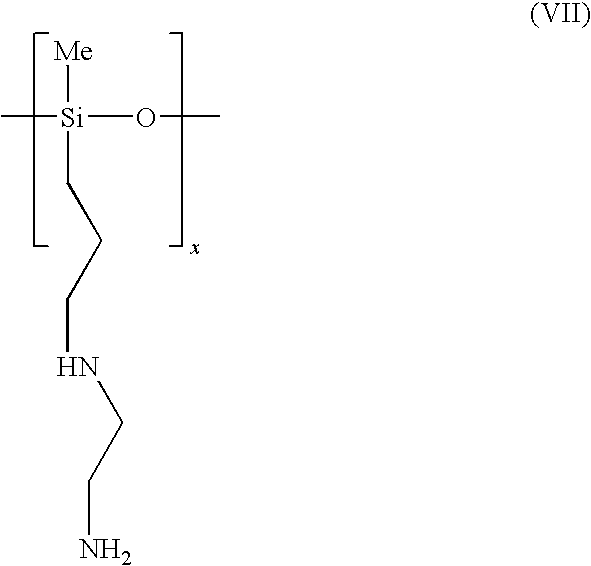

[0040]2.0168 g of aminoethylaminopropyl methylsiloxane oligomer and 4.0292 g of triethylene glycol were charged into a flask and allowed to react with CO2 according to the procedure described in Example 1. The total weight gain was 0.4803 g. This corresponded to 87% of the theoretical amount of weight that should have been gained if all the amine groups had reacted with a stoichiometric amount of CO2. The reaction product was a liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Vapor pressure | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com