Fluid Charged Rotary Heating System

a rotary heating system and fluid charge technology, applied in the direction of fluid friction for heating, domestic stoves or ranges, lighting and heating apparatus, etc., can solve the problem of limited maximum effect, achieve high yield, reduce manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

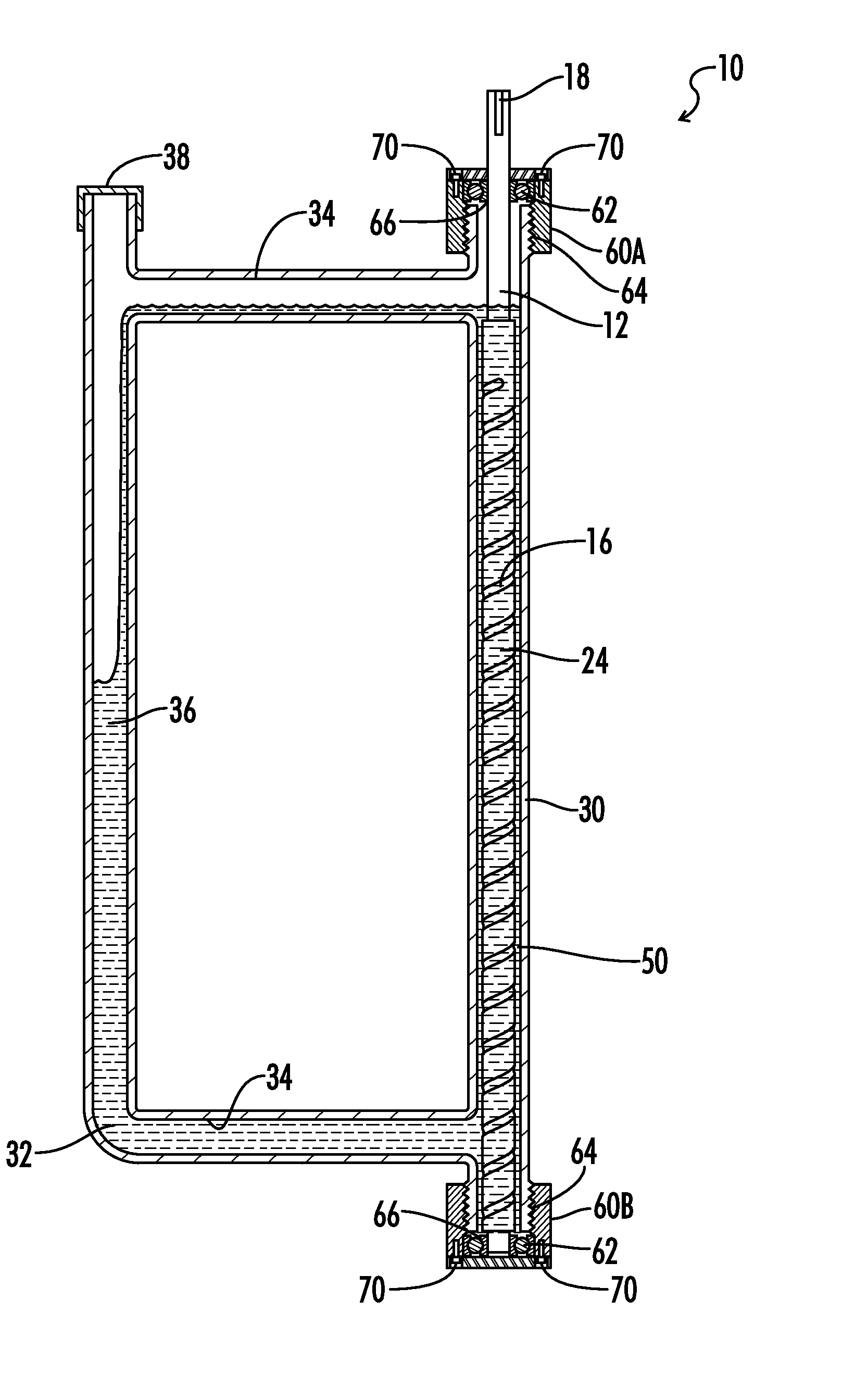

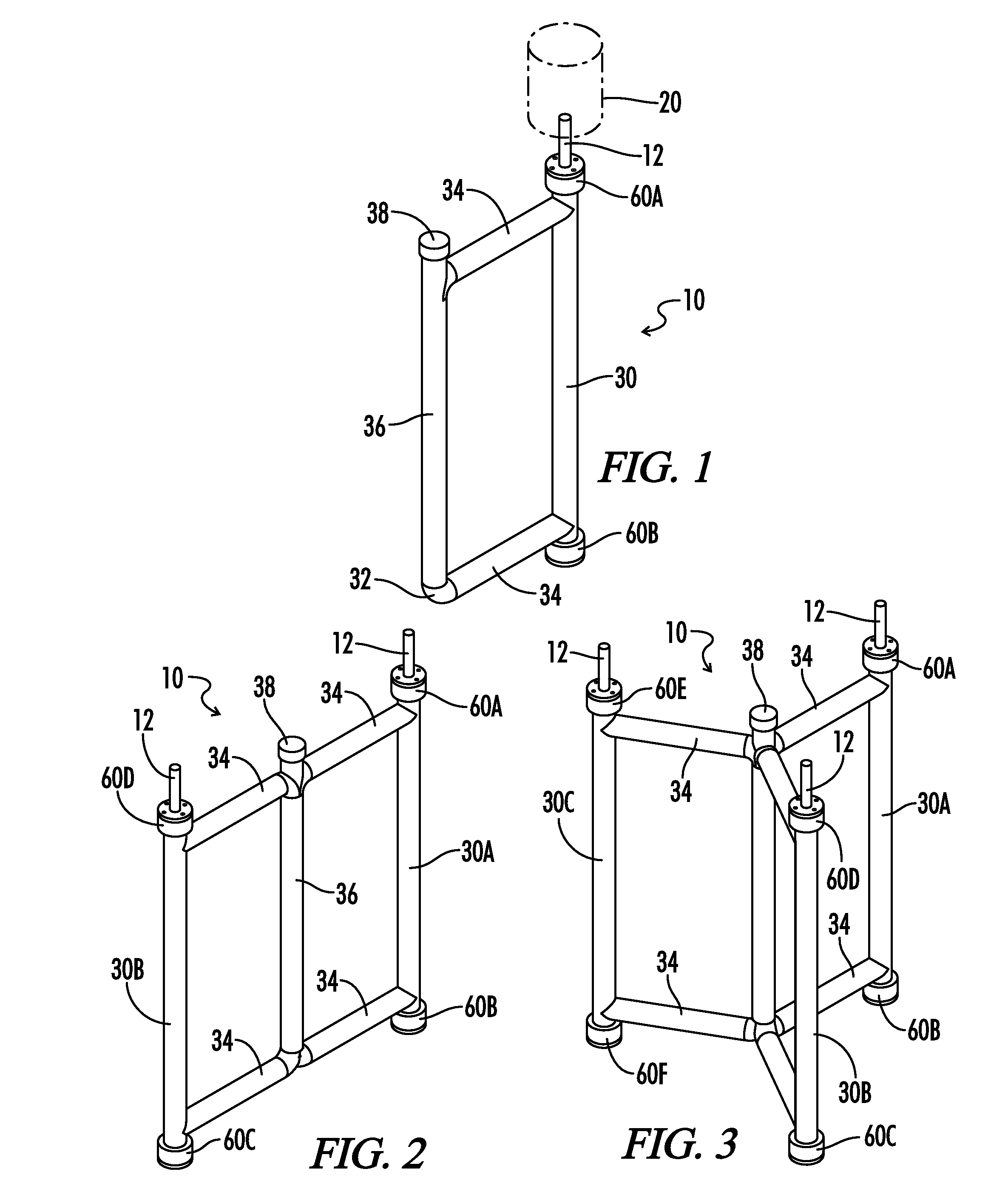

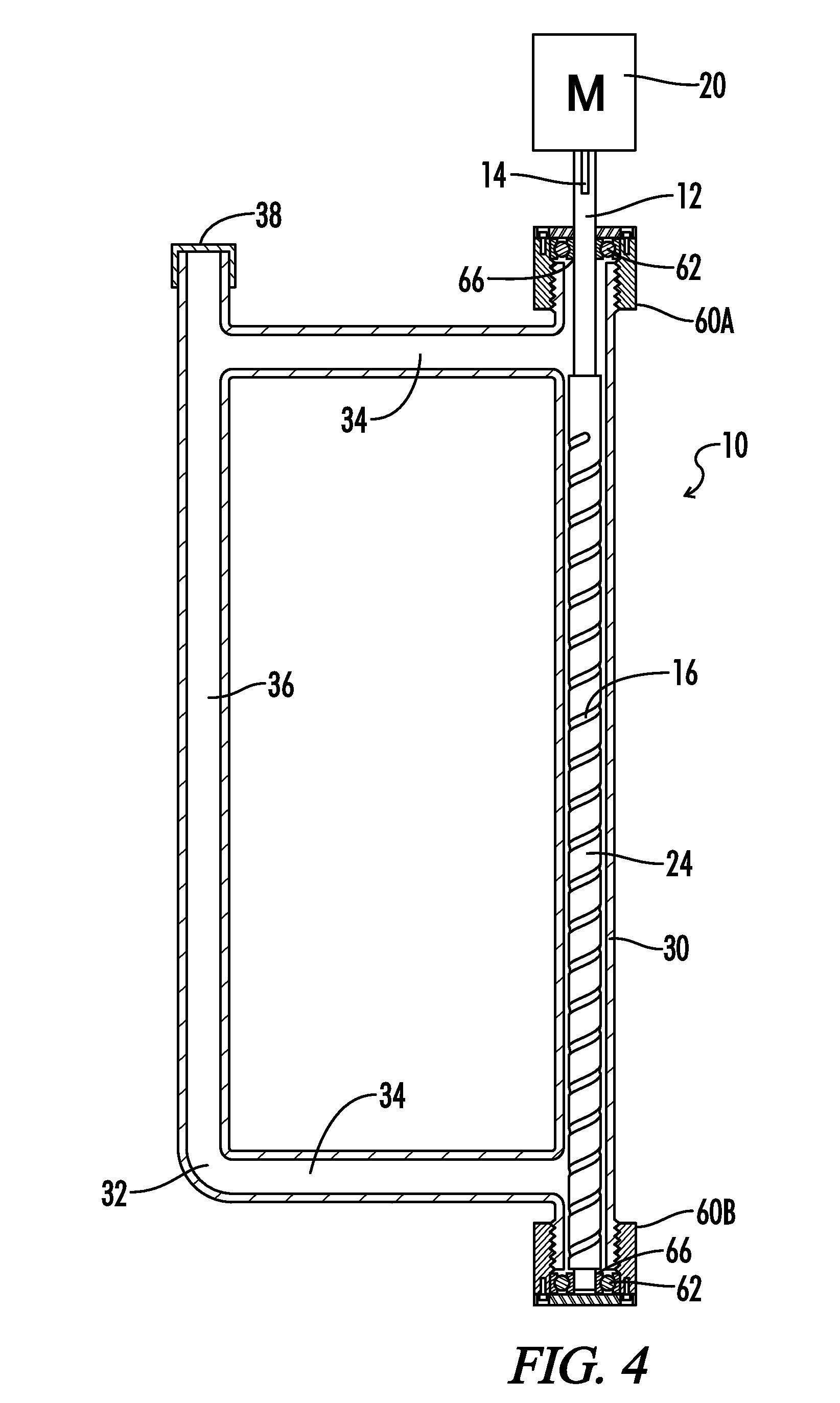

[0026]Referring now to the drawings of the present disclosure in which like numbers represent the same structure in the various views,

[0027]As shown in FIGS. 1-4, device 10 comprises a rotor 12 mounted on a shaft 14, which rotor 12 rotates within a housing 30 in a recirculating inlet and outlet communication with a housing extension 36 via connecting means 34. Shaft 14 in the embodiment shown in FIG. 4 has a primary diameter of ¼″ and may be formed of forged steel, cast or ductile iron, or other materials as desired. Shaft 14 is designed for rigid interference fit with the shaft bore 18 on the rotor 12. (See FIG. 7). Shaft 14 may be driven by an electric motor 20 or other motive means, and may be driven directly, geared, driven by pulley 26, or driven as otherwise desired. In one embodiment, locking pins, set screws or other fasteners may be used to fix rotor 12 with respect to shaft 14. As used in this specification, shaft 14 encompasses any mechanically suitable connecting means f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com