Photo-voltaic cell device and display panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

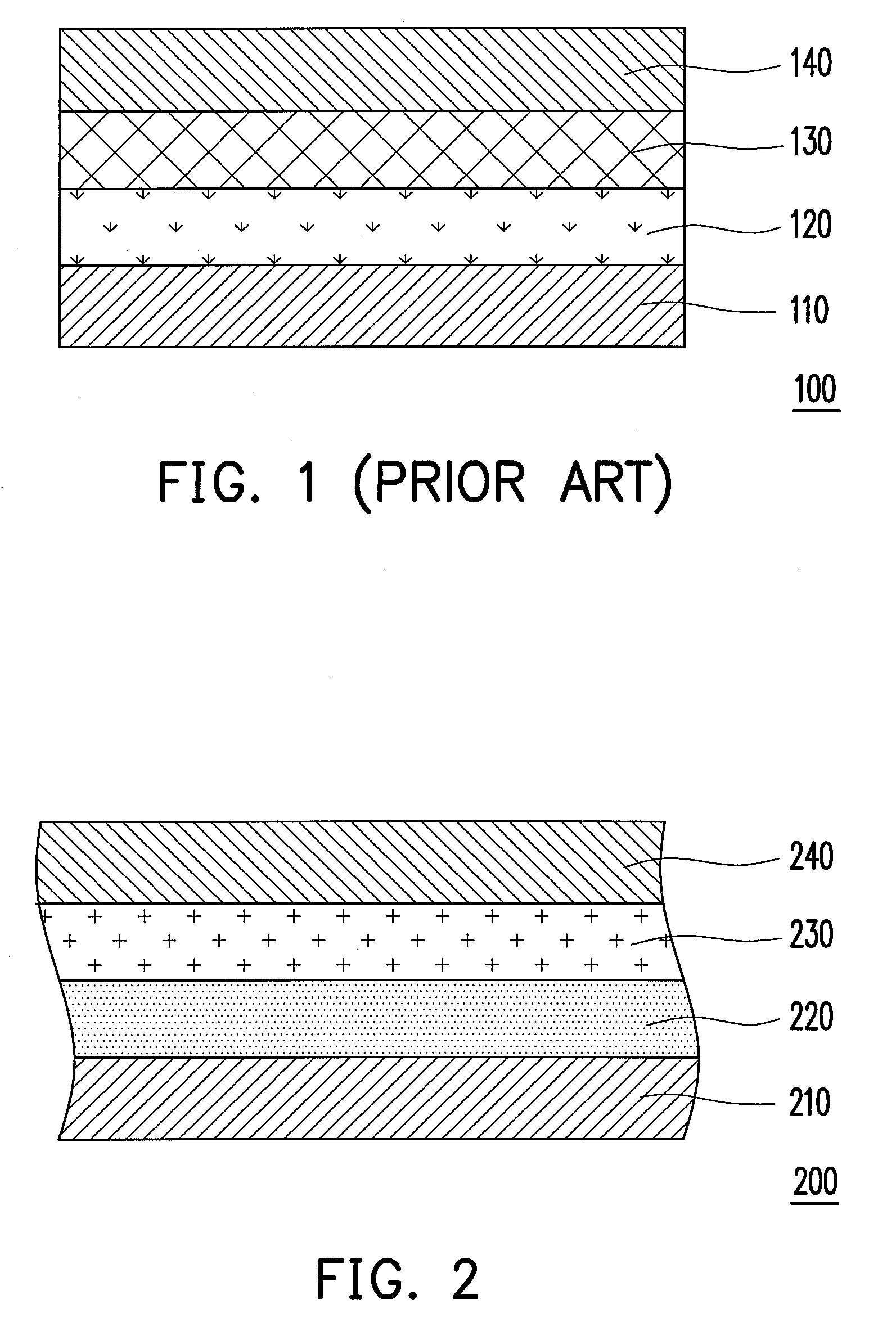

[0035]FIG. 2 is a schematic structural view of a photo-voltaic cell device according to a first embodiment of the present invention. Referring to FIG. 2, the photo-voltaic cell device 200 of the present embodiment includes a first electrode 210, an N-type doped silicon-rich dielectric layer 220, a P-type doped silicon-rich dielectric layer 230, and a second electrode 240. The N-type doped silicon-rich dielectric layer 220 is disposed on the first electrode 210, and the N-type doped silicon-rich dielectric layer 220 is doped with an N-type dopant. The P-type doped silicon-rich dielectric layer 230 is disposed on the N-type doped silicon-rich dielectric layer 220, and the P-type doped silicon-rich dielectric layer 230 is doped with a P-type dopant. The second electrode 240 is disposed on the P-type doped silicon-rich dielectric layer 230.

[0036]Said vertical design can also be changed to a horizontal design or a lateral design (not shown) in an modified embodiment of the present invent...

second embodiment

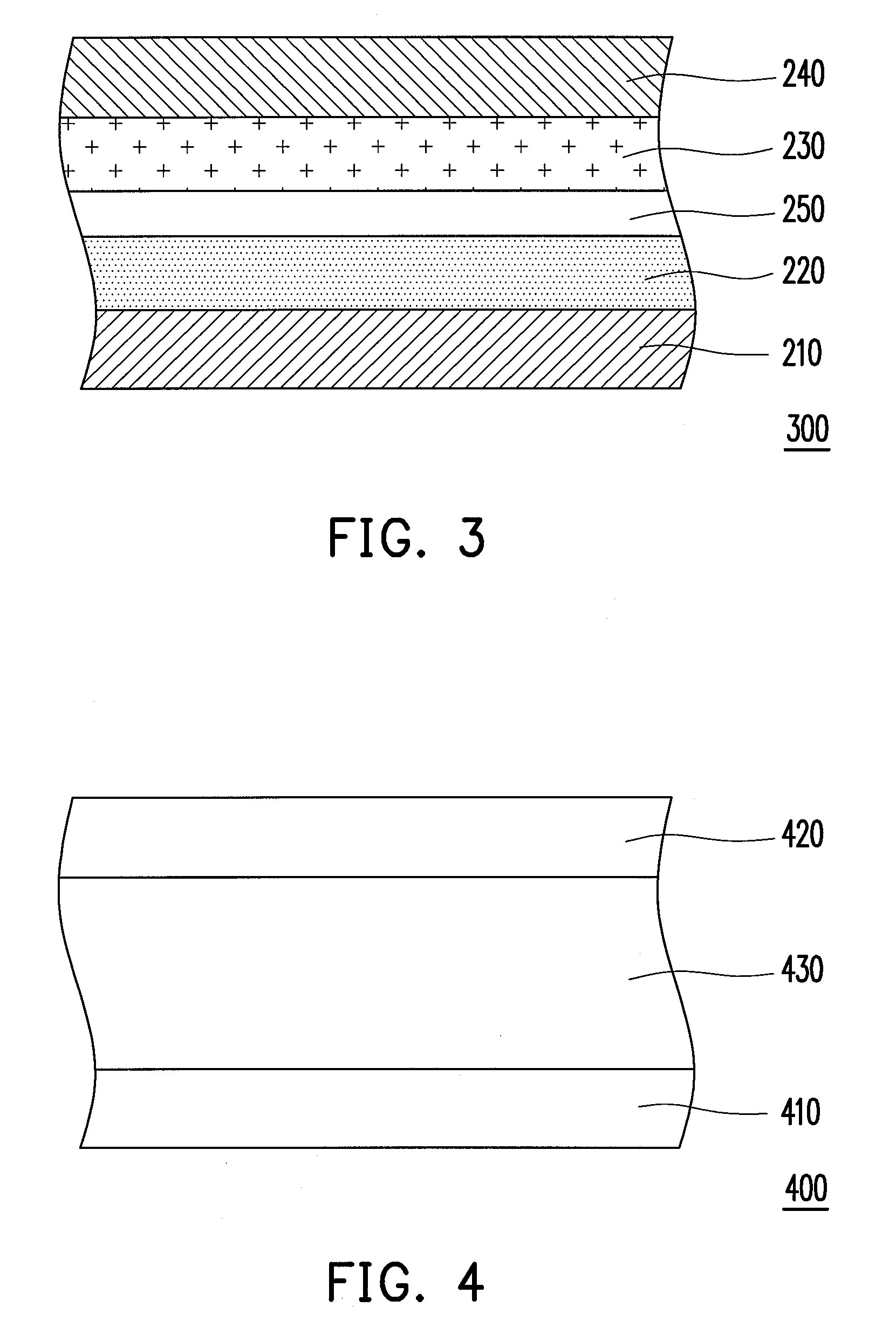

[0049]FIG. 4 is a schematic view of a display panel according to a second embodiment of the present invention. FIG. 5 is a schematic cross-sectional view of a first substrate depicted in FIG. 4. Referring to FIGS. 4 and 5, the display panel 400 of the present embodiment has a pixel region P1 and a sensing region P2. The display panel 400 includes a first substrate 410, a second substrate 420, and a display medium 430 including such as a liquid crystal material, an organic light emitting material, an electrophoretic material, or the like. A pixel array 412 and at least a photo-voltaic cell device 414 are disposed on the first substrate 410. The pixel array 412 is disposed in the pixel region P1 and includes a plurality of TFTs 412a and a plurality of pixel electrodes 412b electrically connected to the TFTs 412a. The photo-voltaic cell device 414 is disposed in the sensing region P2 and includes a first electrode 414a, a first silicon-rich dielectric layer 414b, a second silicon-rich ...

third embodiment

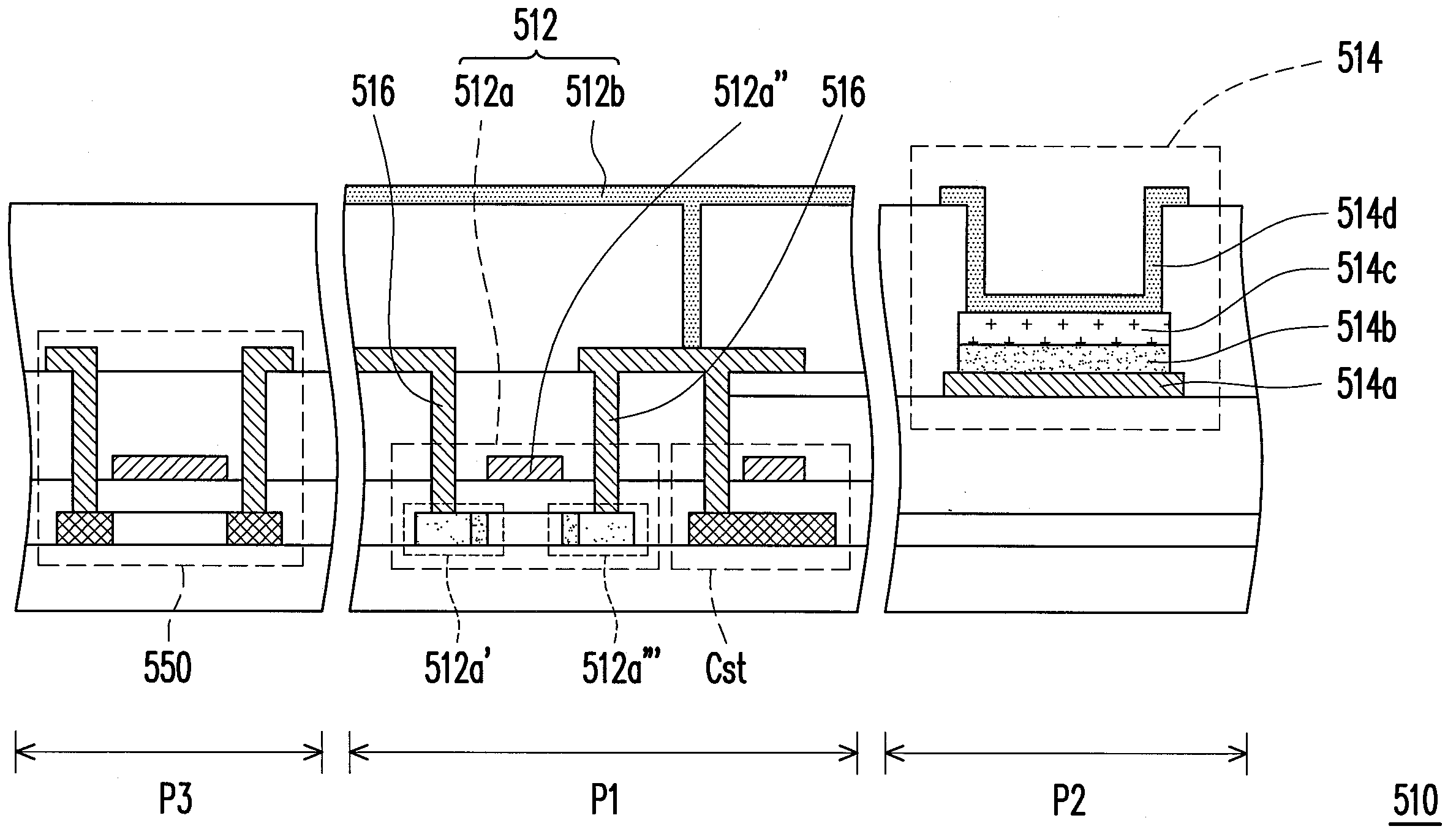

[0059]FIG. 6 is a schematic view of a display panel according to a third embodiment of the present invention. FIG. 7 is a schematic cross-sectional view of a first substrate depicted in FIG. 6. Referring to FIGS. 6 and 7, the display panel 500 of the present embodiment has a pixel region P1 and a sensing region P2. The display panel 500 includes a first substrate 510, a second substrate 520, and a display medium 530. A pixel array 512 and at least a photo-voltaic cell device 514 are disposed on the first substrate 510. The pixel array 512 is disposed in the pixel region P1 and includes a plurality of TFTs 512a and a plurality of pixel electrodes 512b electrically connected to the TFTs 512a. The photo-voltaic cell device 514 is disposed in the sensing region P2 and includes a first electrode 514a, a first silicon-rich dielectric layer 514b, a second silicon-rich dielectric layer 514c, and a second electrode 514d. The first silicon-rich dielectric layer 514b is disposed on the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com