Microdosing Device for Dosing of Smallest Quantities of a Medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

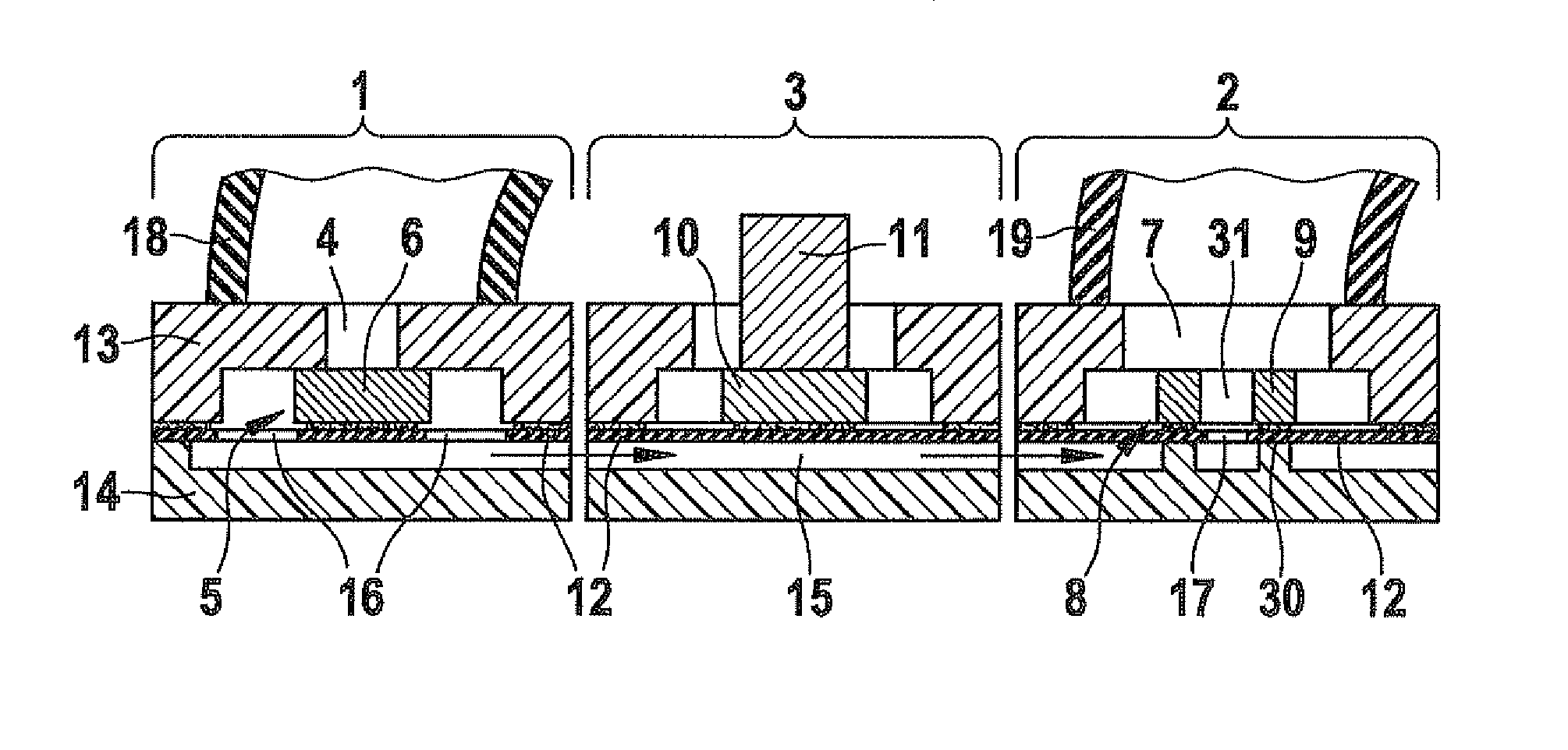

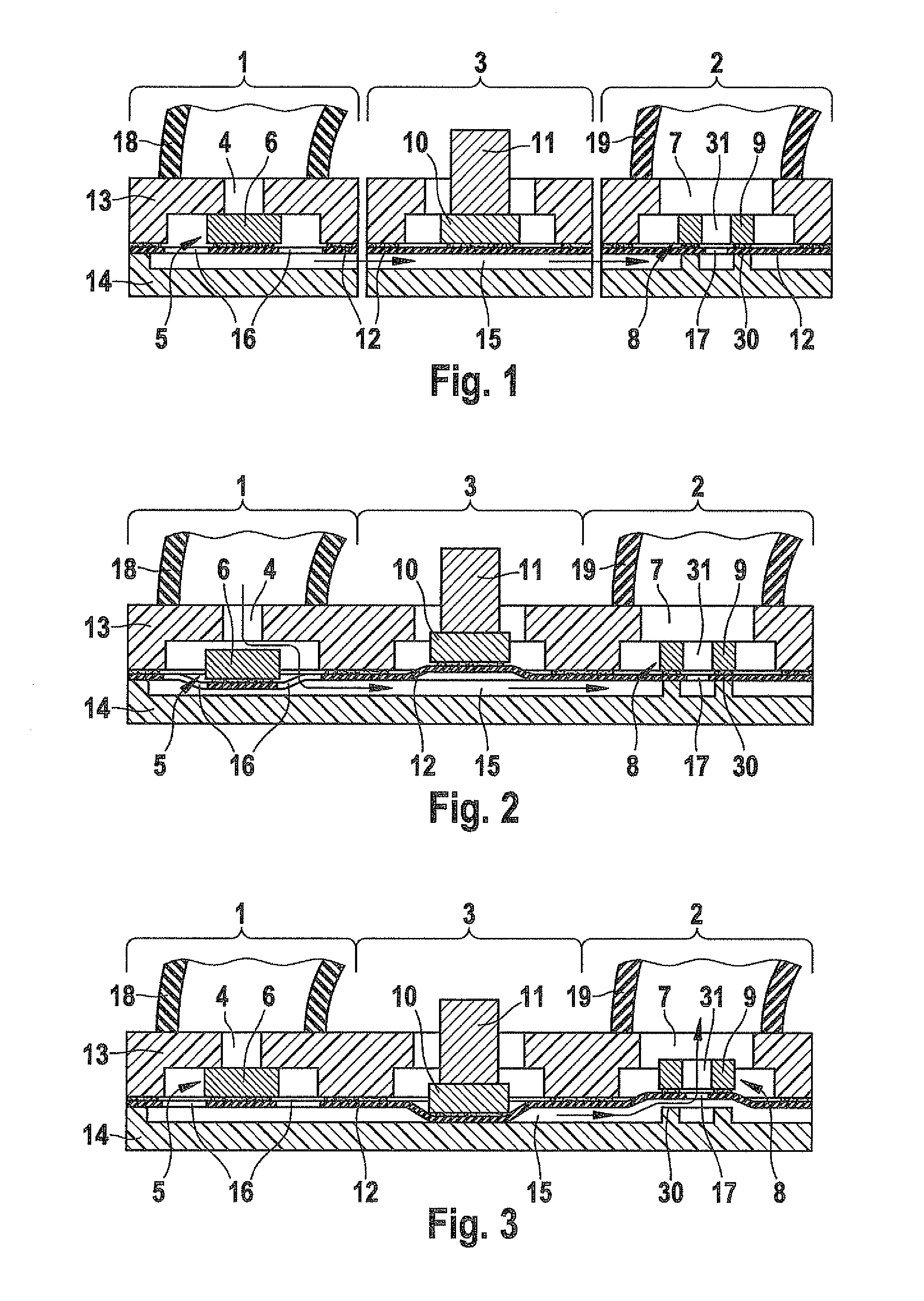

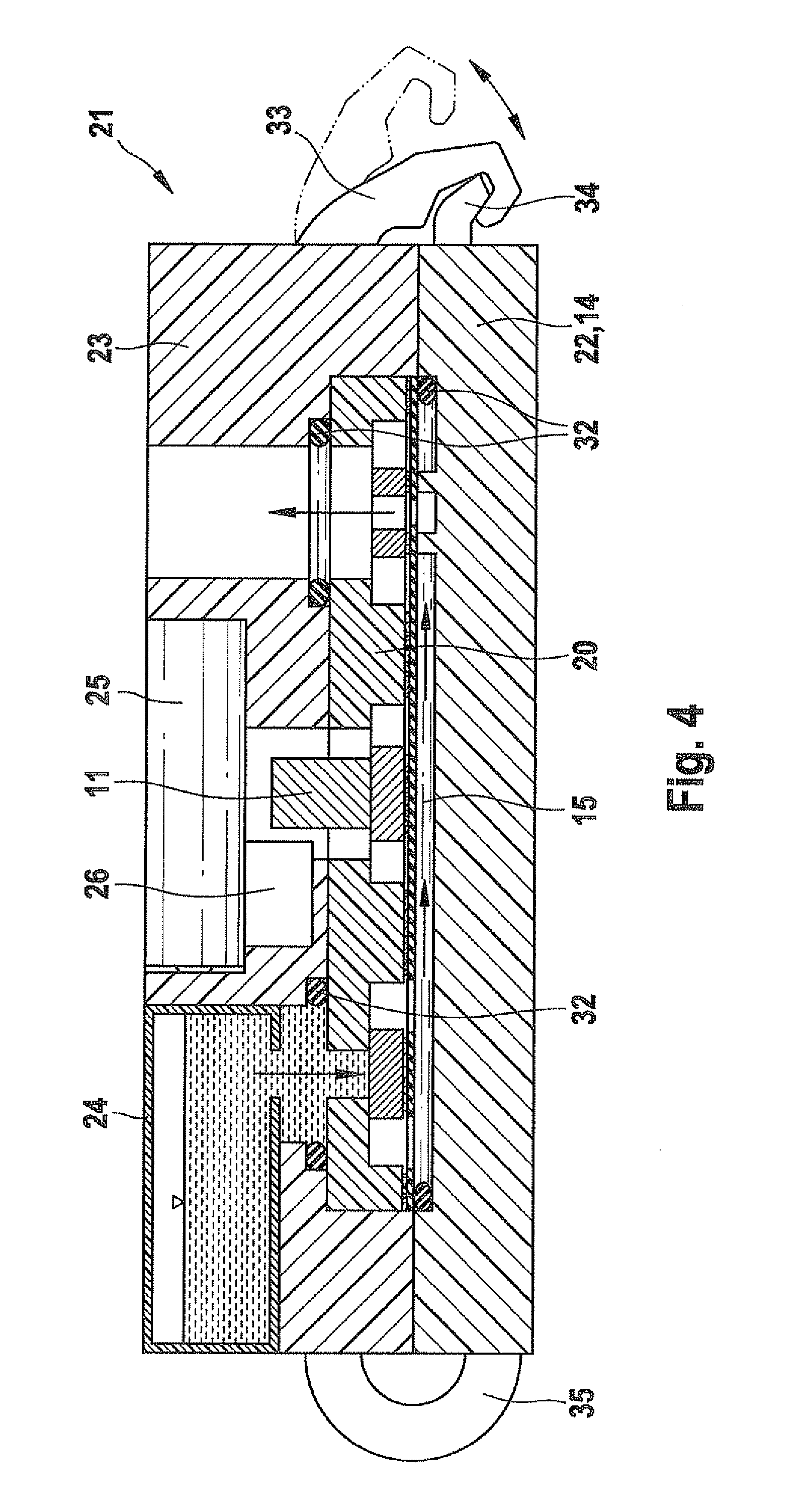

[0027]One may see in each of FIGS. 1 to 3 a schematic cross sectional representation of a microdosing device according to an exemplary embodiment of the present invention. This microdosing device is used for dosing smallest quantities of a medium, and it has an inlet device 1, an outlet device 2 and a pump device 3, which, for reasons of clarity, is shown in FIG. 1 as three functional blocks separated from one another. In actual fact, these three components of the microdosing device, according to the exemplary embodiment of the present invention, are produced directly as a coherent system on a common substrate, as will be explained below.

[0028]Inlet device 1 has an inlet opening 4 and an inlet valve 5 that has an inlet valve piston 6. In an analogous manner, outlet device 2 has an outlet opening 7, an outlet valve 8 and an outlet valve piston 9. Between inlet device 1 and outlet device 2 pump device 3 is provided, which has a pump piston 10, to which is assigned a pump actuator 11. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com