Dual-Pressure Dual-Compartment Fluid Tank

a dual-compartment, fluid tank technology, applied in the direction of heating types, domestic hot water supply systems, lighting and heating apparatus, etc., can solve the problems of increasing heat loss, complex and difficult system construction, and the use of separate hydronics and potable water tanks requires substantially more materials, so as to facilitate the transfer of heat energy between compartments and improve the fluid mixing within the compartments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045]The present invention may be used with any type of fluid heat exchange system and is particularly suited for preventing cross contamination of fluids that are in thermal communication with each other. However, for descriptive purposes, the present invention will be described in use with potable water and hydronics heating systems.

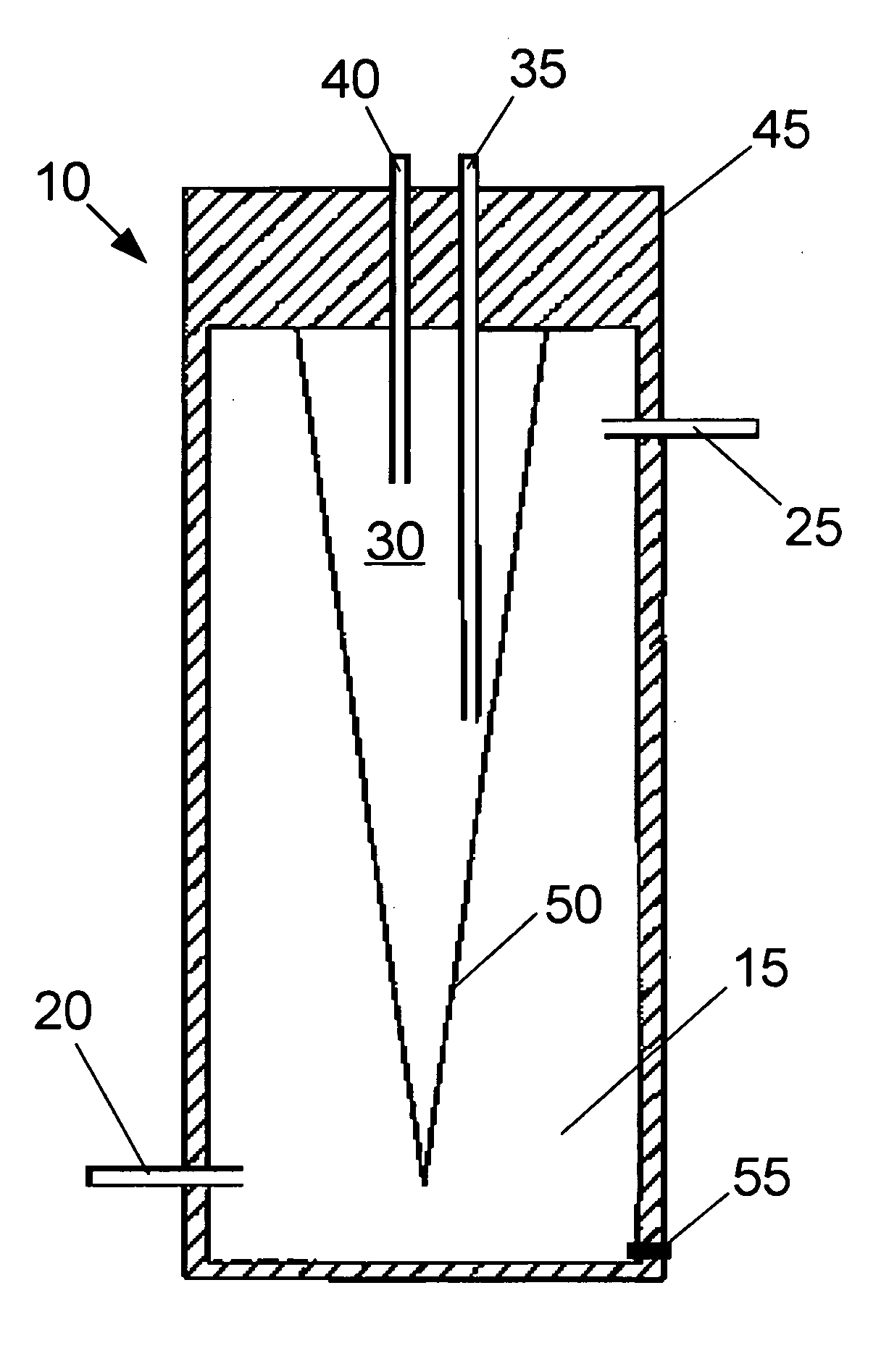

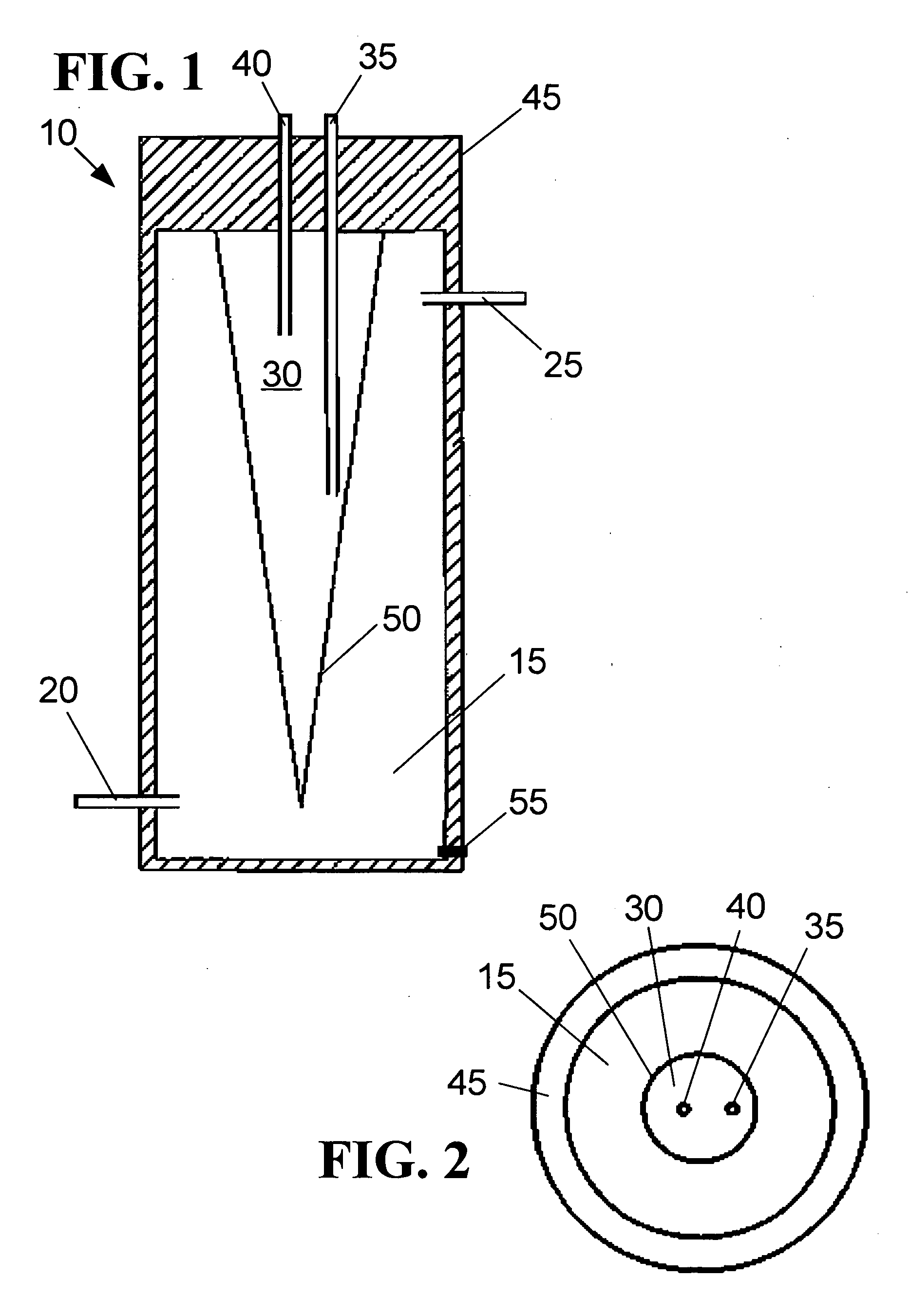

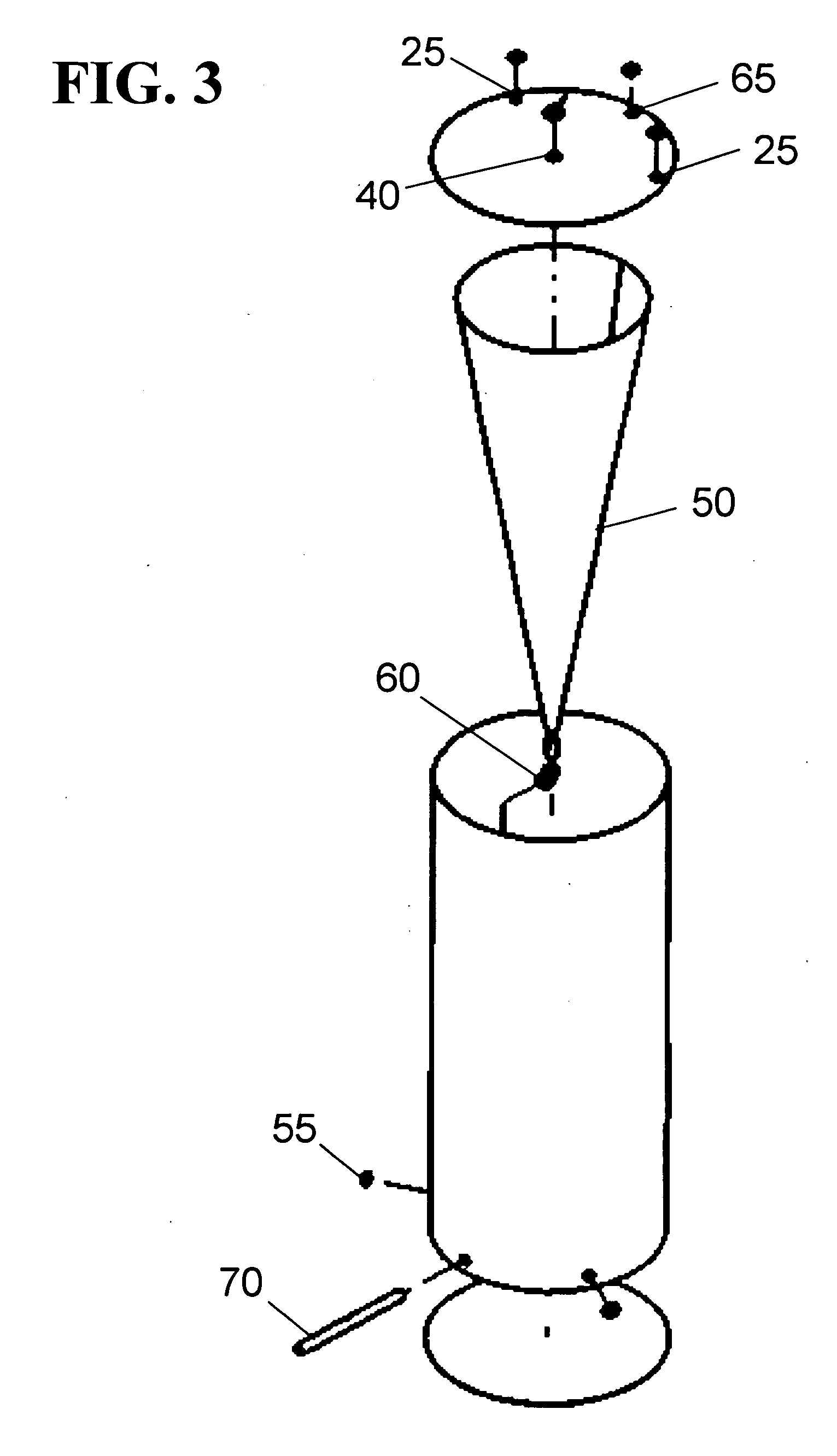

[0046]FIG. 1 shows a side view of a dual compartment hydronics fluid and potable water tank 10. A hydronics compartment 15 or vessel with a hydronics fluid input 20 and a hydronics fluid output 25 may be part of a larger circulation system providing heating to a structure via a plurality of conduits and radiators (not shown). Substantially enclosed within the hydronics compartment 15 is a potable water compartment 30 with a water input 35 and a water output 40. In the embodiment shown in FIG. 1, potable water from a municipal or well source is fed into the water compartment via the water input. Thermal insulation 45 surrounds both of the compartments ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com