Nanowire- based solar cell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

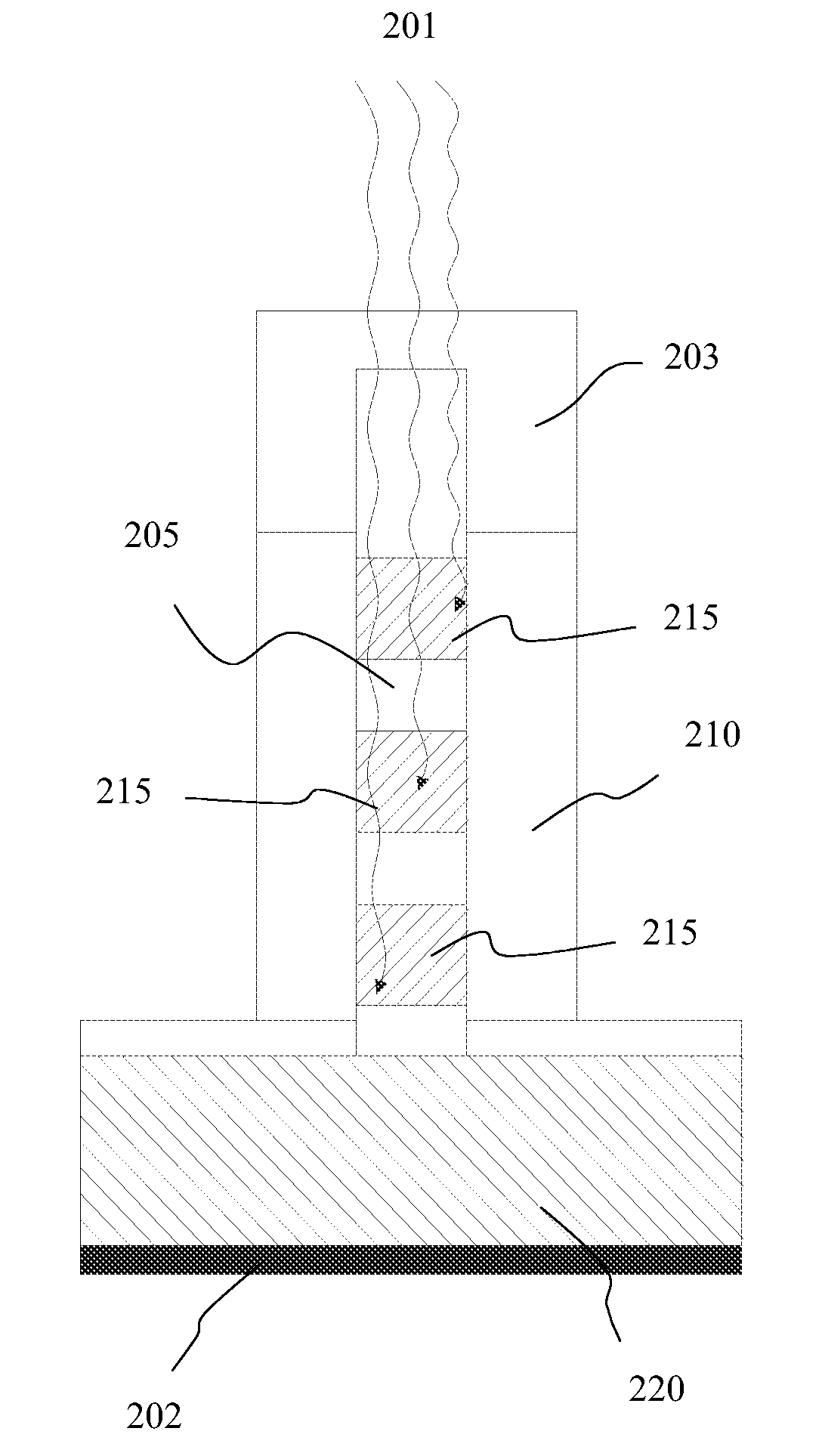

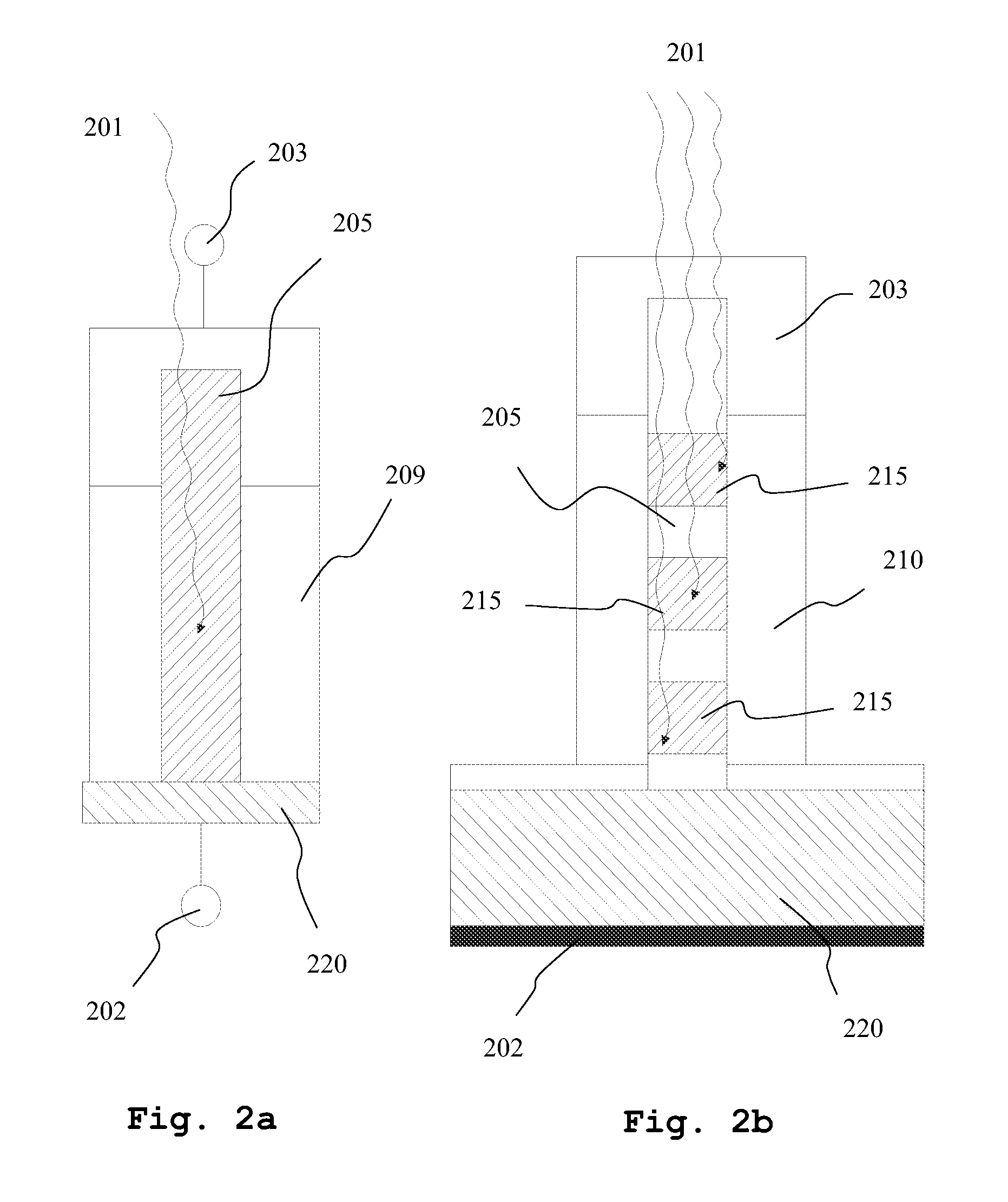

[0035]FIG. 2a schematically illustrates one embodiment of a solar cell structure according to the present invention. A nanowire 205 constitutes the light absorbing part of the solar cell structure and a passivating shell 209 encloses at least a portion of the nanowire 205. Preferably the nanowire protrudes from a substrate 220. The nanowires may protrude substantially perpendicular to the substrate 220 or at an angle.

[0036]Incoming (sun)light 201 is coupled into the nanowire 205 of the solar cell structure. The incoming light generates electron-hole-pairs and preferably the light absorbing part of the solar cell structure, i.e. the nanowire 205, is configured as a pn-junction to establish an electrical field that promotes a current to flow in only one direction through the nanowire 205 between a front contact 203 and a back contact 202. By way of example the front contact 203 and the back contact 202 are respectively, as schematically illustrated in FIG. 2a, electrically connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com