Drain Cartridge Having Removable Valved System

a valve system and cartridge technology, applied in water installations, urinals, constructions, etc., can solve the problems of increasing the cost of waterless urinals, odors that enter the seal, and large amounts of water consumed, so as to eliminate the need for flushing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

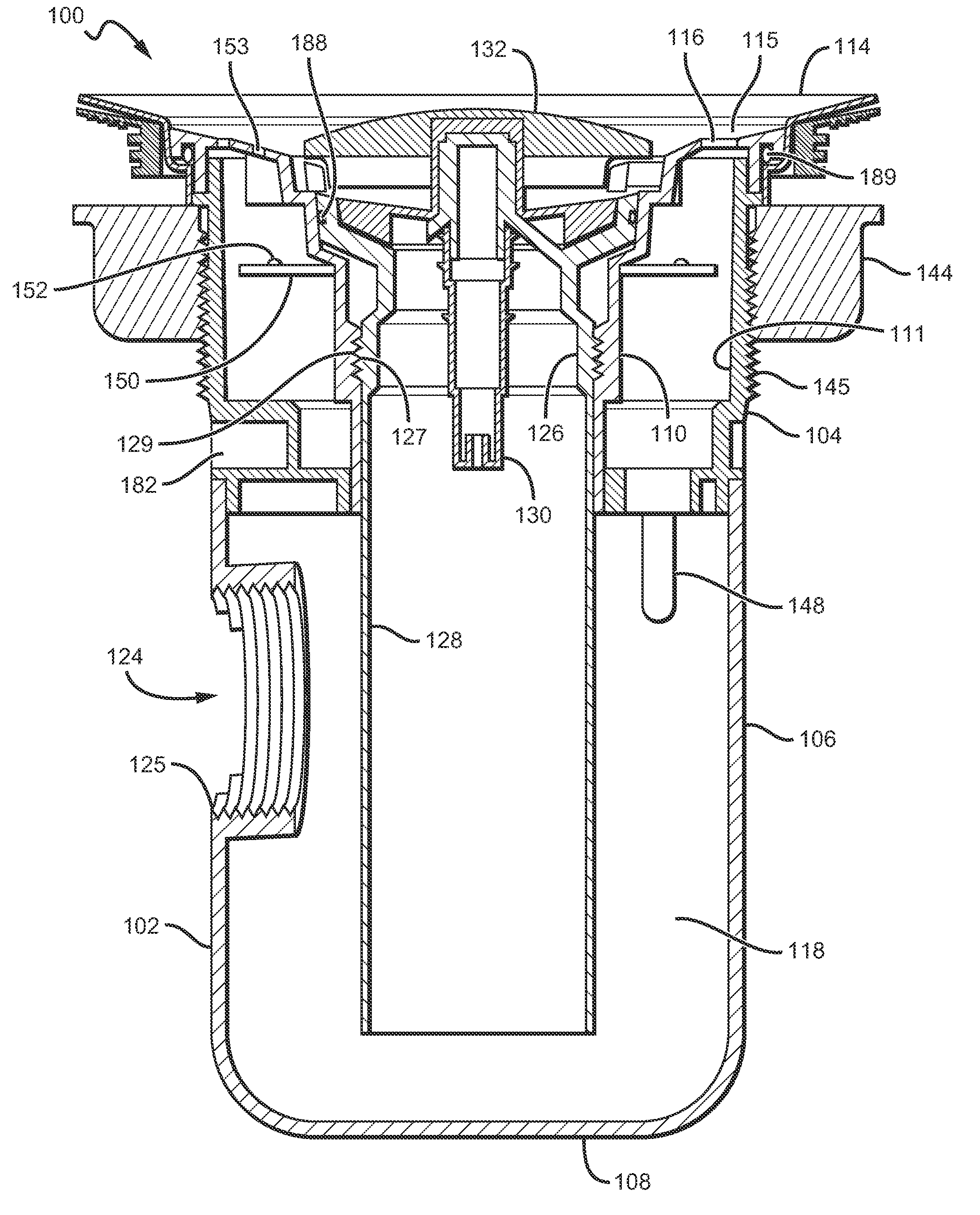

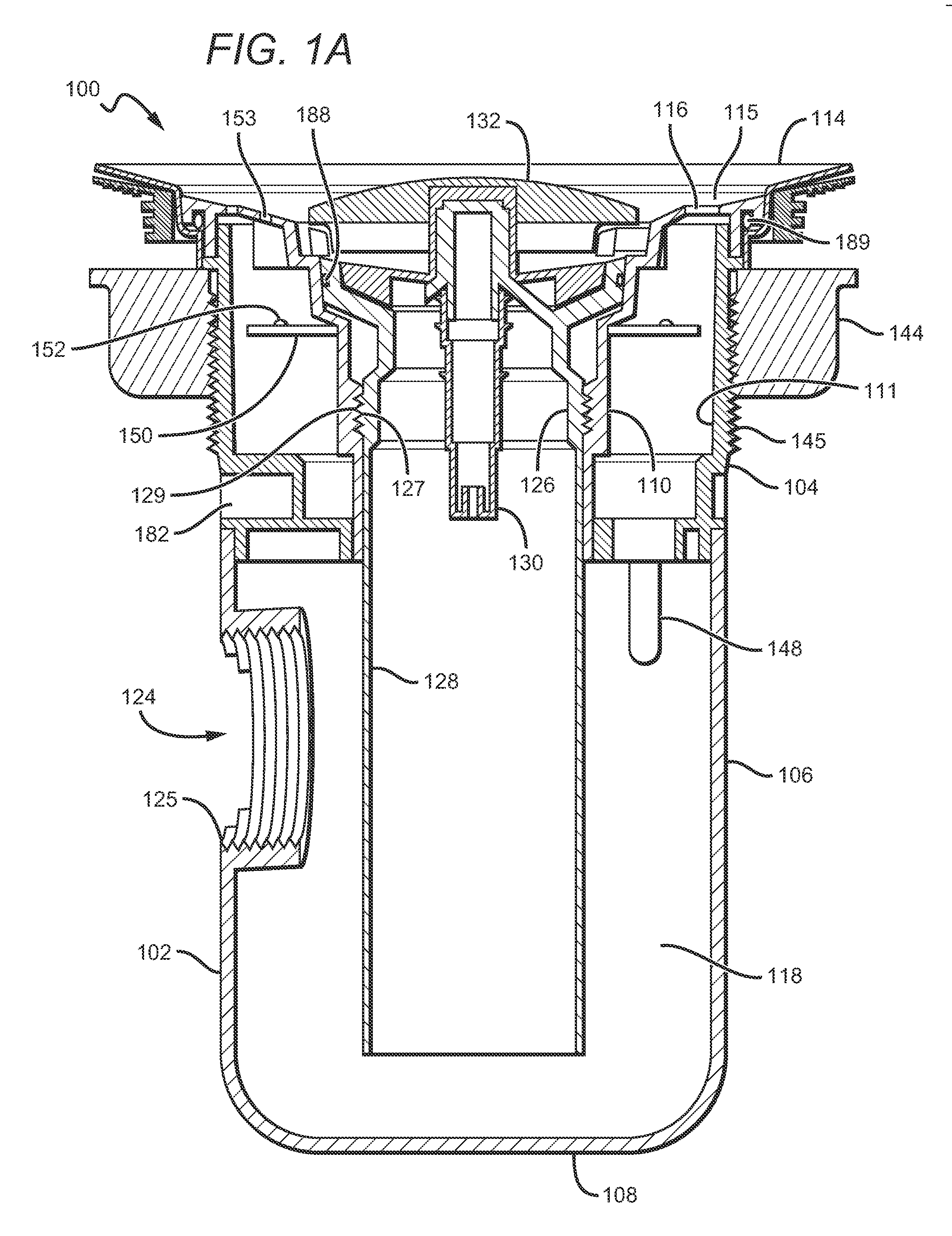

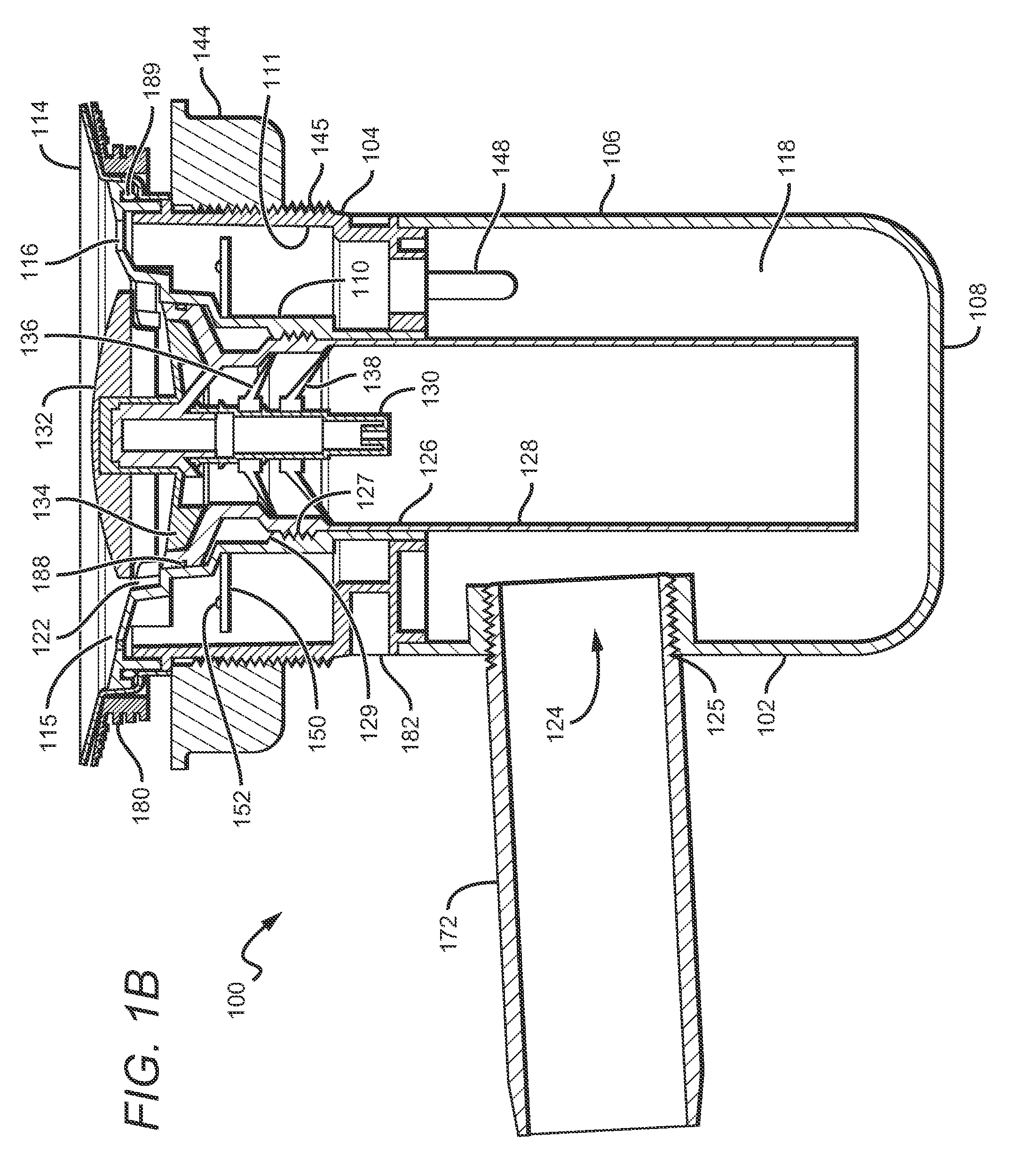

[0045]In FIGS. 1A-1B, a cartridge 100 is shown that regulates a fluid flow and has a housing 102 that comprises an upper housing 104, a lower section 106, and bottom 108. The upper housing 104 can comprise inner and outer portions 110 and 111, respectively, although it is contemplated that the upper housing 104 can comprise a single piece. The upper housing 104 and the lower section 106 of the housing 102 can be fixedly coupled by one or more fastener(s) including, for example, adhesive or other glues, threads or other mechanical fasteners, and combination(s) thereof. Insert 126 can be at least partially disposed within the upper housing 104, and configured to be user-removable from the upper housing 104. Each of the upper housing 104, the insert 126, and the lower section 106 can be composed of any commercially suitable material(s) including, for example, plastics and other polycarbonates, metal, quartz, porcelain, and any combination(s) thereof.

[0046]Cartridge 100 is preferably si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com