Air-fuel ratio control apparatus and air-fuel ratio control method for internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

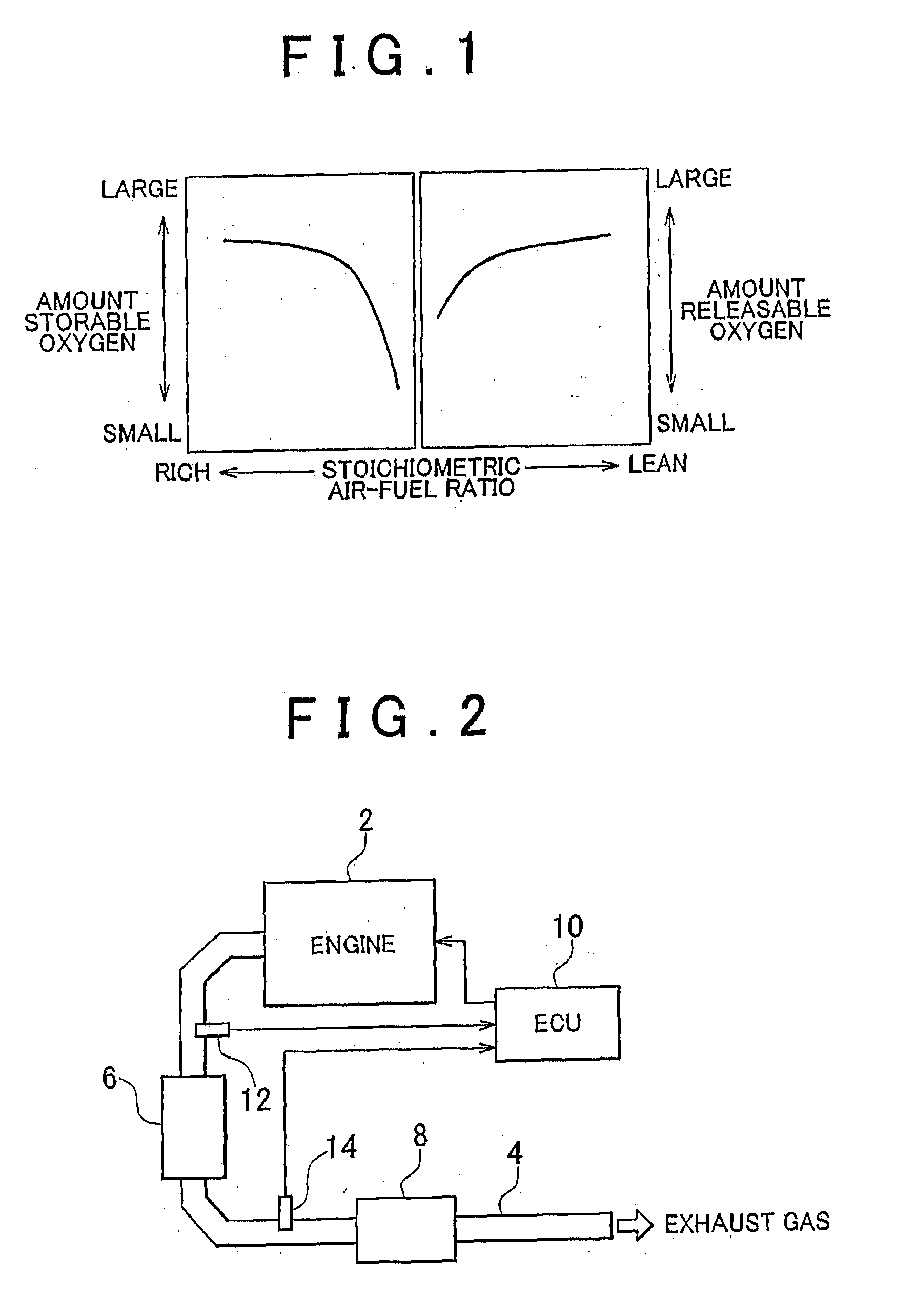

[0025]Hereinafter, an embodiment of the invention will be described with reference to the accompanying drawings. FIG. 2 is a schematic diagram showing an internal combustion engine system that includes an air-fuel ratio control apparatus according to the embodiment of the invention. As shown in FIG. 2, an internal combustion engine 2 is connected to an exhaust passage 4. Two catalysts 6 and 8, which purify pollutants (NOx, CO, and HC) in exhaust gas, are disposed in the exhaust passage 4. At least the catalyst 6 on an upstream side has oxygen storage capacity. It is to be understood that “storage” used herein means retention of a substance (solid, liquid, gas molecules) in the form of at least one of adsorption, adhesion, absorption, trapping, occlusion, and others. The catalyst 6 on the upstream side is disposed close to an exhaust manifold (not shown). The catalyst 8 on a downstream side is disposed under the floor of a vehicle. A linear air-fuel ratio sensor 12 is installed upstr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com