Head hair dyeing method

a dyeing method and head hair technology, applied in the field of head hair dyeing method, can solve the problems of uneven dyeing, difficult to evenly apply these compositions to the head hair, and excessive pressure on the internal pressure of the pressure-tight container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0099]A first part and a second part of a two-part hair dyeing composition having the composition shown in Table 2 were prepared. These parts were filled in the same containers as in Example 1. Further, the same squeeze foamer as in Example 1 was prepared.

TABLE 2Content offirst partFirst part(% by mass)Toluene-2,5-diamine0.14Para-aminophenol0.1Meta-aminophenol0.05Para-amino-ortho-cresol0.12,4-Diaminophenoxyethanol0.15hydrochlorideAqueous ammonia (28% by mass)6.0Ammonium hydrogen carbonate10.5Decylglucoside6.5Trideceth-90.6Laureth-231.8Myristyl alcohol0.2Propylene glycol4.0Ethanol9.0Polyquaternium-70.6Polyquaternium-220.4EDTA-4Na0.1Ascorbic acid0.3Anhydrous sodium sulfite0.4Fragrance0.5WaterBalanceContent insecond partSecond part(% by mass)Sodium laureth sulfate1.9Lauramide propyl betaine0.05Lauryl hydroxysultaine0.05Lauric acid0.04Cetanol1.5Etidronic acid0.04Phosphoric acid (75% by mass)Amountrequired toadjust pHto 3.8Sodium hydroxide solution (48% by0.01mass)Oxyquinoline sulfate0.0...

examples 3 to 7

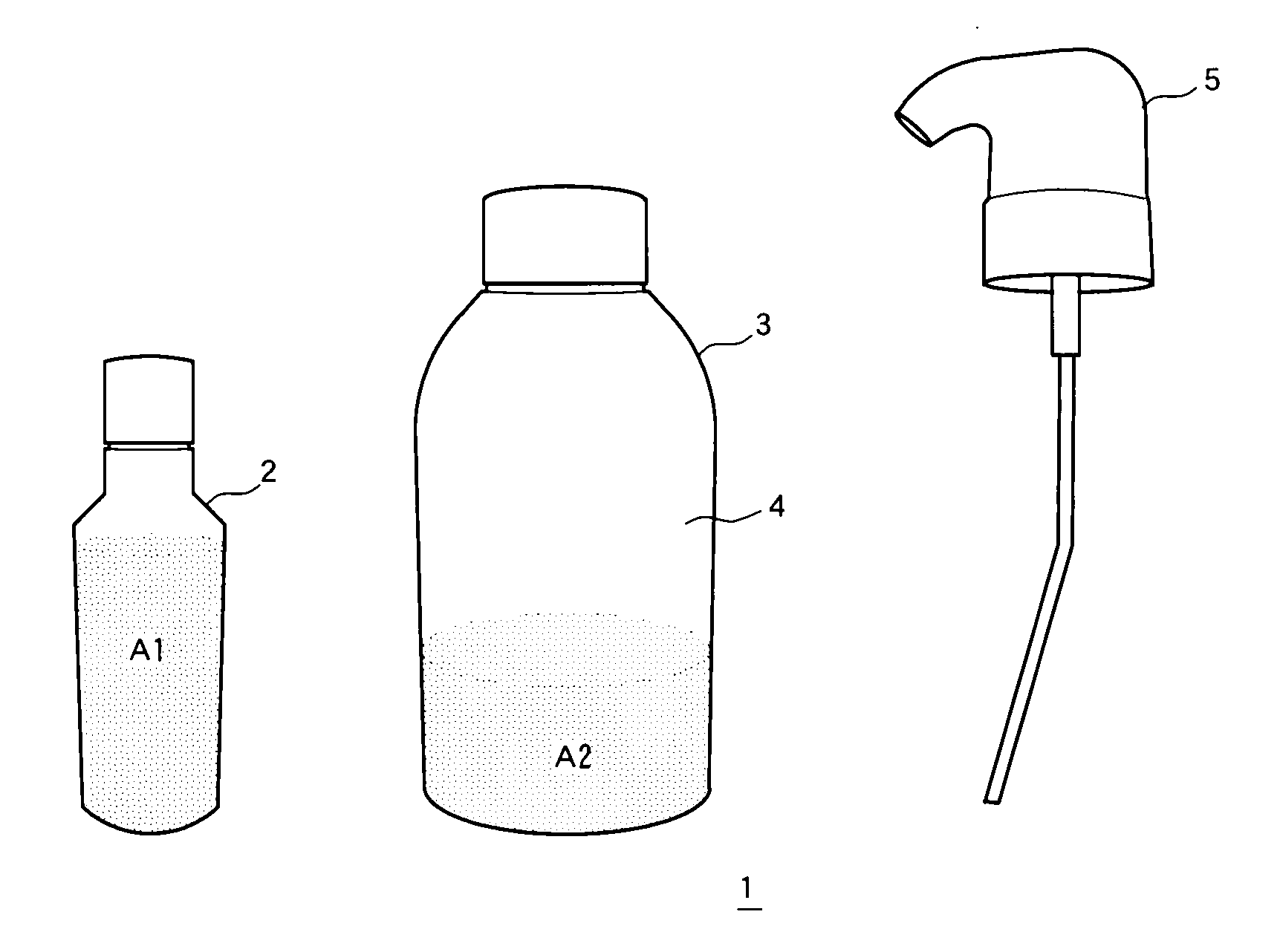

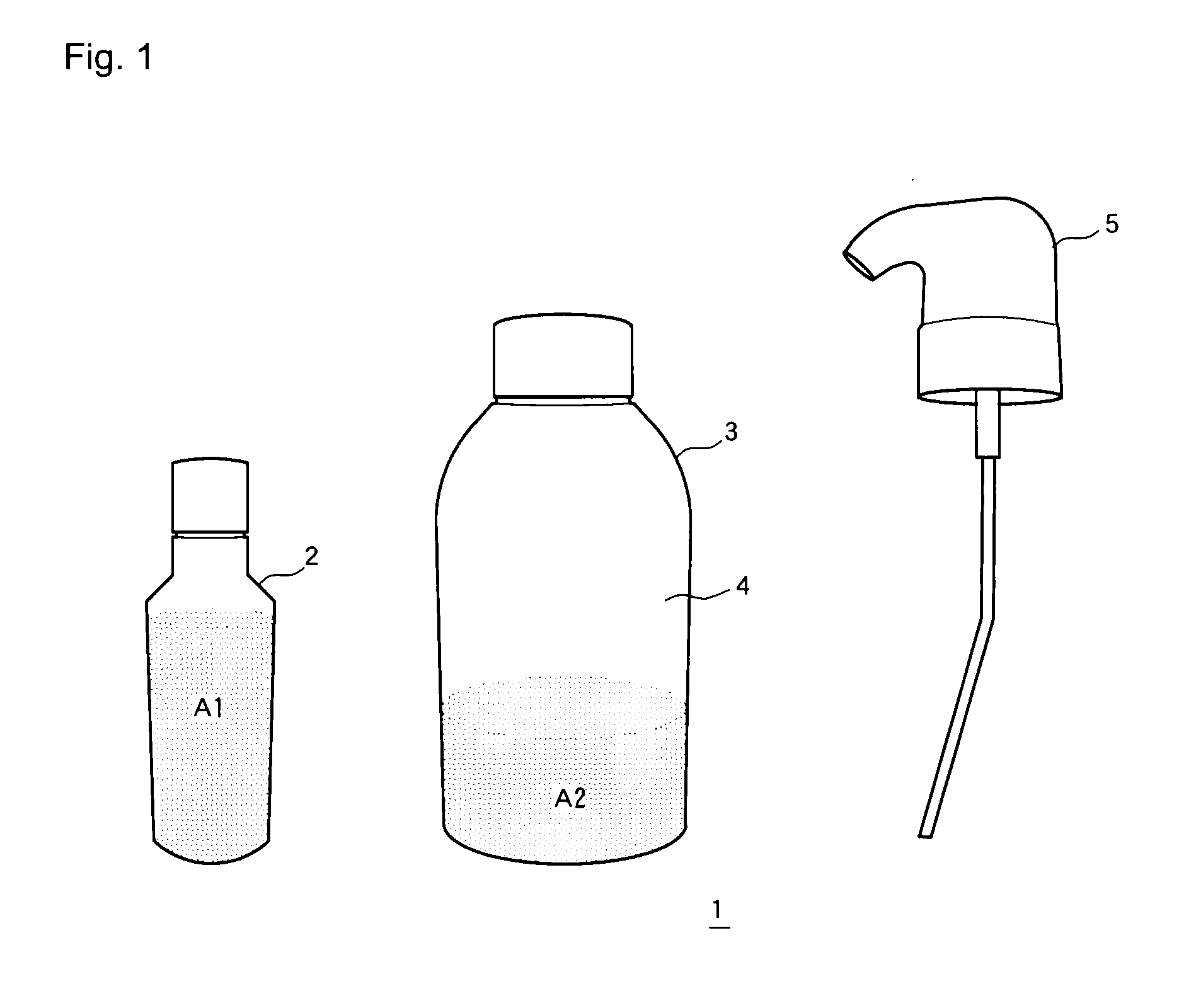

[0103]A first part and a second part having the composition (% by mass) shown in Table 3 were prepared. As shown in FIG. 1, 40 g of a first part (A1) was filled in a first container (2), and 60 g of a second part (A2) in a second container (3) (which also serves as a squeeze container main body (4); internal volume, 210 mL). These containers were left in a refrigerator maintained at 5° C. together with a squeeze foamer (5) (S1 Squeeze Foamer produced by Daiwa Can Company) for 24 hours.

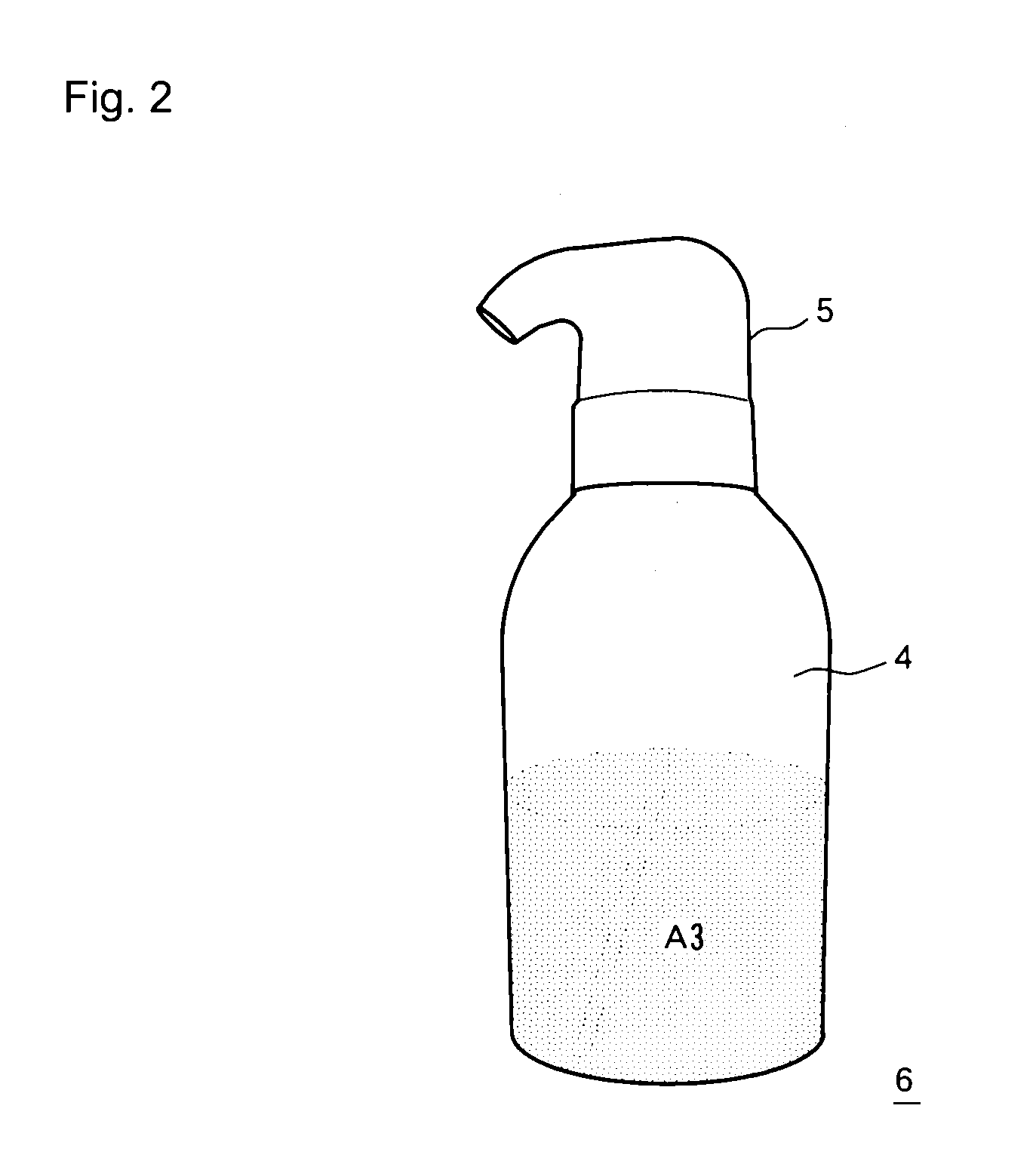

[0104]Immediately after these containers were removed from the refrigerator in a room at 20° C., the first part and the second part were mixed, and a squeeze foamer was mounted on the container, which was given to subjects (Japanese 20's-age females with black hair at a medium length). Subjects were asked to squeeze the container with one hand several times in upright position it and discharge 20 g of the mixture solution into a 1000 mL measuring cylinder. The total volume (mL) of liquid and foam at 1 ...

examples 8 to 15

[0116]First parts and second parts having the compositions (% by mass) shown in Tables 4 to 6 were prepared. As shown in FIG. 1, 40 g of a first part (A1) was filled in a first container (2), and 60 g of a second part (A2) in a second container (3) (which also serves as a squeeze container main body (4); internal volume, 210 mL). Further, a squeeze foamer (5) (S1 Squeeze Foamer produced by Daiwa Can Company) was prepared.

[0117]When subjects (Japanese 20's-age females with black hair at a medium length) received the filled first part and second part and the squeeze foamer and performed hair dyeing by the following procedure, the mixture solution was spread all over the head hair, no dripping was observed, and a uniform hair dyeing result was obtained without uneven dyeing.

[0118]Further, “irritation of scalp” during the hair dyeing was evaluated by subjects according to the following criteria. The results are shown in the columns below the composition in Table 4.

Irritation of Scalp

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com