Exhaust Gas Purification Device

a technology of exhaust gas and purification device, which is applied in the direction of exhaust gas purification components, exhaust treatment electric control, flue gas purification components, etc., can solve the problems of high cost, complex device itself, and inability to effectively decompose nitrogen oxides, and achieve the elimination of particulate matter, the effect of preventing the performance degradation of nitrogen oxide adsorbing material due to sulfur oxide poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

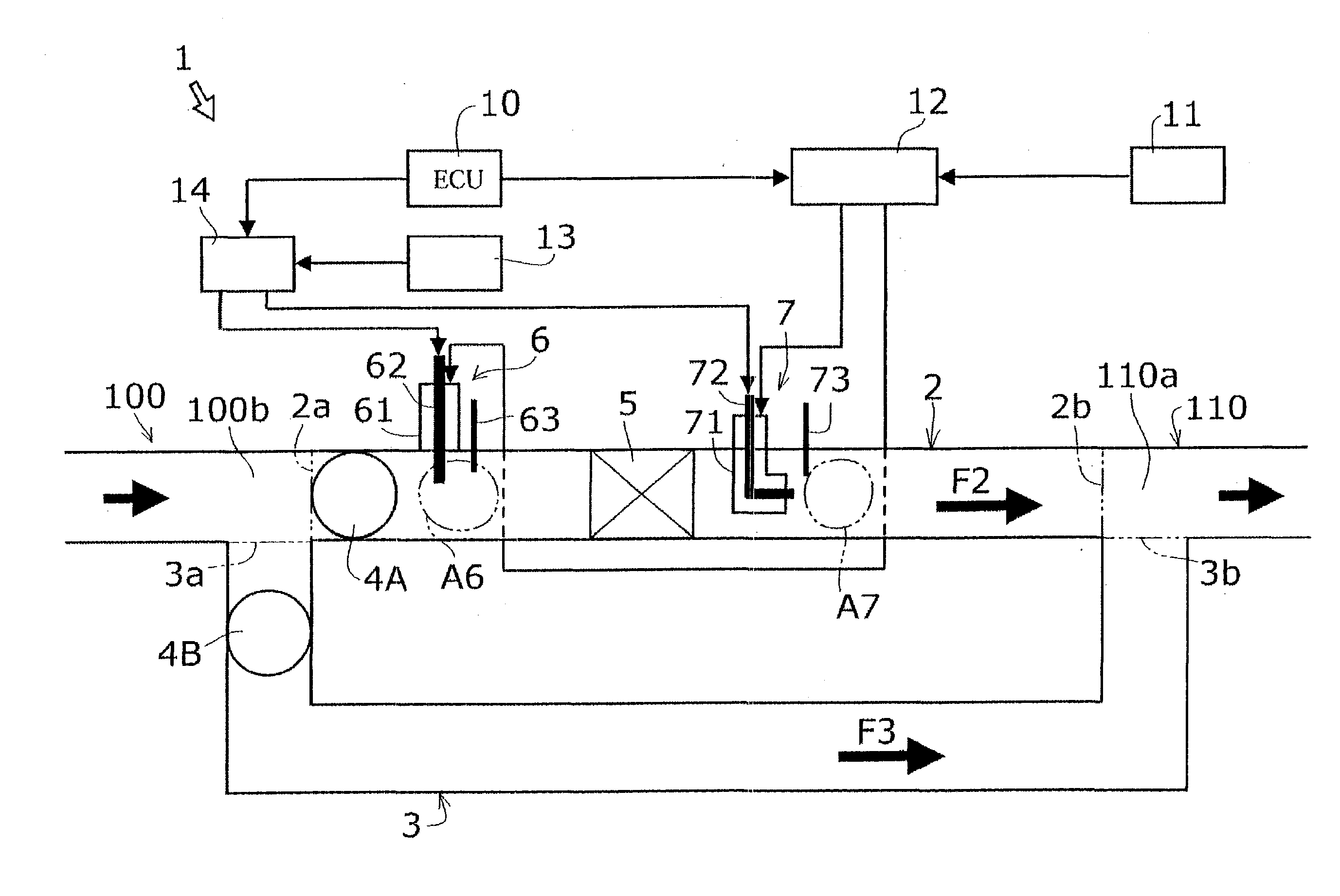

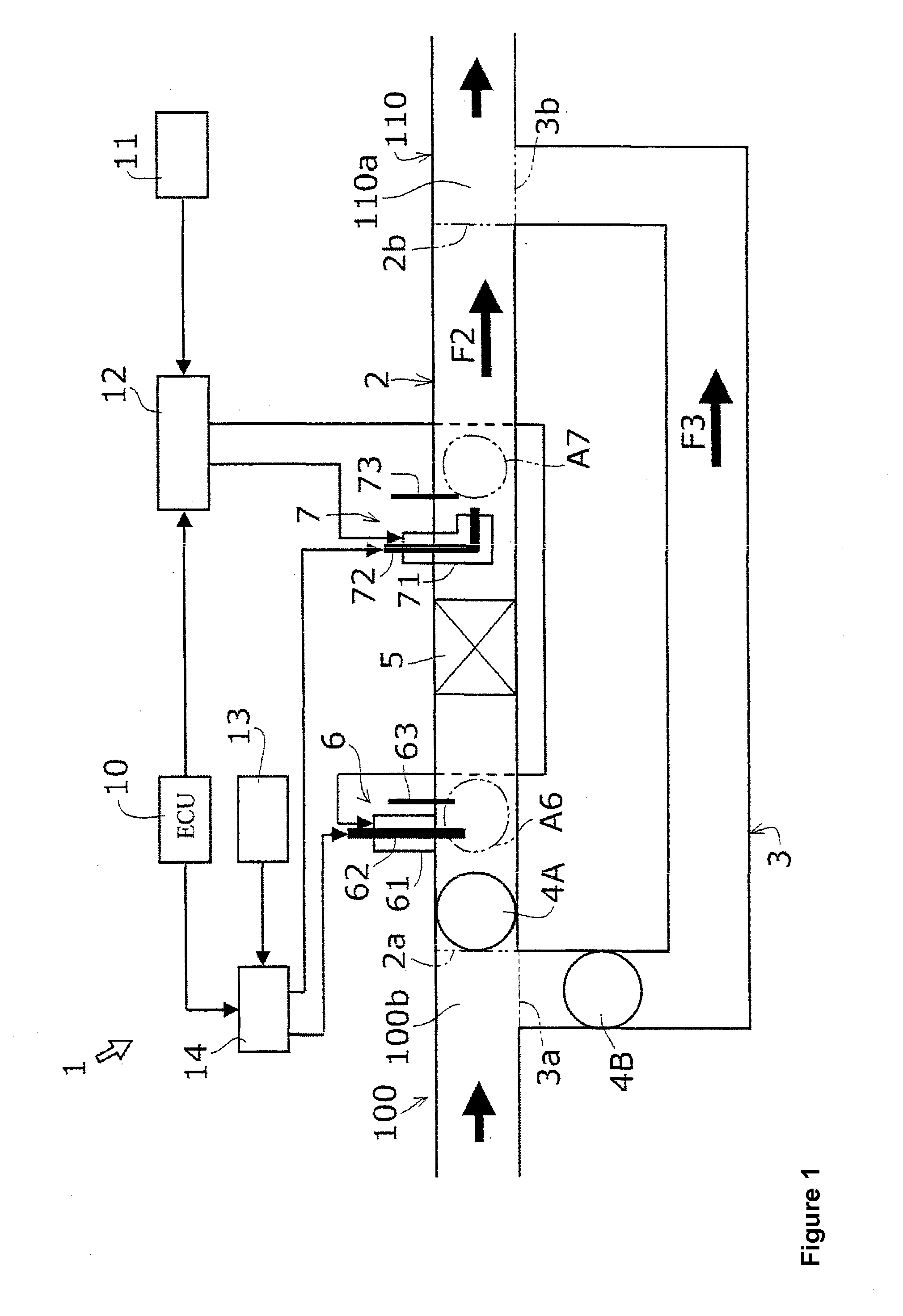

first embodiment

Operation of First Embodiment

[0068]Next, the operation of the exhaust gas purification device 1 will be described below. The controller 10 operates the exhaust gas purification device 1. Normal operation and regeneration operation are performed when the controller 10 operates the exhaust gas purification device 1.

[0069]During the normal operation, the exhaust gas discharged from the exhaust passage 100 on the engine side of the internal combustion engine or the like is passed through the main exhaust passage 2, and the nitrogen oxides contained in the exhaust gas are adsorbed onto the nitrogen oxide adsorbing material 5. During the normal operation, the controller 10 opens the shutoff valve 4A and closes the shutoff valve 4B. At this time, the controller 10 operates neither the adsorbed material detachment unit 6 nor the combustion device 7.

[0070]During the regeneration operation, after the nitrogen oxides adsorbed onto the nitrogen oxide adsorbing material 5 by virtue of the normal...

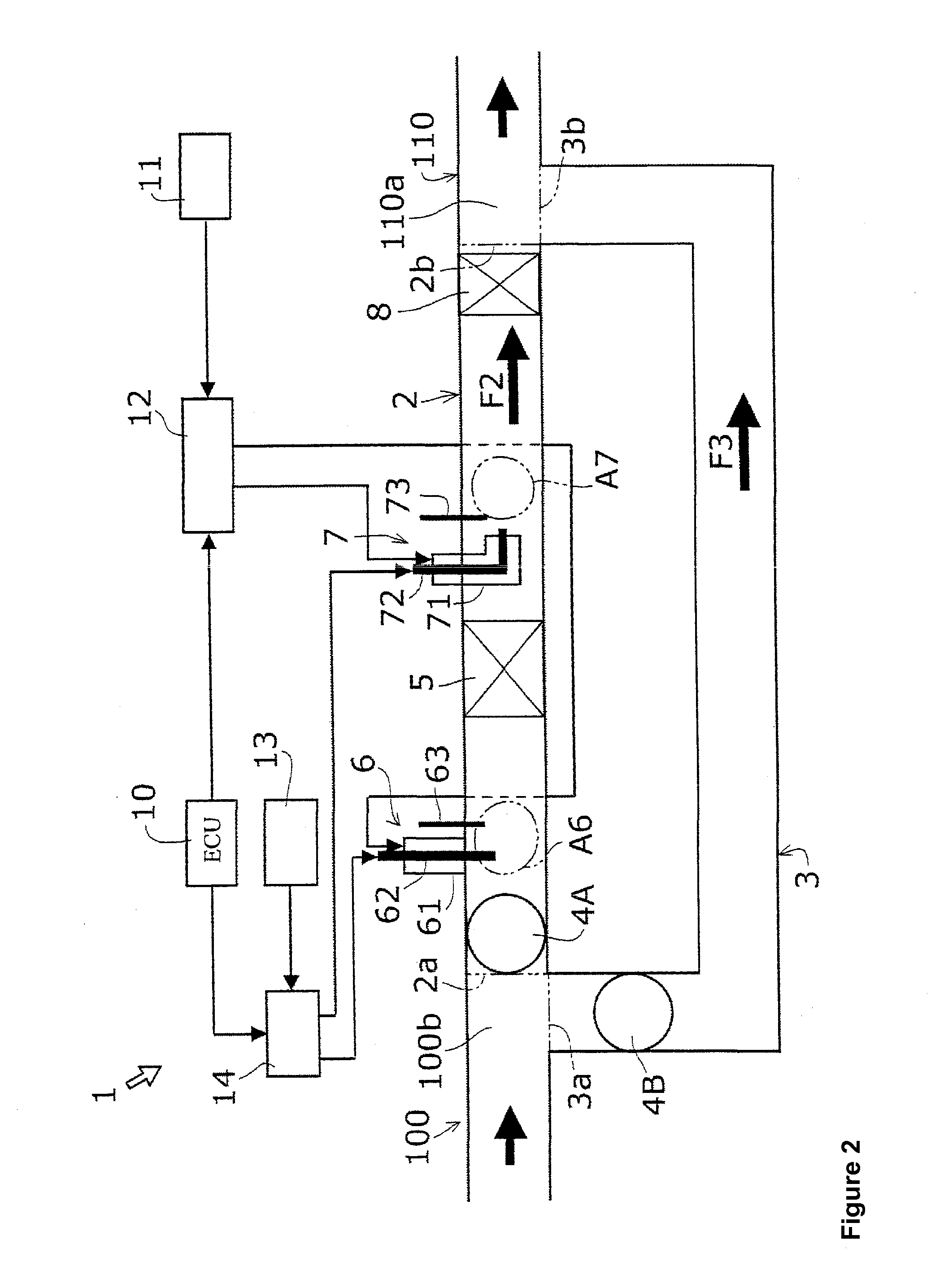

second embodiment

Operation of Second Embodiment

[0089]Next, the operation of the exhaust gas purification device 1, relating to the filter member 8, will be described below.

[0090]In the second embodiment, in addition to the normal operation and the regeneration operation, filter regeneration operation and filter normal operation are performed when the controller 10 operates the exhaust gas purification device 1.

[0091]During the filter regeneration operation, the particulate matter trapped in the filter member 8 is oxidized and eliminated. During the filter regeneration operation, the controller 10 operates the combustion device 7. When the combustion device 7 is operated, a combustion reaction occurs in the zone A7 and on the exhaust downstream side of the zone A7. By this combustion reaction, the particulate matter (carbon) trapped in the filter member 8 is oxidized and eliminated. Even during the filter regeneration operation, the combustion device 7 produces and burns a mixture gas containing exce...

third embodiment

Operation of Third Embodiment

[0102]Next, the operation of the exhaust gas purification device 1, relating to the sulfur oxide adsorbing material 9, will be described below.

[0103]During the normal operation, the nitrogen oxides contained in the exhaust gas are adsorbed onto the nitrogen oxide adsorbing material 5. In addition, the sulfur oxides contained in the exhaust gas are adsorbed onto the sulfur oxide adsorbing material 9. The sulfur oxides are then eliminated from the exhaust gas.

[0104]During the regeneration operation, the controller operates the adsorbed material detachment unit 6. The burned gas is fed to the exhaust downstream side of the zone A6 by the operation of the adsorbed material detachment unit 6. By virtue of the burned gas, a reducing atmosphere and a rising temperature atmosphere are generated around the nitrogen oxide adsorbing material 5, and a reducing atmosphere and a rising temperature atmosphere are also generated around the sulfur oxide adsorbing materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com