Refrigeration apparatus

a technology of refrigerating apparatus and refrigerant, which is applied in the direction of refrigeration machines, gas cycle refrigeration machines, corrosion prevention, etc., can solve the problems of difficult to achieve high operating efficiency, large heat radiation loss of heat exchangers, and temperature difference between refrigerants, so as to reduce defrosting time and reduce the effect of temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

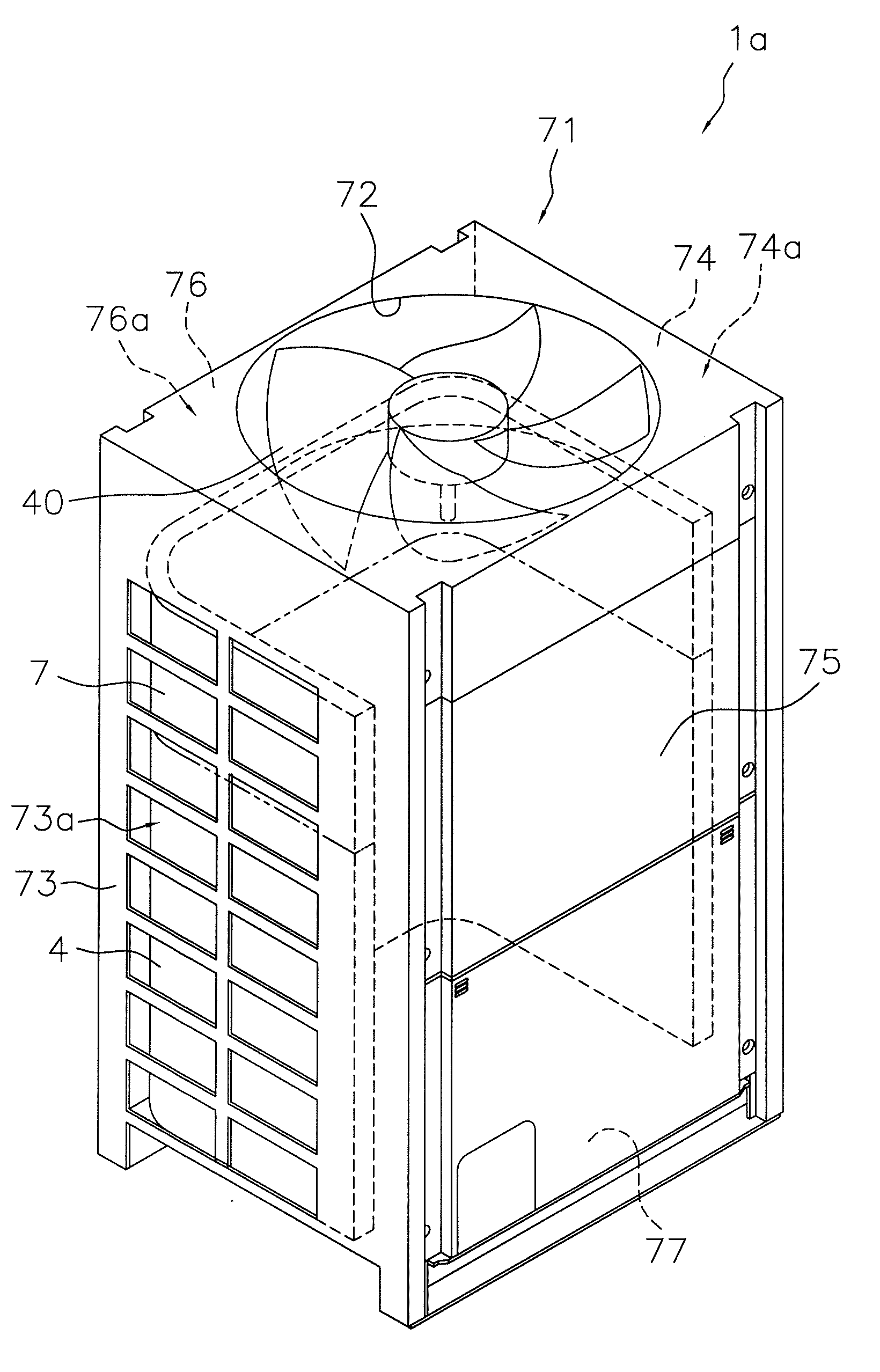

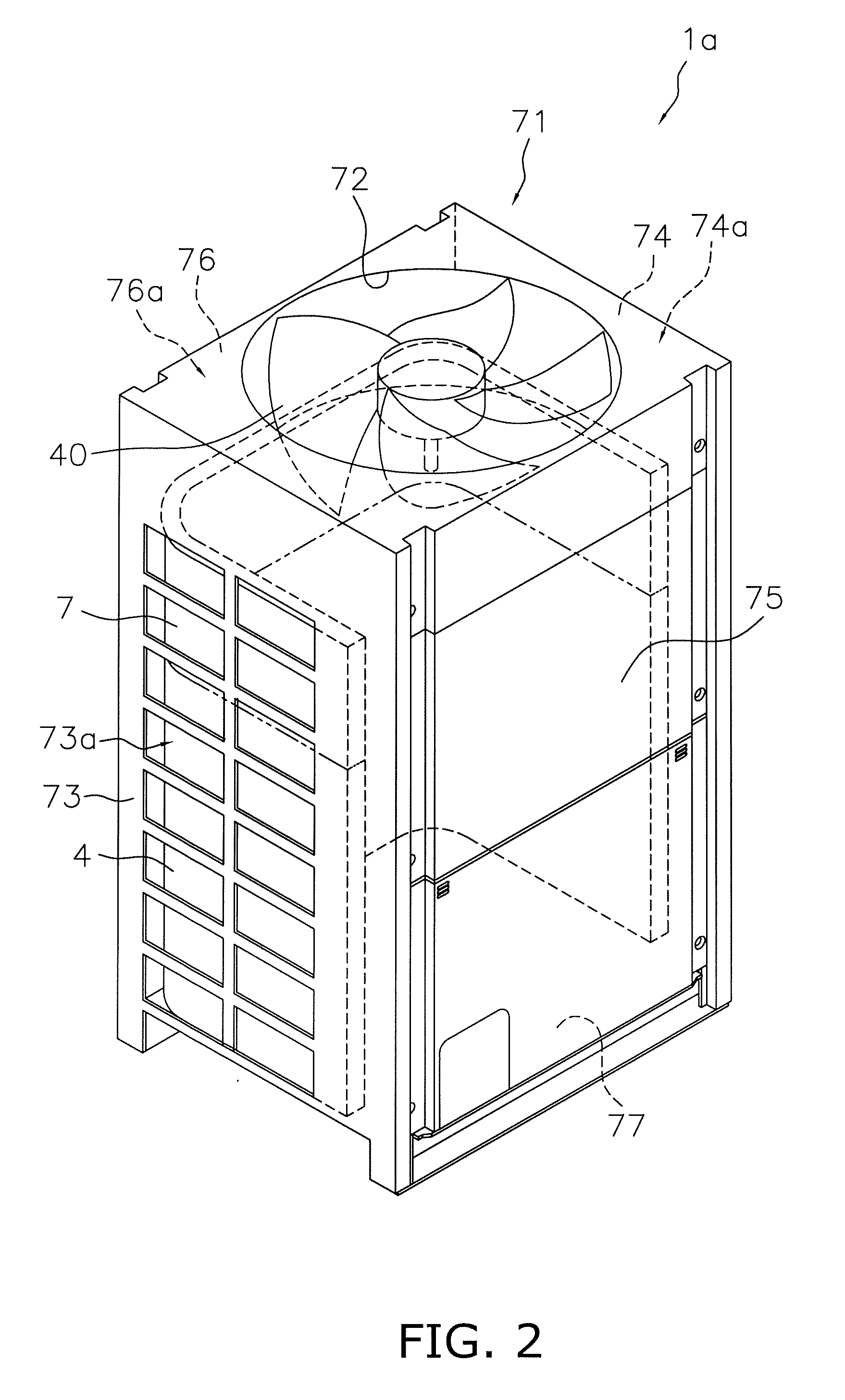

Image

Examples

modification 3

(5) Modification 3

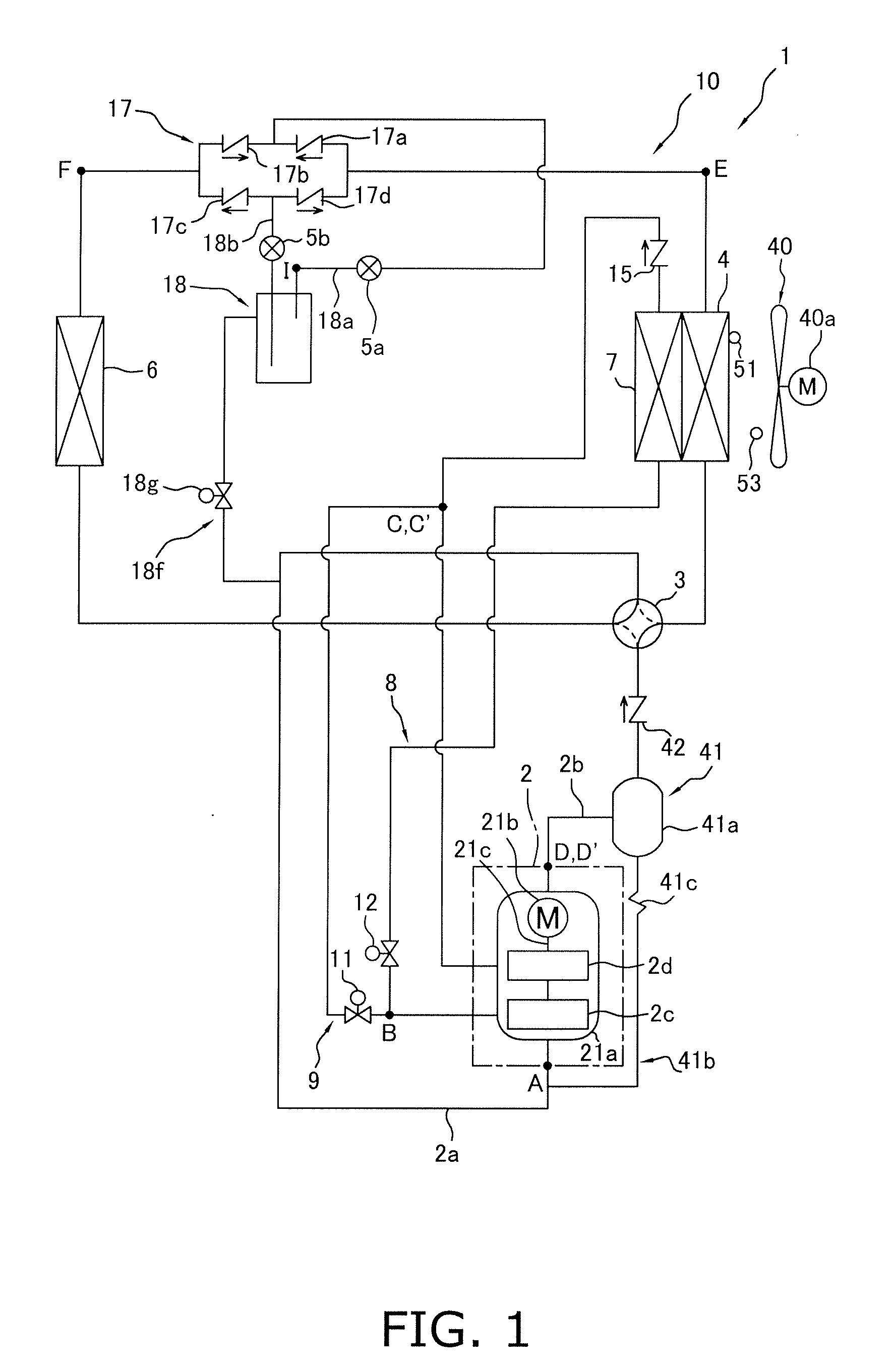

[0140]In the refrigerant circuit 210 (see FIG. 24) in Modification 2 described above, in both the air-cooling operation in which the switching mechanism 3 is brought to the cooling operation state and the air-warming operation in which the switching mechanism 3 is brought to the heating operation state, the temperature of the refrigerant discharged from the second-stage compression element 2d is reduced, the power consumption of the compression mechanism 2 is reduced, and operating efficiency can be improved by performing intermediate pressure injection by the economizer heat exchanger 20 as described above. The intermediate pressure injection by the economizer heat exchanger 20 is believed to be beneficial in a refrigerant circuit configuration having a single usage-side heat exchanger 6, and wherein the pressure difference from the high pressure in the refrigeration cycle to the nearly intermediate pressure of the refrigeration cycle can be used.

[0141]However, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com