Device for increasing the heating and cooling output of a heat pump in heat reclamation in air conditioning units

a heat pump and heat reclamation technology, which is applied in the field of heat reclamation, can solve the problems of increasing the temperature of the heat transfer medium, reducing efficiency, and unsatisfactory heat transfer effect of the heat pump, and achieve the effect of reducing the input of primary energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

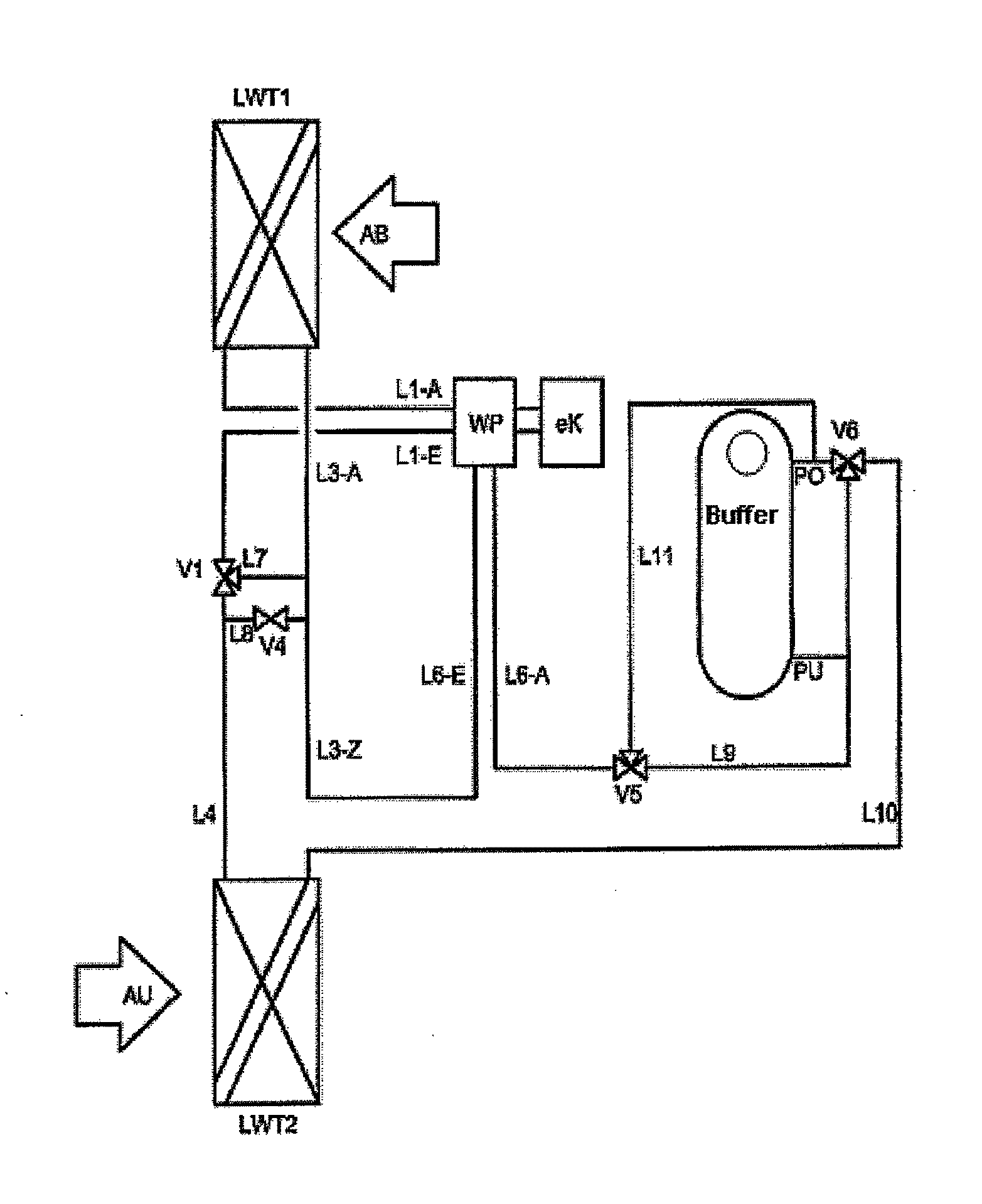

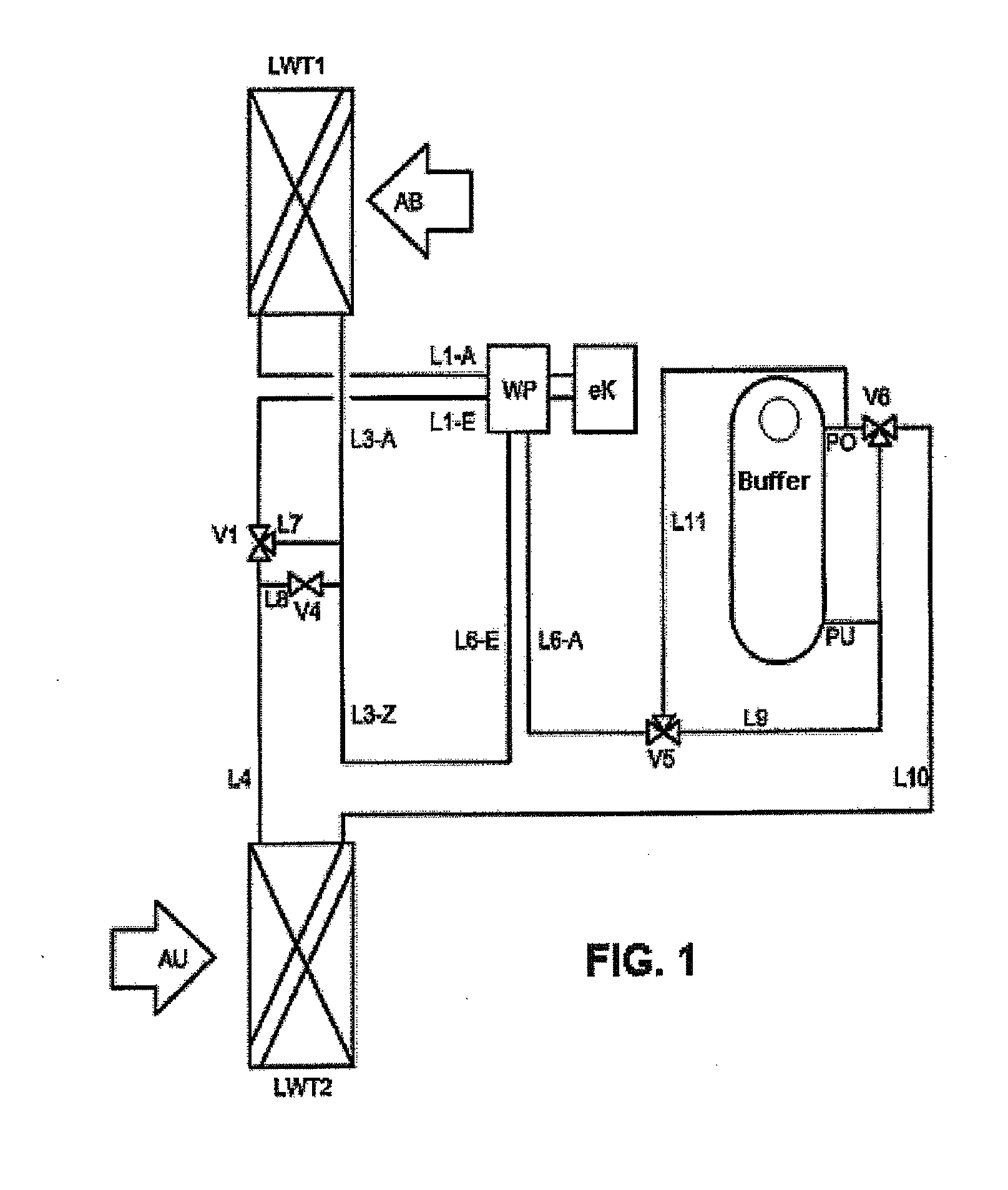

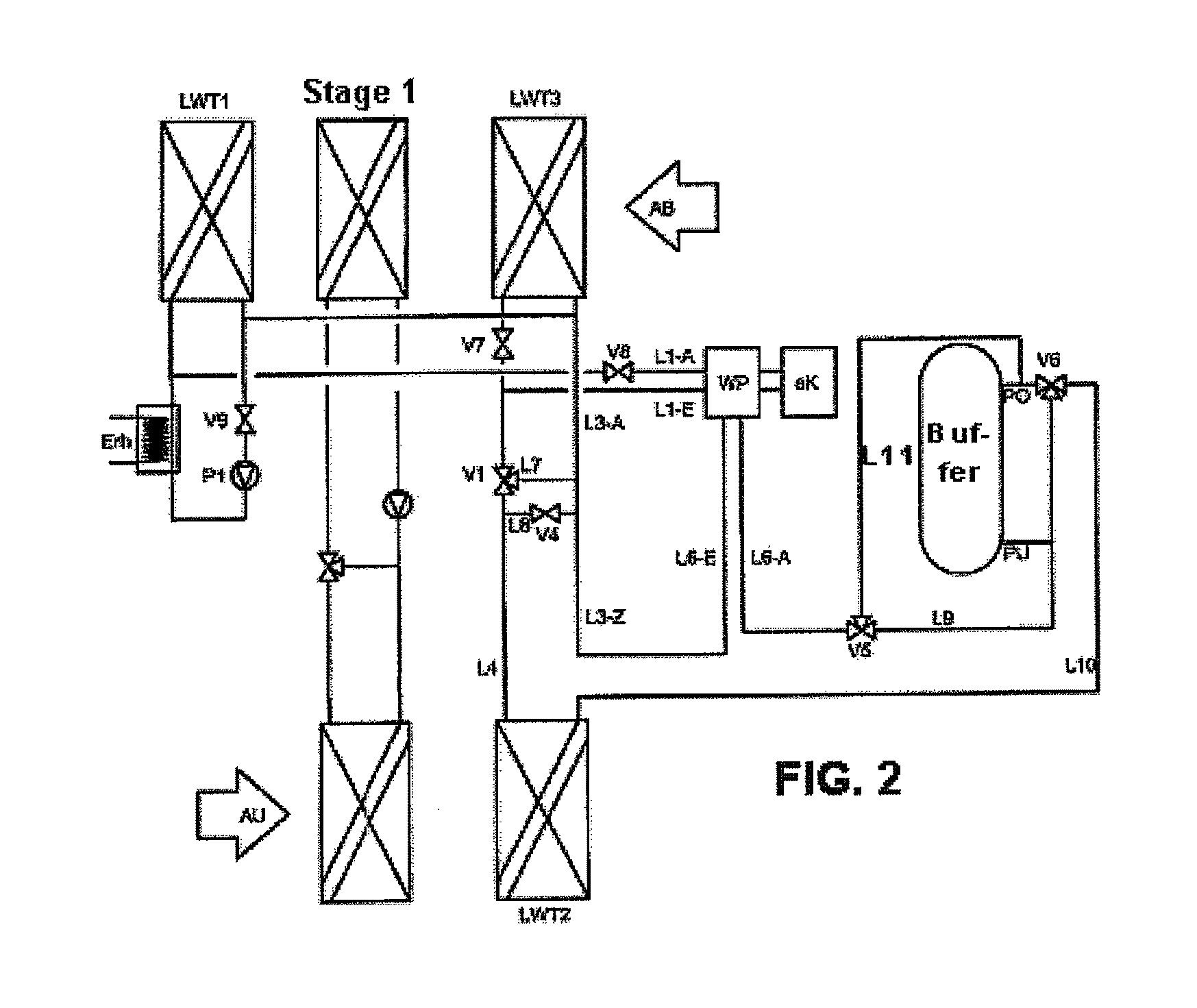

[0048]In a preferred embodiment, a circuit according to FIG. 1 is used. The hydraulic circuit is connected in such a way that it forms an interconnected circulating system when the compressor of the heat pump WP is switched off. FIG. 1 shows the basic incorporation of a buffer reservoir into an interconnected circulating system. In this case, the buffer reservoir may be realized in the form of a so-called stratified reservoir, wherein thermal energy can be stored in and withdrawn from this reservoir layer-by-layer. This is realized due to the corresponding connection with the supply lines PU, PO and the three-way valve V6. The heat pump WP furthermore is assigned to the buffer reservoir in order to supply thermal energy to this buffer reservoir.

[0049]Regarding Operating Mode 1:

[0050]Referring to the system of the FIG. 1, Operating mode 1 occurs when the compressor is switched off and without using the heat pump WP.

[0051]The heat transfer medium is conveyed in the hydraulic circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com