Balance ring system on two planes for a spin rotary machine

a technology of balance rings and rotary machines, applied in the field of washing machines, can solve problems such as major problems such as vibration caused by imbalance, and achieve the effects of reducing the number of parts required, reducing the cost of production, and simplifying the manufacture of the machin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Theoretical Approach

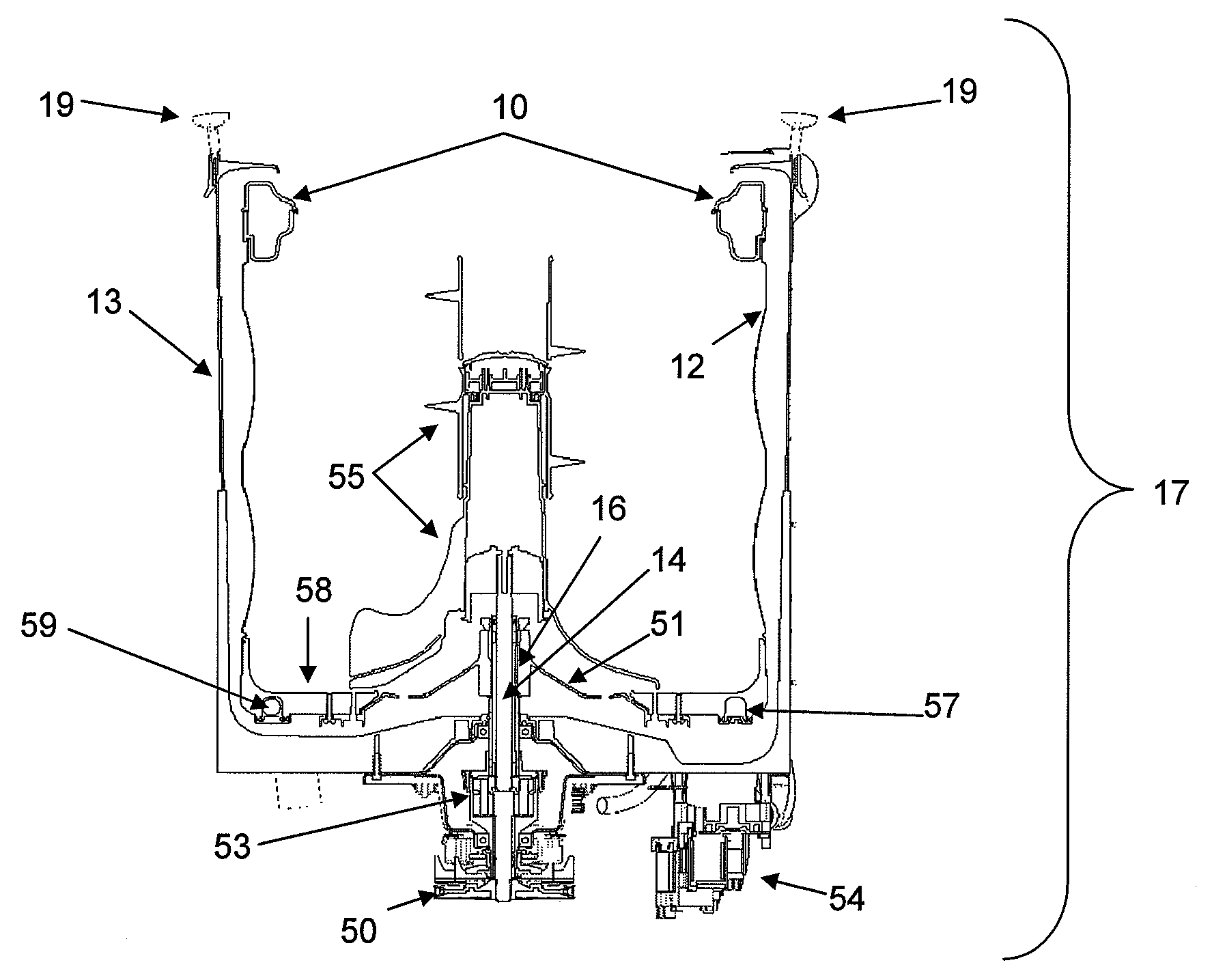

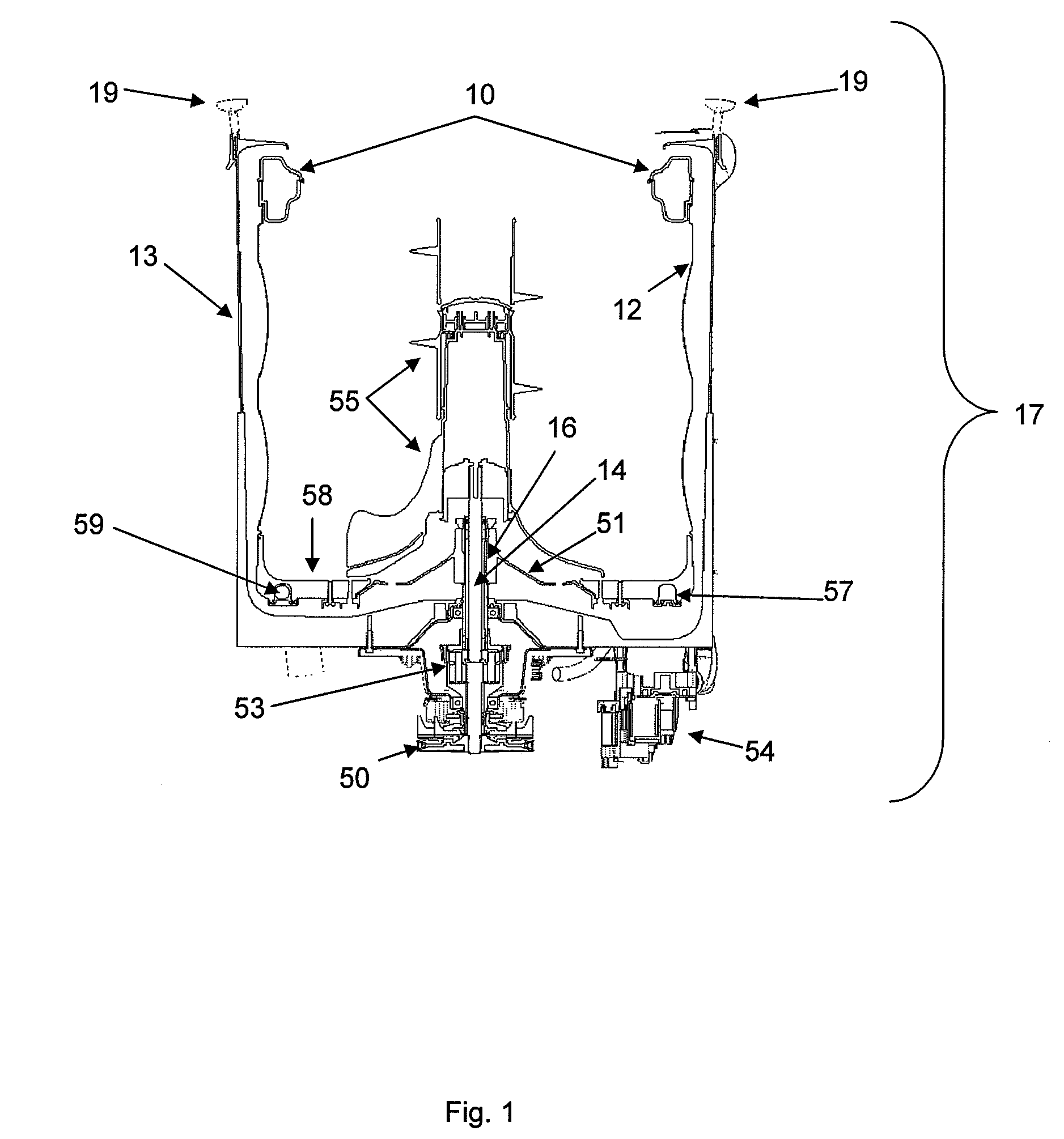

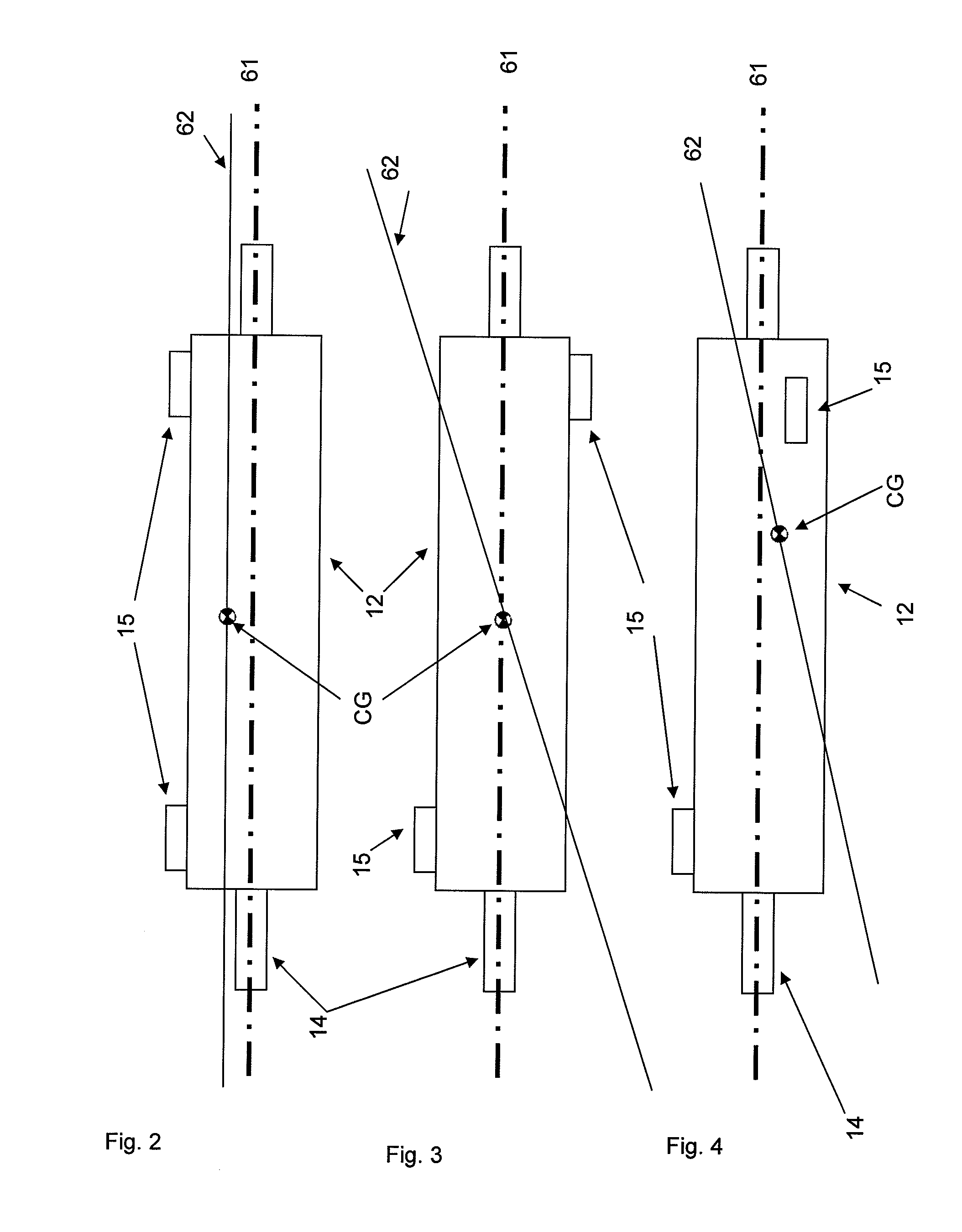

[0055]The imbalance in a rotor can occur due to various causes, one of them can be due to the rotor's manufacturing method, having set more material in a specific point of the rotor, or on the contrary, due to a lack of uniformity in the density of the material. Sometimes, it may occur that other phenomena can cause the undesired vibrating effects in the washing machines, such as a deficient alignment of its shafts, defective bearings, inadequate lubrication of the bearings or supporting points that cause friction, mechanical looseness, and a deficient alignment of the bands with the pulleys, etc. The most interesting cause for purposes of the present invention is the imbalance due to the internal loads in the rotor. As can be deducted from FIG. 1, a washing basket 12 of a sub-washing machine 17 is set up within a tub 13. This basket 12 is moved or driven by a shaft 14 which is rigidly coupled with the bottom part of the basket 12, usually by means of a central p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com