Auxiliary vacuum device for a central vacuum cleaning system

a vacuum cleaning and auxiliary technology, applied in the field of central vacuum cleaning system, can solve the problems of high cumbersomeness, limited power of auxiliary devices, and long hose length, and achieve the effect of reducing accidental activation of devices and simple construction and design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]With reference to the annexed drawings the preferred embodiment of the present invention will be herein described for indicative purpose and by no means as of limitation.

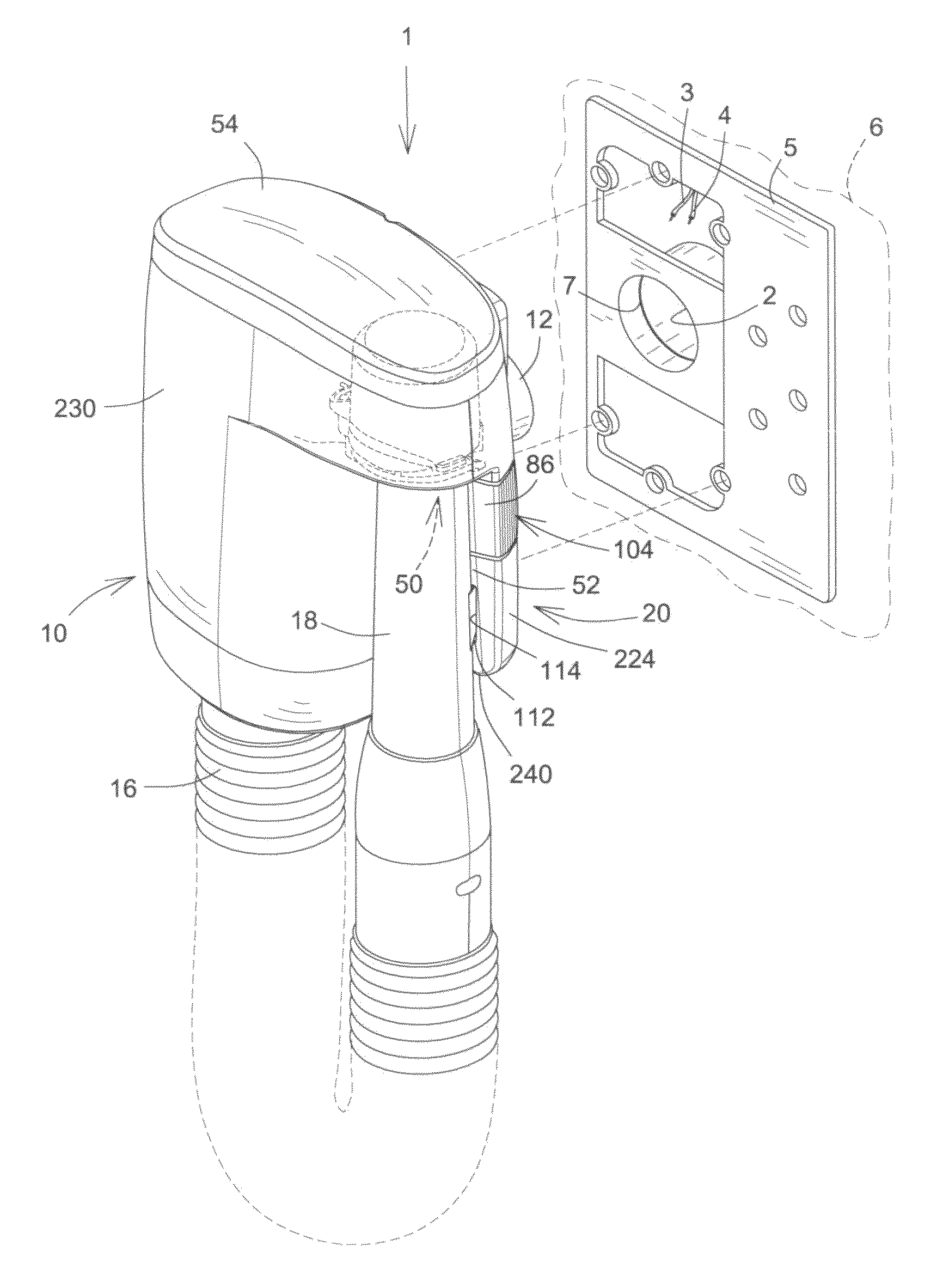

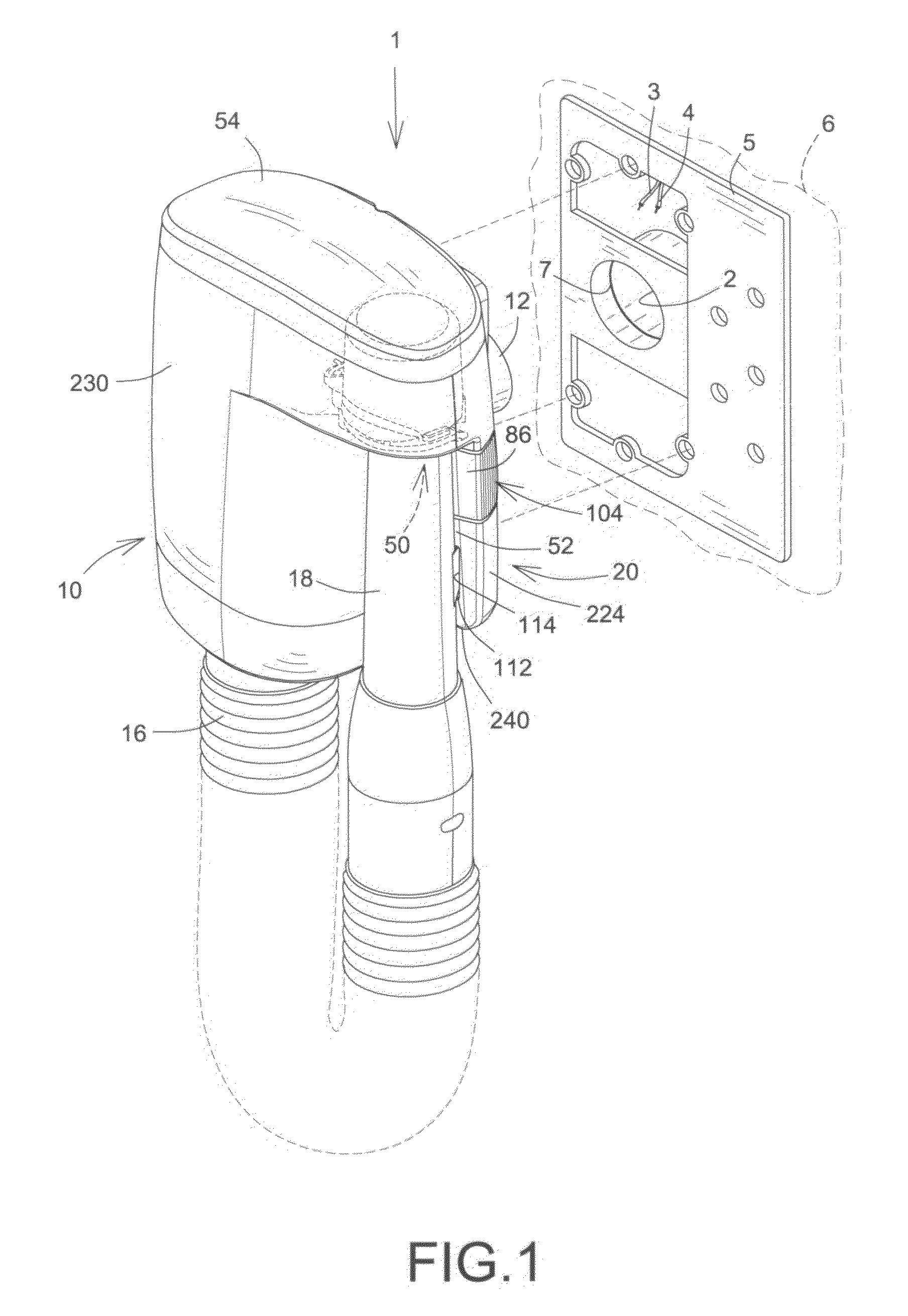

[0021]In FIG. 1, there is illustrated an auxiliary vacuum device, shown generally as 1, which is mountable on a mounting plate 5. Mounting plate 5 incorporates an inlet opening 2 of a central vacuum cleaning system (not shown) which incorporates an electrically powered vacuum generating unit, including a motor, for generating a vacuum. The operation of vacuum generating unit is controlled by the device 1 in the manner hereinafter defined. Suitable low voltage electrical wires 3, 4, connected to an electrical power supply and to the electrically powered vacuum generating unit, are provided and protrude from a rear aperture 300 in the mounting plate 5 which is installed in or on a wall 6 of the area of occupancy or premises in which the central vacuum cleaning system is installed.

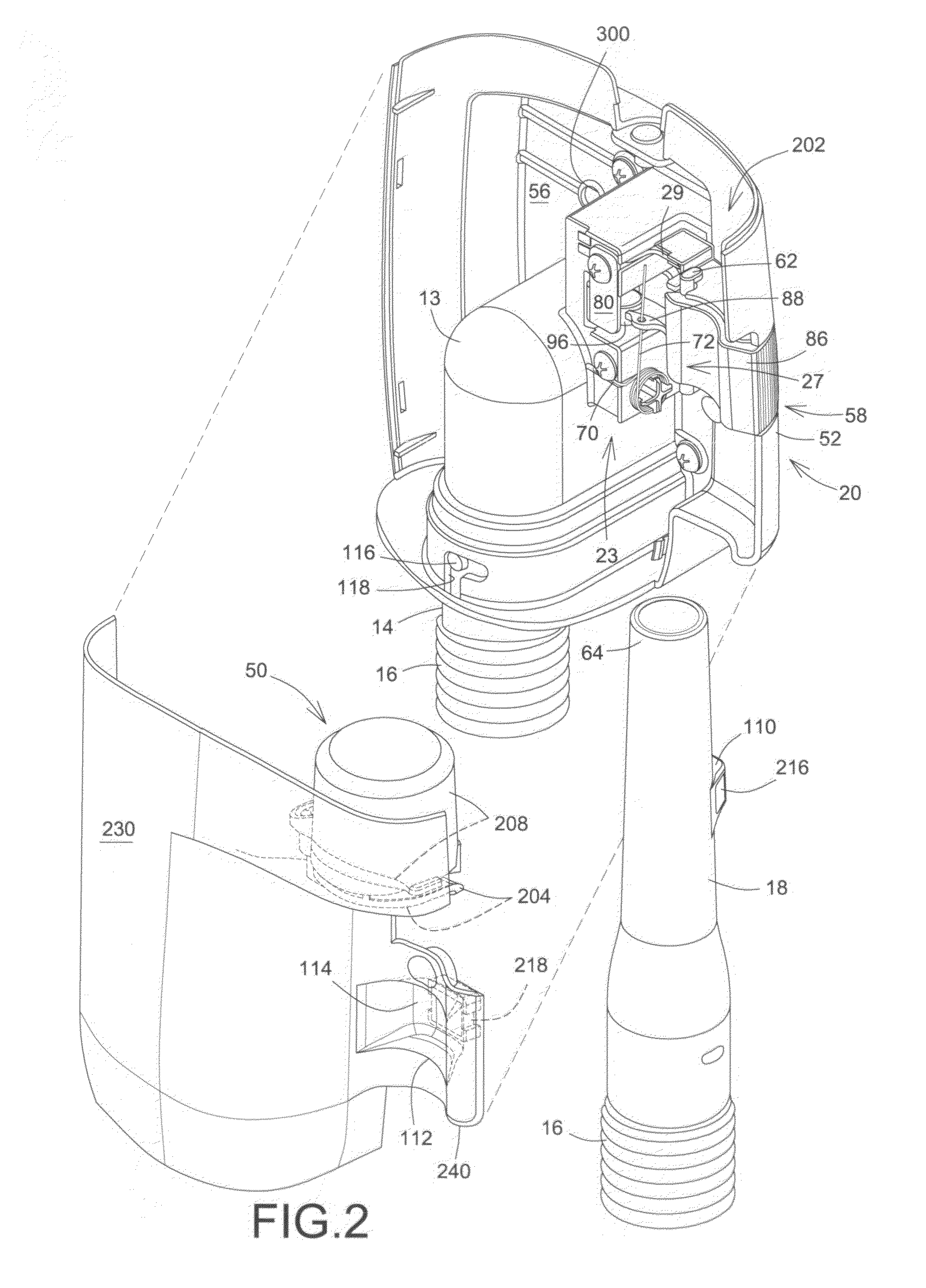

[0022]Referring now to FIGS. 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com