Method of Lubricating an Internal Combustion Engine

a technology of internal combustion engine and lubricating method, which is applied in the direction of lubricant composition, fuel, mixing, etc., can solve the problems of detergents delivering limited tbn, corrosive acids form during combustion, and sludge and other deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

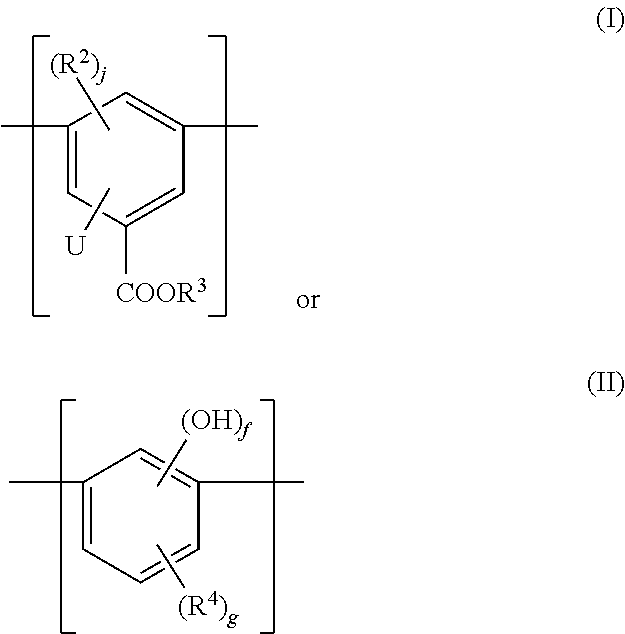

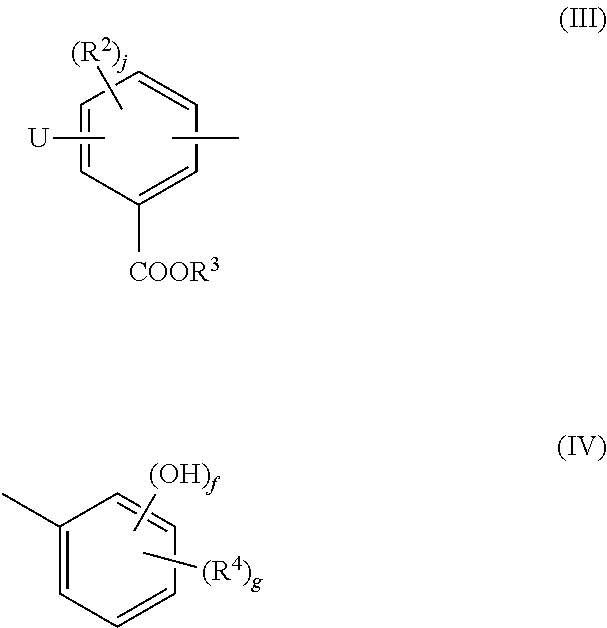

Image

Examples

examples

Preparative Examples of Dispersions

[0082]A series of dispersions containing a metal base, an organic medium and a surfactant are prepared from a slurry comprising 40 wt % to 50 wt % of the metal base, 6 wt % to 15 wt % of a surfactant and the remained a hydrocarbon fluid, typically solvent neutral 100 mineral oil. 2 kg to 5 tonnes of the slurry is milled in a horizontal bead mill with a milling chamber of suitable size appropriate for the scale of the operation. The bead size filling the chamber (typically 65 vol. %) is typically in the range 0.7 mm to 0.1 mm diameter (e.g. 0.3 mm+ / −0.05 mm beads). After a suitable amount of milling, typically 4 to 20 minutes residence time (i.e. the actual time the dispersion spends in the mill) the required particle size is achieved (i.e. ≦1 μm) as determined by Coulter® LS230 Particle Size Analyser. The dispersion is easy to pour and stable for several weeks between −20° C. and +60° C., showing no tendency to stratify or to form a gel. The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com