Reduction of unpolymerized monomers in high internal phase emulsion foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

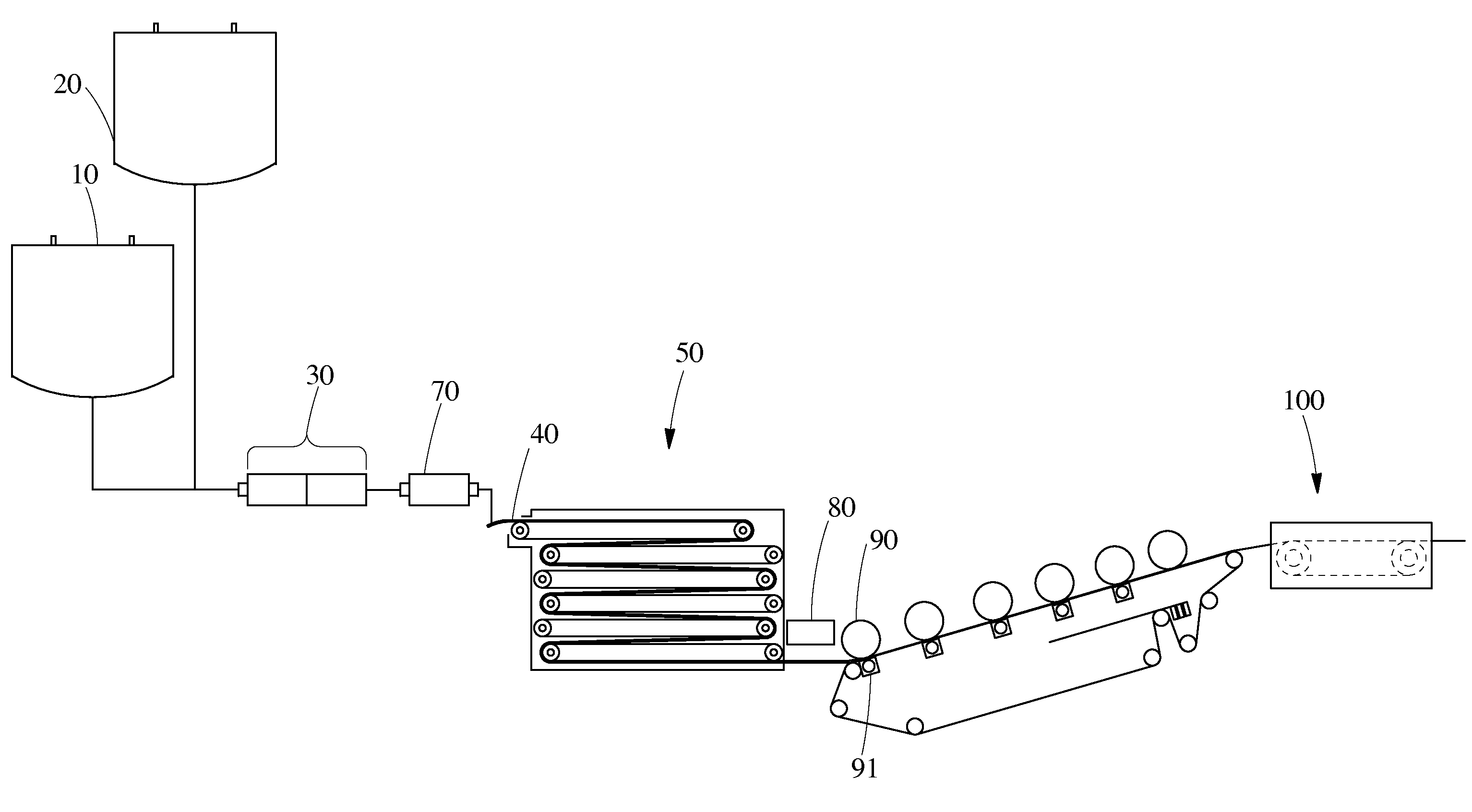

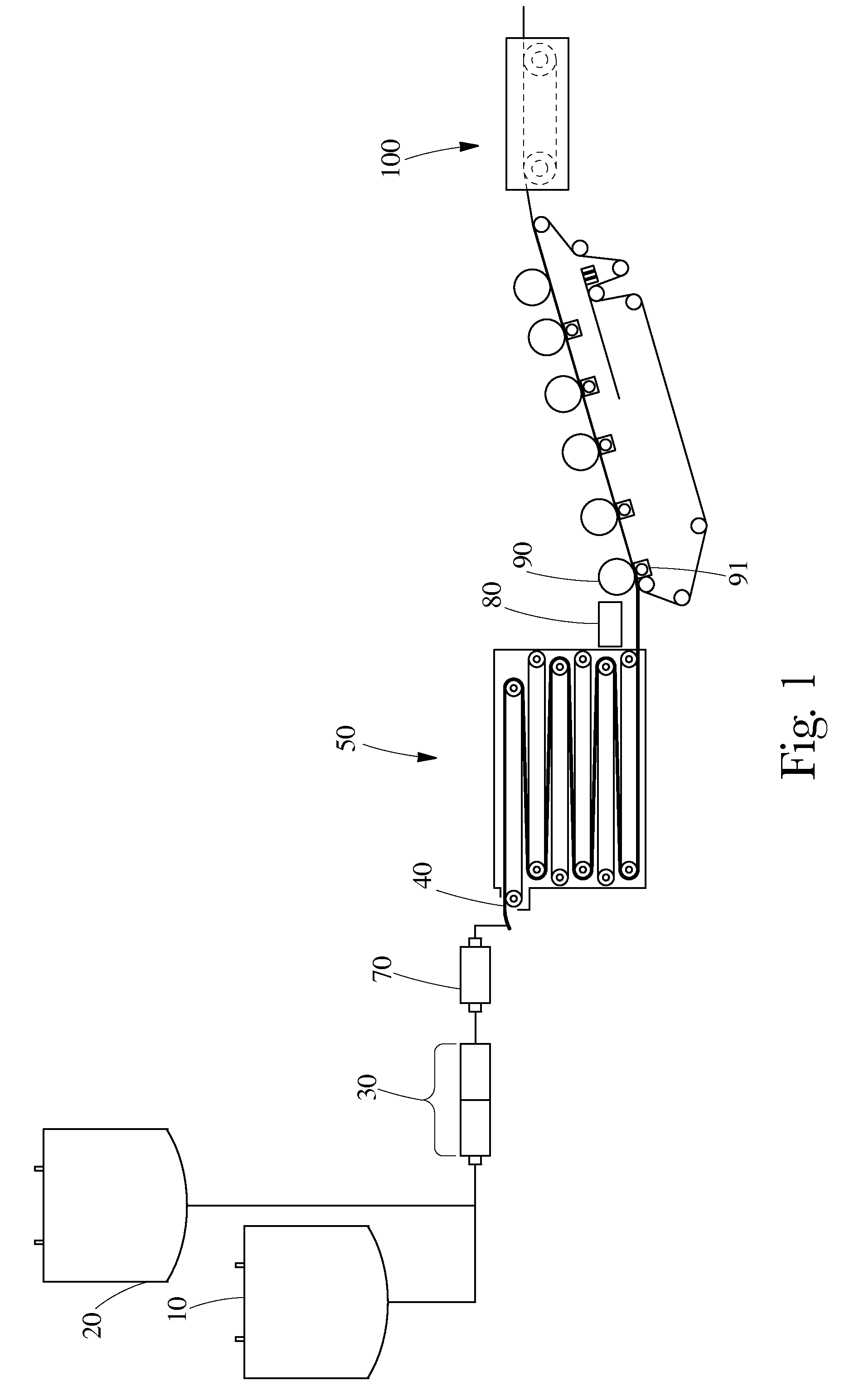

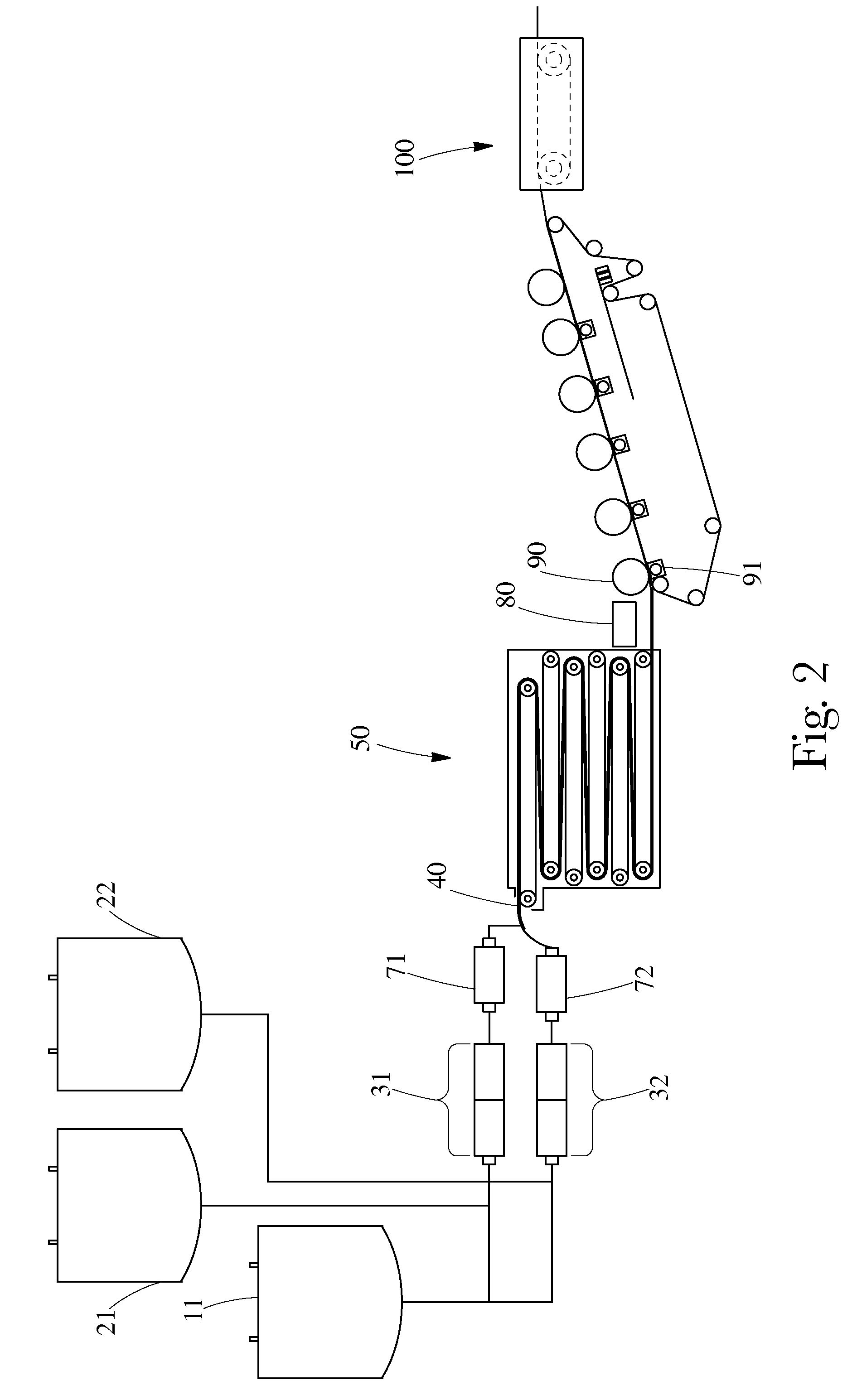

Image

Examples

example

[0042]Preparation of High Internal Phase Emulsions (HIPE) and their subsequent polymerization into absorbent foams are illustrated in the following example. The HIPE samples comprised two layers—a bottom layer and a top layer, wherein the bottom layer had a smaller average pore size of 30 microns and the top layer had a larger average pore size of about 80 microns.

[0043]A. Small Cell Layer HIPE Formation

[0044]Small Cell Layer Components:

[0045]To prepare the bottom small cell layer of the HIPE the aqueous phase, oil phase, and initiator contained the following components as shown below in Table 1.

TABLE 1% Amount Based onOil PhaseTotal Weight of Oil Phase2-ethylhexyl acrylate (EHA)36.7%2-ethylhexyl methacrylate (EHMA)37.61%ethyleneglycol dimethacrylate (EGDMA)17.43%dimethyl ammonium methyl sulfate0.93%(DTDMAMS)Polyglycerol succinate (PGS)6.48%Photoinitiator - Darocur 1173*0.99%Aqueous Phase% Amount Based on Total Weight of Aqueous PhaseCaCl23.85%Water:oil ratio26:1% Amount Based on To...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com