Real time monitoring of indium bump reflow and oxide removal enabling optimization of indium bump morphology

a technology of indium bumps and real-time monitoring, which is applied in the field of semiconductor devices, can solve the problems of inability to obtain a reliable, high-density bump pattern high-quality process, and the tendency of indium bumps to oxidize,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]In the following description of the preferred embodiment, reference is made to the accompanying drawings which form a part hereof, and in which is shown by way of illustration a specific embodiment in which the invention may be practiced. It is to be understood that other embodiments may be utilized and structural changes may be made without departing from the scope of the present invention.

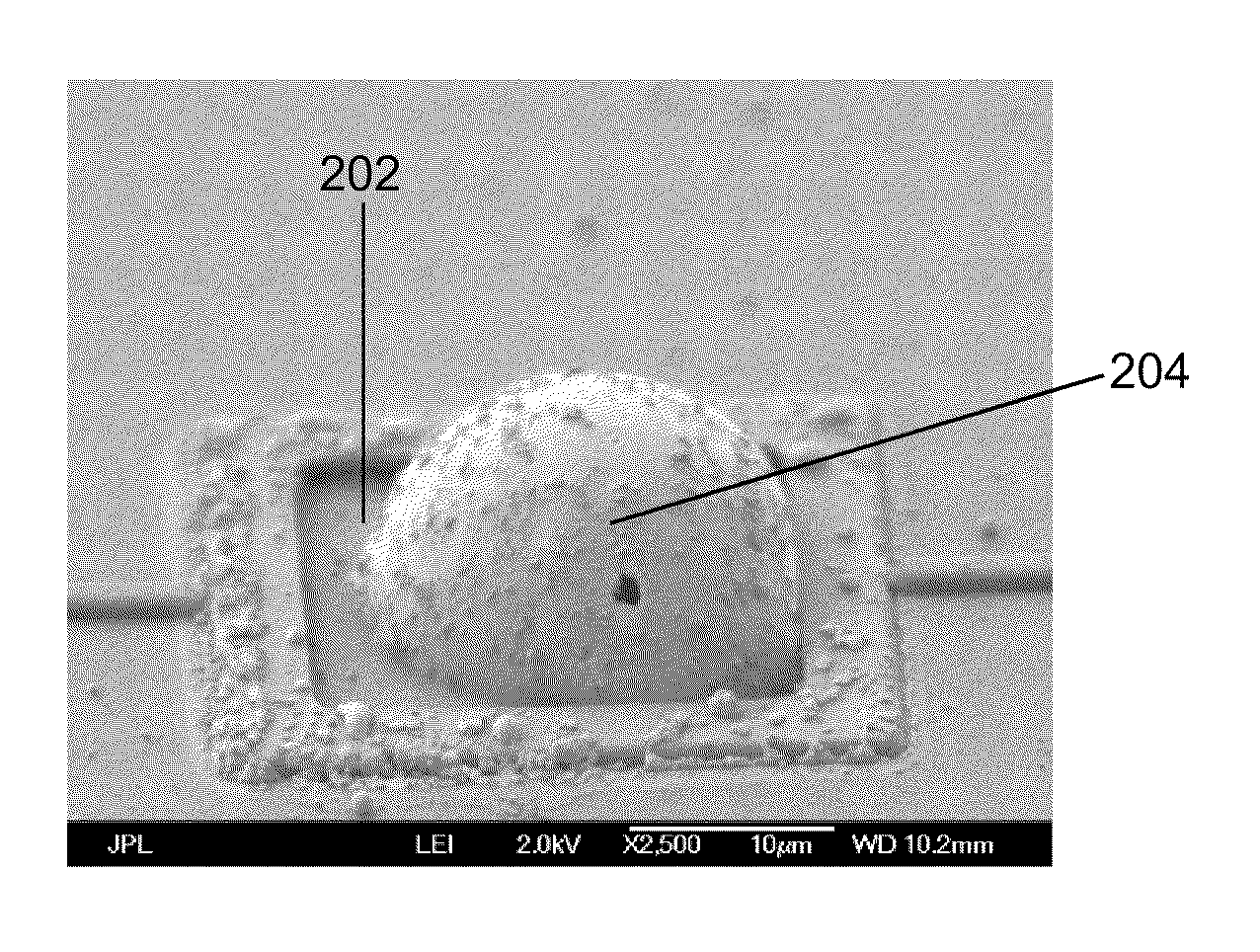

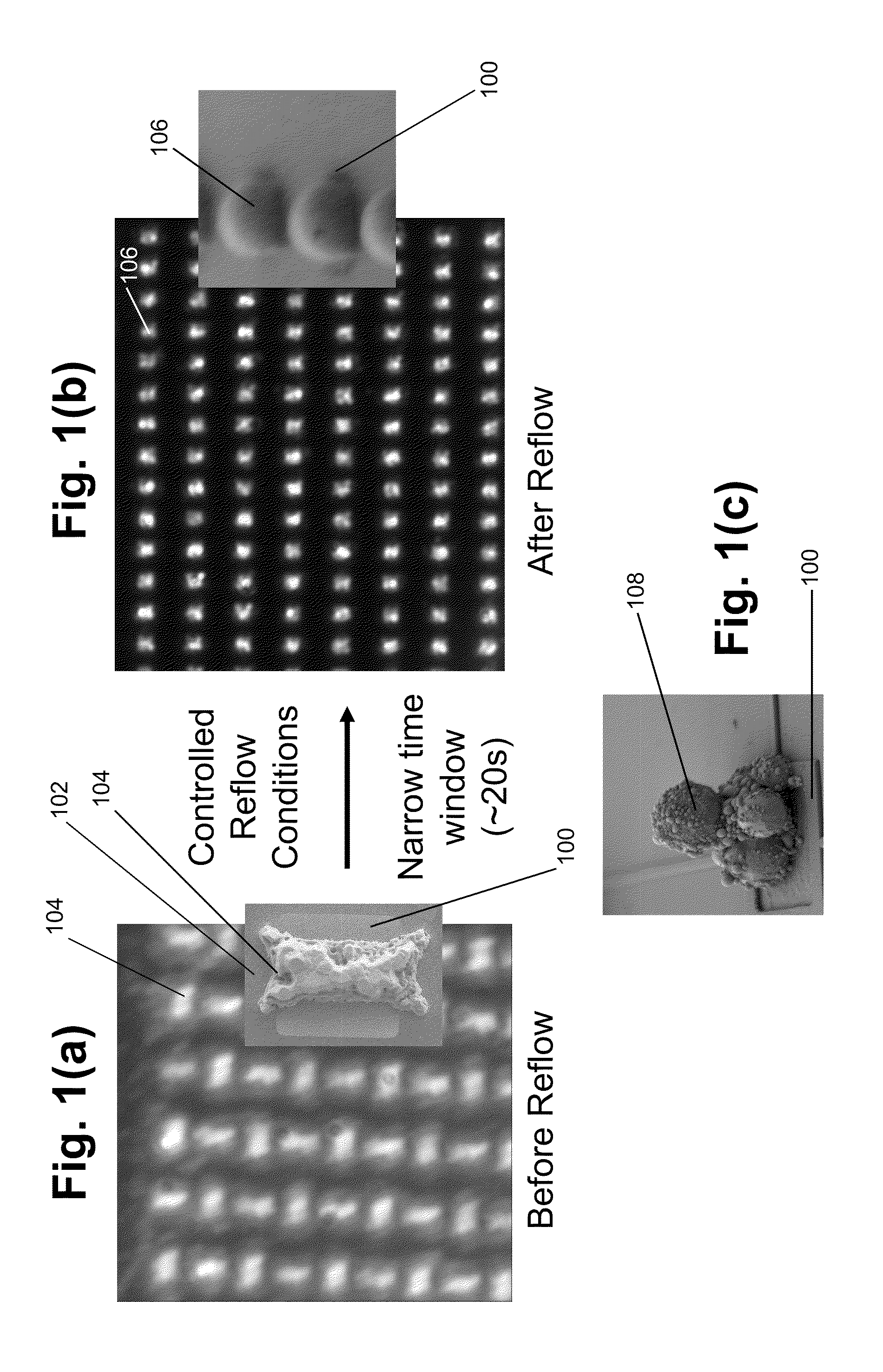

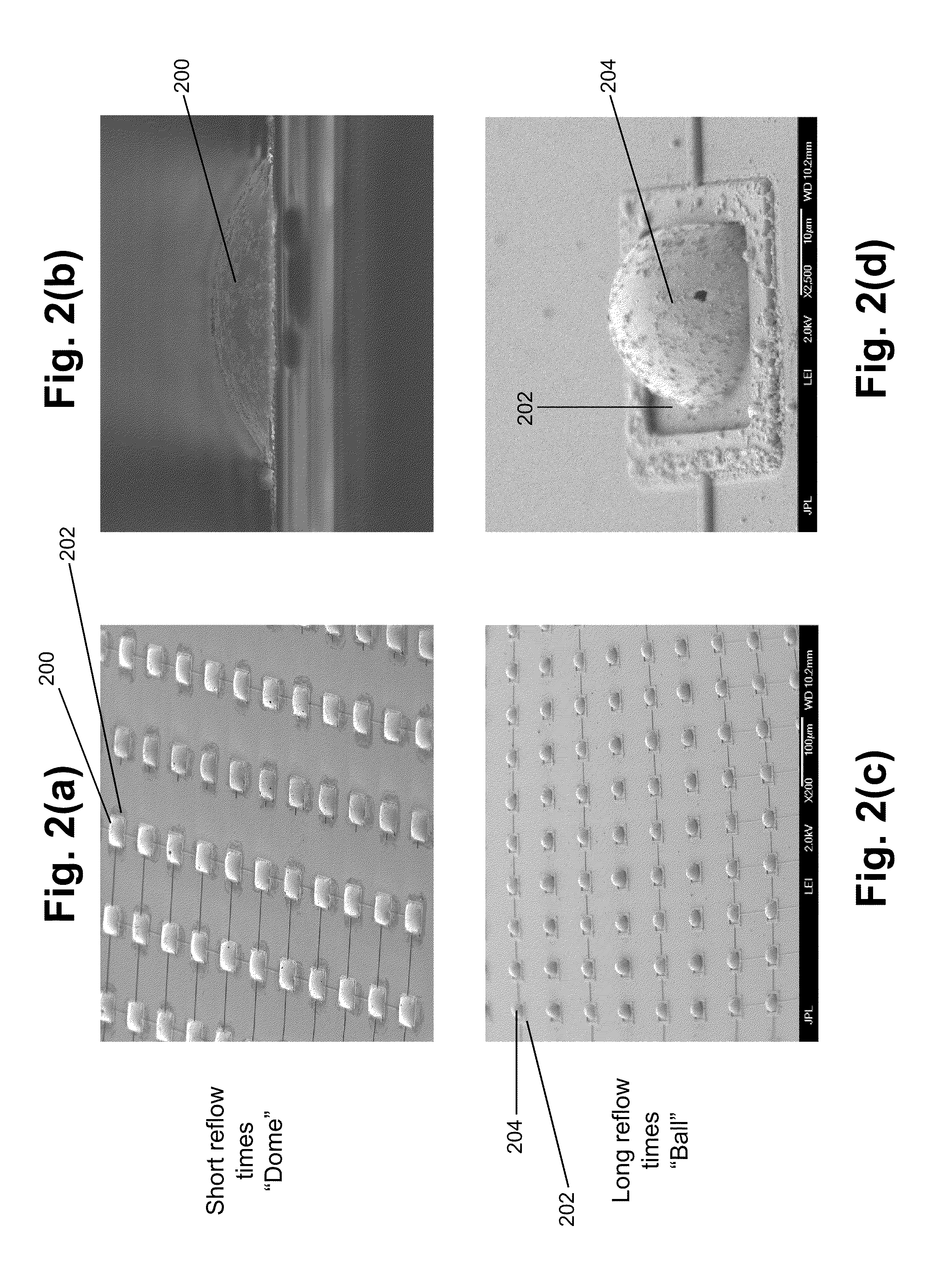

[0048]Overview

[0049]One or more embodiments of the present invention include both a process for removing indium oxide from indium bumps used in flip chip hybridization (bump bonding), a process for reflowing these indium bumps into a highly wetted configuration (dome shape) versus less desirable unwetted shapes (rectangles or spheres), and a way to monitor this transition in real time. This is the first known demonstration of the production of indium “domes” for hybridization. The reflow and indium oxide removal processes are attained by exposing detector and readout samples, with indium bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com