Thermal storage system for use in connection with a thermal conductive wall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

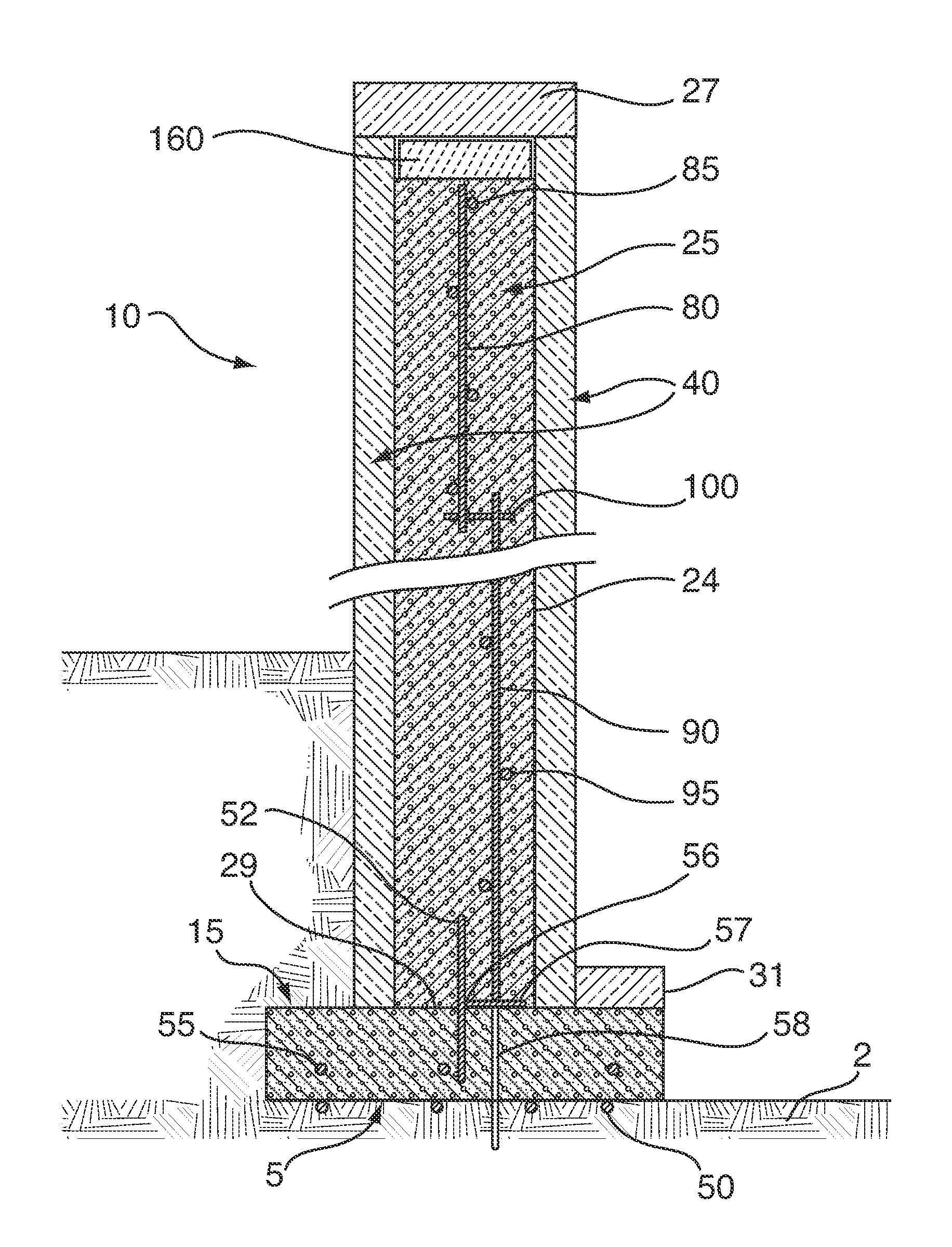

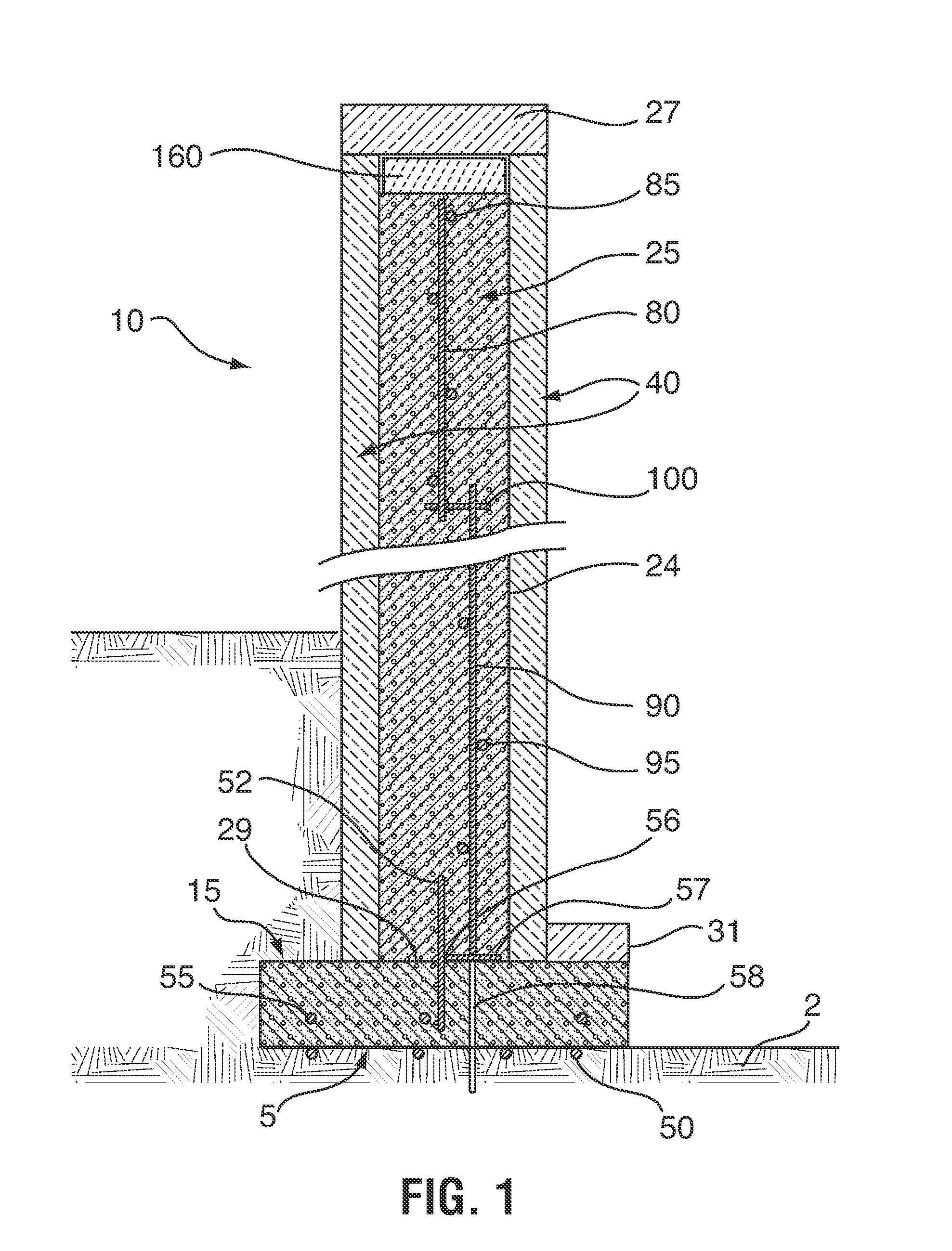

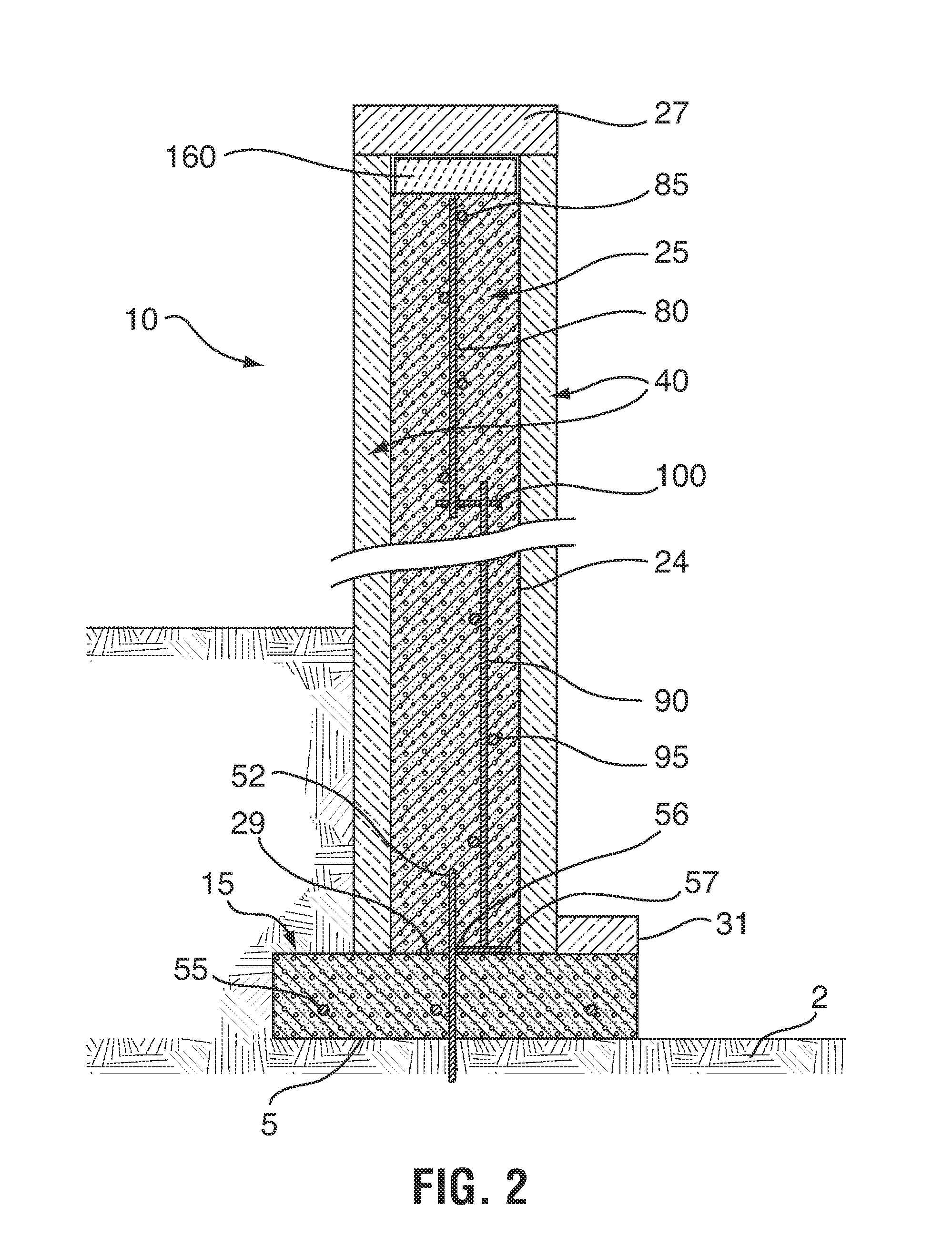

Image

Examples

example

By way of example, the thermal storage system of the present invention was tested using the following input parameters:

VariableValueUnitCommentssoil thermal conductivity1.5W / mKThis value is fixed and estimated for dry soilpipe thermal conductivity0.51W / m · KThis value is fixed and known for pipe selectedinside pipe temperature80° C.This value is fixed and knowndesired ground temperature23° C.This value is chosen as a set pointinside pipe radius0.013mThis value will depend on pipe selectionoutside pipe radius0.019mThis value will depend on pipe selection and isselectable and variabledistance from pipe to1.119mThis value is chosen by installing engineer andfootingwill depend on applicationmaximum volumetric2500000J / m3 · KThis value is fixed and estimated for dry soilspecific heat of soilminimum volumetric2000000J / m3 · KThis value is fixed and estimated for dry soilspecific heat of soilspecific heat of working3558.8J / kg · KThis value is known for this working fluidfluid (50-50 water / gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com