Ferrous sintered alloy and process for producing the same as well as ferrous-sintered-alloy member

a technology which is applied in the field process for producing the same as well as ferrous sintered alloy member, can solve the problems of poor recyclability, difficult smelting of elements, and raising the production cost so as to improve the strength of ferrous sintered alloy, the effect of reducing the cost of smelting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

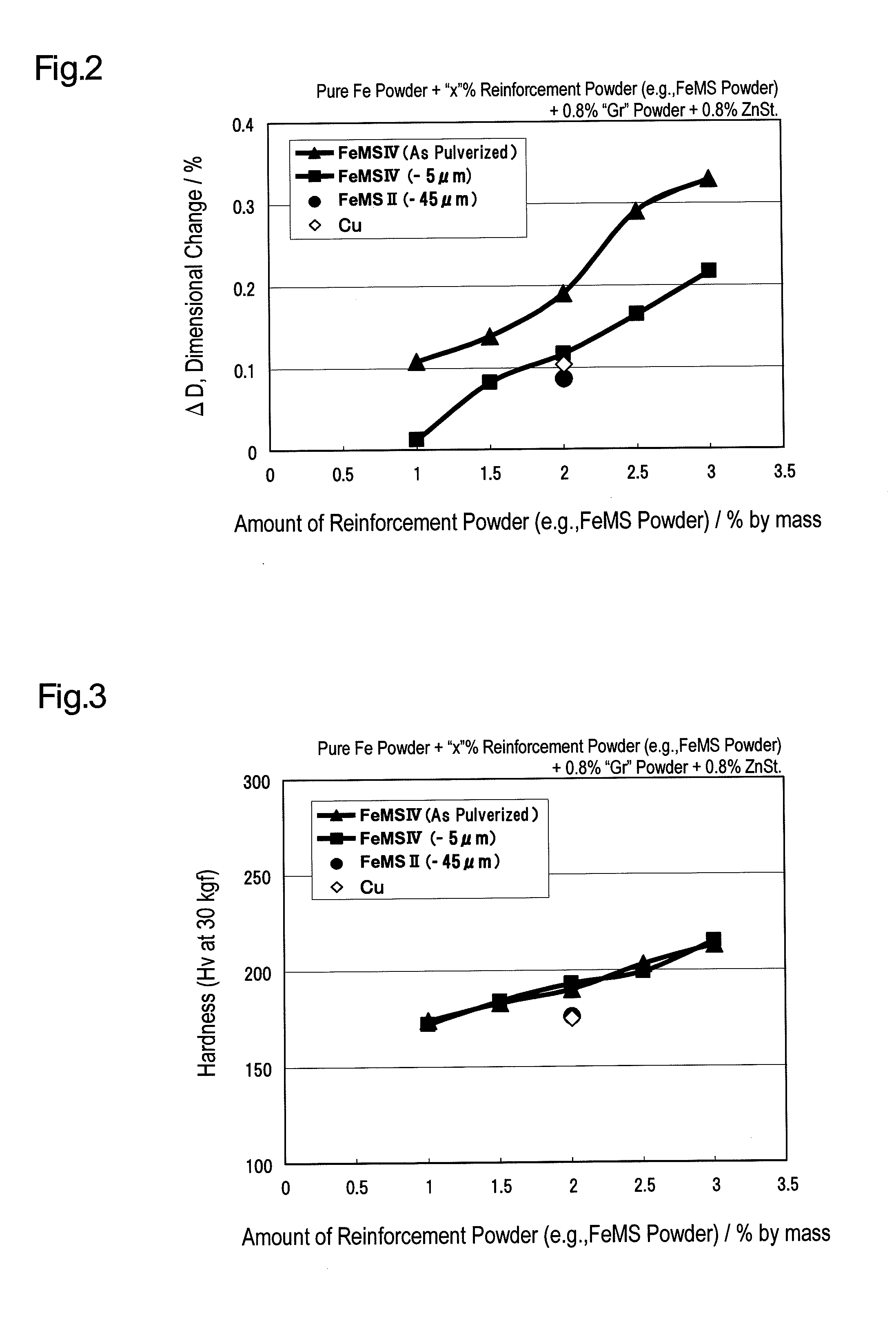

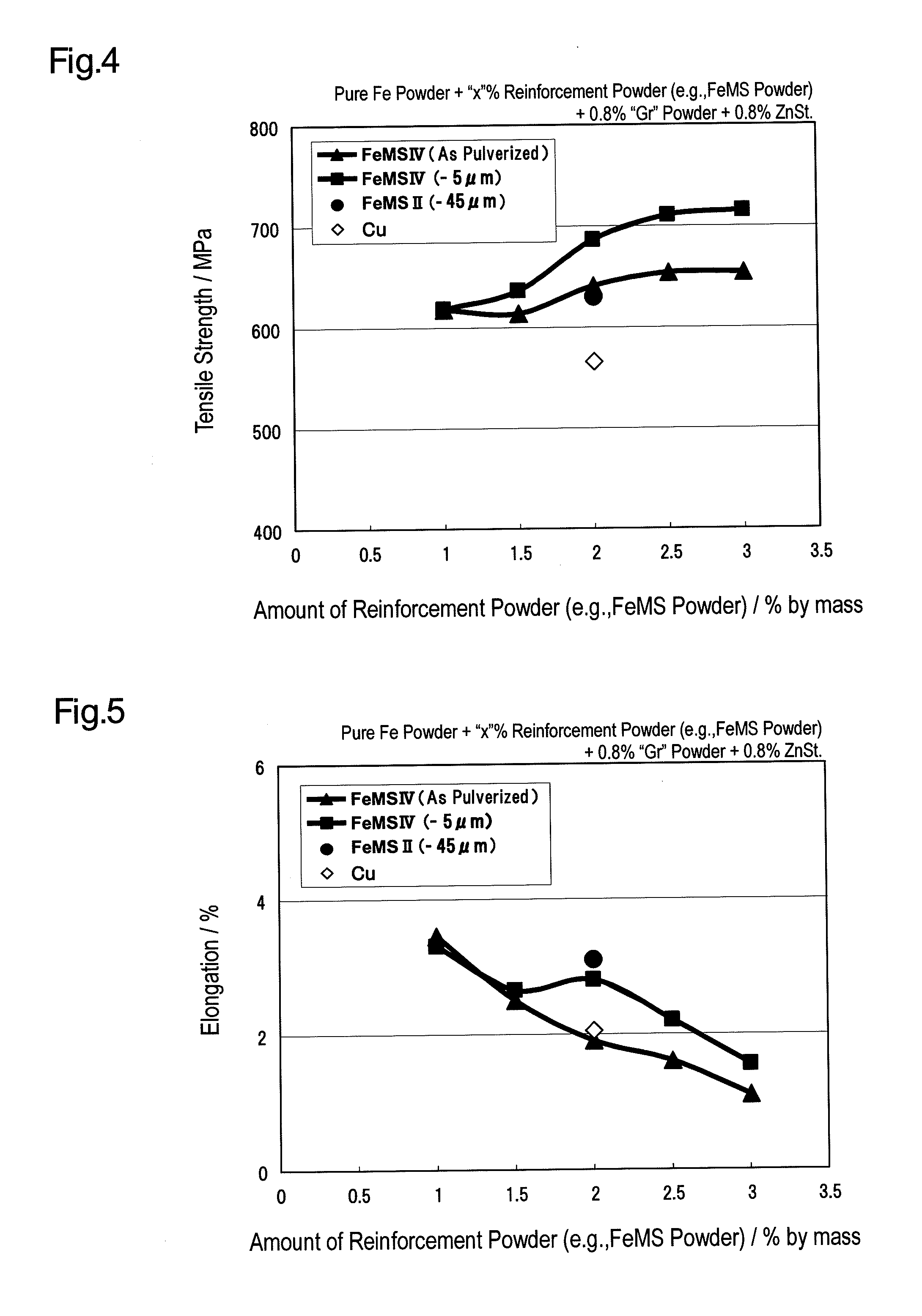

[0147]The present invention will be explained hereinafter in more detail while naming specific examples.

[0148]>

[0149](1) As a reinforcement powder to be blended to an Fe-system powder, the following were made ready: two kinds of FeMS powders with different compositions that are given in Table 1; and a Cu powder (“DistaloyACu” (or Fe-10% Cu) with particles diameters of from 20 to 180 μm, a product of HOEGANAES AB Corp.).

[0150]First of all, an FeMSII powder (or Fe—Mn—Si powder), one of the FeMS powders, was made by pulverizing an ingot (or solid metal casting) in air, ingot which was die cast in an Ar gas atmosphere and whose blended composition was Fe-50 Mn-30 Si (units: % by mass). Next, an FeMSIV powder (or Fe—Mn—Si—C powder), the other one of the FeMS powders, was made by pulverizing silicomanganese (e.g., JIS #3) in air, silicomanganese which was produced by NIHON DENKO Corp.

[0151]Any one of the powders was processed by pulverization for 30 minutes using a vibration milling machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com