Internal combustion engine with modified shaft

a technology of internal combustion engine and shaft, which is applied in the direction of valve drive, machine/engine, oscillatory slide valve, etc., can solve the problems of inefficiency and restrictive linear airflow of valves, and achieve the effects of improving fuel economy, improving airflow and horsepower gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

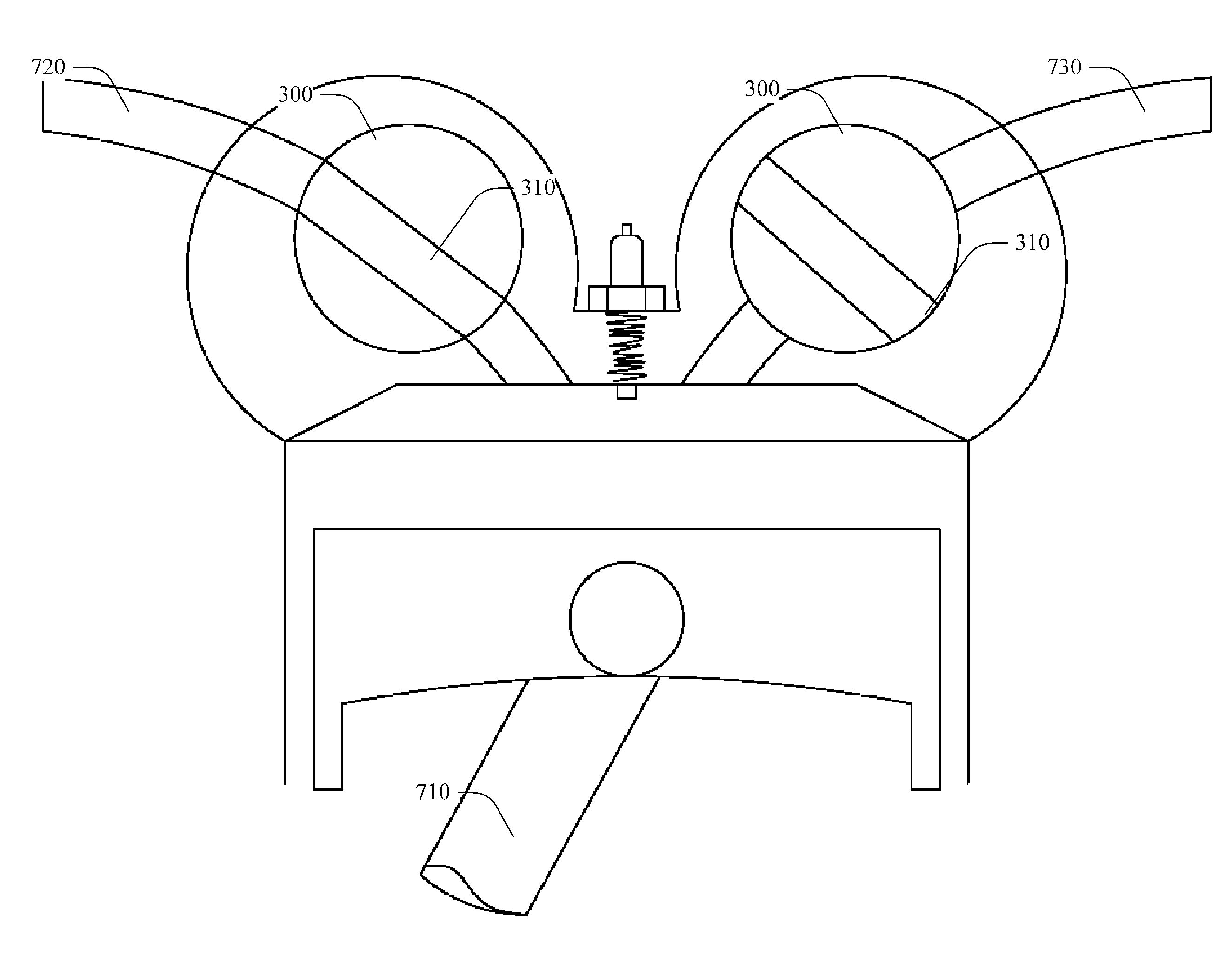

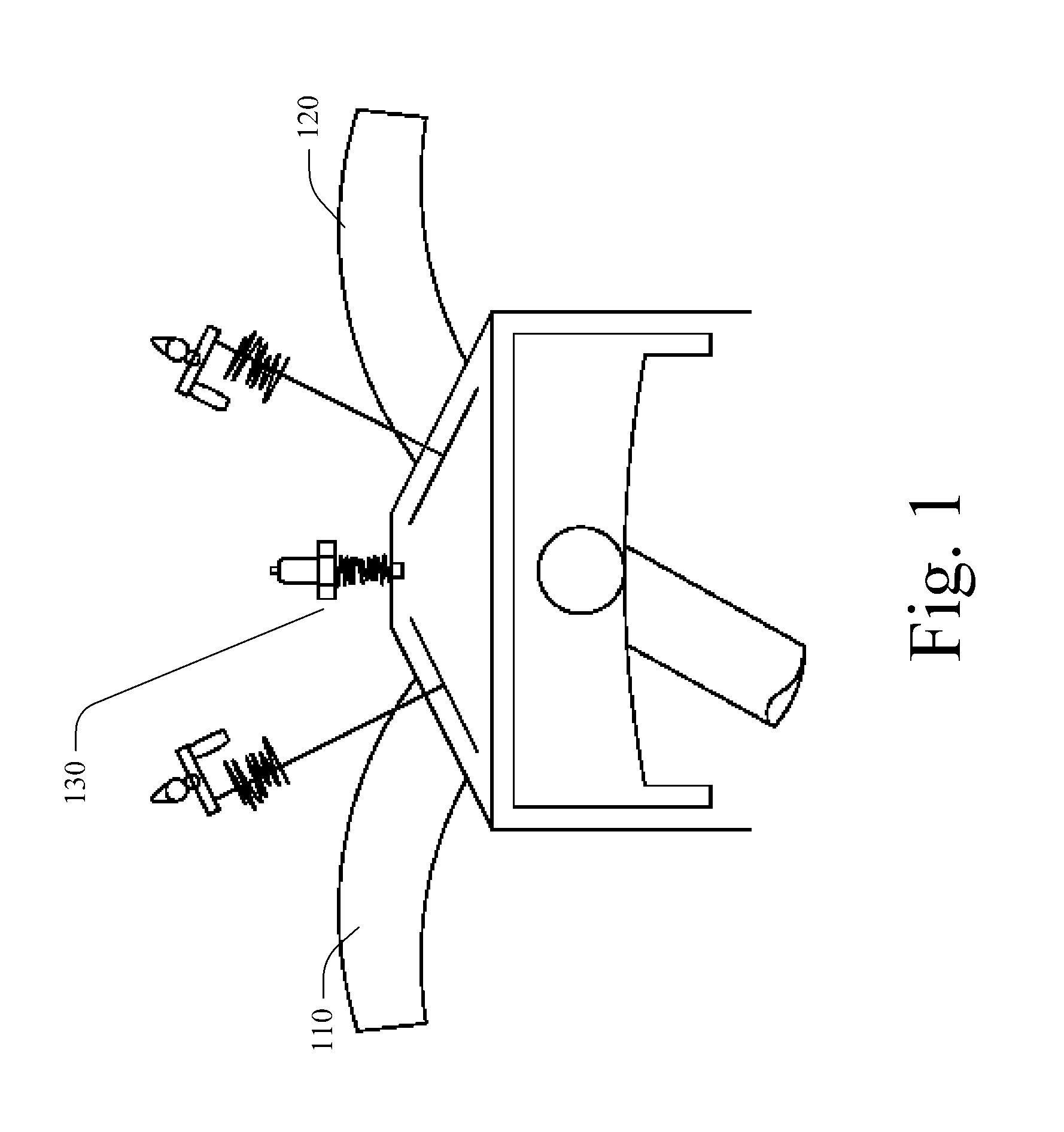

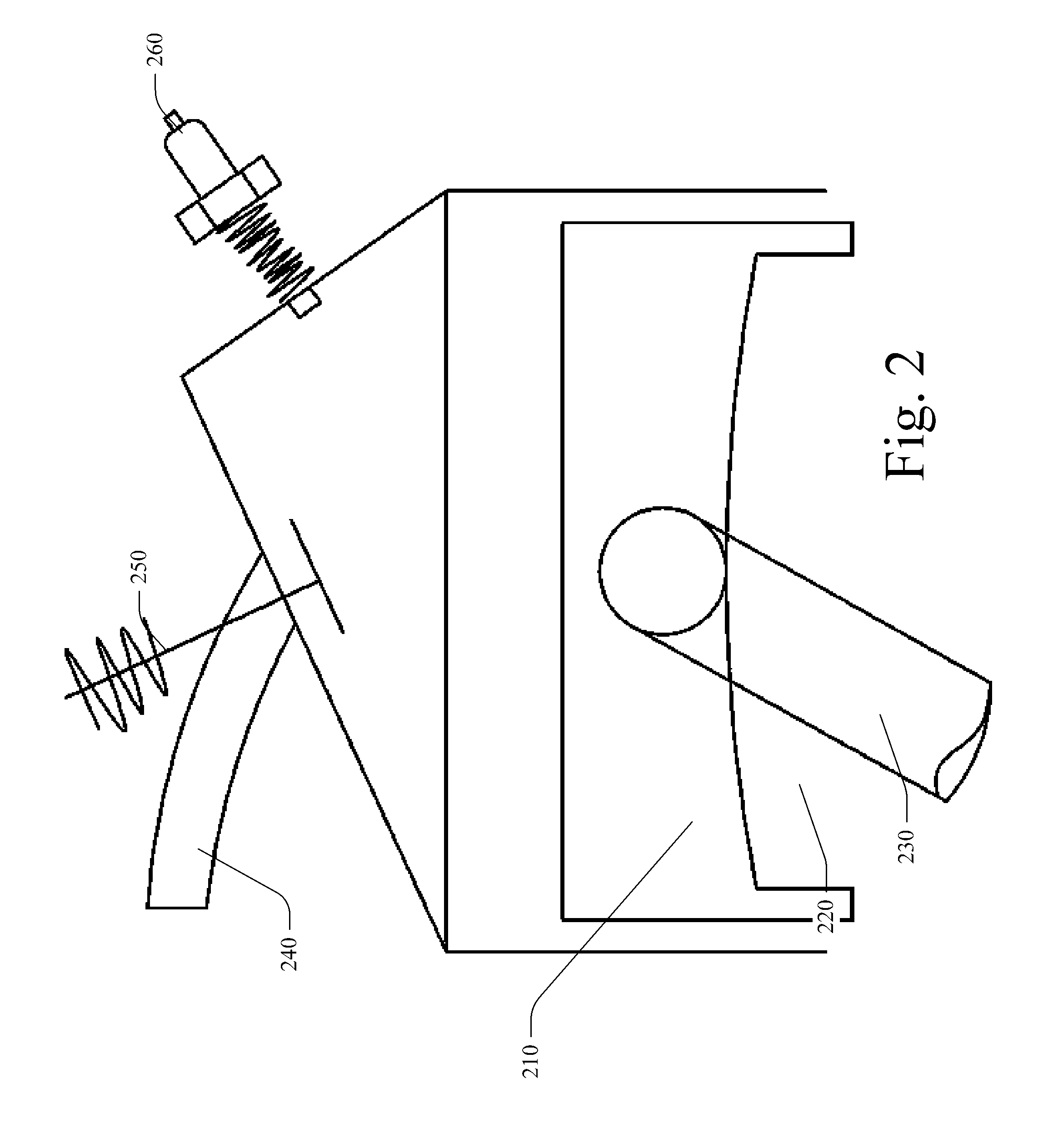

[0028]FIG. 1 depicts a typical piston cylinder arrangement for a single- or dual-overhead cam arrangement whereby the valves permit entry and exit of air. In this arrangement, the valves are integral to the operation of this four-stroke engine. For the four-stroke engine, the first stroke is the piston moving in a downward motion, and the intake valve 110 of FIG. 1 is open to permit air entry. On the upward stroke of the piston, the valves are closed. On the third stroke, the piston is moving in the downward direction and, at the same time, the valves are still closed. Near the bottom of the power stroke, the exhaust valve 120 opens, allowing spent gases to exit during the fourth (exhaust) stroke. Typical single- or dual-overhead cam arrangements show a hemispherical chamber, cylinder, piston, connecting rod, and valve arrangement whereby an intake valve (left) and exhaust valve (right) introduce air into the engine and permit the exit of combustion byproducts. In this design, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com