Low Temperature High Efficiency Condensing Heat Engine for Propelling Road Vehicles

a high-efficiency condensing heat engine and high-efficiency technology, which is applied in the direction of machines/engines, mechanical equipment, lighting and heating apparatus, etc., can solve the problems of large waste low efficiency inherent in basic design and operating principles, and large waist of heat energy generated by burning gasoline. achieve high efficiency and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

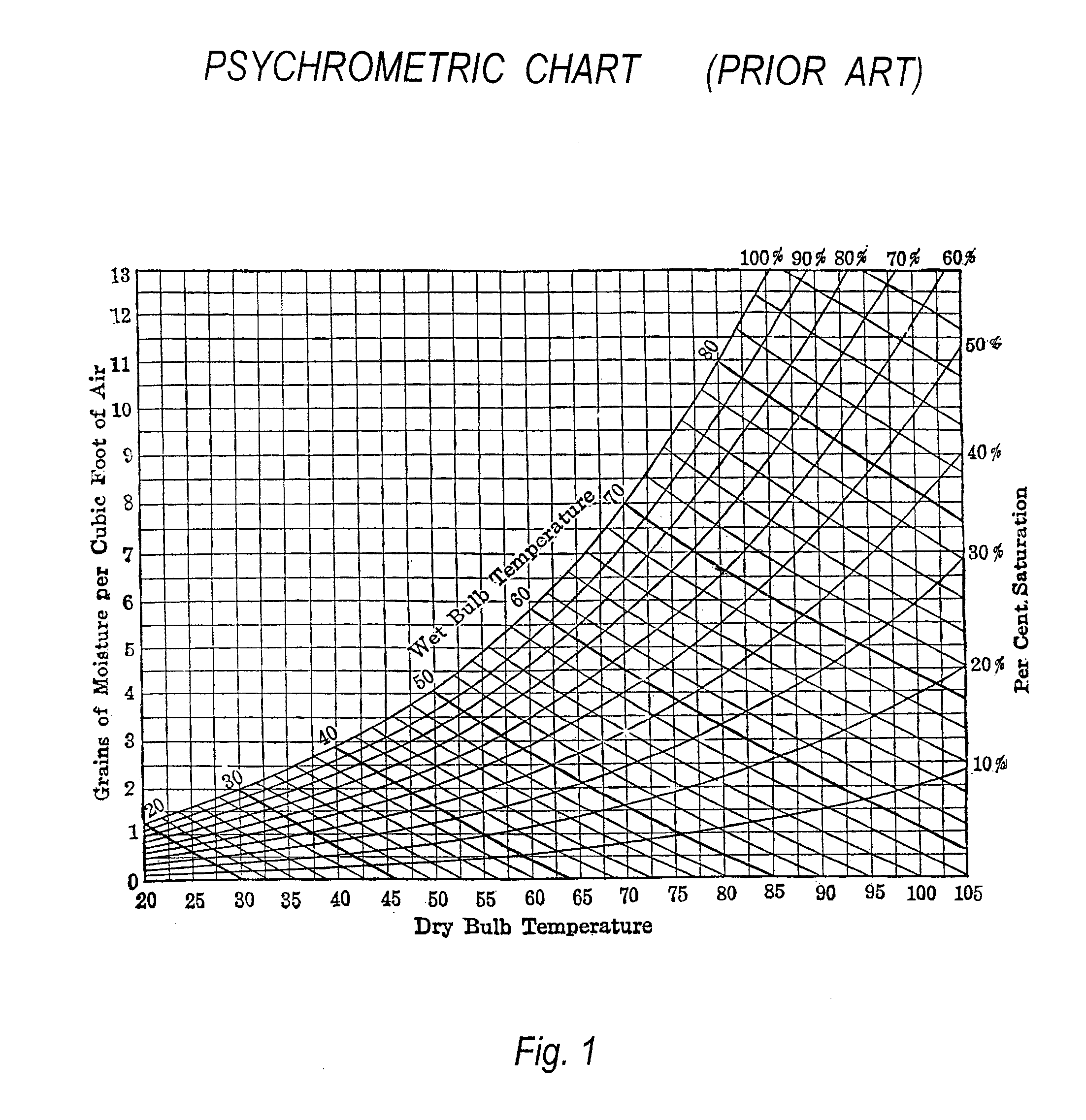

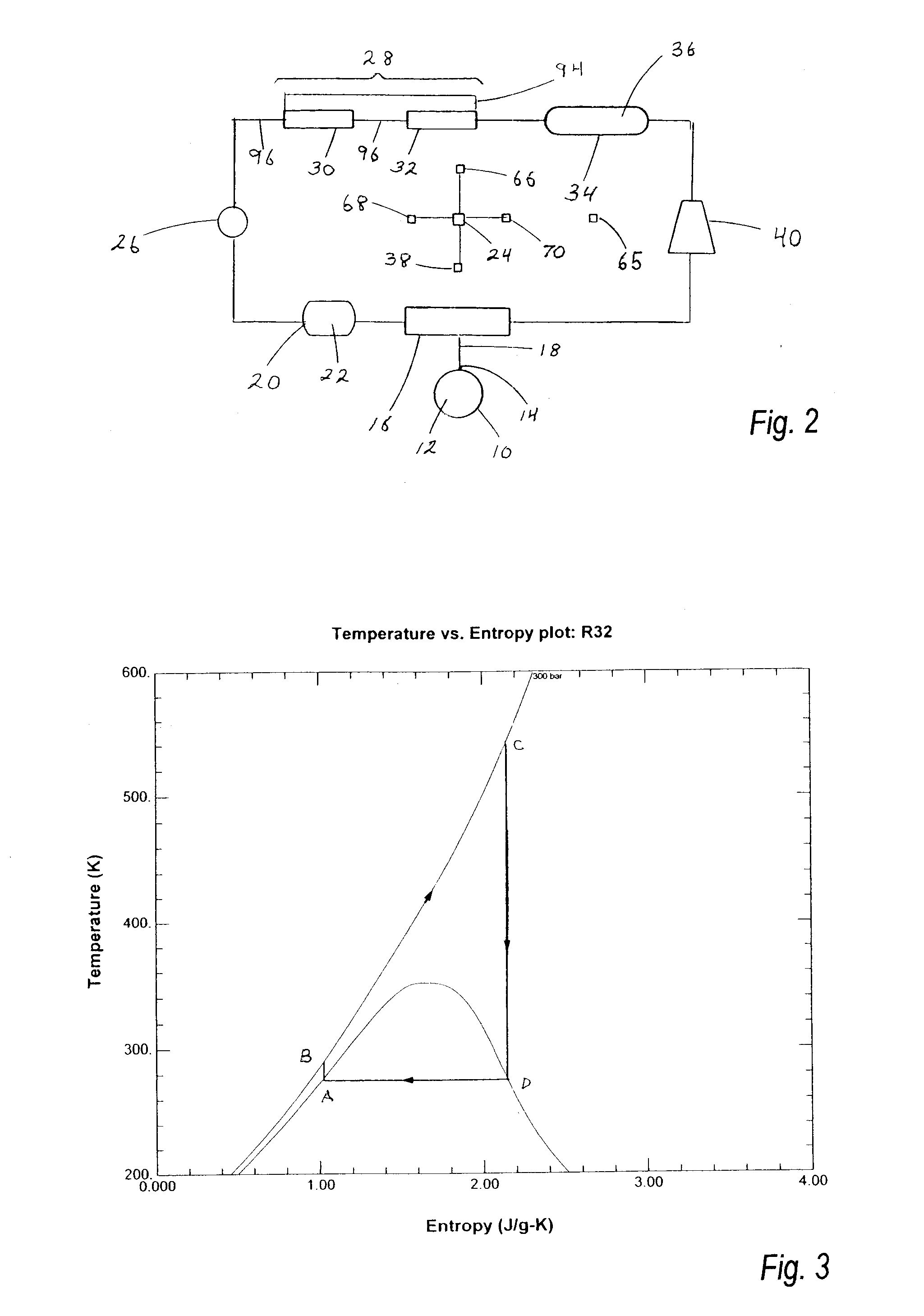

[0020]The invention presented herein is a silent, non-polluting, closed-cycle condensing heat engine for propelling road vehicles operating at low temperatures designed to enable essentially all of the input heat energy to be absorbed by the working fluid to achieve a fuel efficiency (miles per gallon of fuel consumed) far exceeding that of conventional internal combustion engines that are currently used for propelling passenger carrying automobiles. This is achieved by shifting the operating temperatures significantly downward such that the low temperature heat reservoir is at a sub-ambient temperature that is maintained by evaporating small amounts of water utilizing the fact that water has an unusually high latent heat of vaporization. This enables the temperature of the high temperature heat reservoir to be shifted significantly downward that can be maintained by burning small amounts of a clean burning fuel where almost all of the heat of combustion is used for heating the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com