Heat dissipation system with hygroscopic working fluid

a working fluid and heat dissipation system technology, applied in the direction of heating types, lighting and heating apparatus, domestic cooling apparatus, etc., can solve the problems of poor air cooling process efficiency, few opportunities for once-through cooling in the future, and inferior cooling of air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

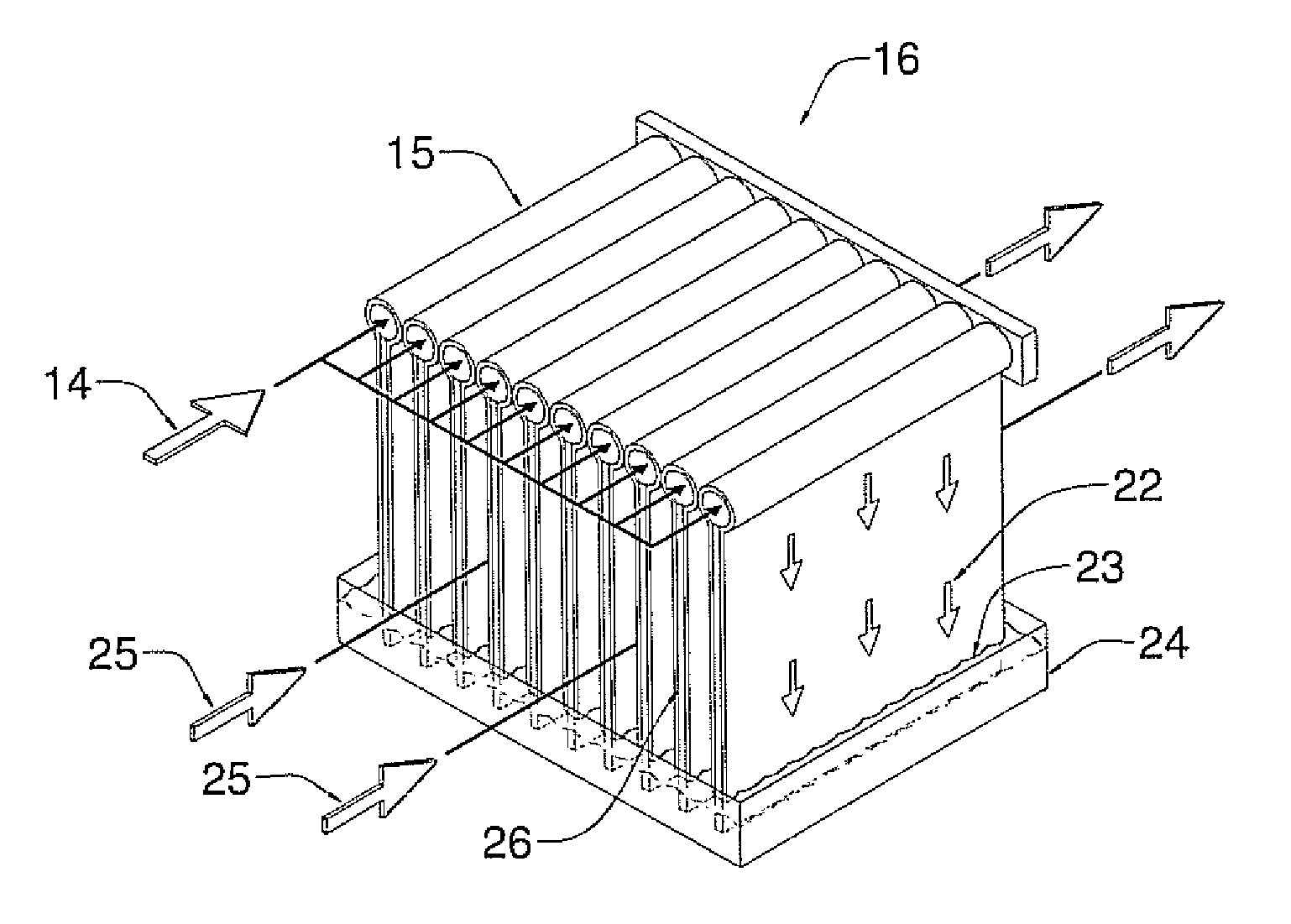

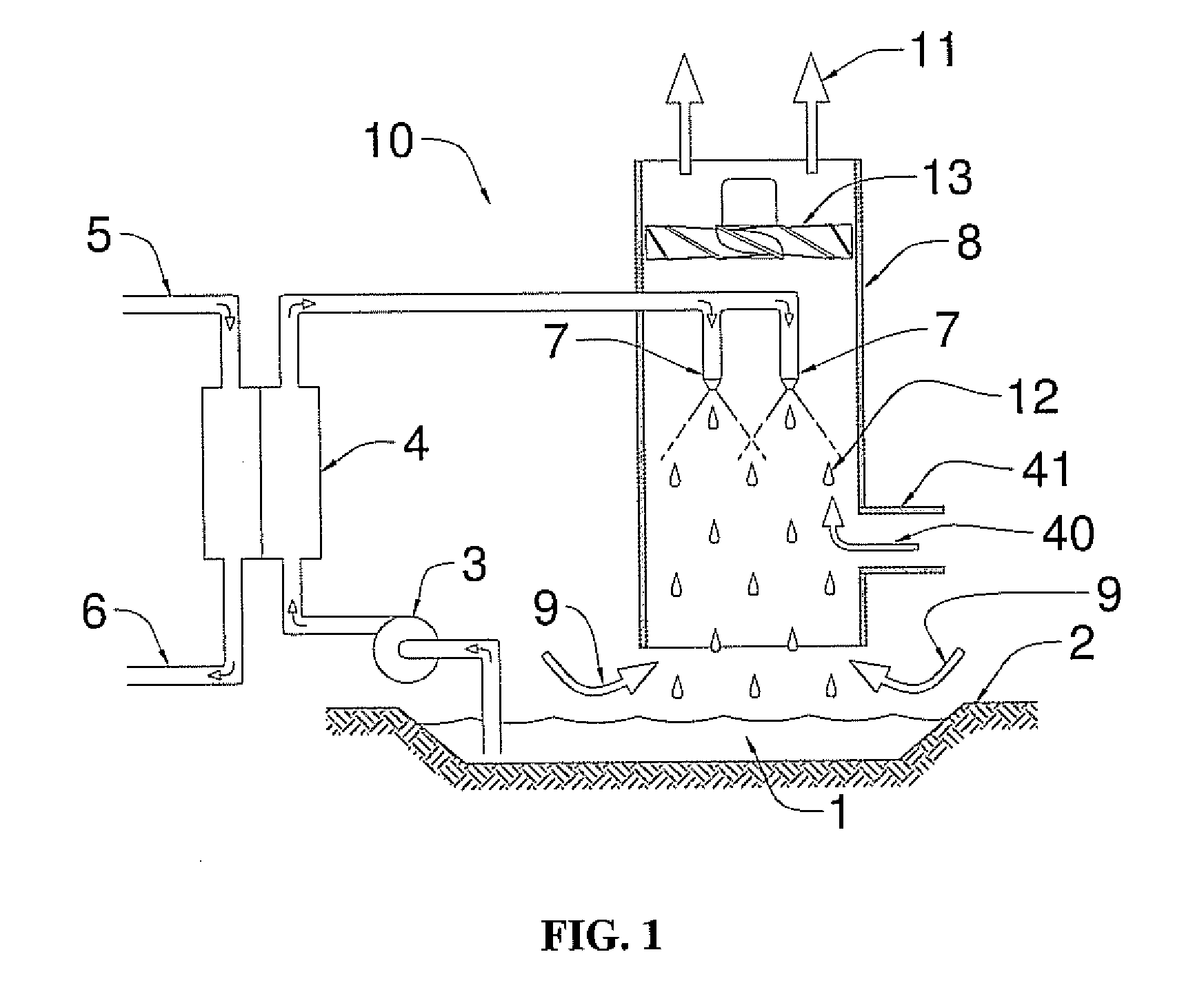

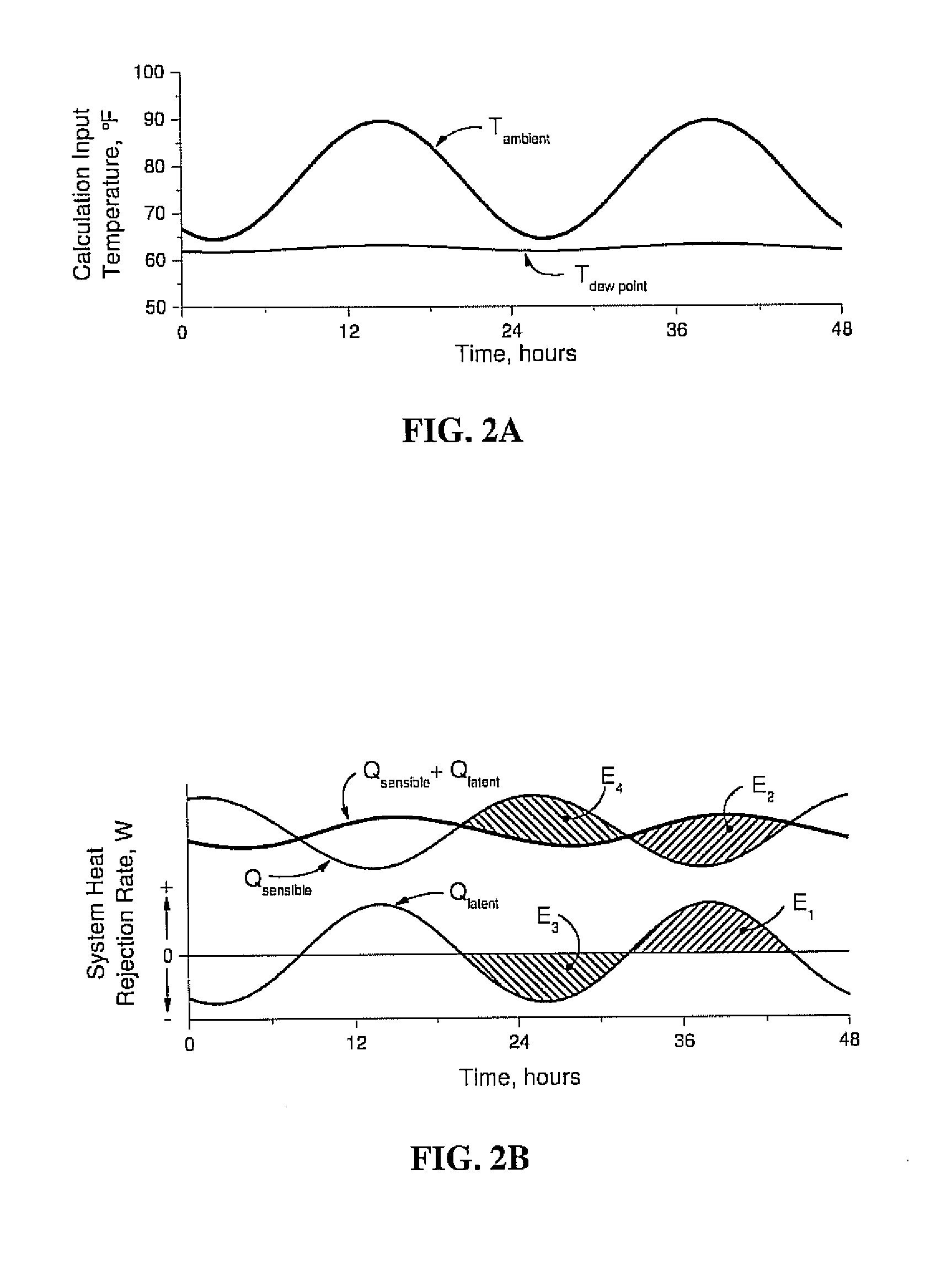

[0021]The heat dissipation system described herein circulates a hygroscopic working fluid to transfer heat from a process requiring cooling directly to the ambient air. The hygroscopic fluid is in liquid phase at conditions in which it is at thermal and vapor pressure equilibrium with the expected local ambient conditions. The fluid is composed of a solution of a hygroscopic substance and water. In one embodiment, the hygroscopic substance itself should have a very low vapor pressure compared to water in order to prevent significant loss of the hygroscopic component during cycle operation. The hygroscopic component can be a pure substance or a mixture of substances selected from compounds known to attract moisture vapor and form liquid solutions with water that have reduced water vapor pressures. The hygroscopic component includes all materials currently employed for desiccation operations or dehumidifying operations including hygroscopic inorganic salts, such as LiCl, LiBr, CaCl2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com