Isolated Counter-Flow Air Heat Exchanging Device with Vertical Structure

a counter-flow air and heat exchange technology, which is applied in indirect heat exchangers, lighting and heating apparatus, heating types, etc., can solve the problems of large energy consumption of air conditioning equipment, large energy source problem, and increase in the number of used conventional air conditioning equipment, etc., to achieve large heat exchange performance, small floor area, and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

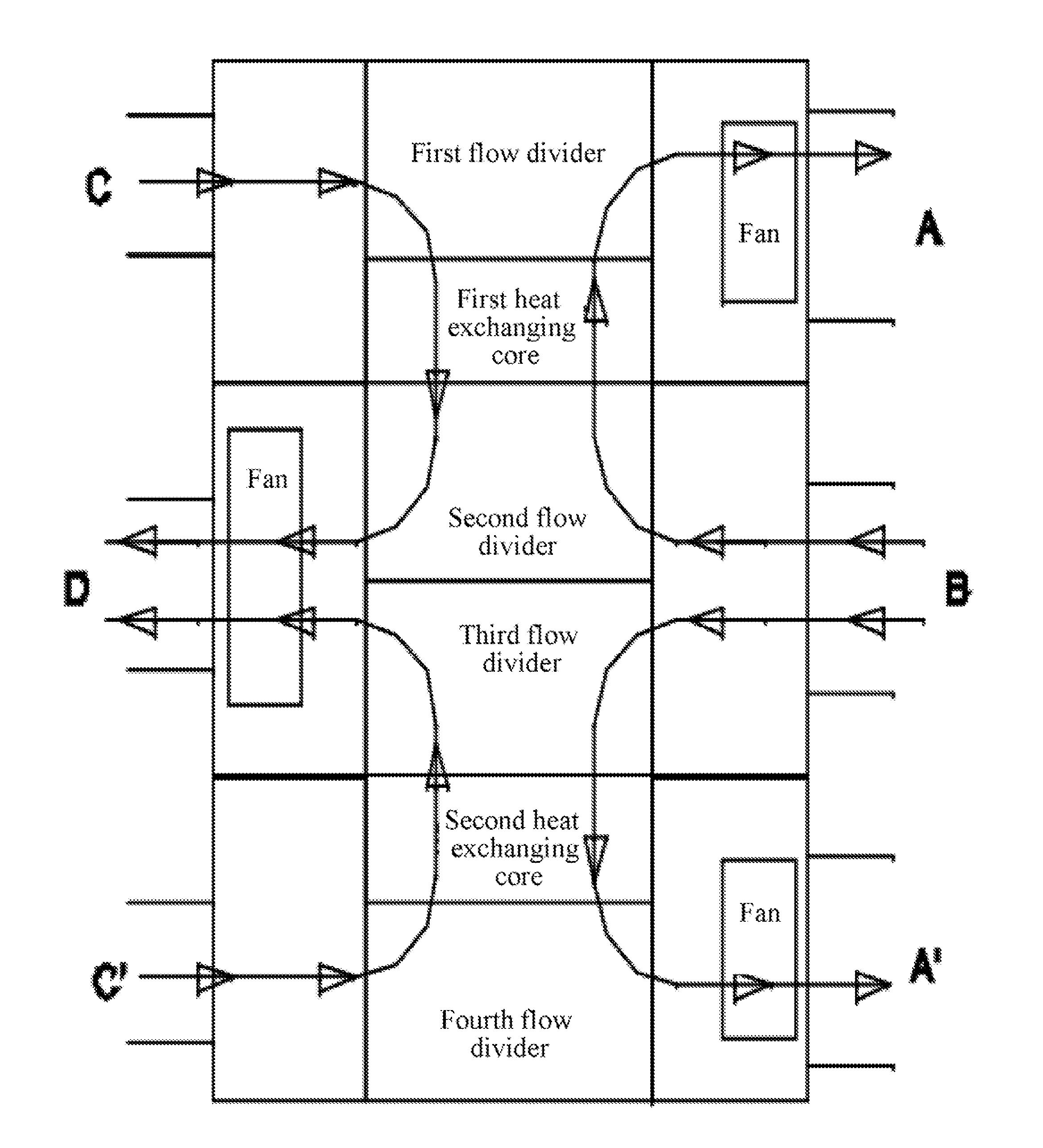

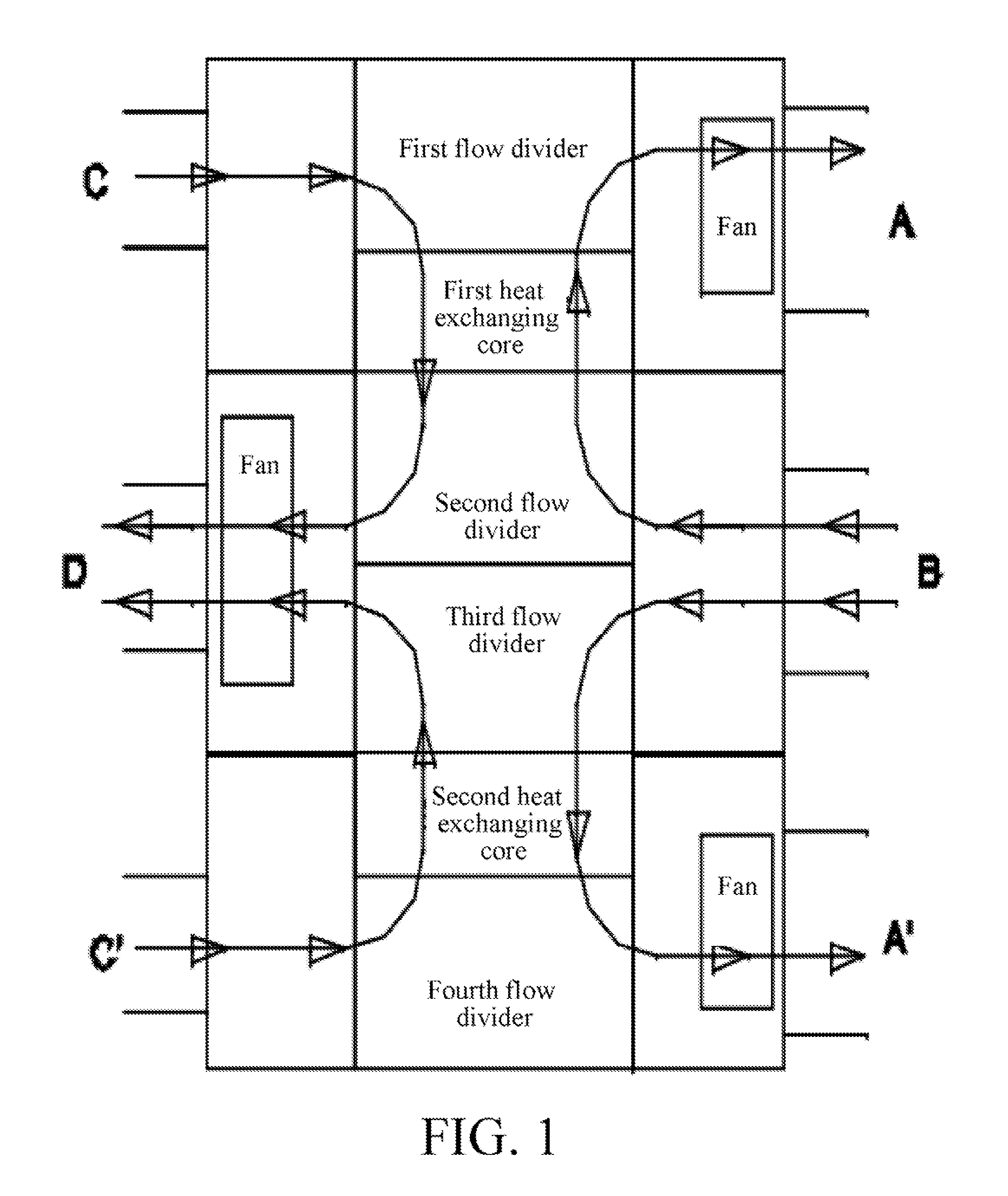

[0019]As shown in FIG. 1, a main body structure of an isolated counter-flow air heat exchanging device (an air heat exchanging device for short) provided in the present invention is formed with two heat exchanging cores, four flow dividers, three fans, and six air ports along a vertical direction. A first flow divider, a first heat exchanging core, a second flow divider, a third flow divider, a second heat exchanging core, and a fourth flow divider are disposed inside the main body structure from top to bottom. Three air ports are distributed respectively at two sides of the main body structure. Among the air ports, A, A′, D are air outlets, B, C, C′ are air inlets, and they form four wind channels independent from one another. The air port A, the first flow divider, the first heat exchanging core, the second flow divider and the air port B form a first wind channel, the air port C, the first flow divider, the first heat exchanging core, the second flow divider and the air port D fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com