Engine Flushing System

a technology of engine flushing and components, applied in the direction of propulsive elements, marine propulsion, vessel construction, etc., can solve the problems of engine failure, engine failure, engine shutdown, etc., and achieve the effect of quick, effective removal and increased flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

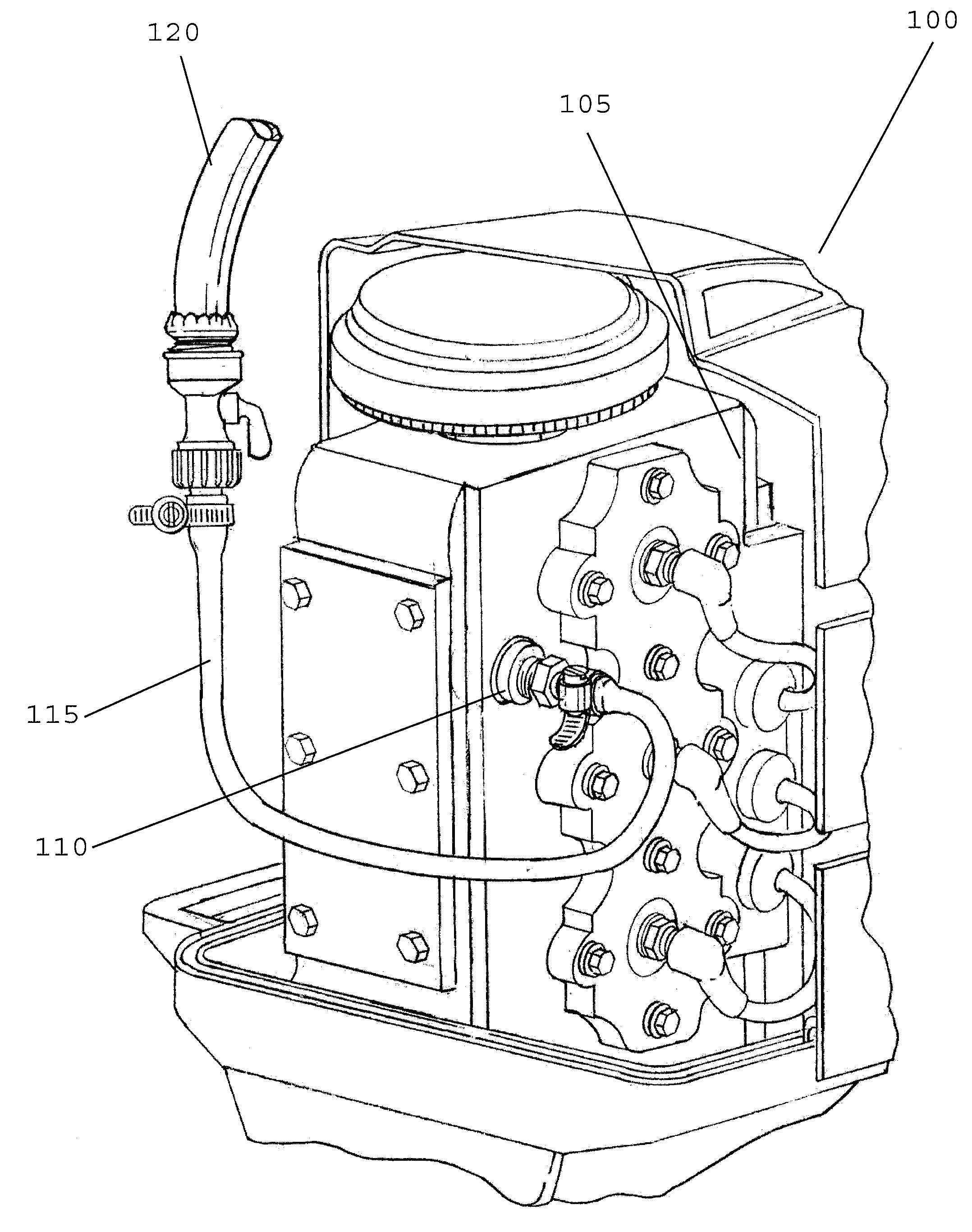

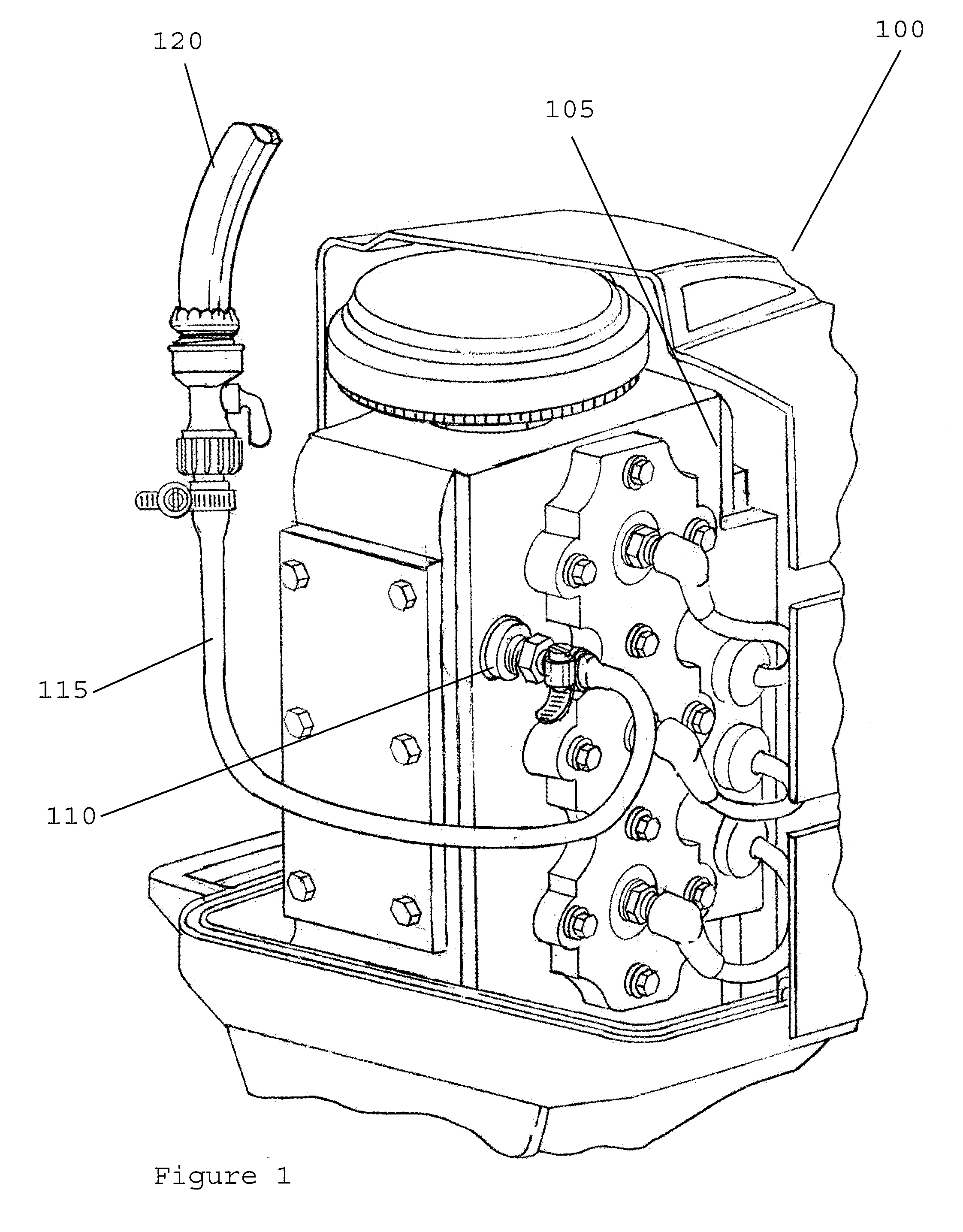

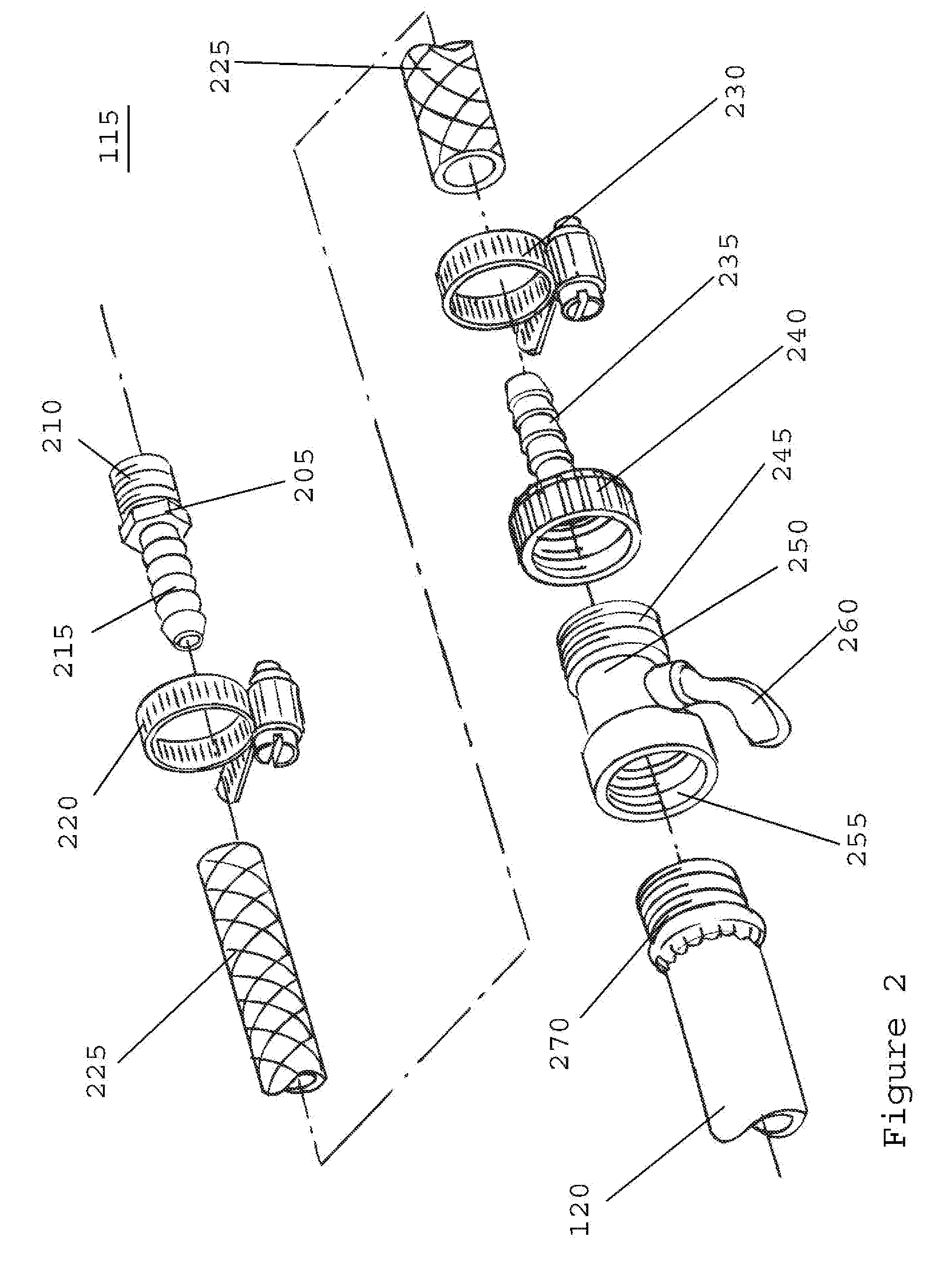

[0026]The exemplary embodiments of the present invention may be further understood with reference to the following description and the related appended drawings, wherein like elements are provided with the same reference numerals. The exemplary embodiments of the present invention are related to an apparatus for flushing an outboard engine. Specifically, the apparatus attaches to an upper portion of the power head of the engine and flushes the internal cooling components of the engine. The exemplary embodiment is described with reference to an outboard motor, but those skilled in the art will understand that the present invention may be implemented on any motor that requires flushing of the internal passages of the cooling system.

[0027]As best seen in FIG. 1, a perspective view of an engine flushing apparatus 115 attached to an outboard marine engine 100 is shown. Marine engine 100 is a standard outboard engine with a tapping access plug 110 on the power head 105 of the engine. Engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com