Membrane pump head for a homogenizer or a high-pressure pump

a technology of high-pressure pumps and membrane pumps, which is applied in the direction of applications, flexible wall reciprocating engines, mechanical equipment, etc., can solve the problems of major product losses, unacceptable service life of seals, and forged pump blocks which are extremely expensive to manufacture, and achieves the effect of simple manufacturing and more economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

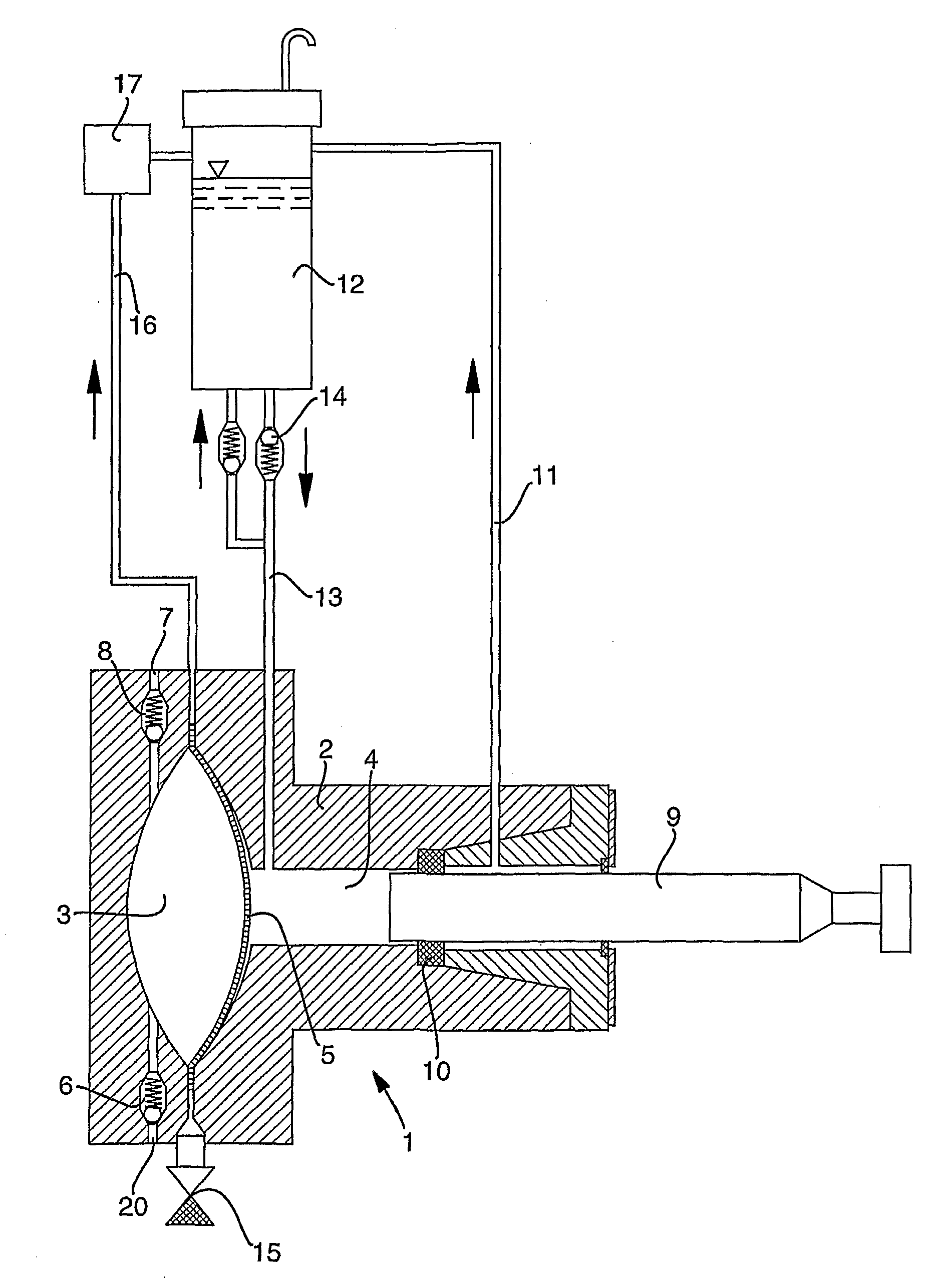

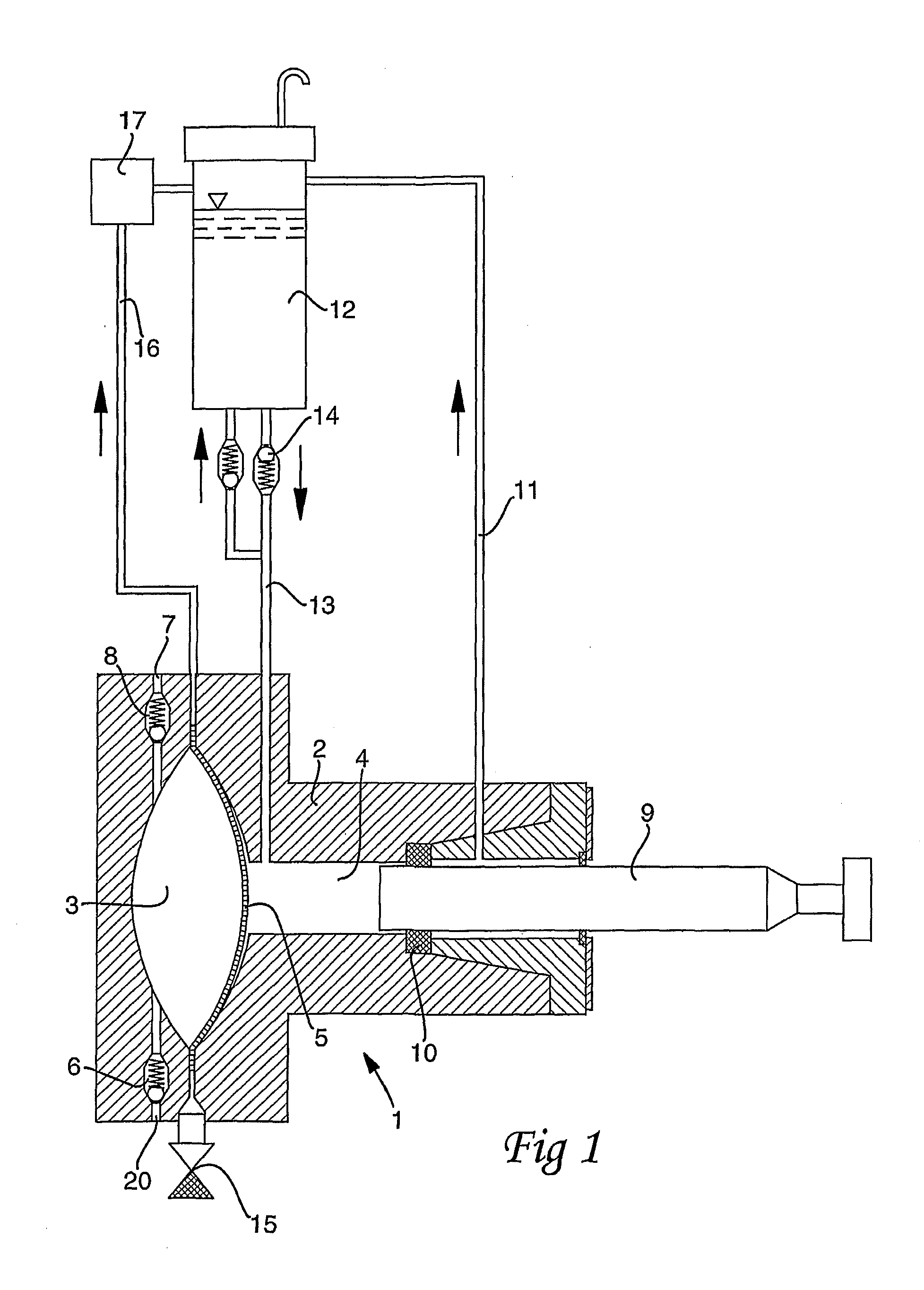

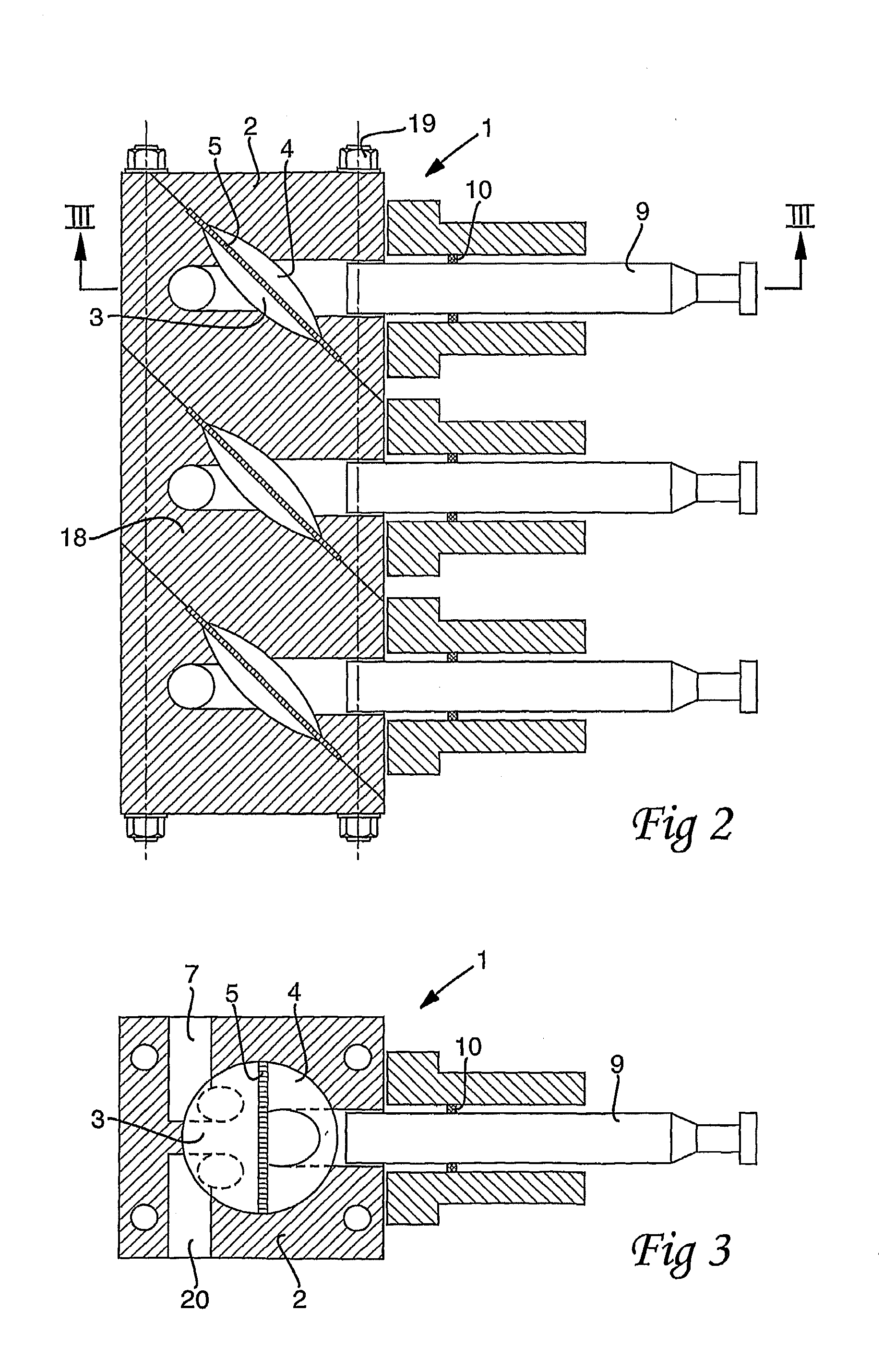

[0023]FIG. 1 shows a membrane pump head 1, as it may appear in principle. The membrane pump head 1 comprises a pump housing 2 which encloses a product chamber 3 and a hydraulic chamber 4. The product chamber 3 and the hydraulic chamber 4 are separated by means of a membrane 5.

[0024]The product chamber 3 is connected to a product inlet 20. The product inlet 20 is provided with a valve 6. The product chamber 3 is also connected to a product outlet 7. The product outlet 7 is provided with a valve 8.

[0025]A piston 9 acts in the hydraulic chamber 4, which is filled with a hydraulic fluid, preferably oil. The piston 9 is sealed against the pump housing 2 by means of a seal 10. The seal 10 is of a type which withstands high pressure and it is lubricated constantly by the hydraulic fluid. The excess flow of hydraulic fluid is led via the conduit 11 to a hydraulic fluid container 12 which, when necessary, replenishes hydraulic fluid in the hydraulic chamber 4 through the conduit 13 and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com