Cosmetic container

a container and cosmetic technology, applied in the field of containers, can solve the problems of content deterioration, weakness of traditional cosmetic containers, and no more satisfying for modern women, and achieve the effects of preventing air from entering the tube, excellent air tightness, and protecting the content contained in the tube from deterioration or hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

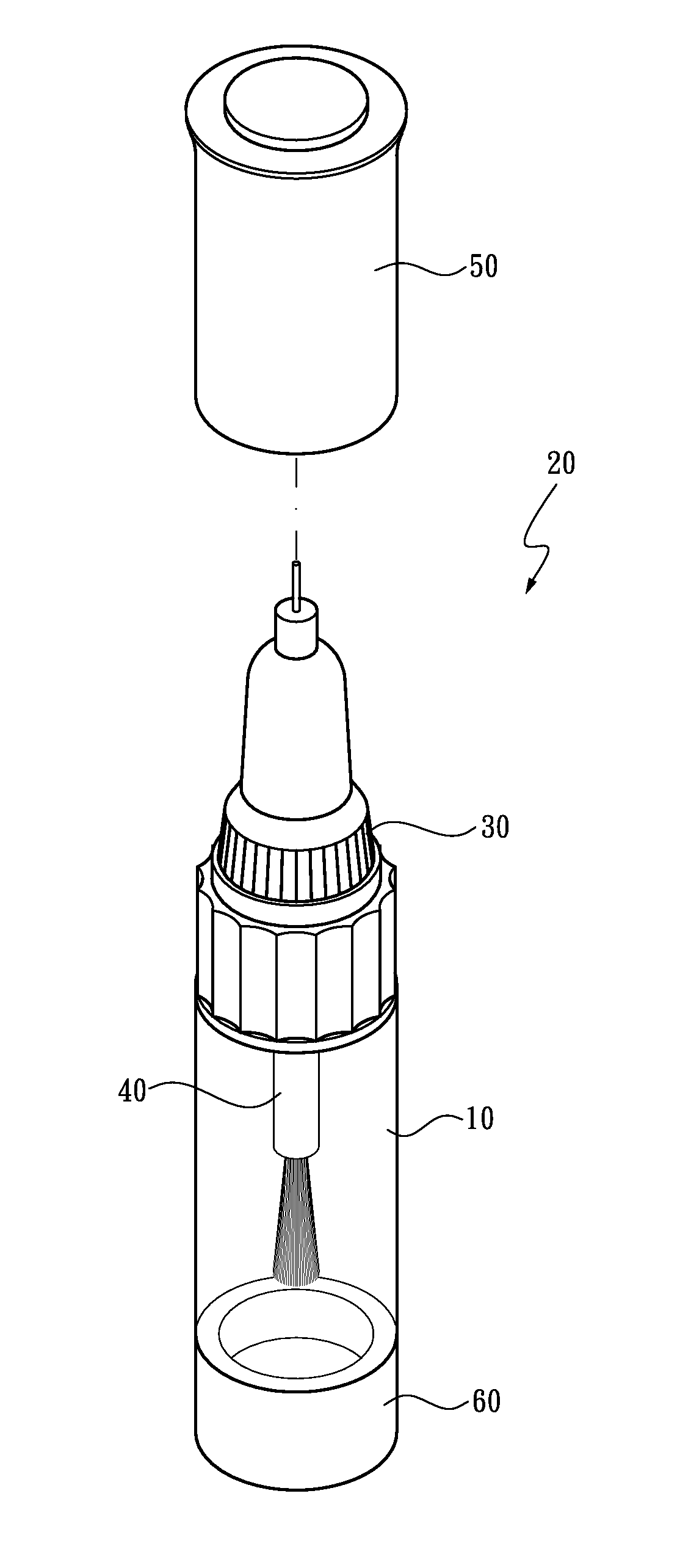

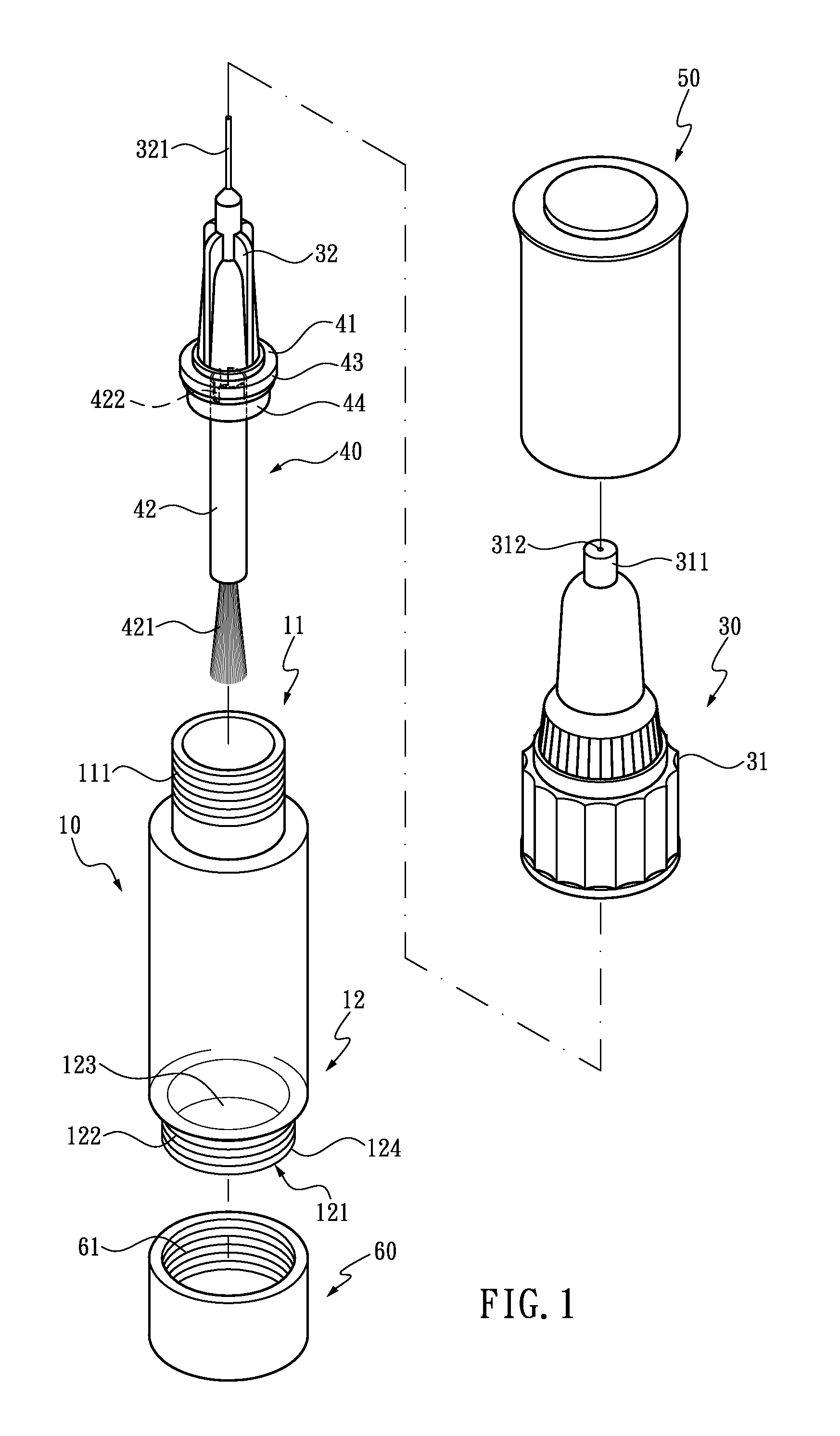

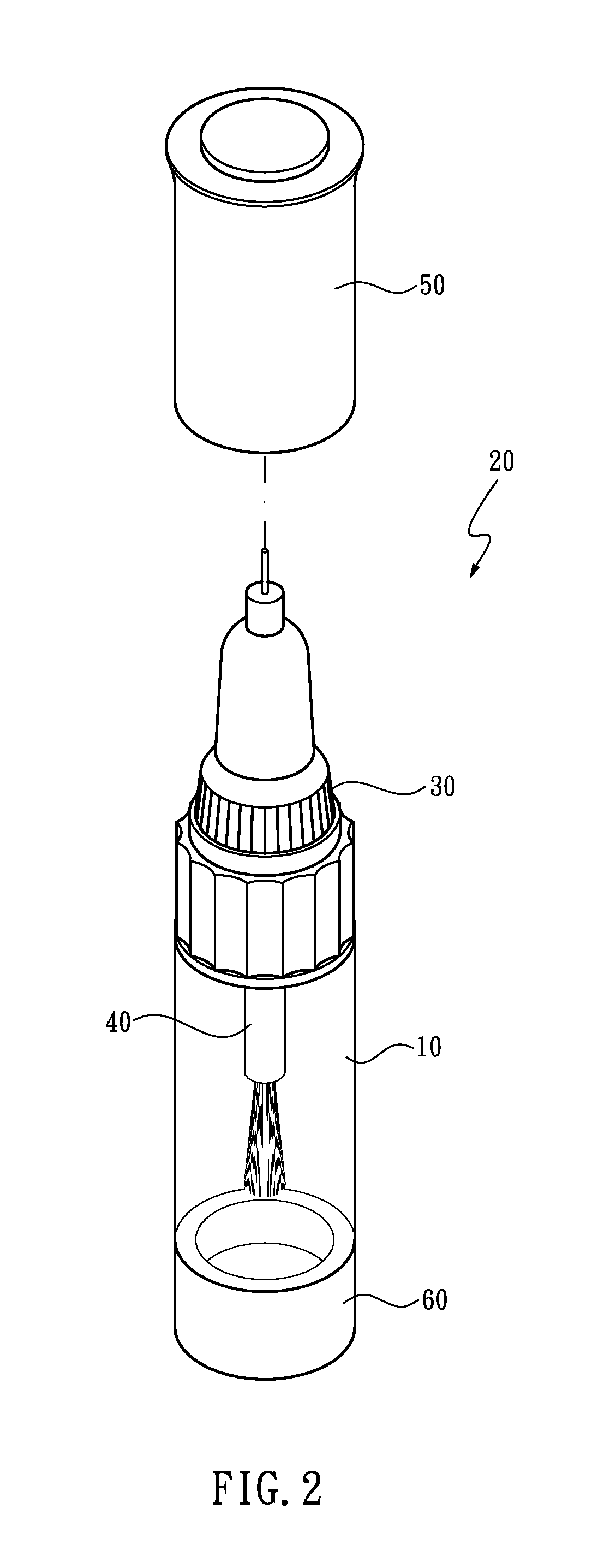

[0025]Referring to FIG. 1 through FIG. 4, a cosmetic container of the present invention comprises primarily a tube 10, a painting assembly 20 and an attached member 60, which will be described in detail below.

[0026]The tube 10 is in nature a container with an open end 11 and a close end 12, and is made of PET. The open end 11 has its outer periphery formed with at least one external thread 111. The close end 12 has a connecting section 121, whose outer periphery is also formed with at least one thread 122. The connecting section 121 has a bottom 123 with a flat surface or a concave surface, so that a right-angle or acute-angle connecting rim 124 is formed between the connecting section 121 and the bottom 123.

[0027]The painting assembly 20 includes a pen segment 30 screwed with the external thread 111 of the open end 11, a brush segment 40 wedged in the pen segment 30 and an upper cap 50 mounted around the pen segment 30.

[0028]The pen segment 30 has a pen head cover 31 and a pen head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com