In-situ vaporizer and recuperator for alternating flow device

a heat recovery apparatus and vaporizer technology, applied in lighting and heating apparatus, combustion types, roads, etc., can solve the problems of difficult vapor stream handling, poor transient operation, and significant thermal mass of traditional vaporizers and boilers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

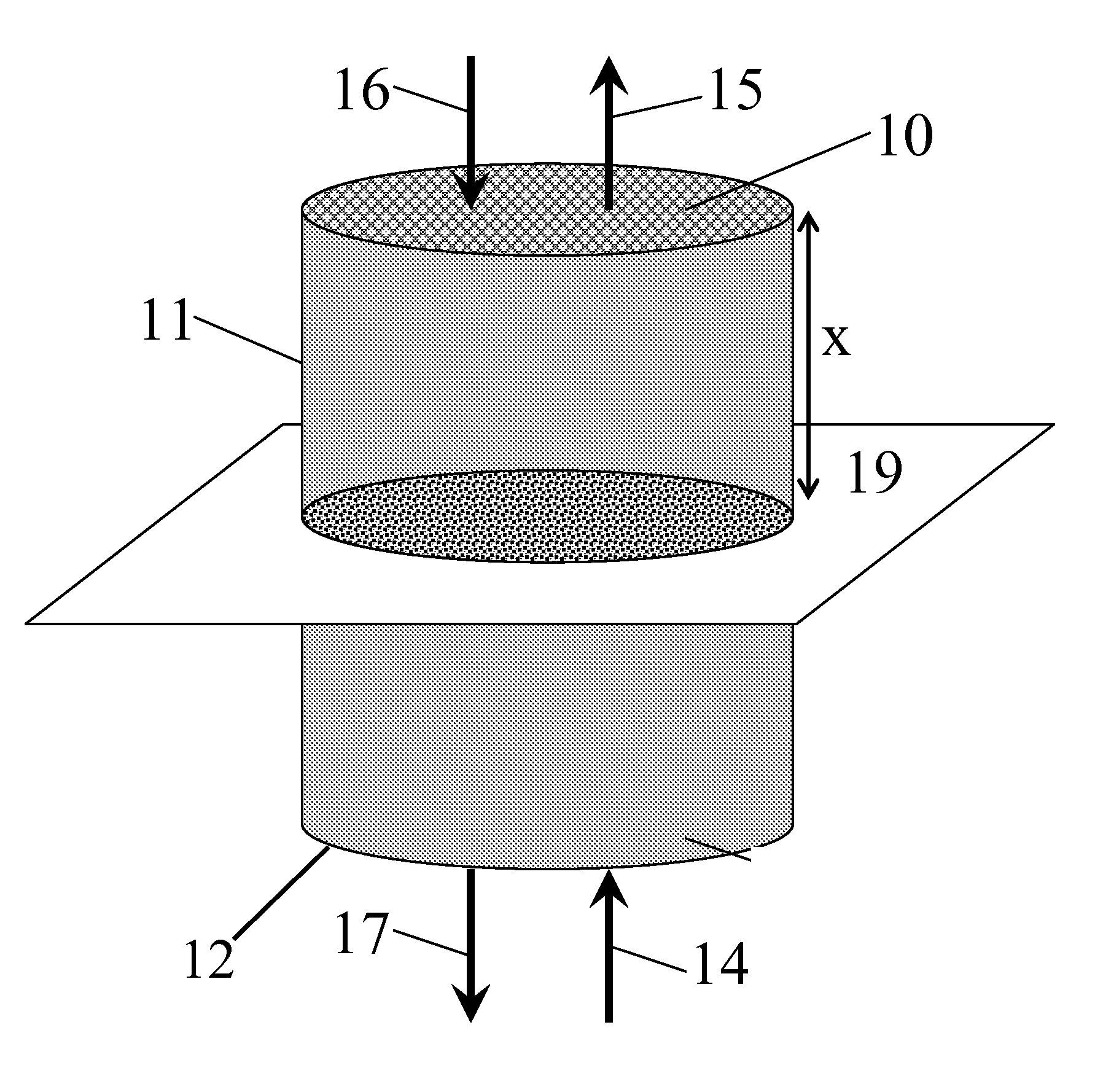

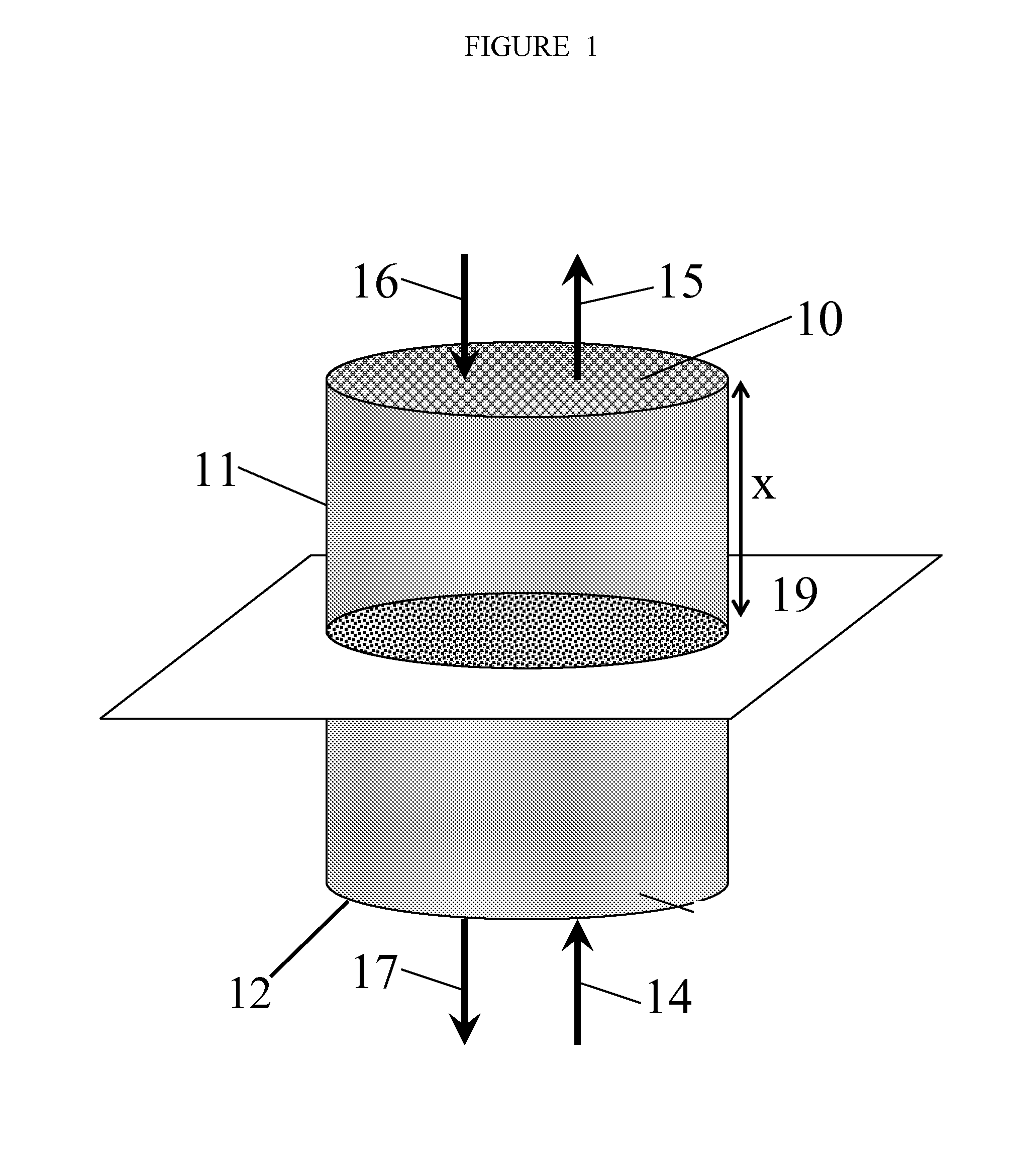

[0011]The present invention is directed to a device for converting a supplied liquid stream(s) to a gaseous vapor stream. More particularly, the invention relates to a device operating in a cyclic process whereby a liquid hydrocarbon and, optionally, a water mixture is converted into a mixture of hydrocarbon vapor and optionally steam. One particular application is for vaporization of a liquid hydrocarbon and water stream for use in a pressure swing steam reforming process.

[0012]The device is designed for continuous operation through a cyclic two-stage process. The first stage is a vaporization mode, and the second stage is a reheating mode. We have discovered particular design criteria or features that produce an in-situ vaporizer and heat recovery device capable of large dynamic ranges of operation, minimal pressure drop, corrosion resistance, and be sufficiently compact and light weight for mobile applications. These features include specifications on geometry, heat capacity and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com