Hard Rock Rotary Drill Bit and Method of Drilling Using Crowned Cutter Elements

a cutter element and drill bit technology, applied in the field of drill bits, can solve problems such as easy chipping, and achieve the effects of preventing excessive wear, increasing the longitudinal movement of the drill string and the drill bit, and increasing the speed of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

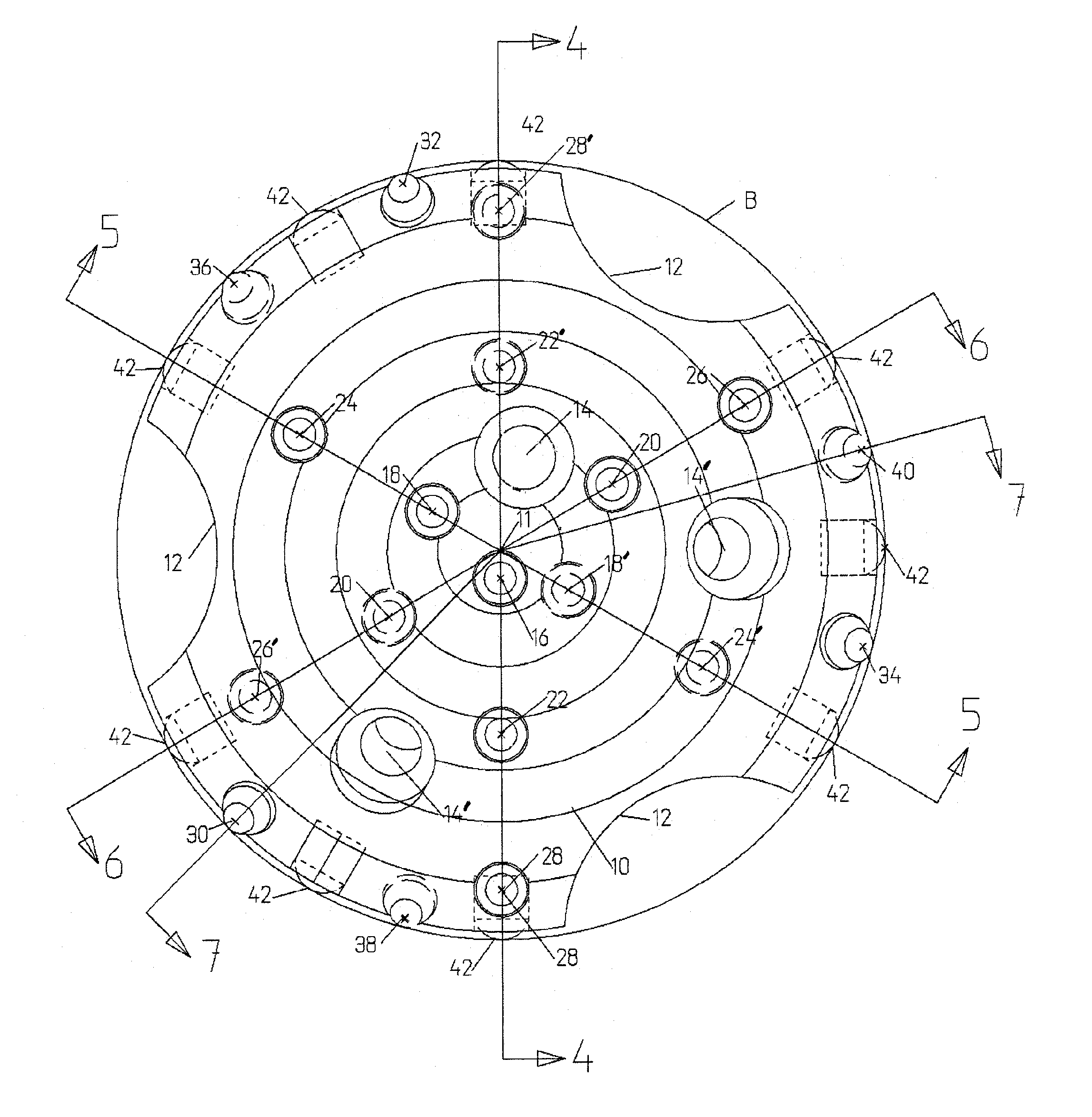

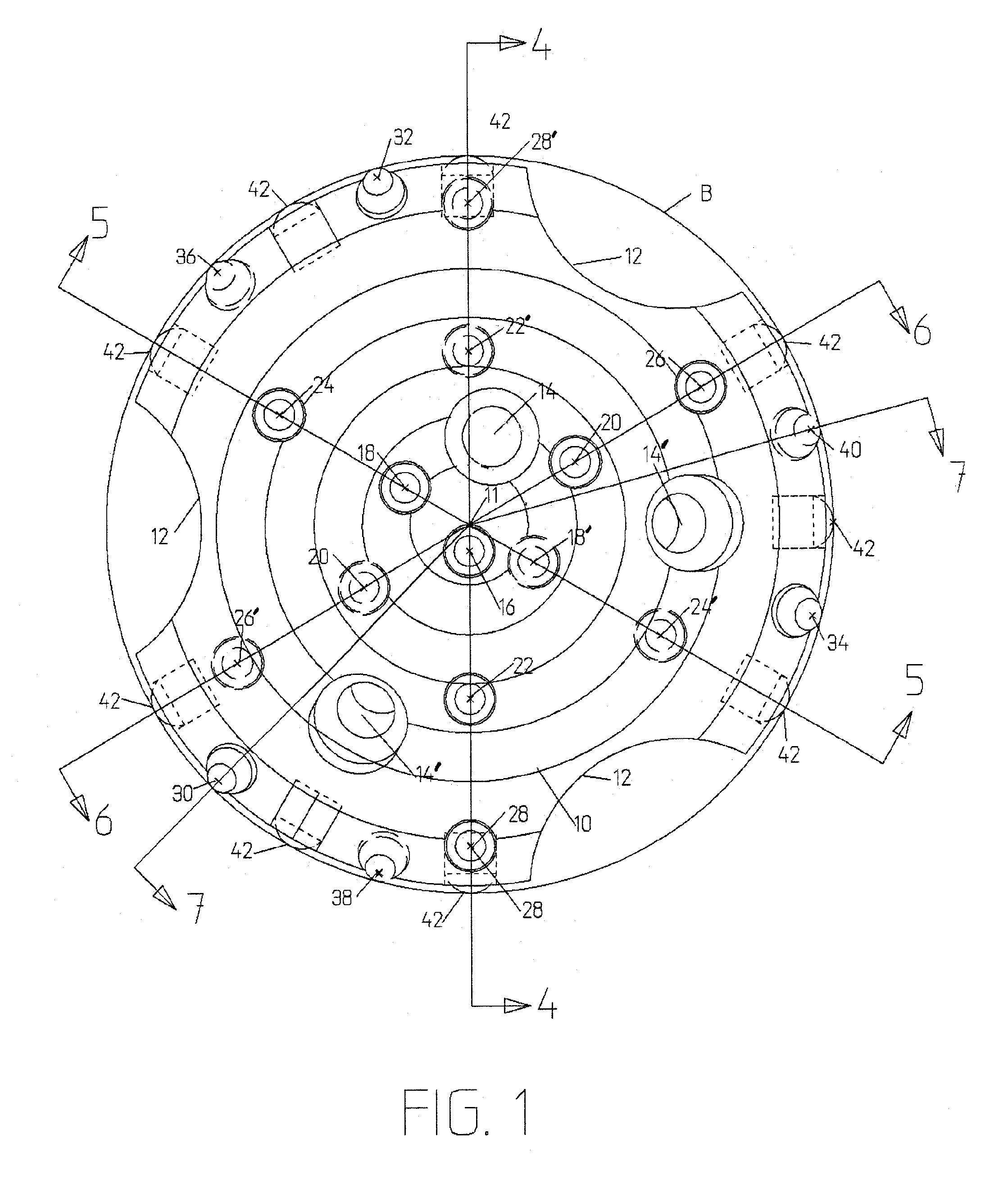

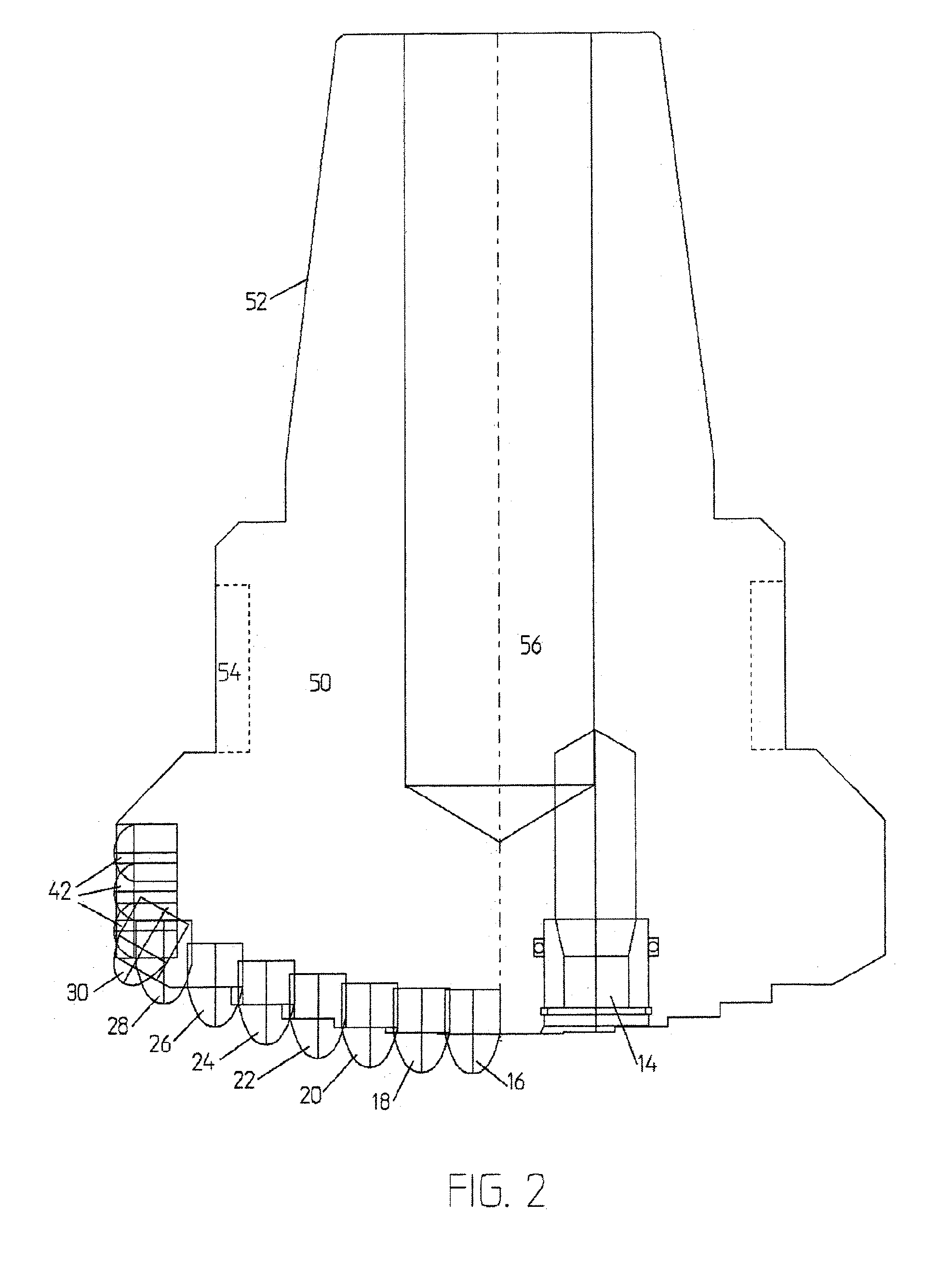

[0014]FIG. 1 is a detailed schematic layout of the drill bit face 10 of the present application showing the arrangement of the polycrystalline diamond compact cutters (PDC) of the present embodiment. Although applicant has described these as PDC elements, other hard faced cutter element inserts might be substituted, such as cubic boron nitride (PCBN), depending on the hardness of the rock being bored, without departing from the spirit or intent of this disclosure. Junk slots 12 and a plurality of jetting nozzle passages 14 and 14′ permit generous use of fluid to both cool the drill bit and flush cuttings away from the bore face.

[0015]The central cutter element 16 is affixed to the drill bit adjacent the central longitudinal axis 11 of the drill bit. Central cutter element 16 is the first to engage the face of the bore and scuffs and scores the face. Since the angle of incidence of the central cutter element 16 is virtually at 90° to the rock face, no or little chipping force is expe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com