Conjugate fibers for stockings

a technology of conjugate fibers and stockings, applied in the direction of yarn, filament/thread forming, transportation and packaging, etc., can solve the problems of reducing washing durability, serious comfort issues, and wearer stuffy or sticky feeling, and achieves high crimping property, high transparency, and soft texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

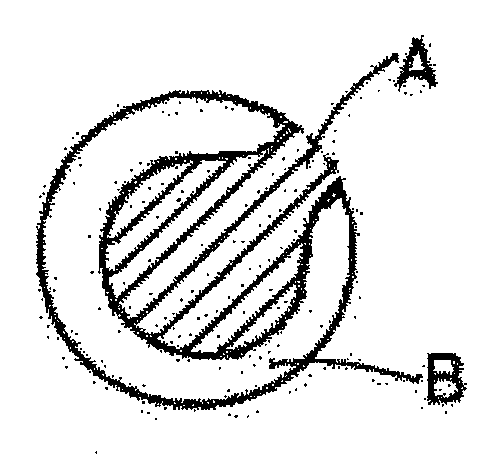

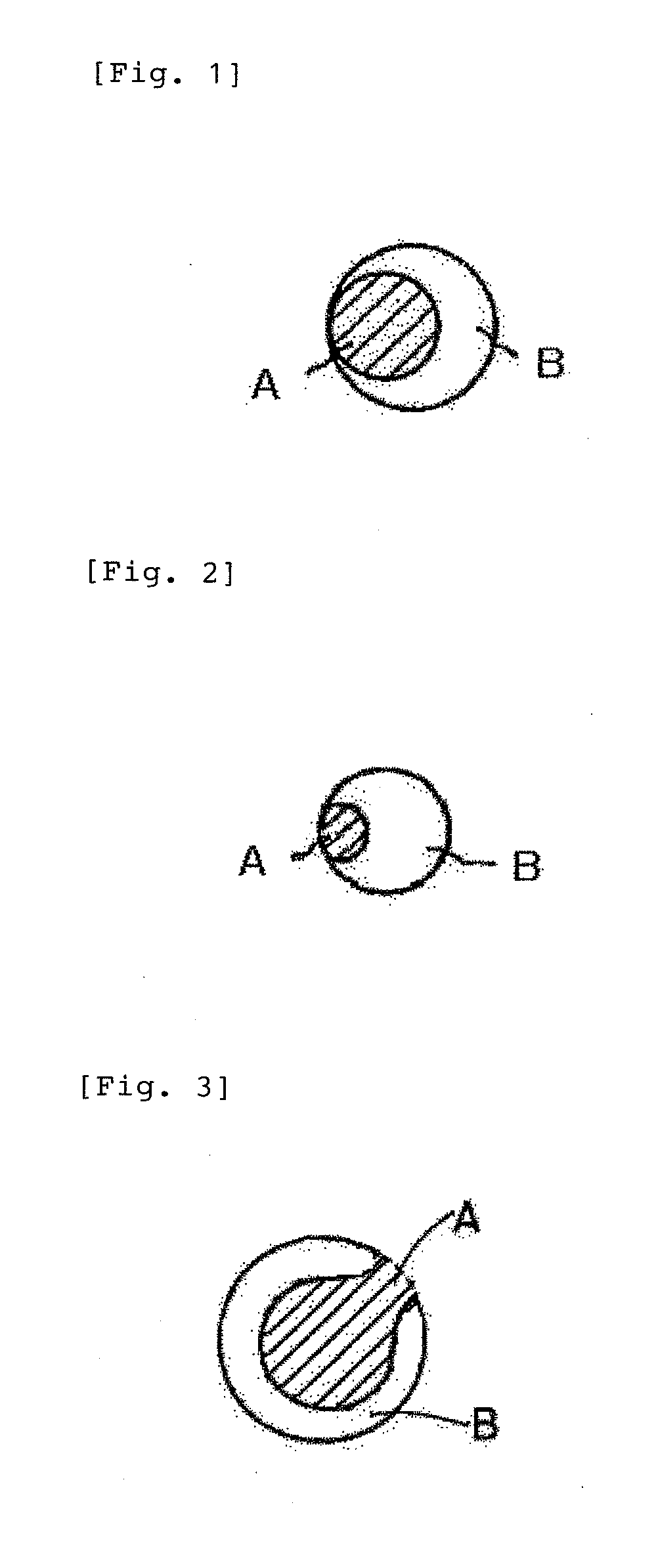

[0055]a polyether block amide copolymer (Pebax MV1074 manufactured by Arkema) and nylon 6 (manufactured by Mitsubishi Chemical Corporation) which were melted separately were spun into a conjugate fiber (an angle of exposure was 33.5°) at an area ratio of the copolymer to nylon 6 of 50 / 50, the conjugate fiber having the cross-section shown in FIG. 1, and then the undrawn yarn having the single filament fineness of 35 dtex was taken up.

[0056]The undrawn yarn was drawn at room temperature under the condition of a draw speed of 800 m / minute and a draw ratio of 3.28 times. The drawn yarn was wound into a pirn at a winding hardness in the range of 80 to 75, thereby a 22 dtex / 2f conjugate fiber for stockings was obtained.

[0057]No crimp was observed in the appearance of a cop of the conjugate fiber, but when 1 to 2 minutes had passed since the fiber was released from the cop, spiral crimps were observed. The percentage crimp was 62%.

[0058]The conjugate fiber was knitted into stockings using...

example 2

[0062]Stockings were prepared in the same manner as in Example 1, except that the total fineness / the number of filaments was changed to 19 dtex / 2f.

[0063]The obtained conjugate fiber had a percentage crimp of 52%.

[0064]The obtained stockings were well dyed and excellent in transparency and touch. The conjugate fiber according to the present invention could be used for knitting stockings without any crimp processing because of its crimp characteristic, thereby high productivity was achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com