Image sensor IC

a technology of image sensor and pixel, applied in the field of image sensor, can solve the problems of increasing manufacturing costs, inability to achieve sufficient uniformity, and inability to achieve photoelectric conversion characteristics, etc., to suppress the variation in the photoelectric conversion characteristic of pixels, uniform film thickness, and the effect of constant formation speed and film quality of protective film formed on each of the pixels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

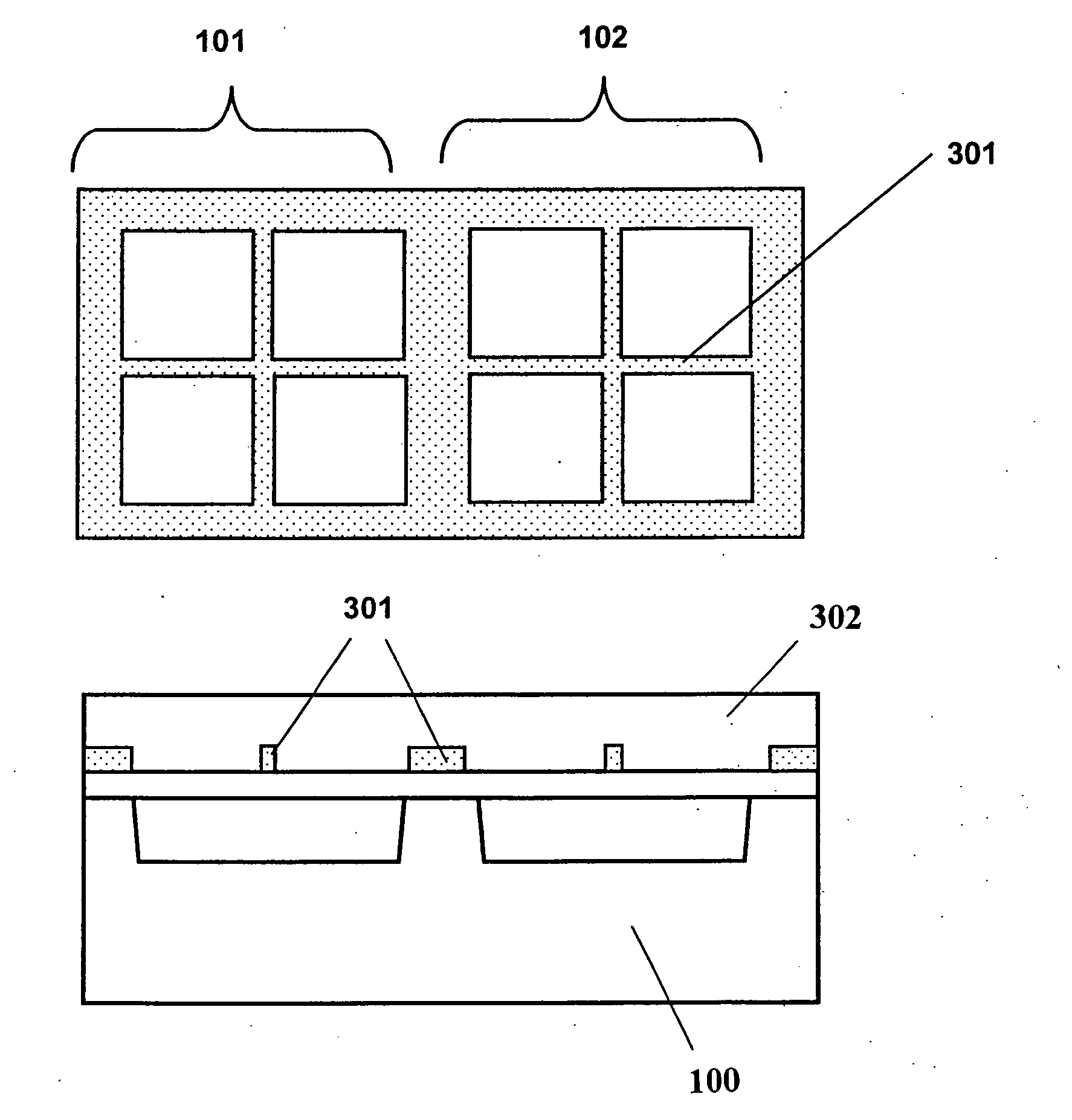

[0021]FIG. 1 is a schematic top view showing pixel regions of an image sensor according to the present invention.

[0022]A plurality of pixel regions 101, 102, 103, and 104 are covered with a light-transmissive conducive material 201 for potential fixation, which is formed of a polycrystalline silicon thin film. The light-transmissive conductive material 201 covering the pixel regions 101, 102, 103, and 104 has the same potential as a whole. The light-transmissive conductive material 201 is electrically connected so as to hold the same potential as the substrate potential of the silicon substrate on which the image sensor is formed through the connection is not shown in FIG. 1. As a result, at the time of forming a protective film on the pixel regions thereafter, each potential of underlying pixel regions can be kept substantially constant over the entire pixel regions in the image sensor IC. Thus, a formation speed and film quality of the protective film formed on each pixel can also...

second embodiment

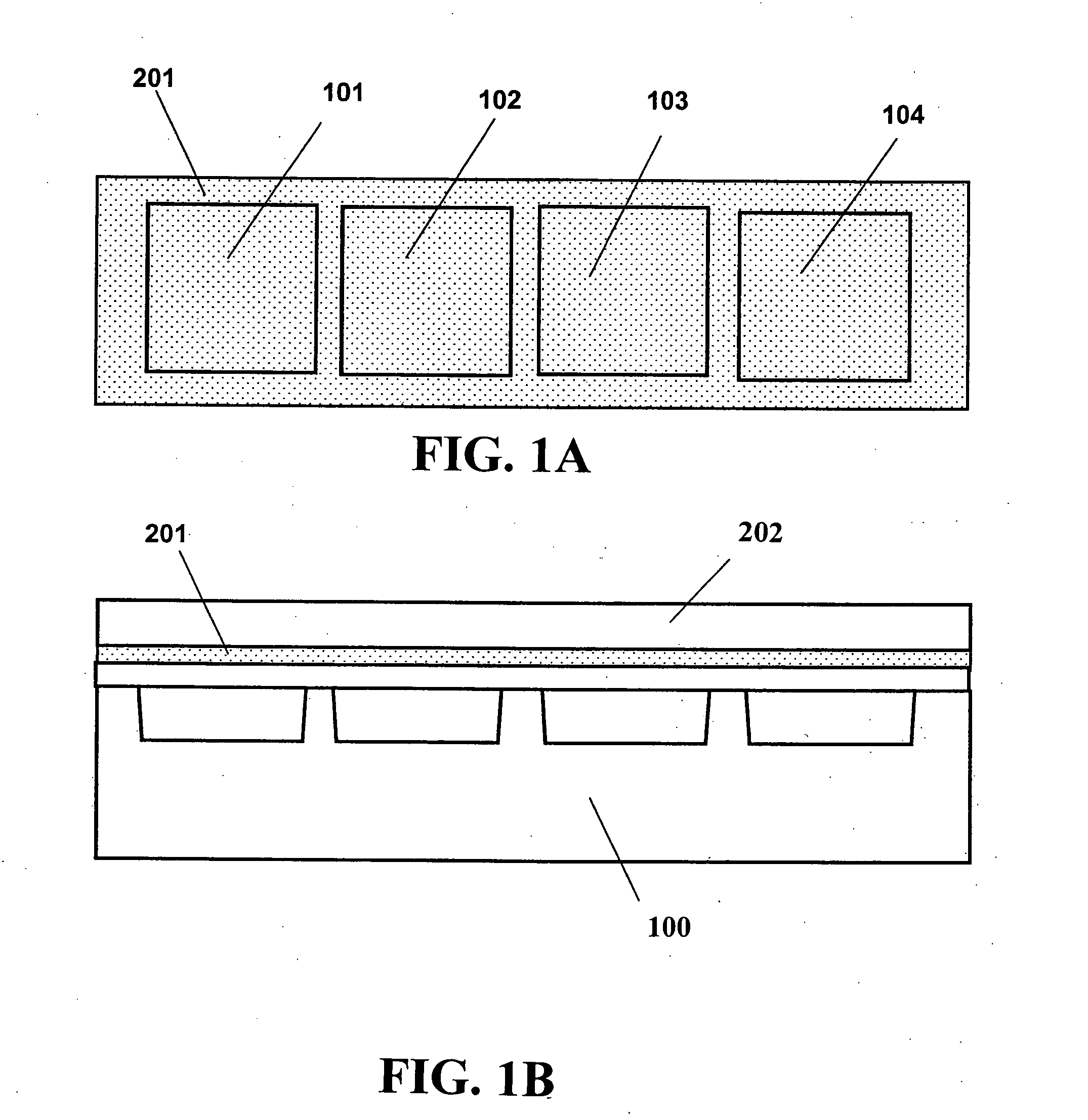

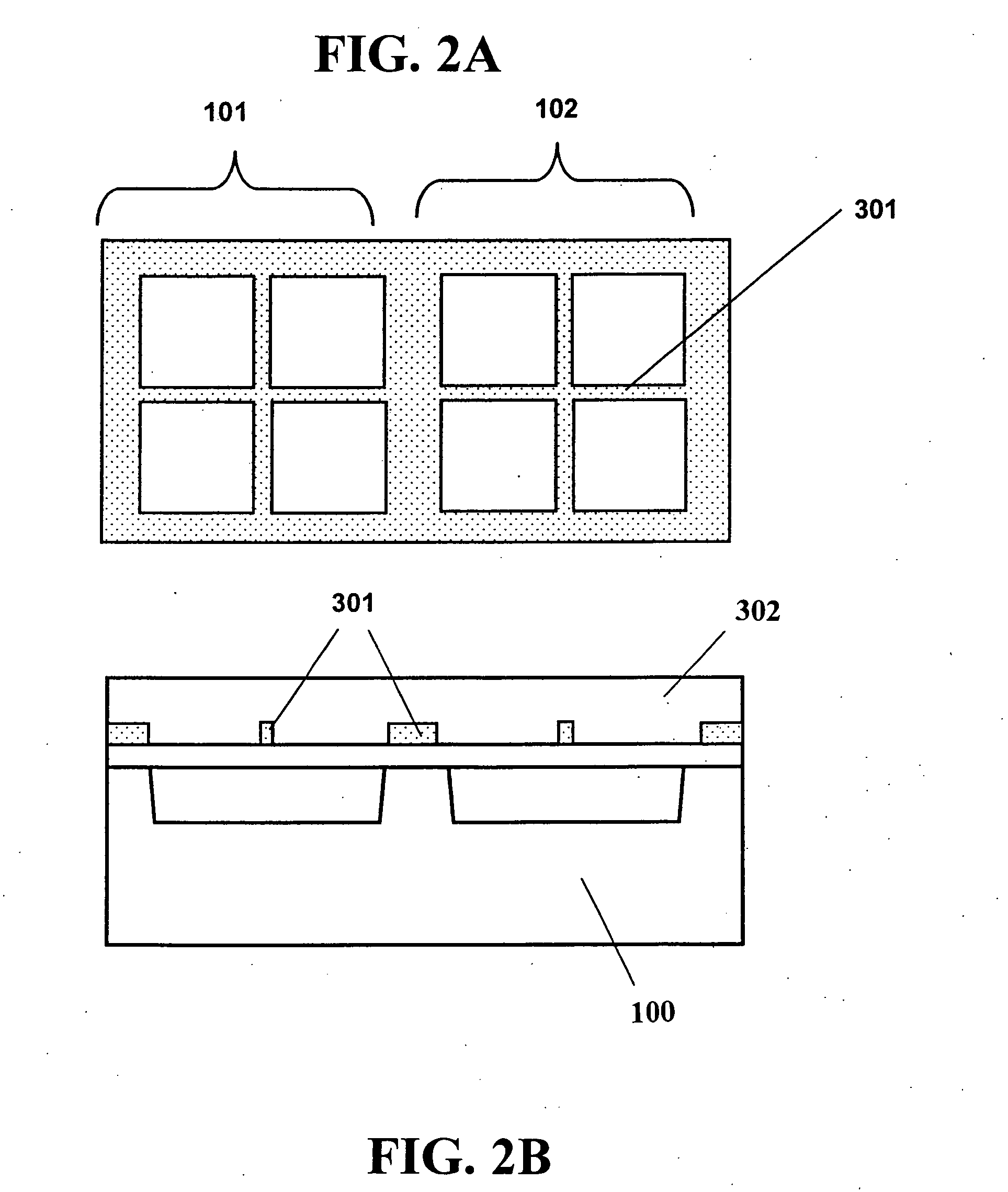

[0025]FIG. 2 is a schematic top view showing pixel regions of an image sensor according to the present invention.

[0026]The pixel region of the image sensor according to the first embodiment and that of the second embodiment are different from each other in the following point. In place of the shape of the light-transmissive conductive material 201 for potential fixation, which is formed of a polycrystalline silicon thin film or the like covering the pixel region 101, as shown in the example of FIG. 1, a light-transmissive conductive material 301 for potential fixation, which is formed of a polycrystalline silicon thin film or the like having a shape with an opening formed therein so as not to block the incident light into one pixel region 101, is formed in a cross shape in the second embodiment.

[0027]As described in the example of FIG. 1, the light-transmissive conductive material may be formed of a polycrystalline silicon thin film having a thickness of, for example, 2000 Å or smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com