Patents

Literature

32results about How to "Constant intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

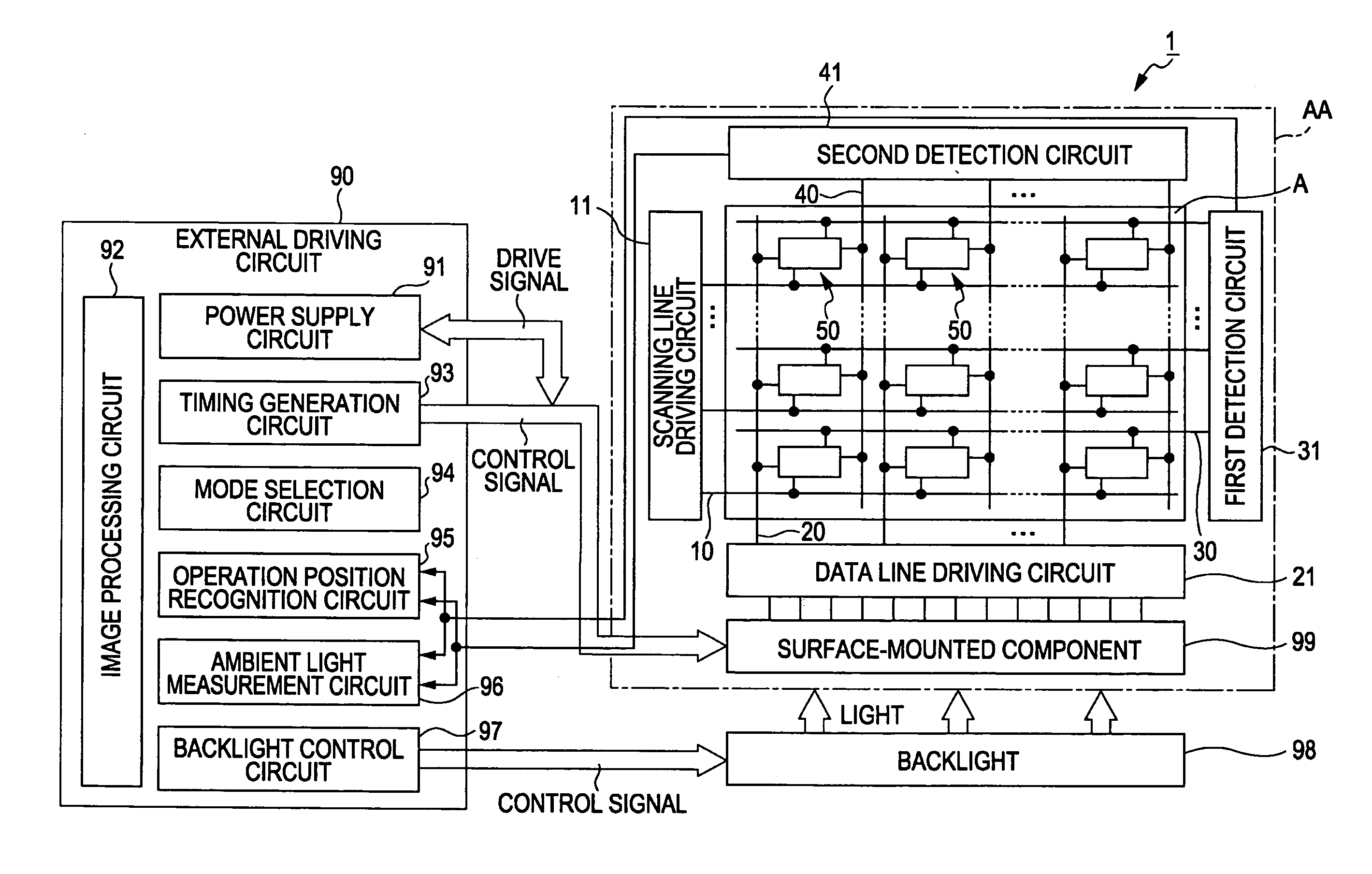

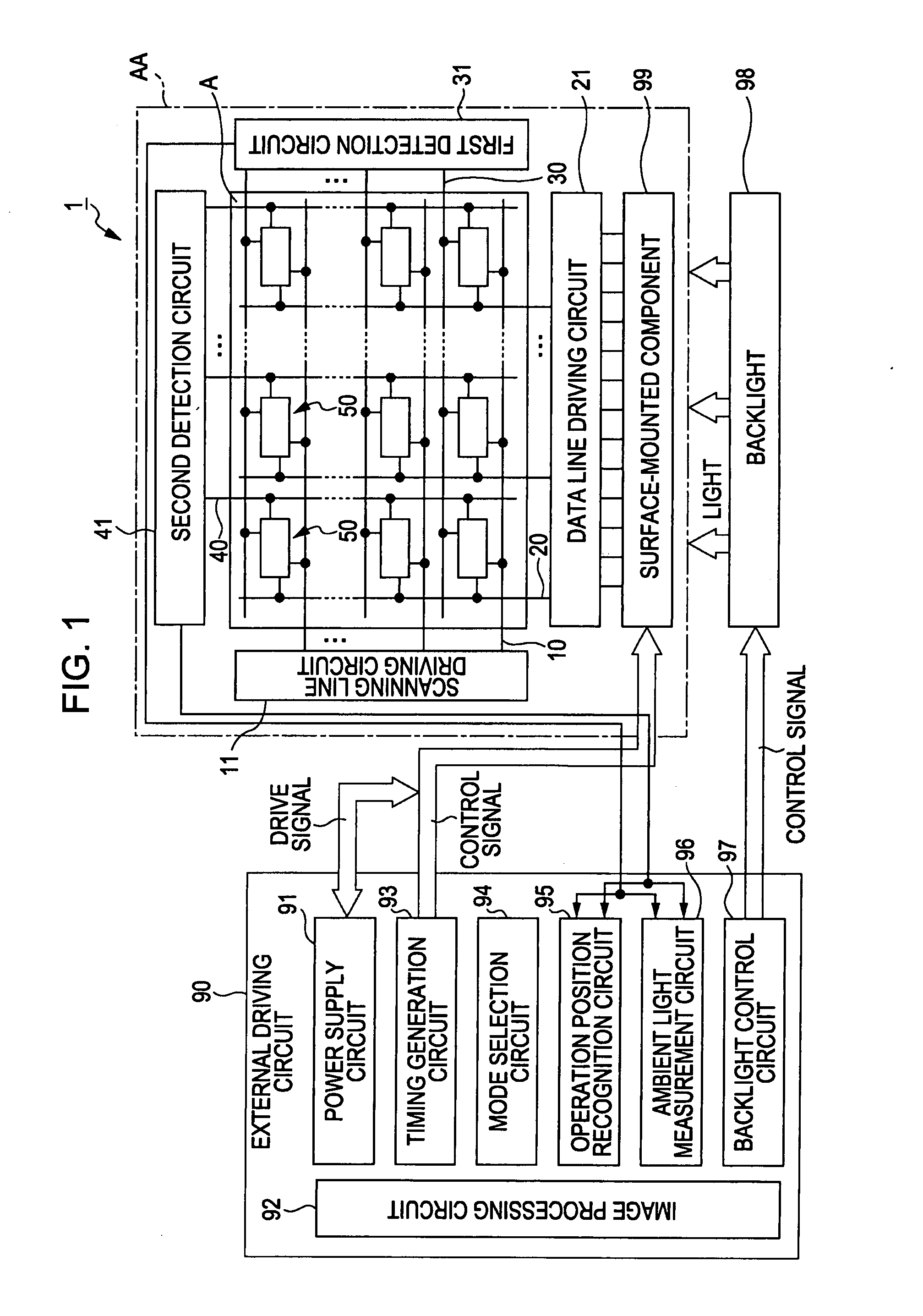

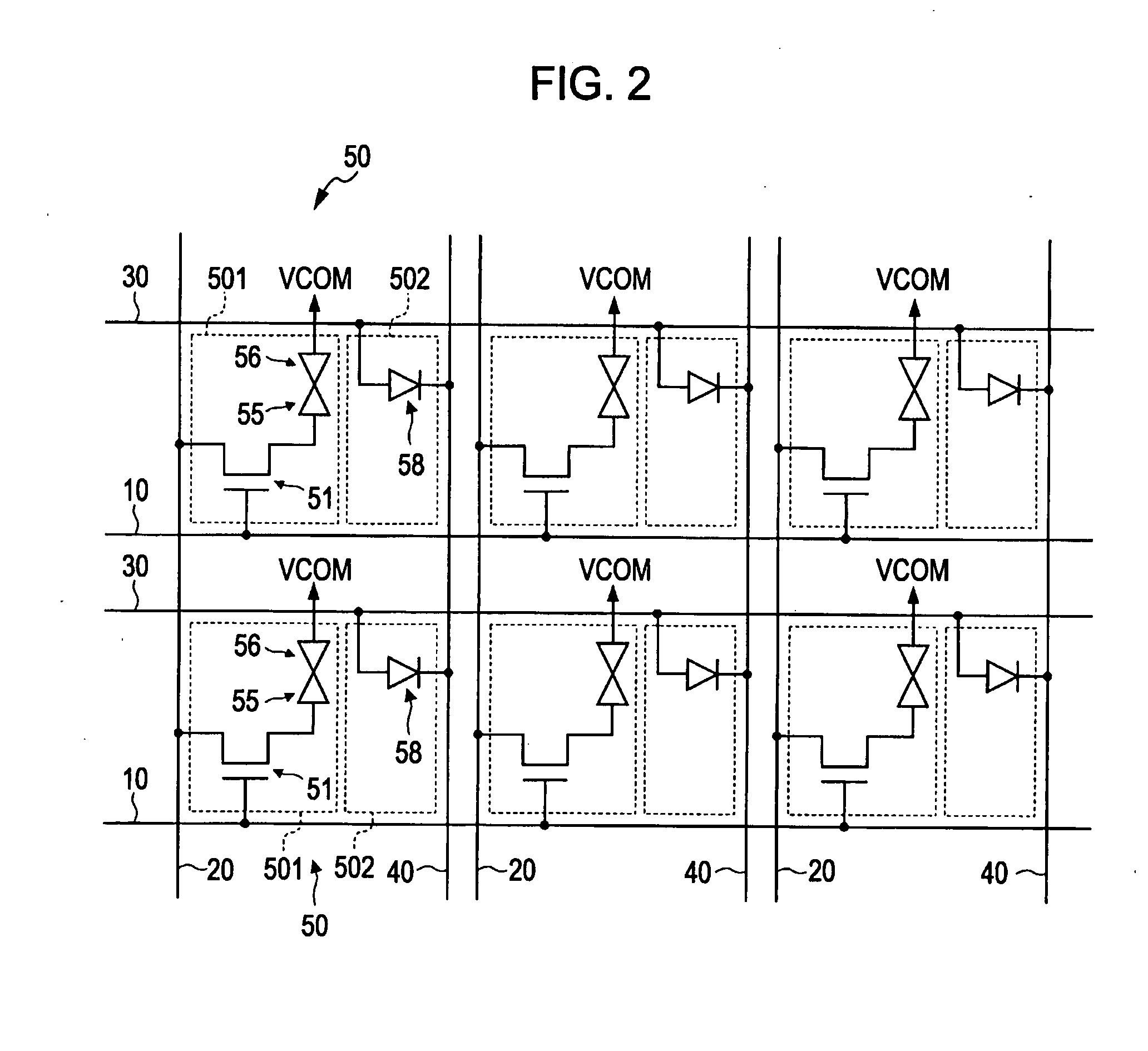

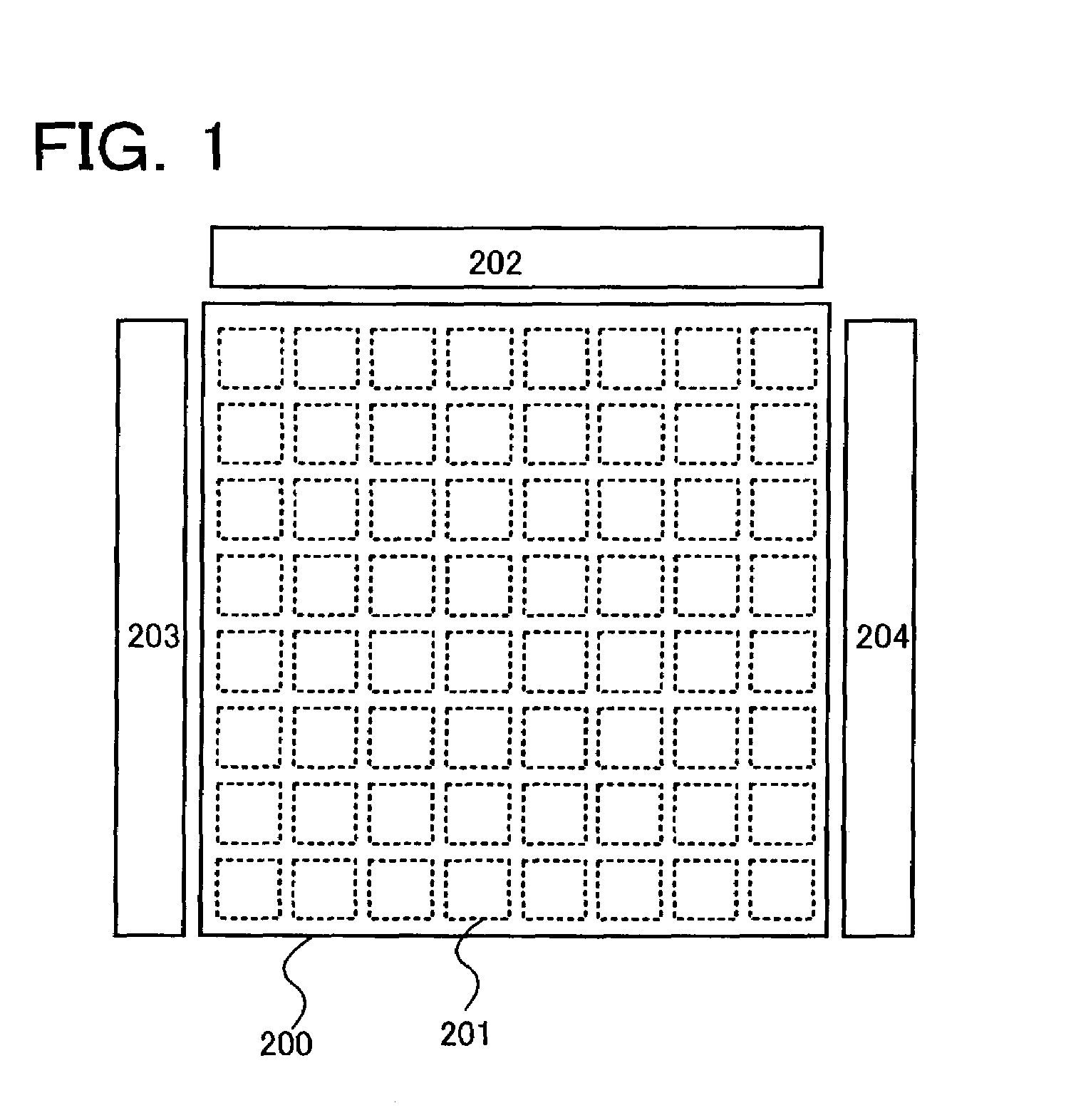

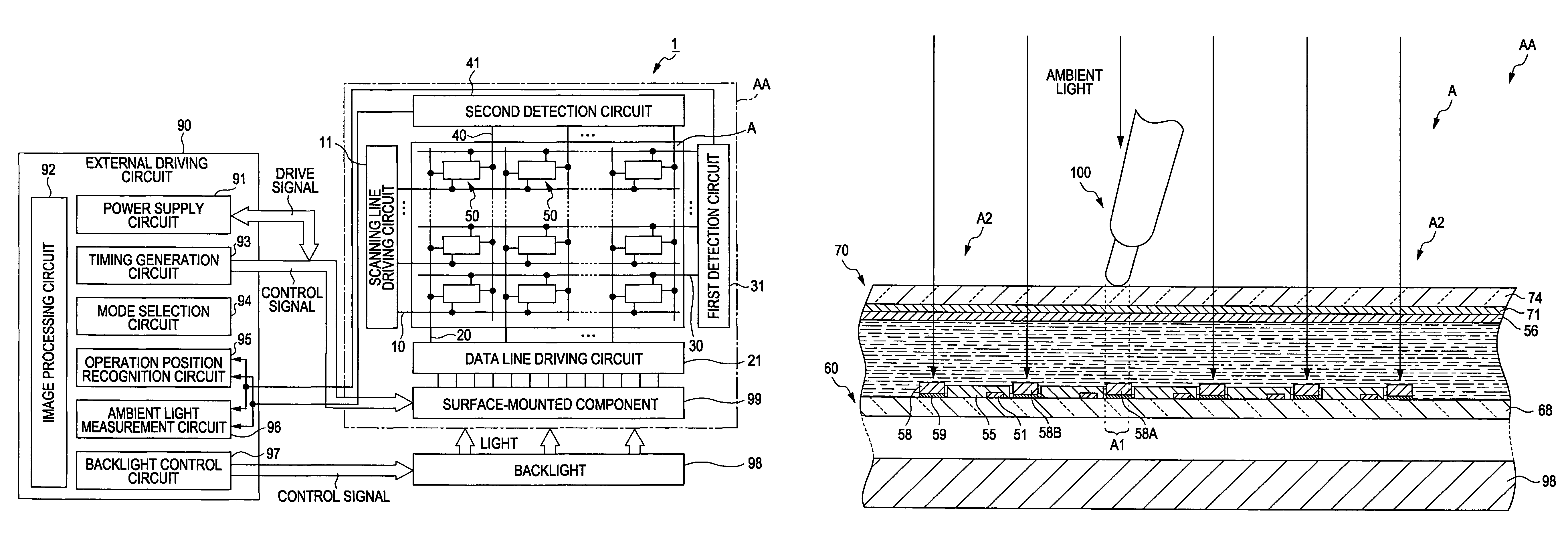

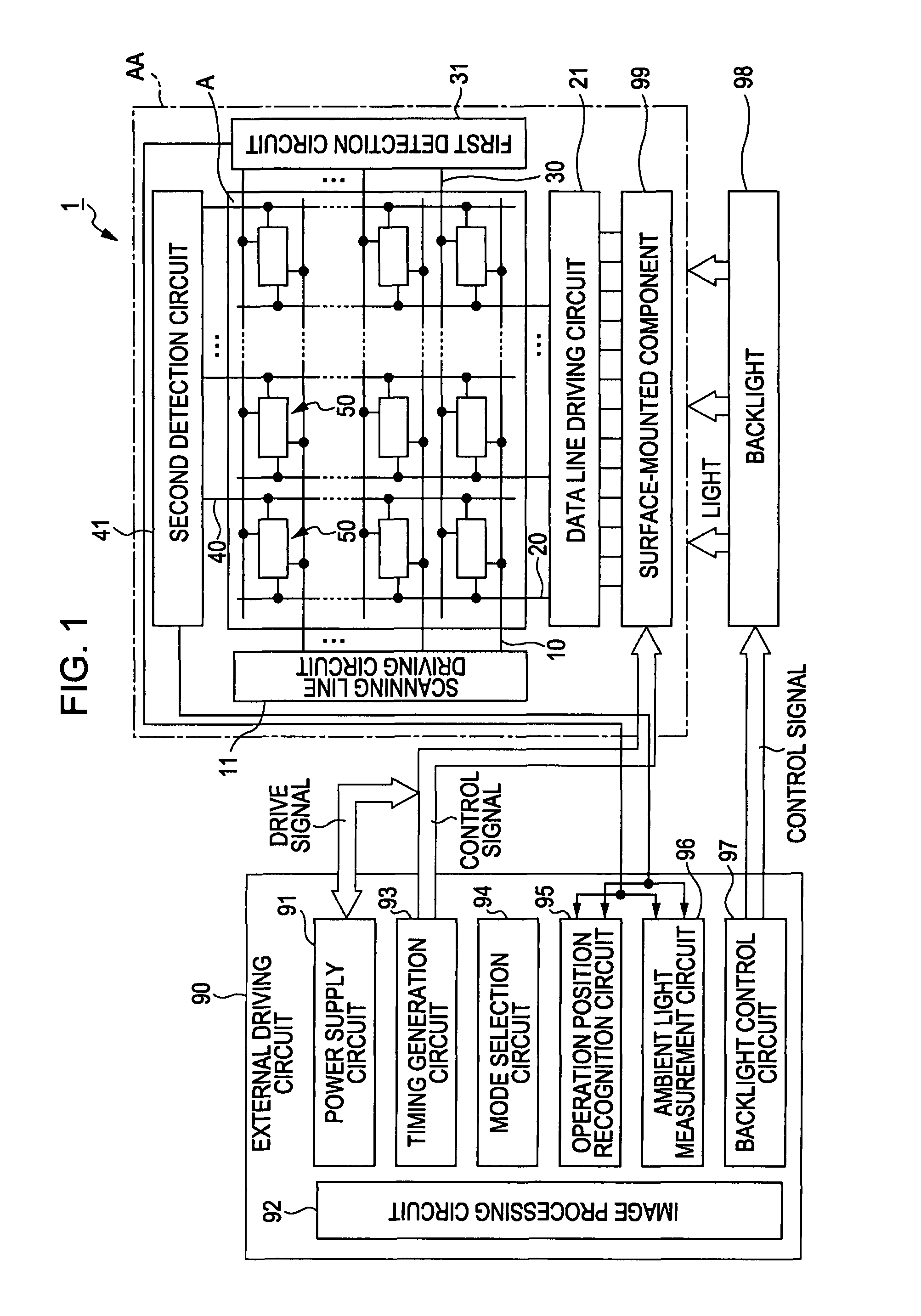

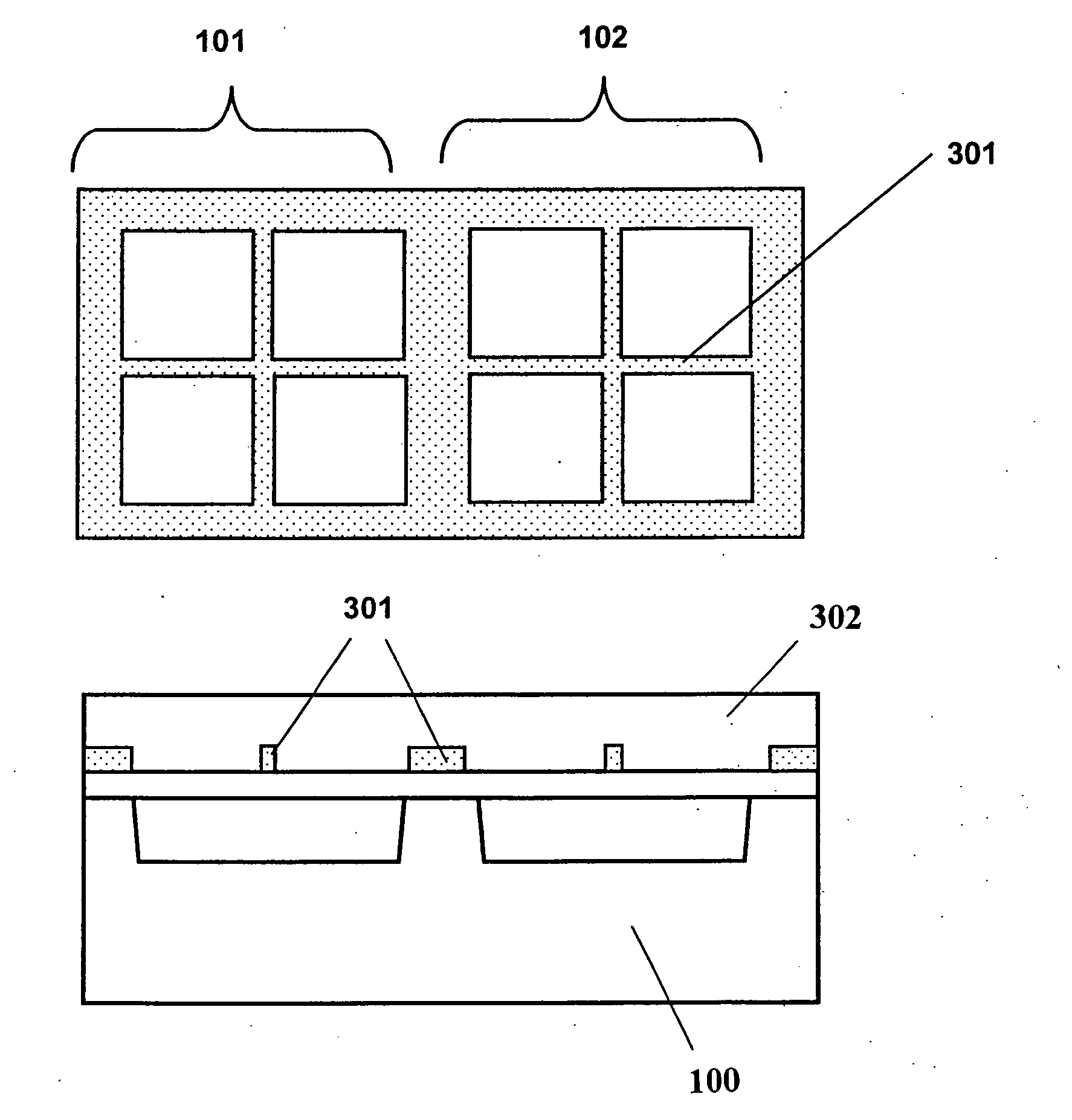

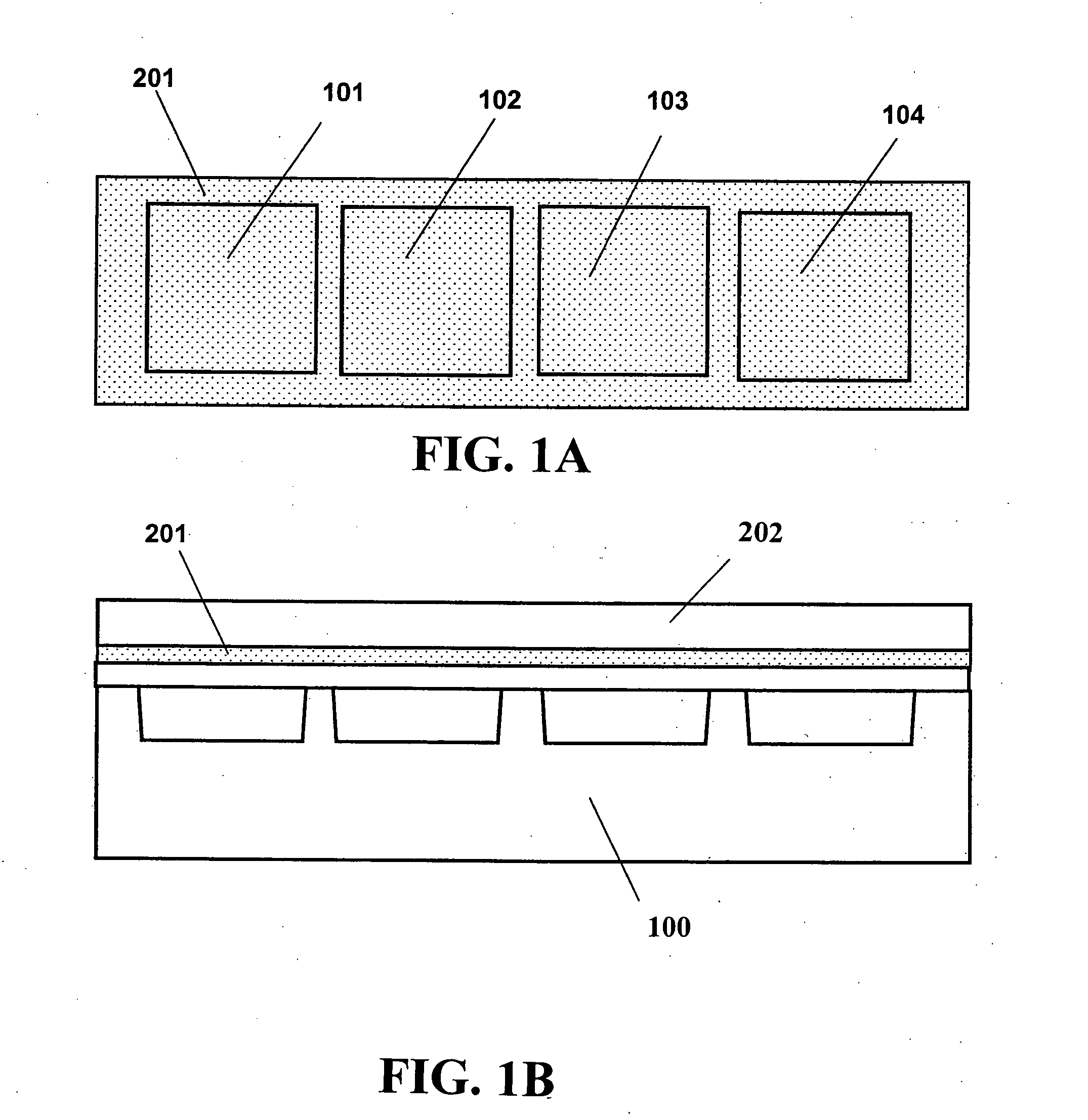

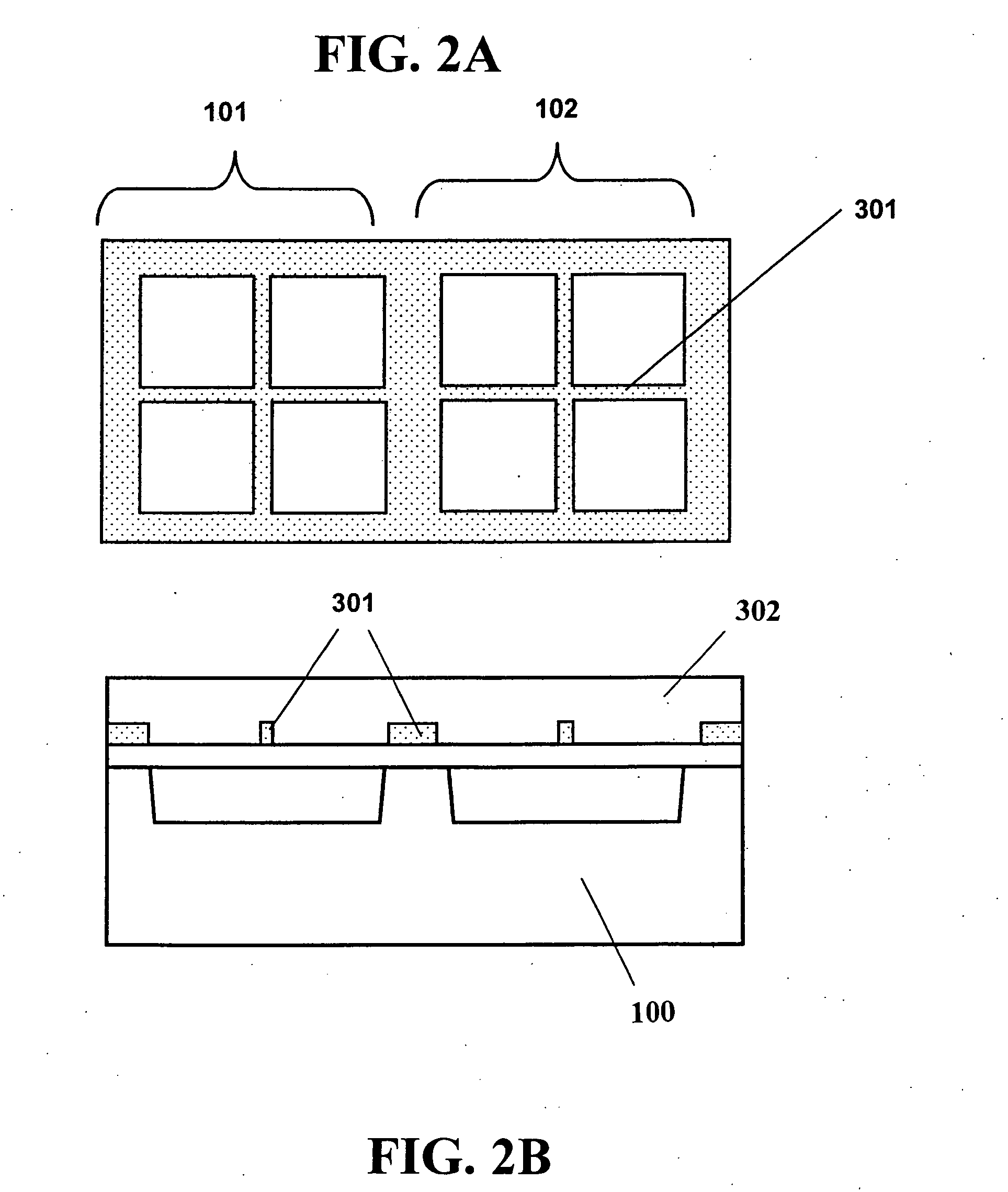

Electro-optical device and electronic apparatus

InactiveUS20070216637A1Constant intensityMeasurement accuracy of the ambient light intensity can be increasedStatic indicating devicesInput/output processes for data processingEngineeringLight intensity

An electro-optical device includes a display unit having a plurality of pixels, and the display unit is divided into a plurality of areas. The electro-optical device also includes a plurality of optical sensors that are provided for the plurality of areas, each of the optical sensors being configured to detect a light intensity, and a controller that selectively performs recognition of an operation position on the display unit or measurement of an ambient light intensity on the basis of the light intensities detected by the plurality of optical sensors.

Owner:JAPAN DISPLAY WEST

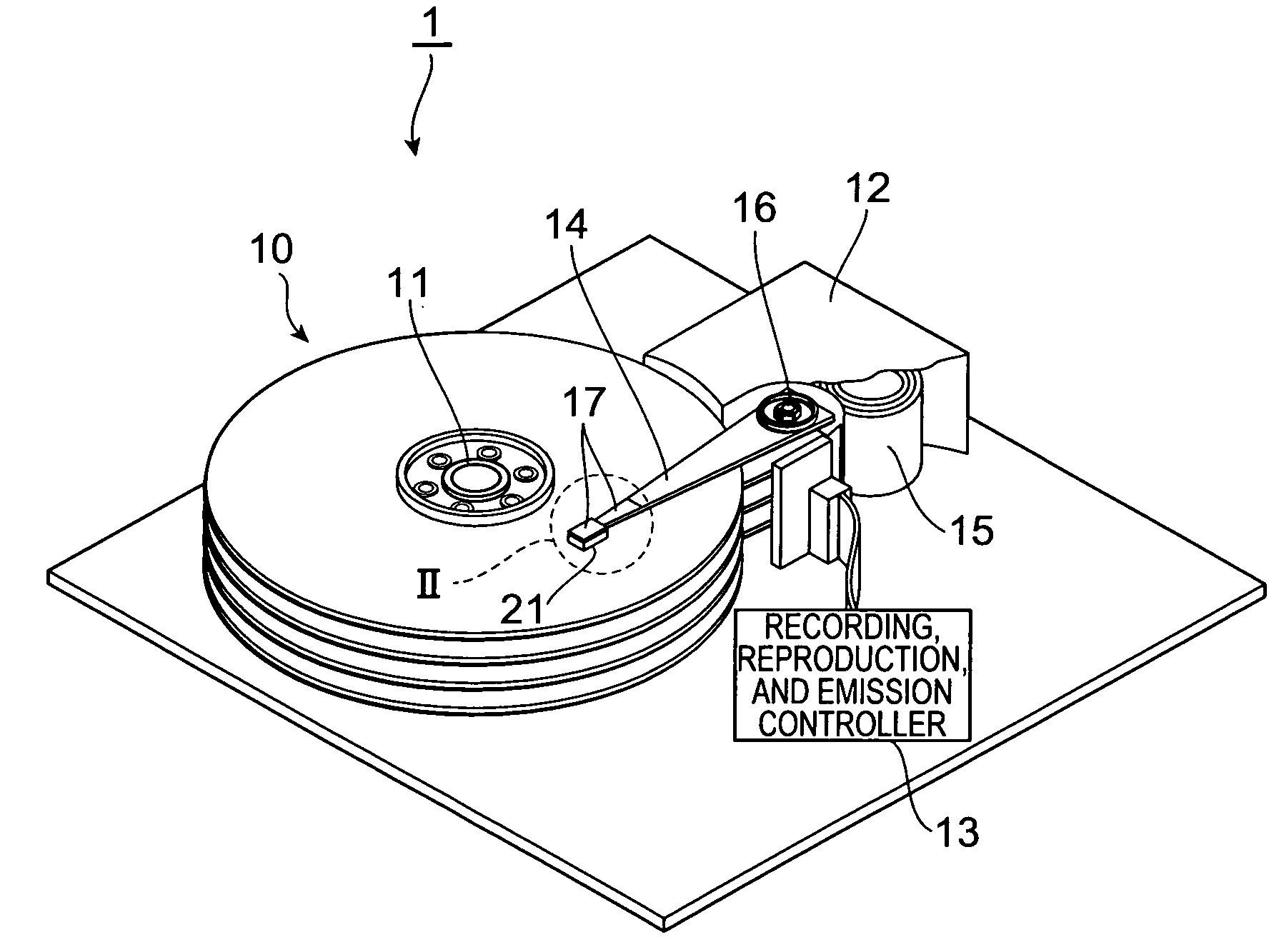

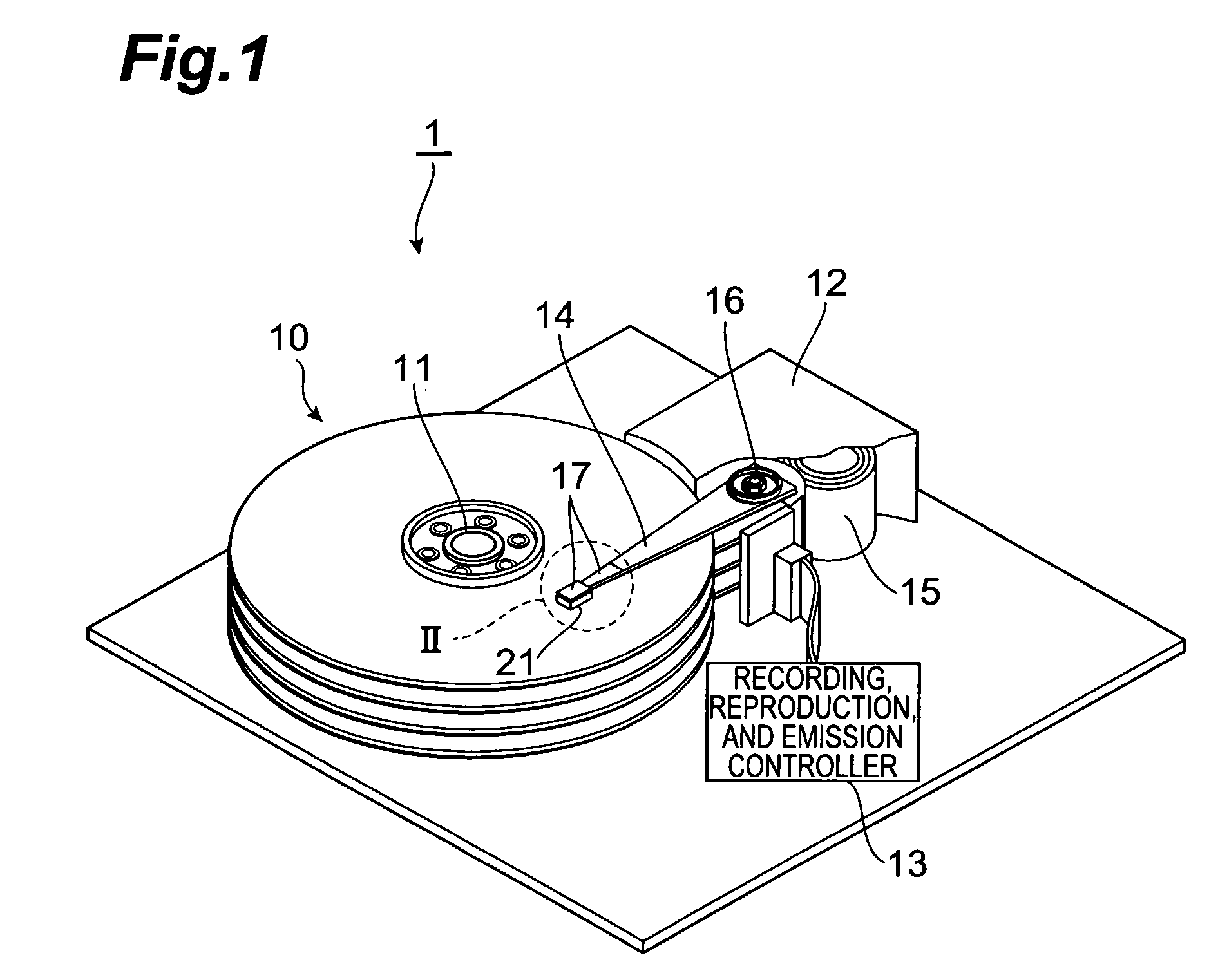

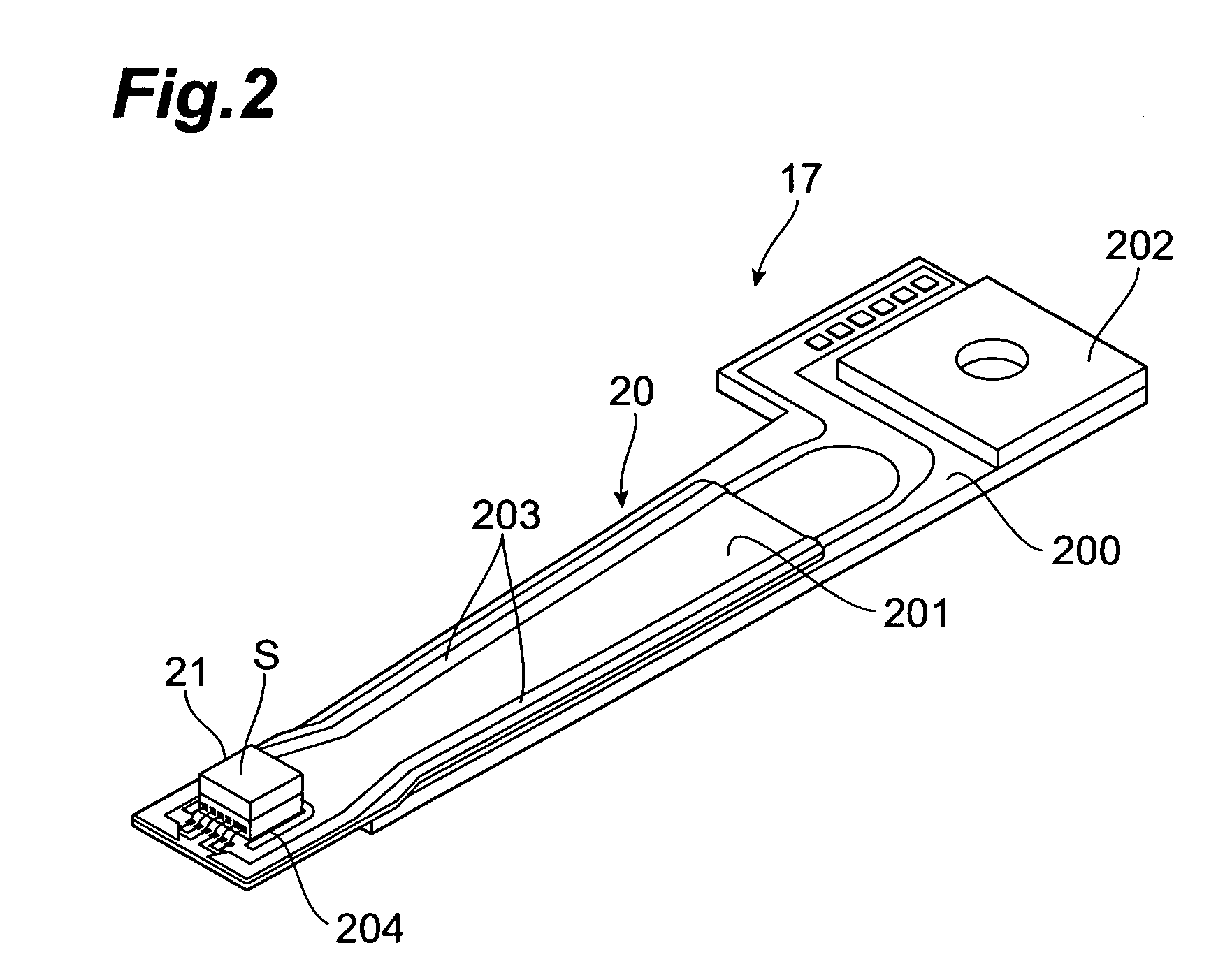

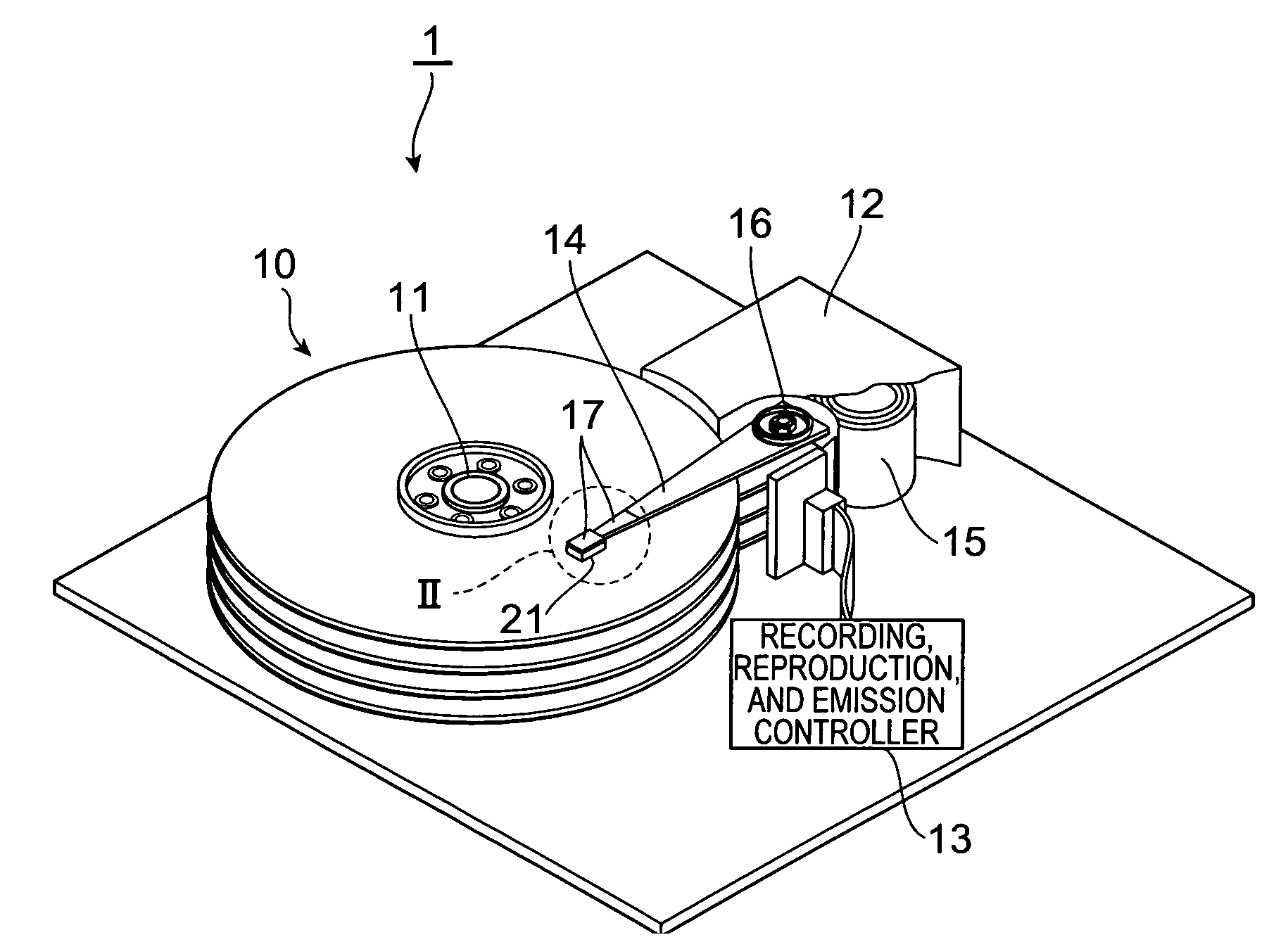

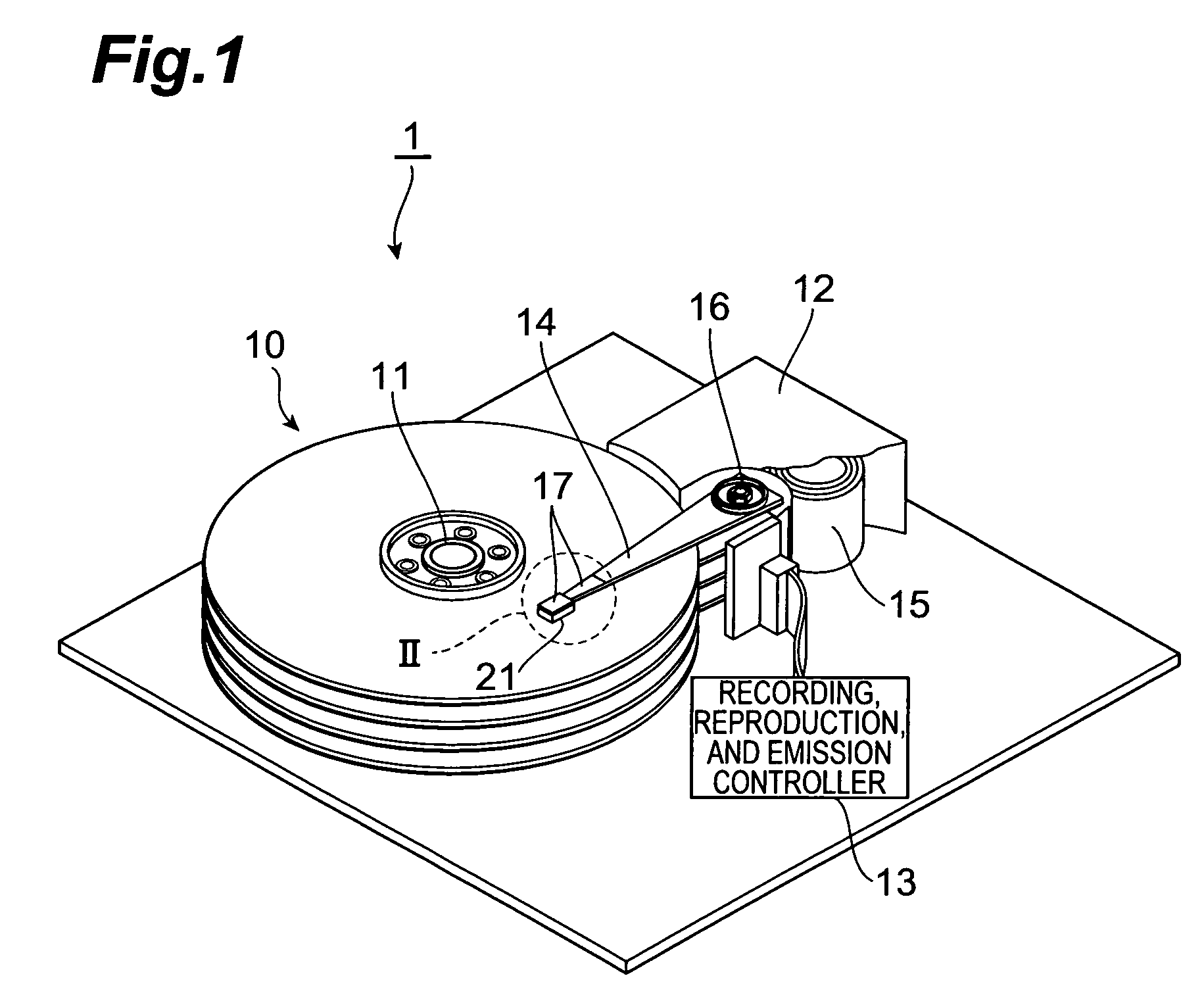

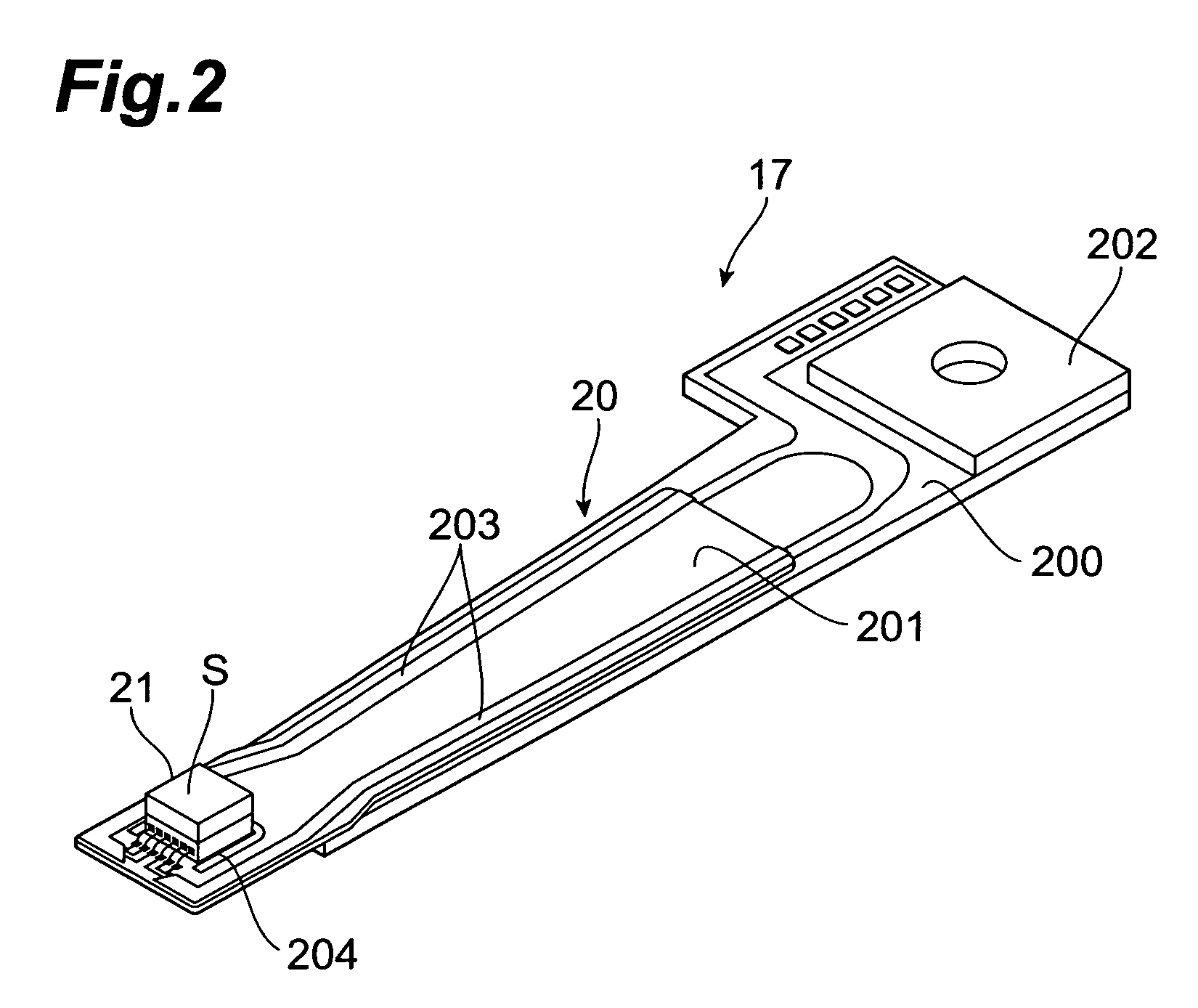

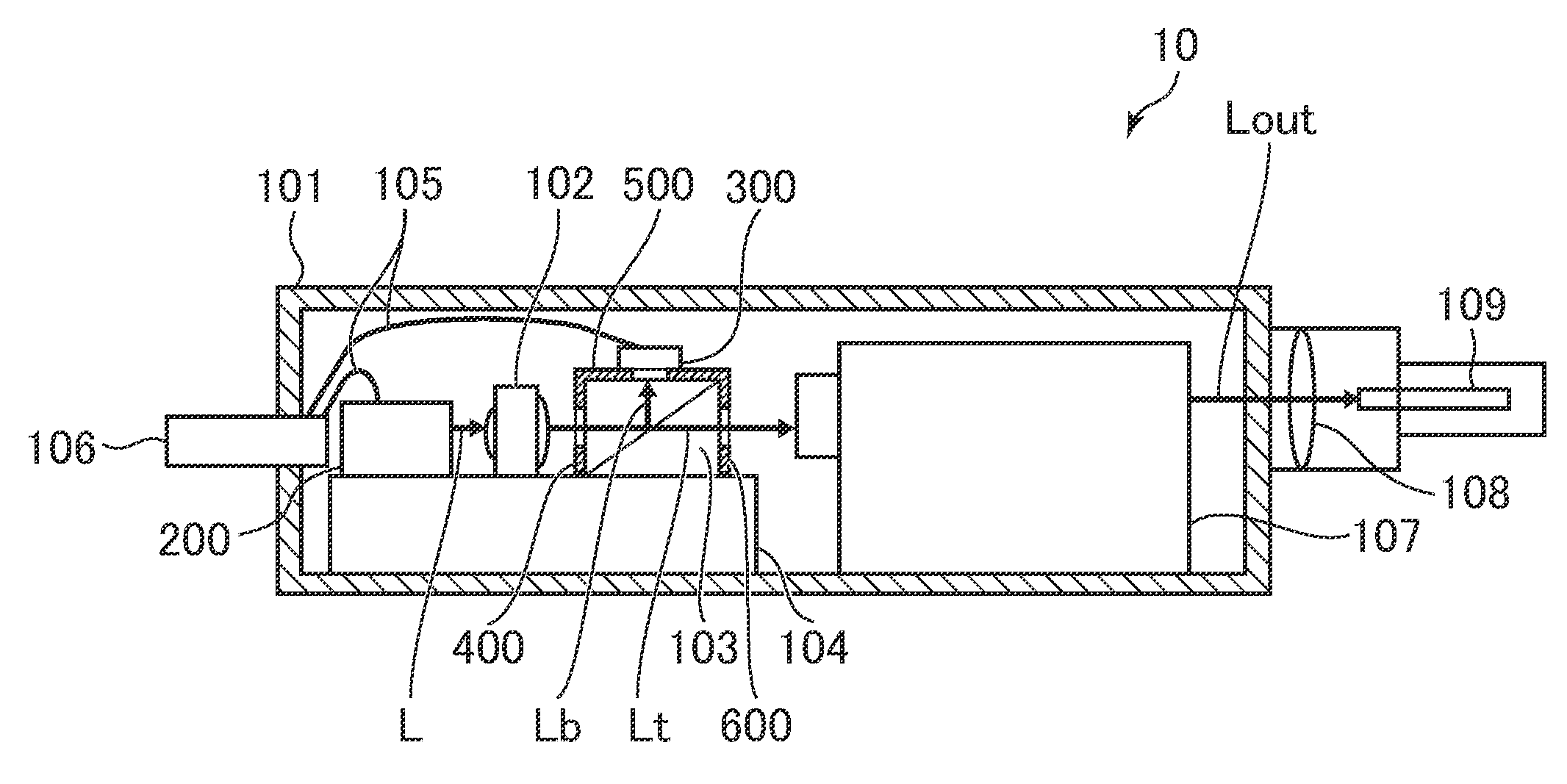

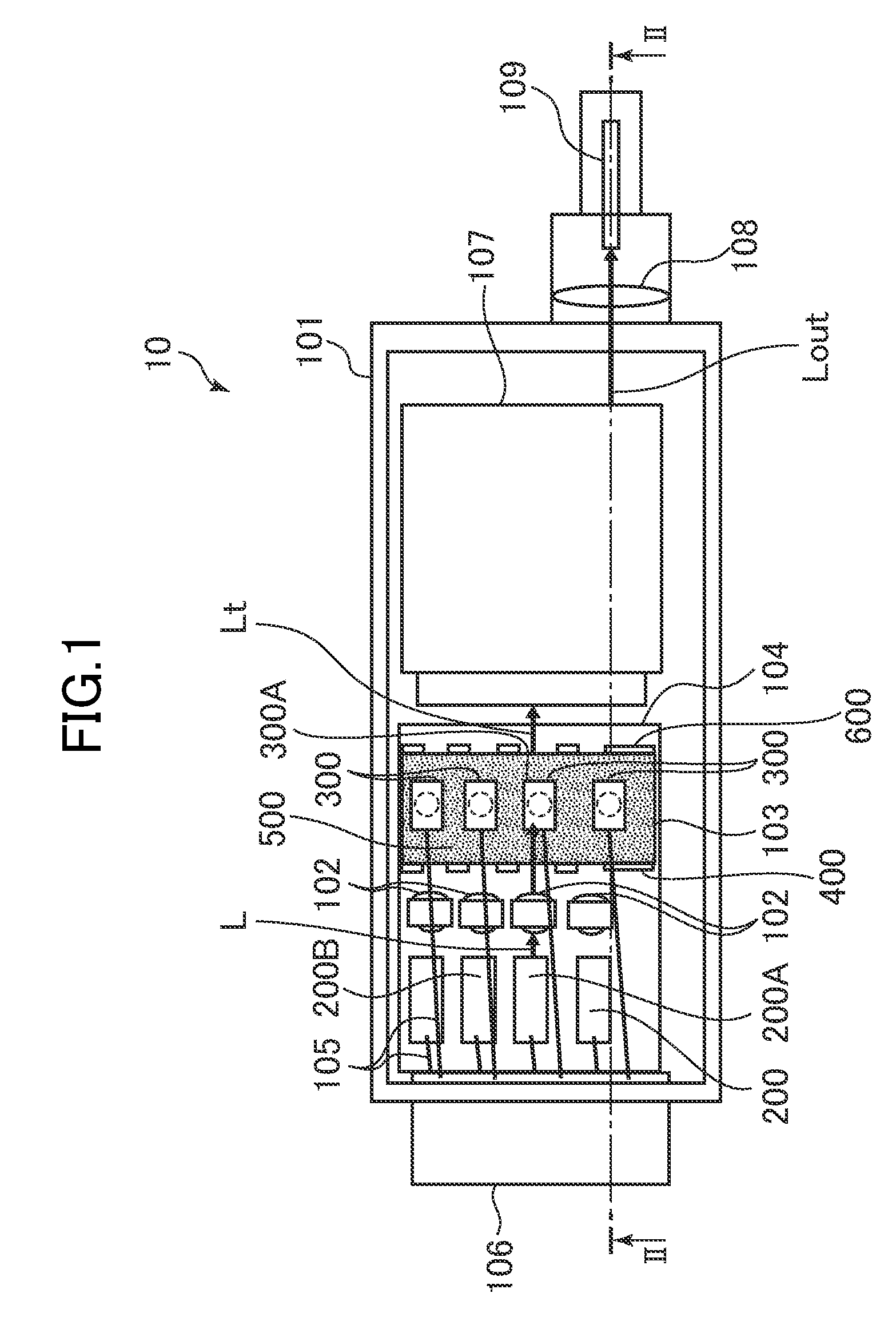

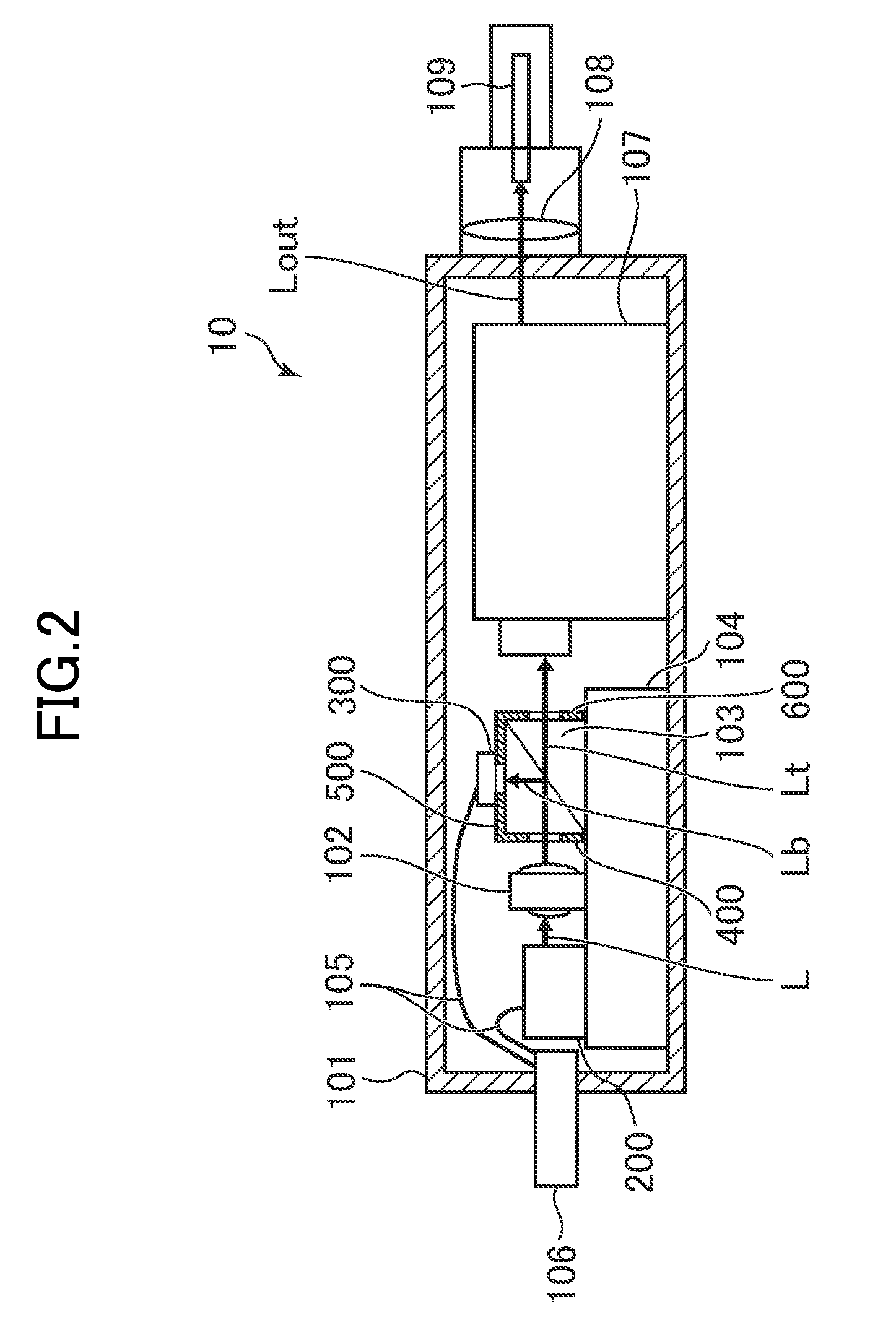

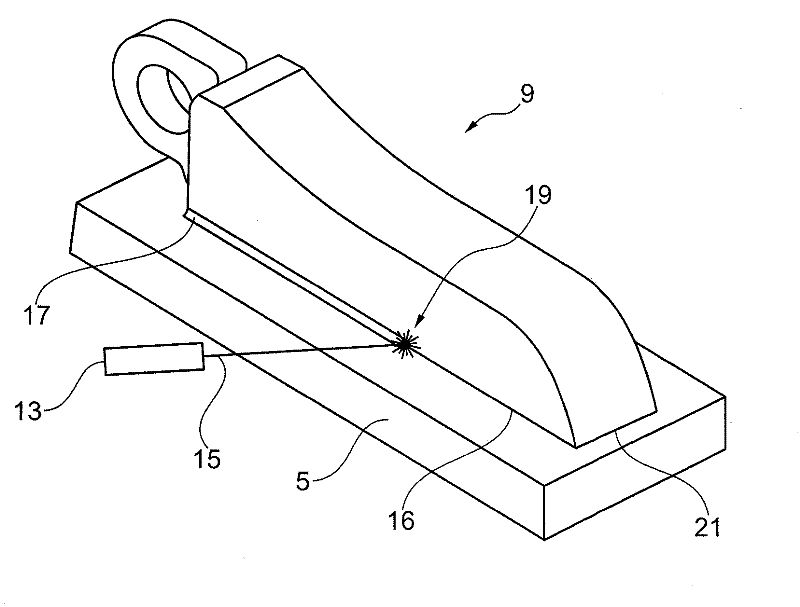

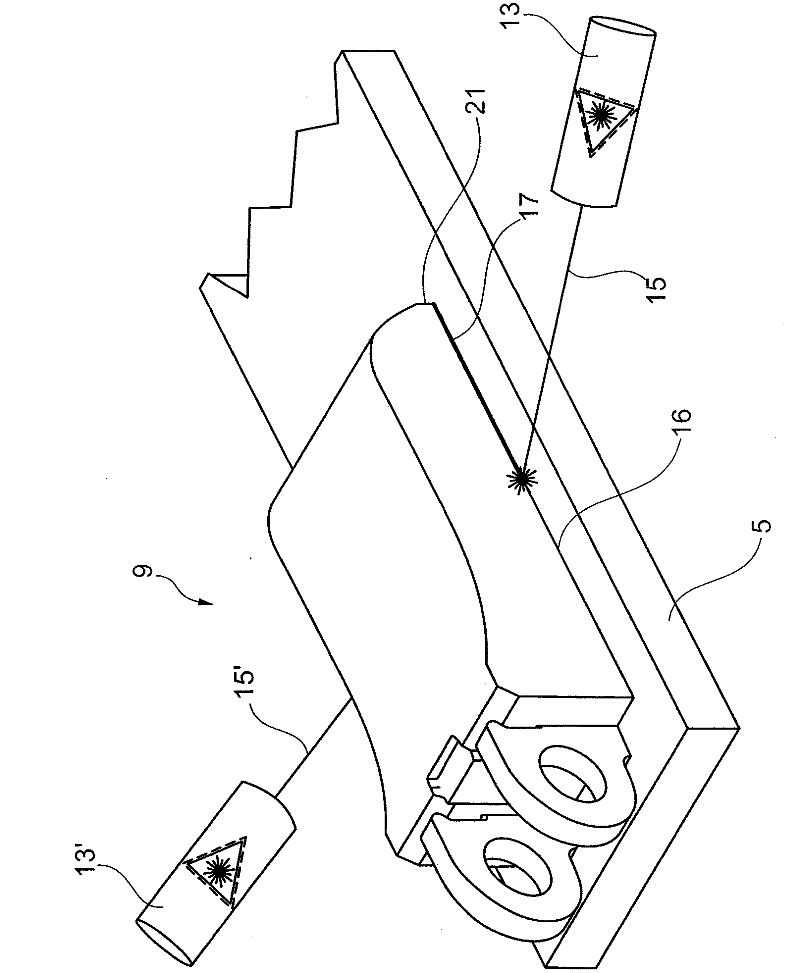

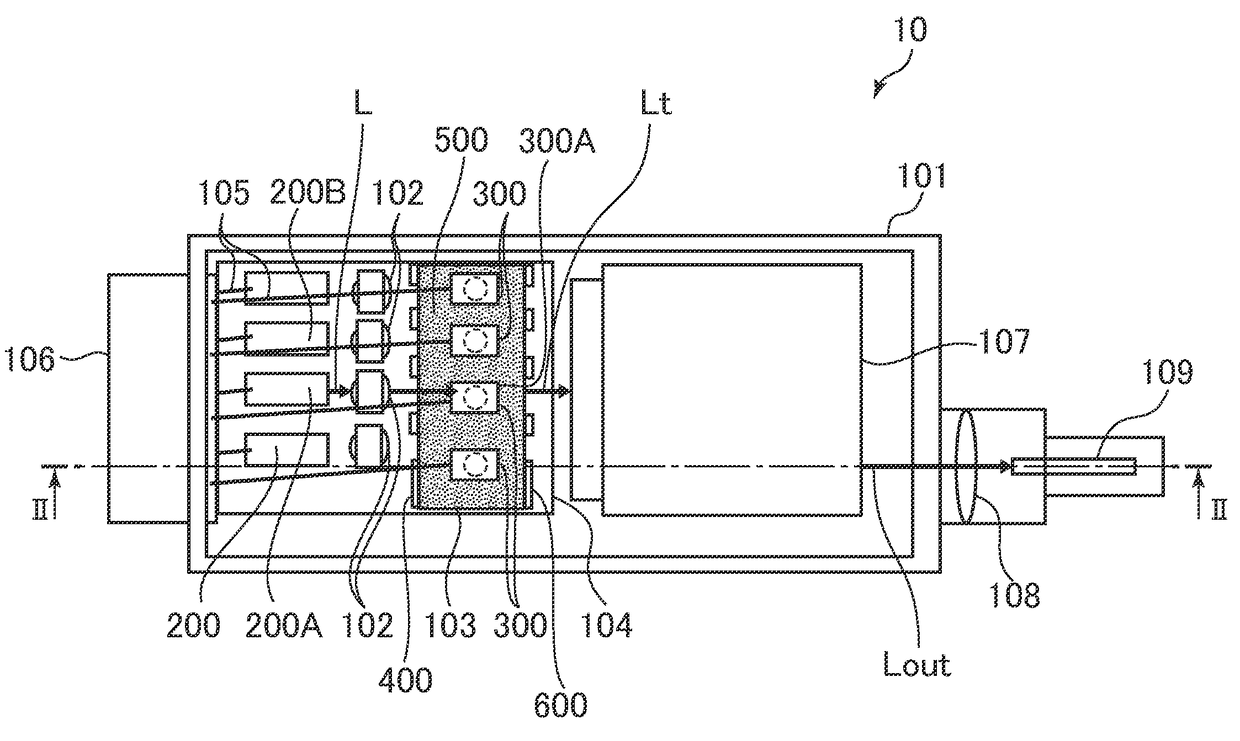

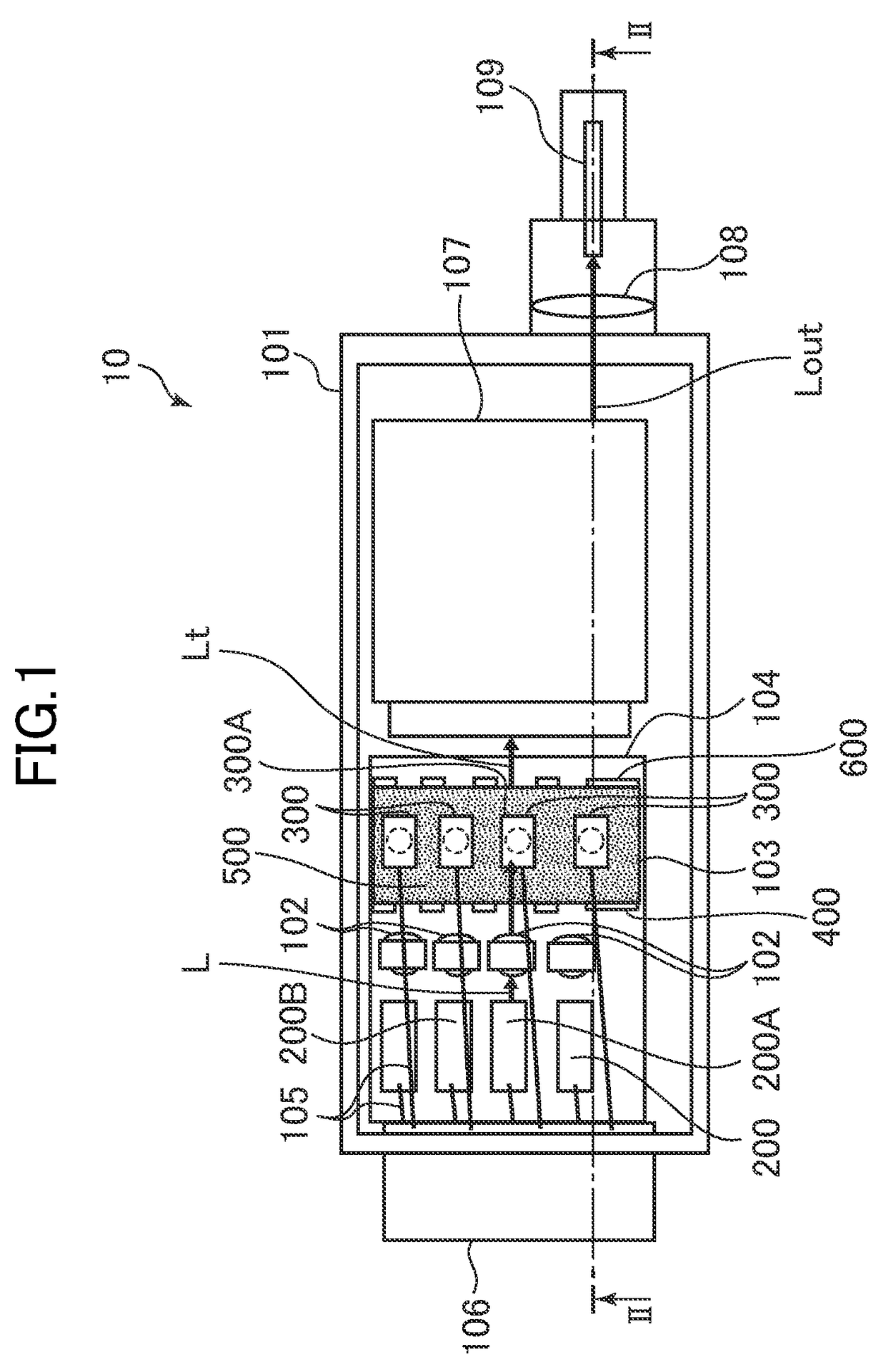

Thermally assisted magnetic head, head gimbal assembly, and hard disk drive

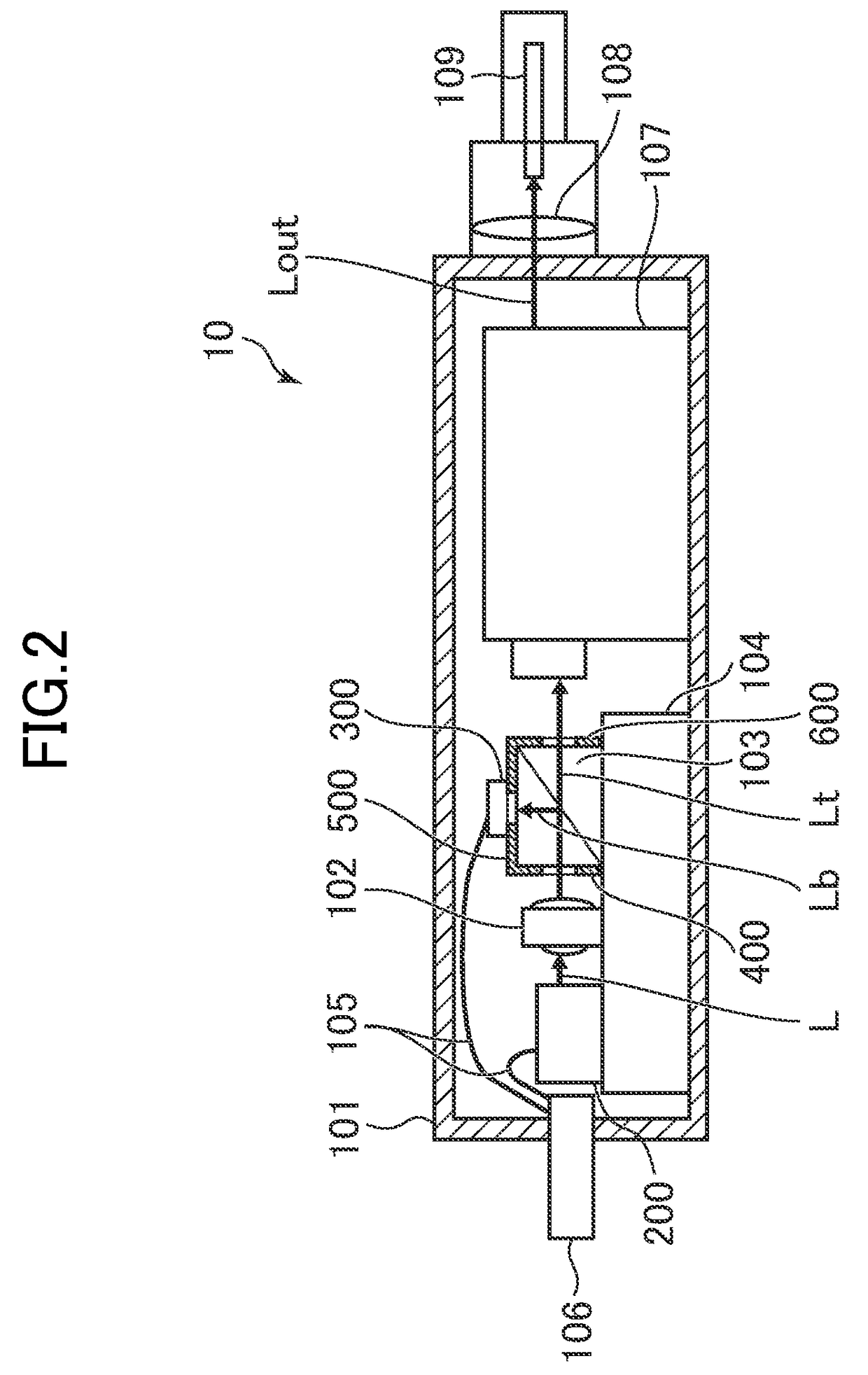

ActiveUS20080158709A1Complex structureKeep intensity of emitted lightCombination recordingRecord information storageHard disc driveEngineering

A thermally assisted magnetic head comprises: a slider substrate, a first surface located opposite to a medium-facing surface, and side surfaces located between the medium-facing surface and the first surface; a magnetic head portion having a near-field light generator on the medium-facing surface side, and a magnetic recording element, the magnetic head portion being fixed to one of the side surfaces; and a laser diode element a relative position of which to the slider substrate is fixed so that emitted light thereof can reach the near-field light generator; a relation of λin<λmax is satisfied, where λin is a wavelength of the emitted light from the laser diode element immediately before the emitted light reaches the near-field light generator, and λmax is a wavelength of irradiating light at which an efficiency of generation of near-field light generated from the near-field light generator is maximum.

Owner:TDK CORPARATION

Thermally assisted magnetic head, head gimbal assembly, and hard disk drive

ActiveUS7876646B2Complex structureKeep intensity of emitted lightCombination recordingRecord information storageHard disc driveEngineering

A thermally assisted magnetic head comprises: a slider substrate, a first surface located opposite to a medium-facing surface, and side surfaces located between the medium-facing surface and the first surface; a magnetic head portion having a near-field light generator on the medium-facing surface side, and a magnetic recording element, the magnetic head portion being fixed to one of the side surfaces; and a laser diode element a relative position of which to the slider substrate is fixed so that emitted light thereof can reach the near-field light generator; a relation of λin<λmax is satisfied, where λin is a wavelength of the emitted light from the laser diode element immediately before the emitted light reaches the near-field light generator, and λmax is a wavelength of irradiating light at which an efficiency of generation of near-field light generated from the near-field light generator is maximum.

Owner:TDK CORPARATION

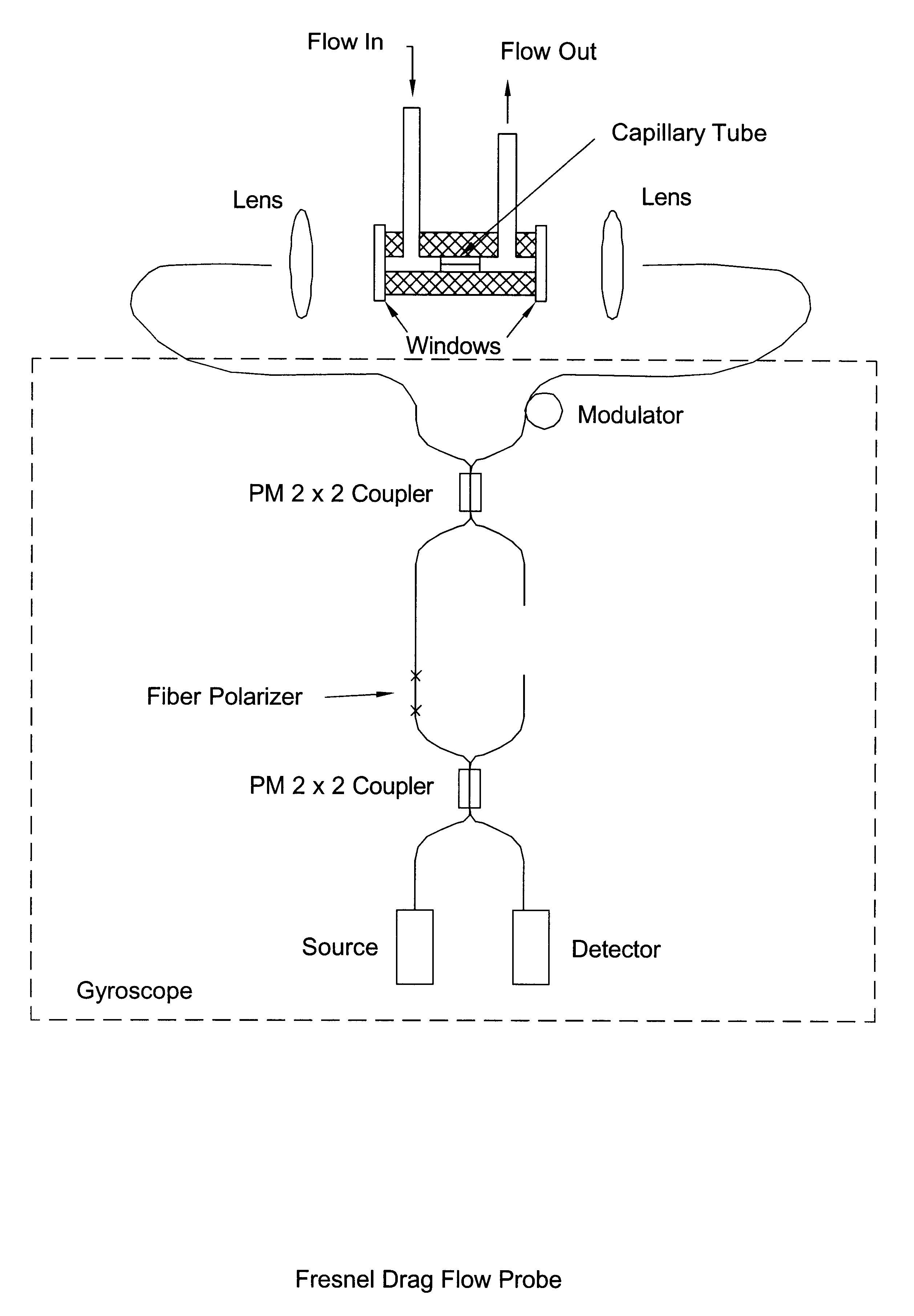

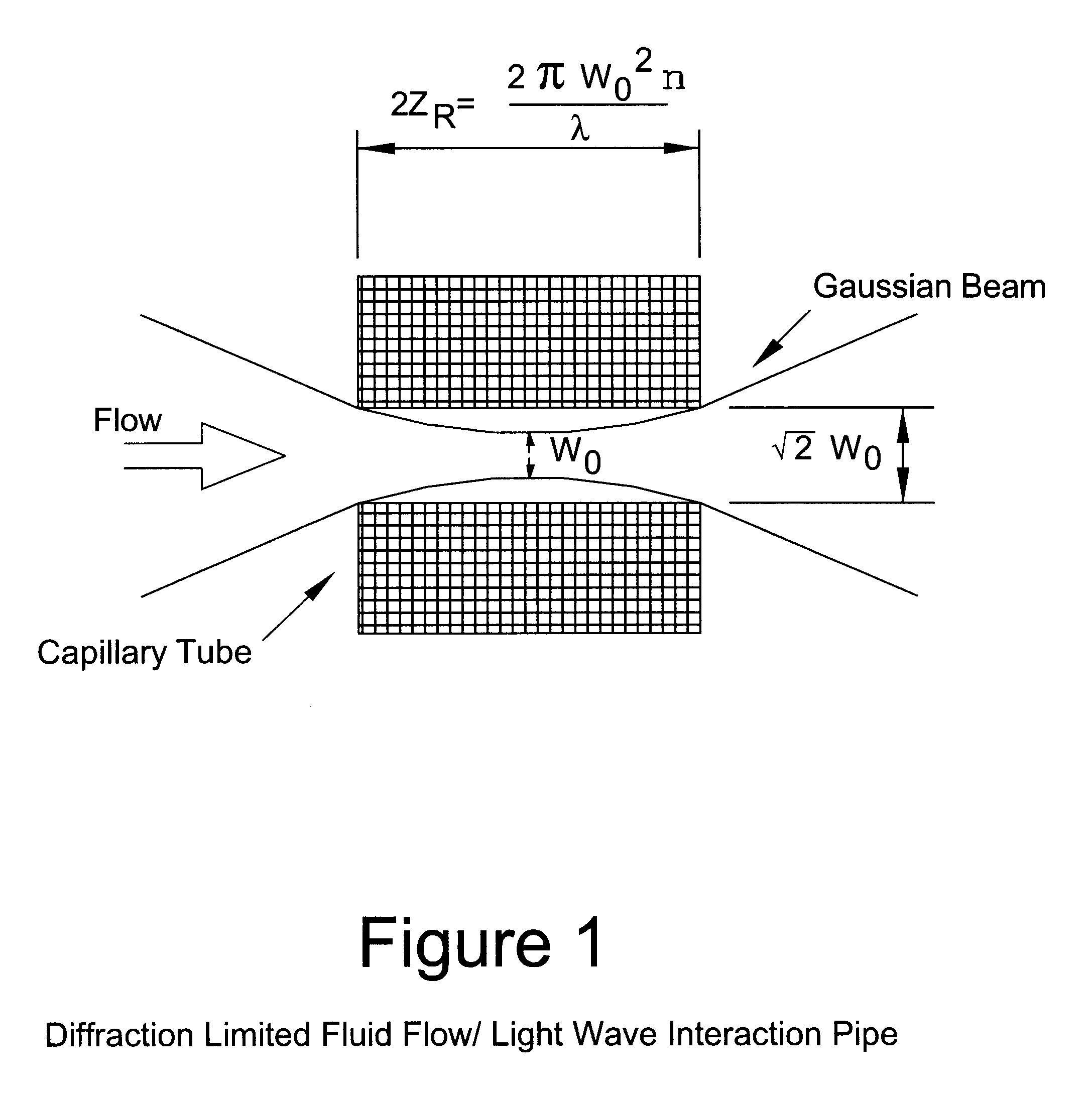

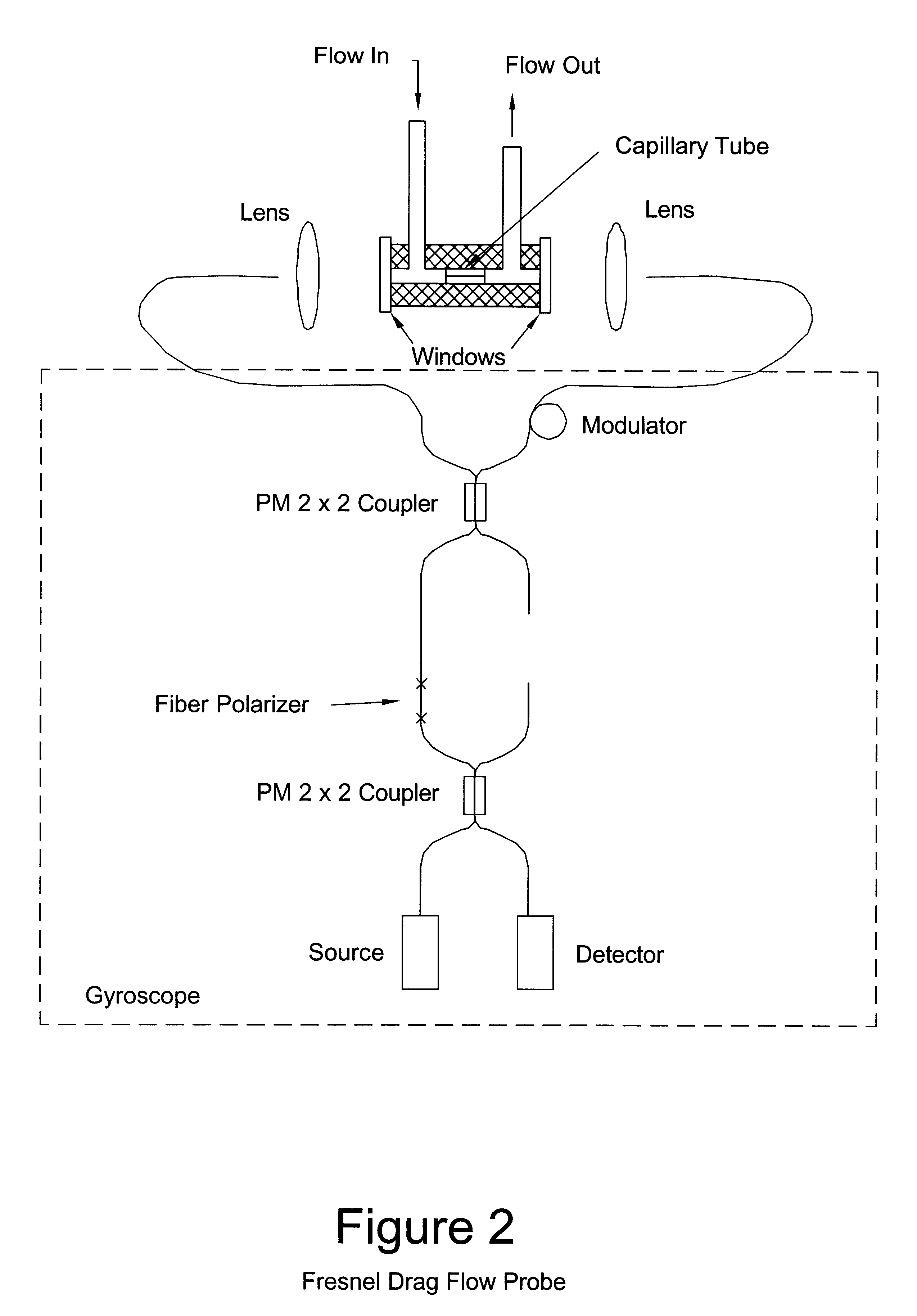

Fiber optic alignment system and method

InactiveUS6545261B1High sensitivityHigh resolutionVolume/mass flow measurementInvestigating moving fluids/granular solidsFiberPhotovoltaic detectors

A method and system for aligning optical fibers includes aperturing the optical beams from the optical fibers at two points along a path. Photodetectors are placed on the apertures and the positions of the tips of the optical fibers are controlled using actuators to center the optical beams within the apertures.

Owner:BLAKE JAMES N +1

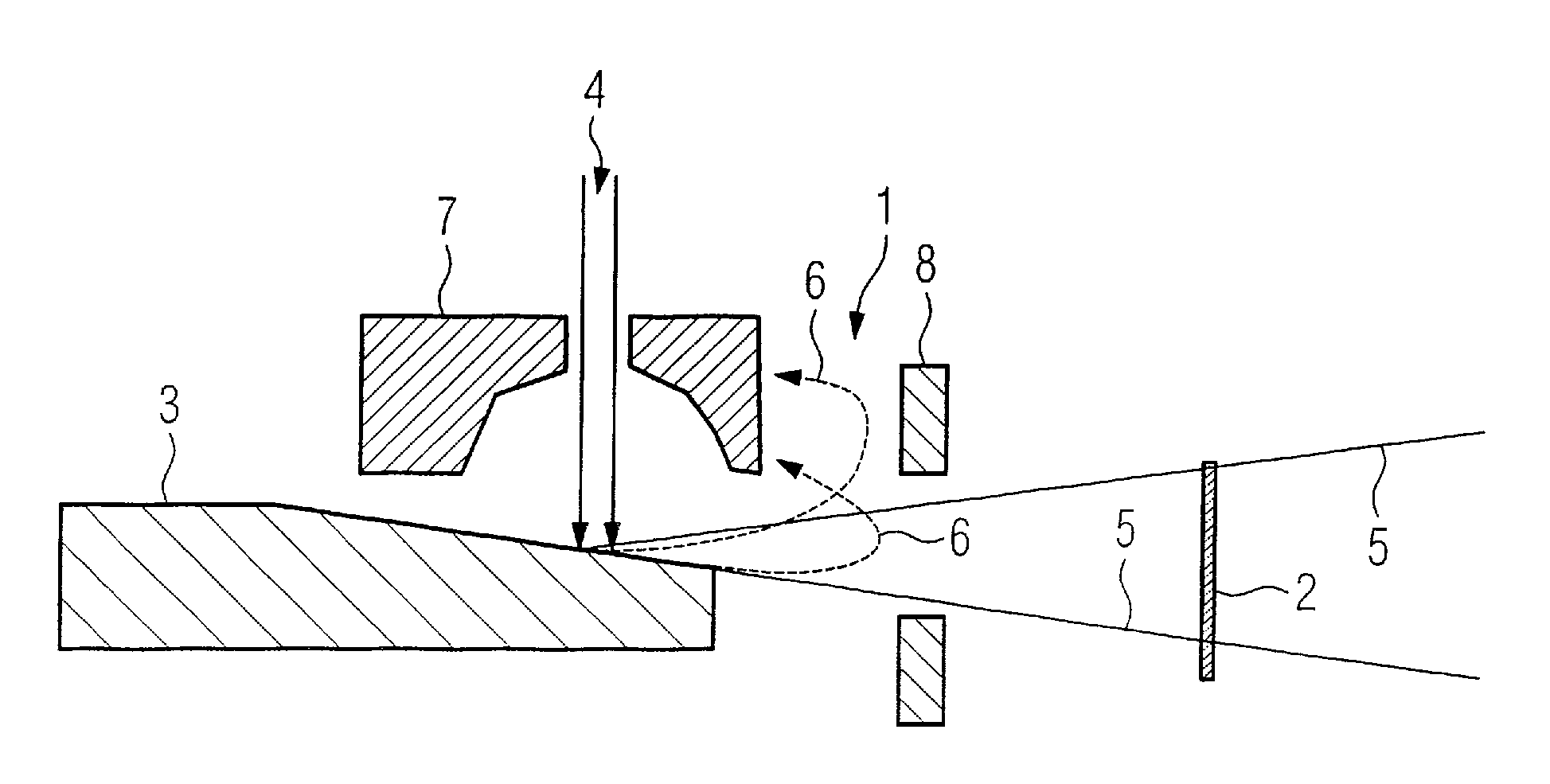

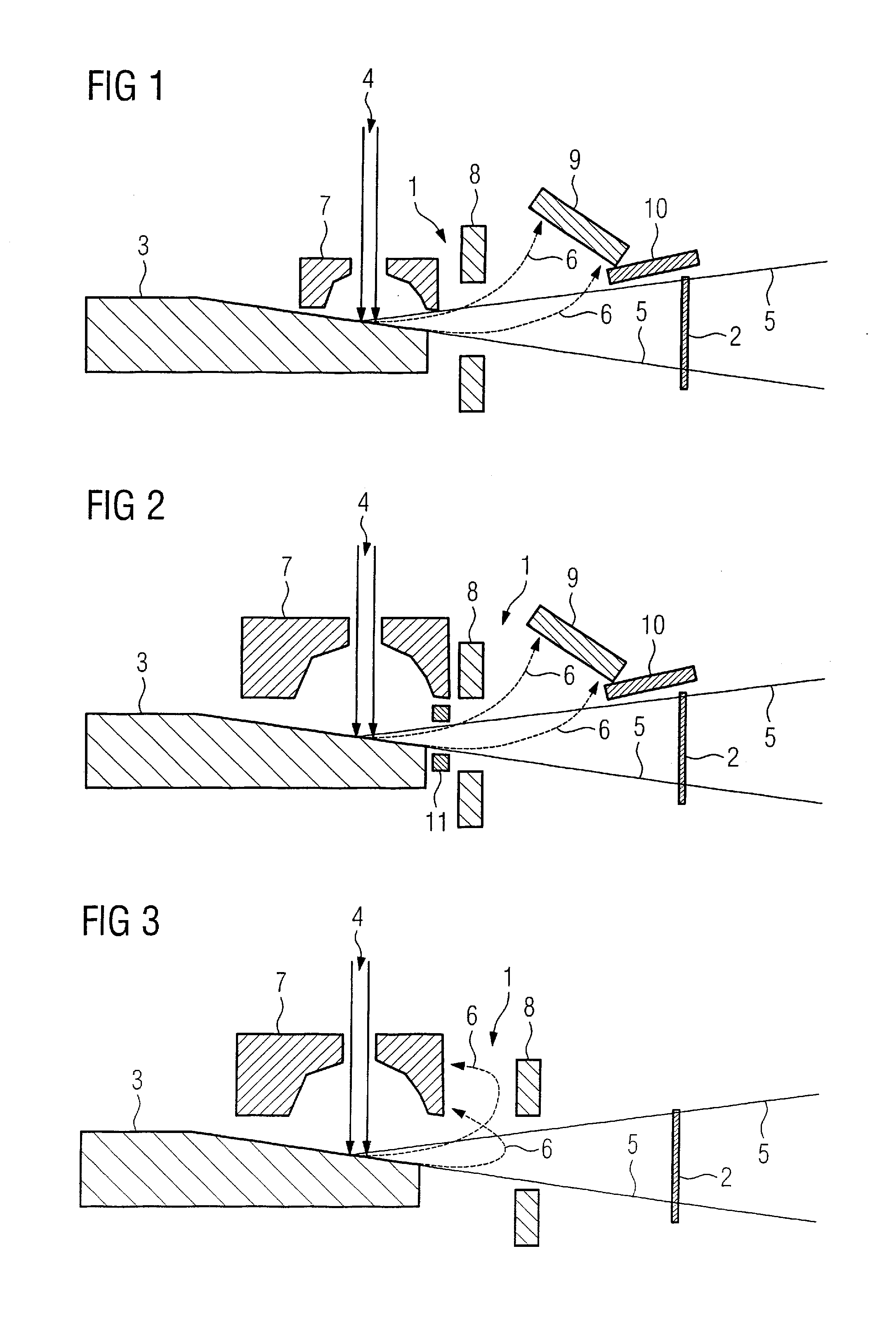

X-ray tube with backscatter protection

InactiveUS20100046716A1Constant intensityImprove reliabilityX-ray tube vessels/containerX-ray tube shielding arrangementsSoft x rayElectron source

An x-ray tube has a vacuum housing containing an anode that generates usable x-ray radiation upon being struck by electrons generated by an electron source. The usable x-ray radiation escapes from the vacuum housing through an x-ray exit window. A backscatter electron barrier device arranged in the vacuum housing affects the backscatter electrons in the region of the usable x-ray radiation such that no backscatter electrons reach the x-ray exit window. Such an x-ray tube exhibits an invariably constant x-ray intensity and a high reliability.

Owner:SIEMENS AG

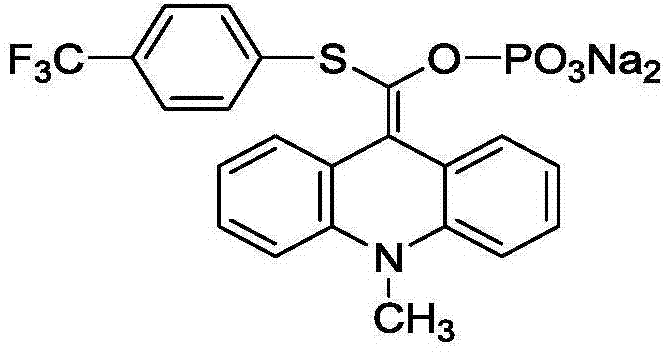

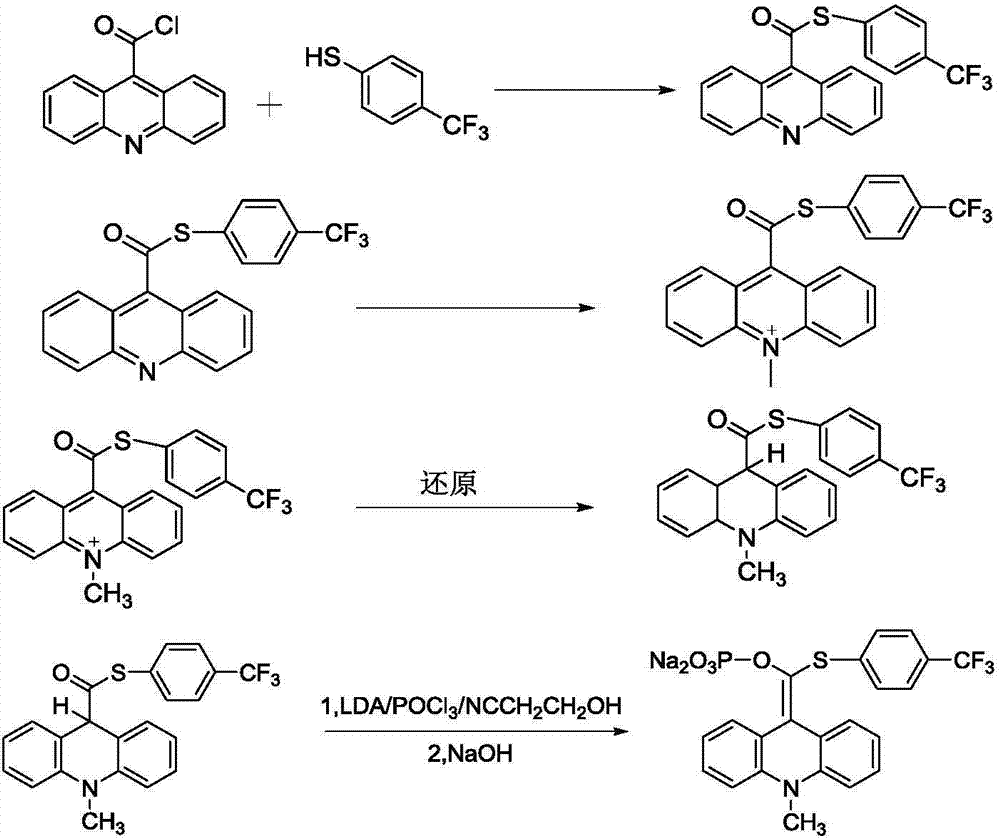

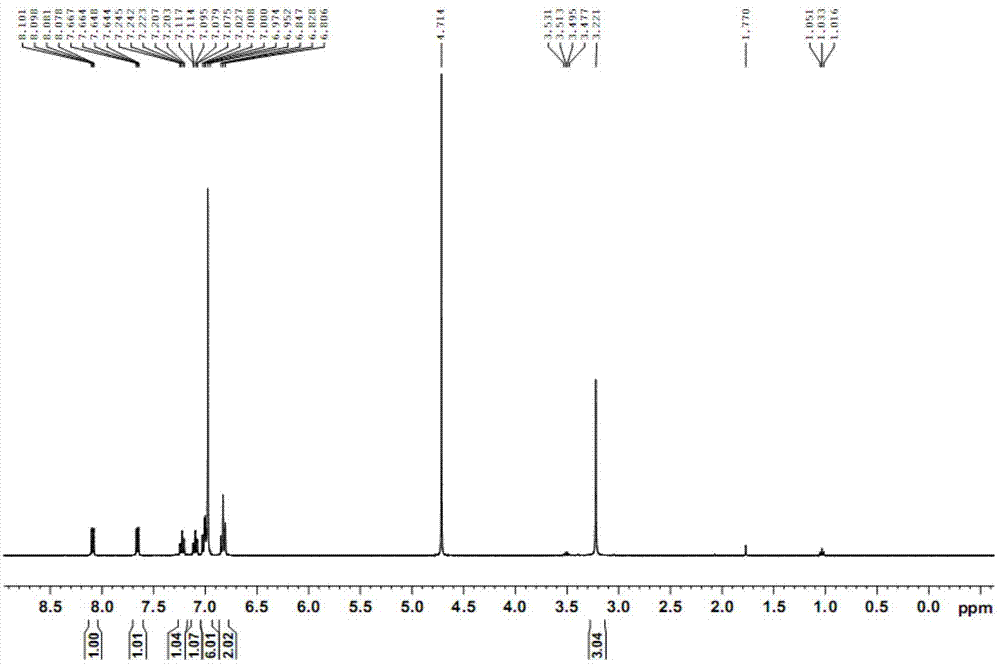

Acridinium ester derivative, synthesis method and application thereof

InactiveCN104761584AEasy to useHigh sensitivityPhosphorus organic compoundsLuminescent compositionsThiocarboxylic acidSynthesis methods

The invention discloses an acridinium ester derivative, a synthesis method and application thereof. The chemiluminescent acridinium ester derivative provided by the invention has a structural formula shown as formula I. The invention further discloses a synthesis method for the compound shown as formula I, and the method includes: (1) synthesizing acridine-9-thiocarboxylic acid p-trifluoromethylbenzene ester; (2) synthesizing 10-methyl-acridine-9-thiocarboxylic acid p-trifluoromethylbenzene ester; (3) synthesizing 10-methyl-9, 10-dihydroacridine-9-thiocarboxylic acid p-trifluoromethylbenzene ester; and (4) synthesizing TfS-APS. The acridinium ester derivative provided by the invention can be used as an immunoassay tracer to a chemiluminescence immunoassay reagent system with alkaline phosphatase (ALP) as the marker enzyme. The application effect in a kit proves that the acridinium ester derivative involved in the invention can detect 1*10<-19>mol ALP molecules, and has the advantages of high sensitivity, long luminescence duration, simple use, constant intensity under room temperature condition, and no need for precise temperature control, etc.

Owner:BEIJING LEADMAN BIOCHEM

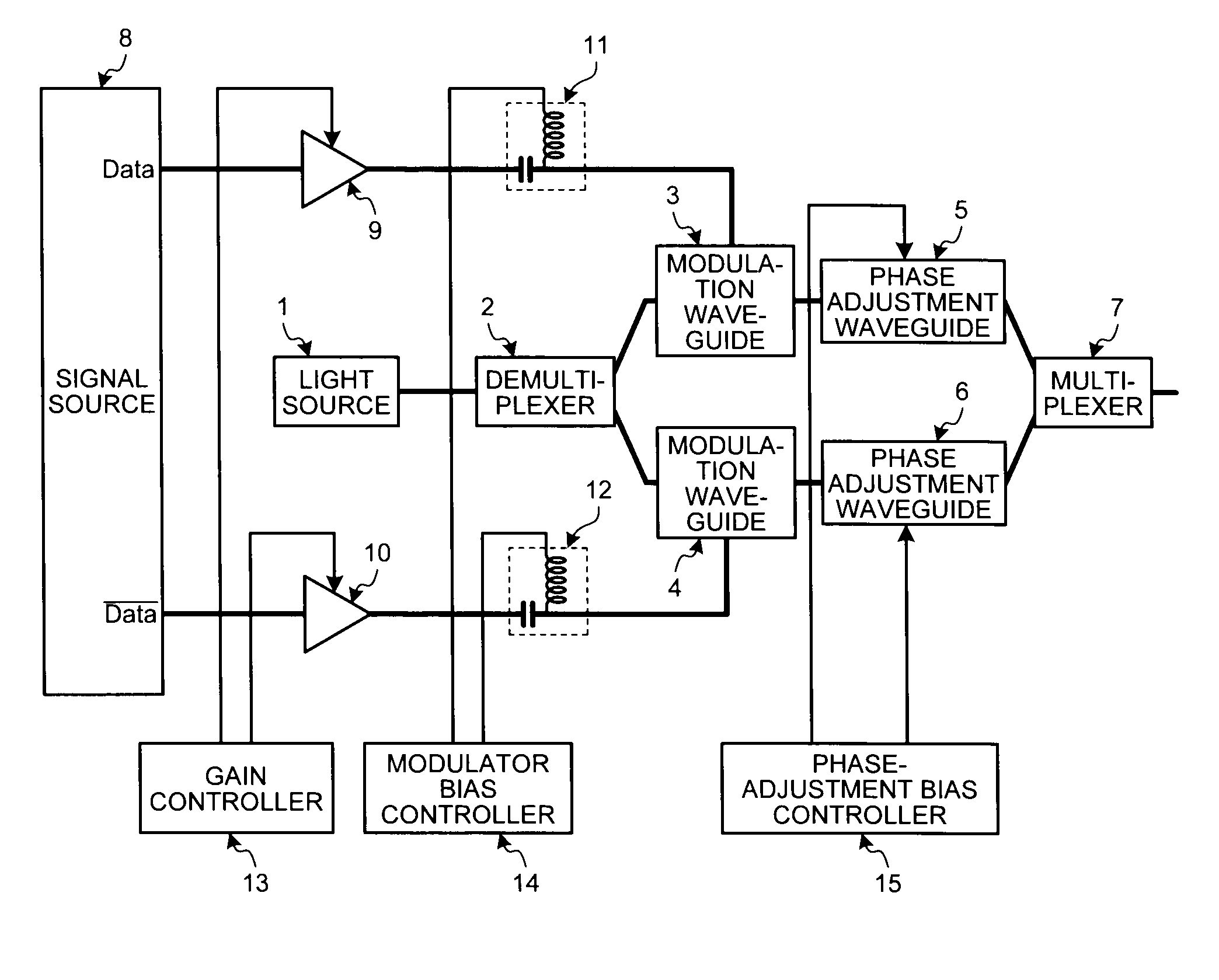

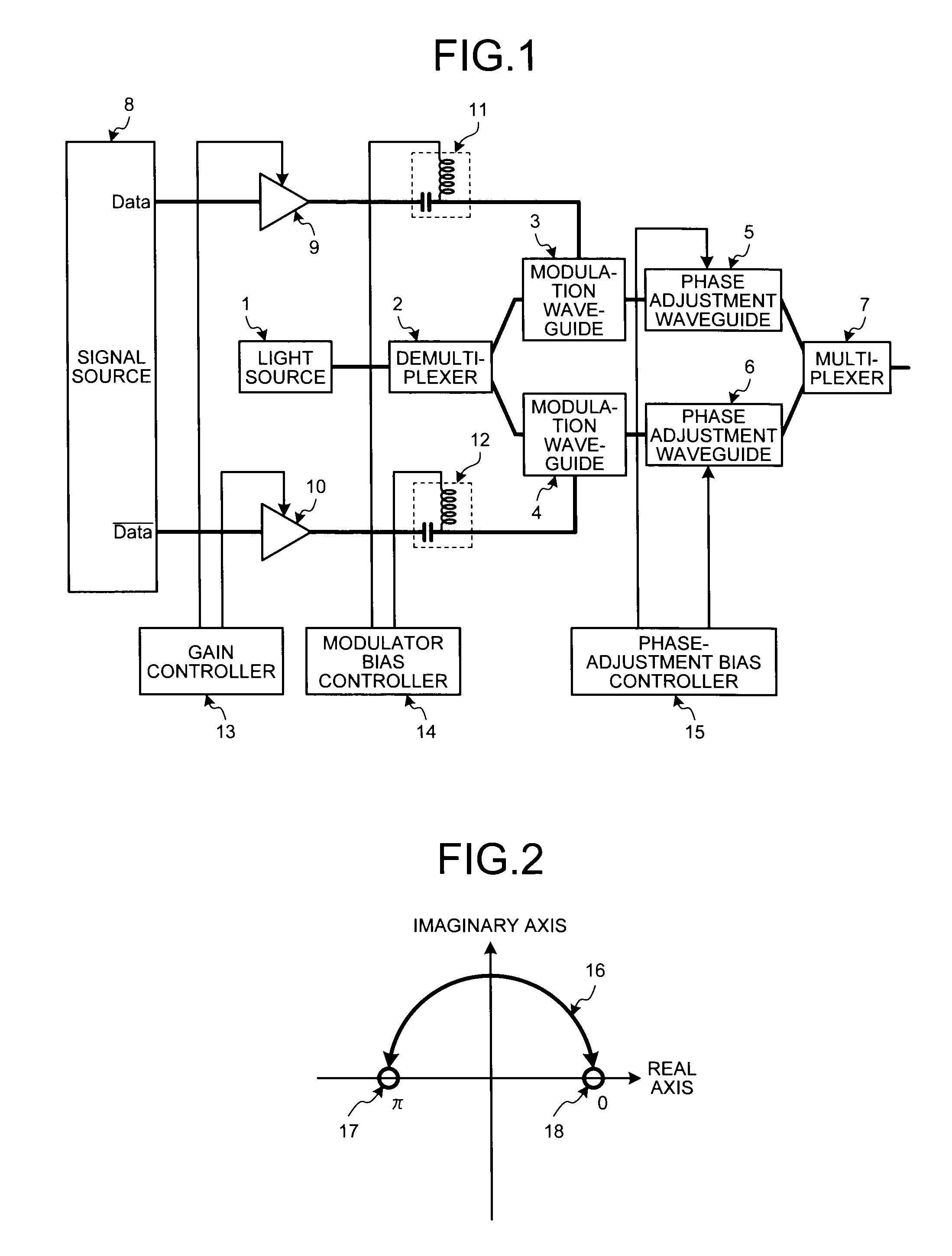

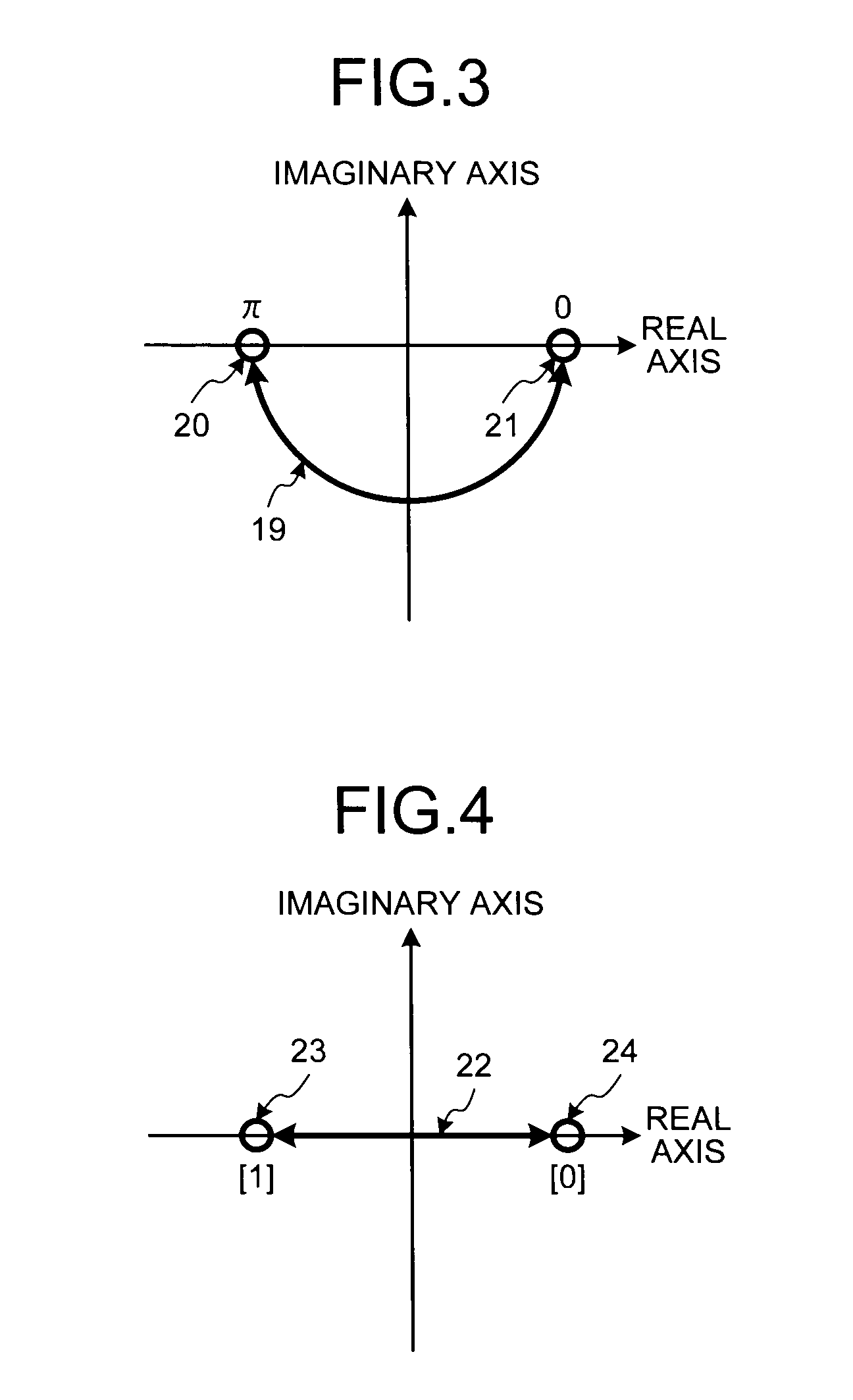

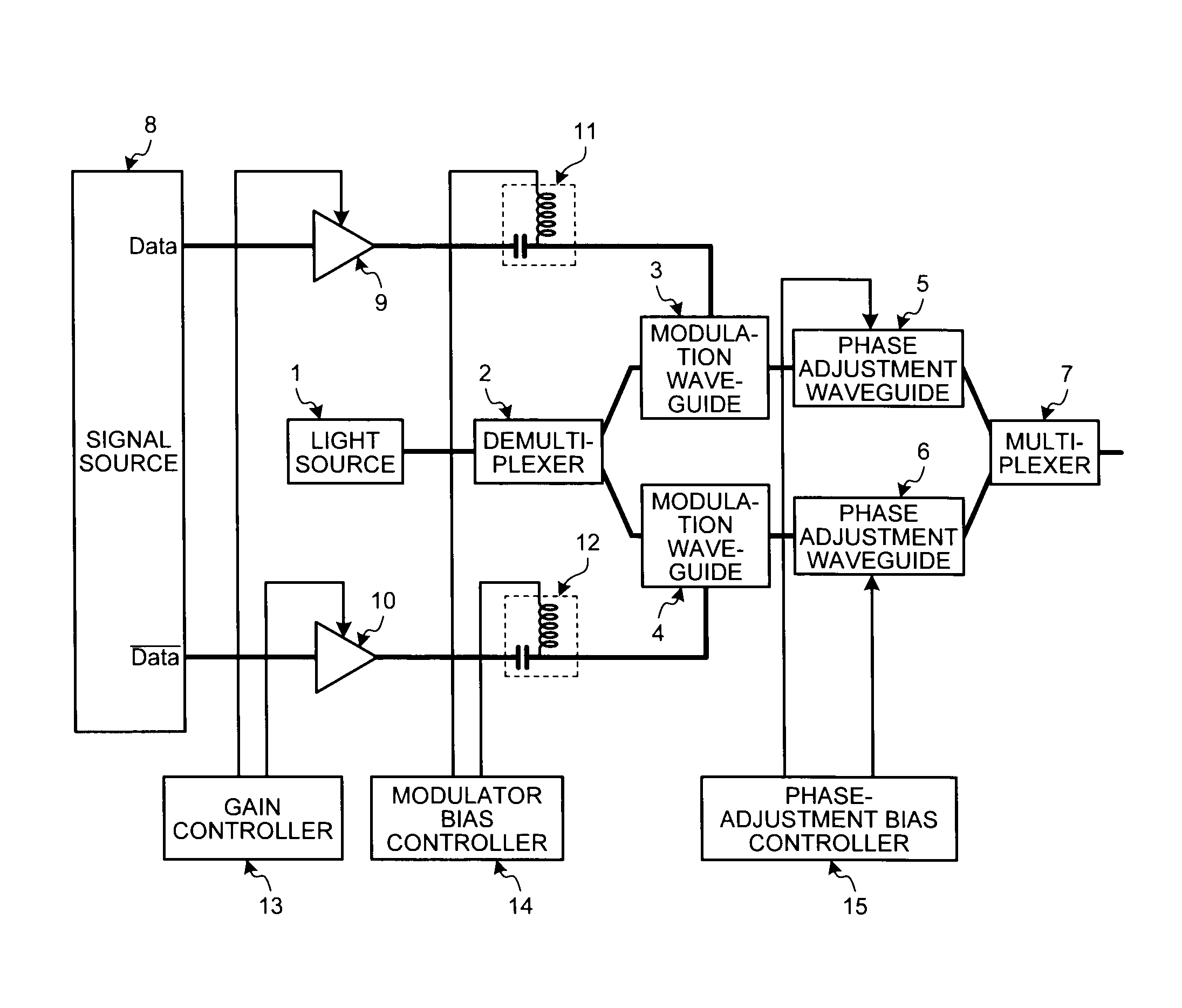

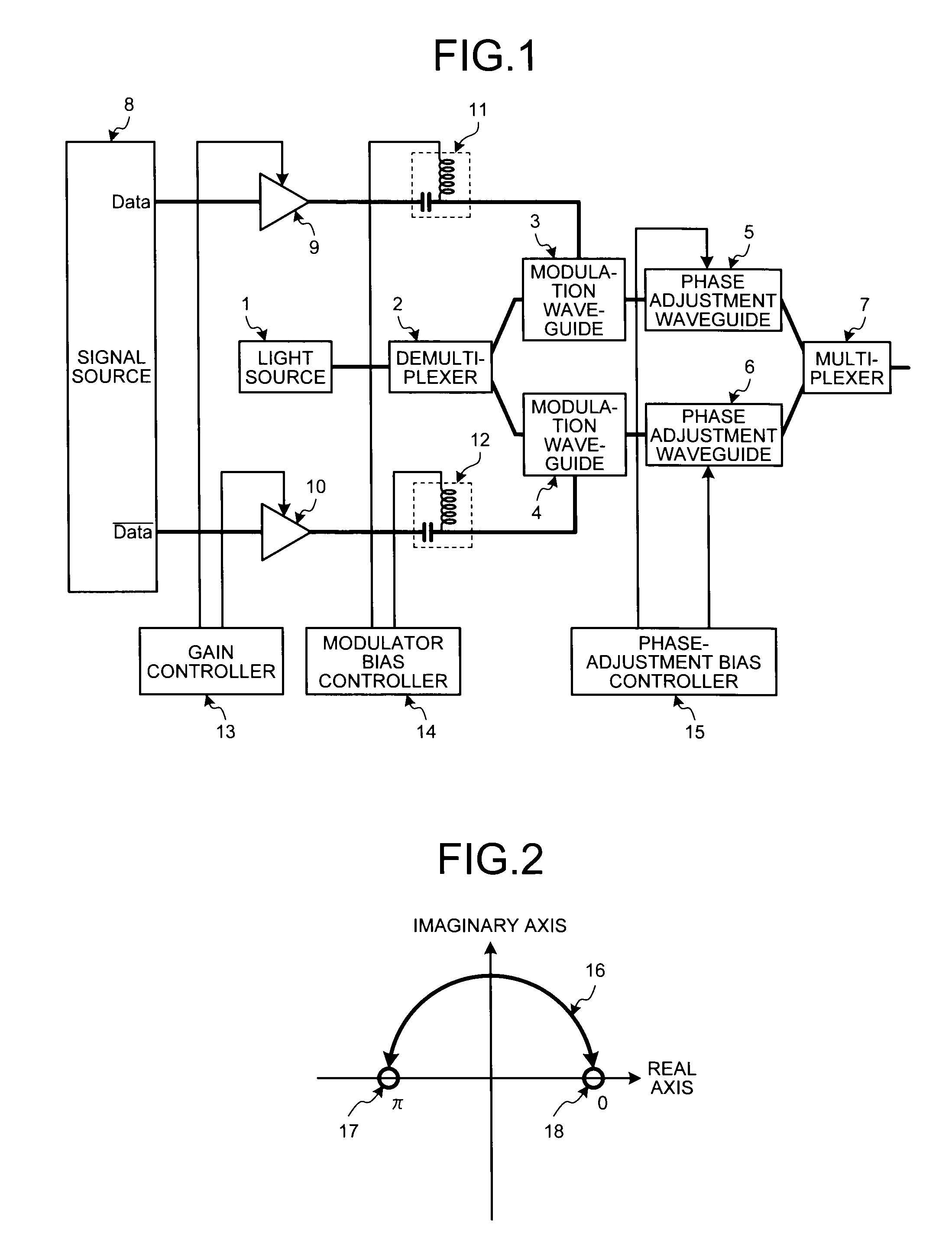

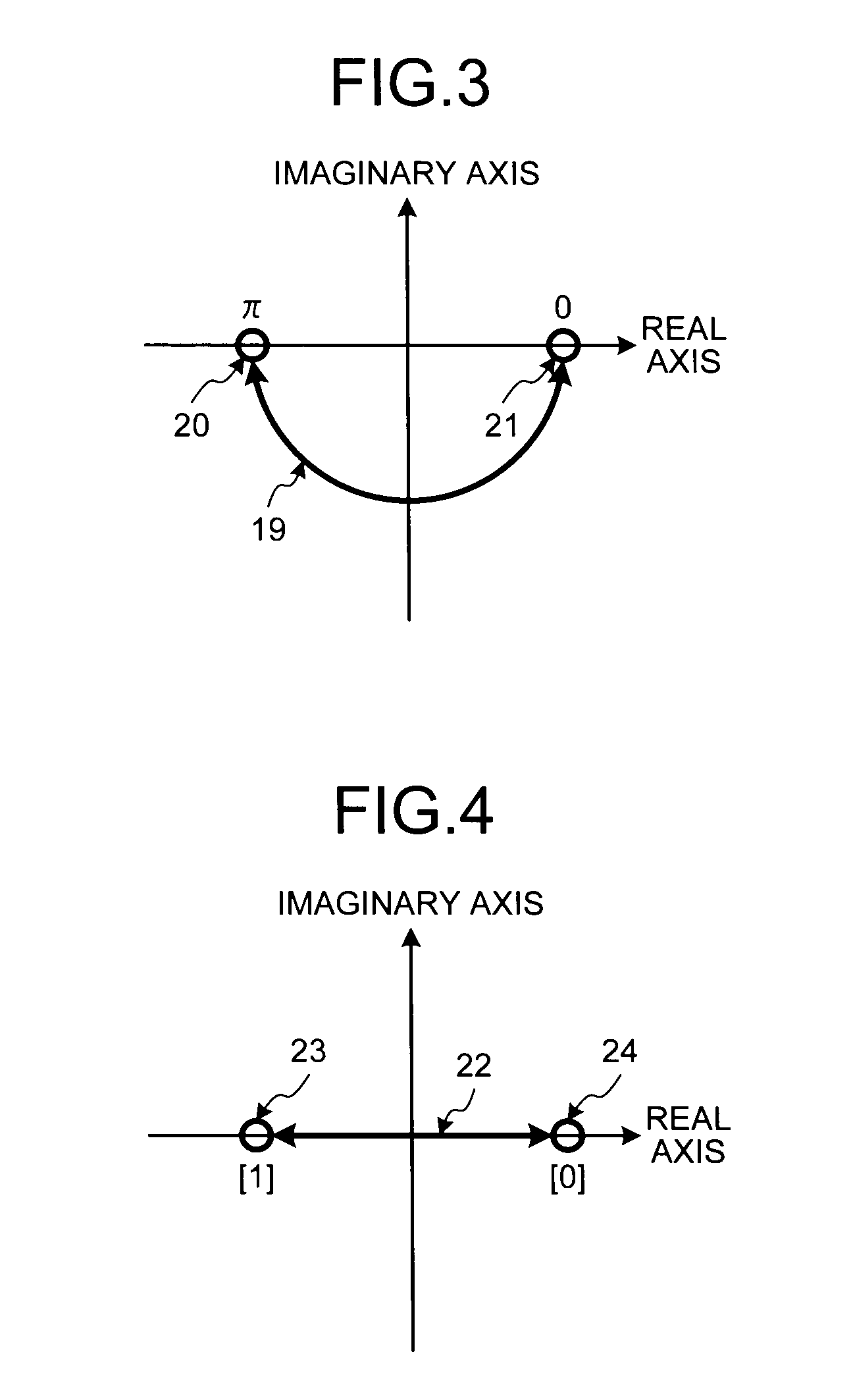

Optical modulator and optical modulation method

ActiveUS20120314277A1Solve problemsConstant intensityLaser detailsFibre transmissionMultiplexerWaveguide

An optical modulator includes first and second modulation waveguides, a demultiplexer, first and second phase adjustment waveguides that changes phases of a light of the first and second modulation waveguides, a multiplexer that combines light outputs from the first and second phase adjustment waveguides, a gain controller and a modulator bias controller in which voltages of the first and second modulation signals are controlled so that a result of adding light from the first modulation waveguide to light from the second modulation waveguide where light from the first modulation waveguide has a predetermined phase is equal to a result of adding light from the first modulation waveguide to light from the second modulation waveguide where light from the second modulation waveguide has a predetermined phase. A phase-adjustment bias controller that controls phase amounts changed by the first and second phase adjustment waveguides so as to cancel phase errors.

Owner:MITSUBISHI ELECTRIC CORP

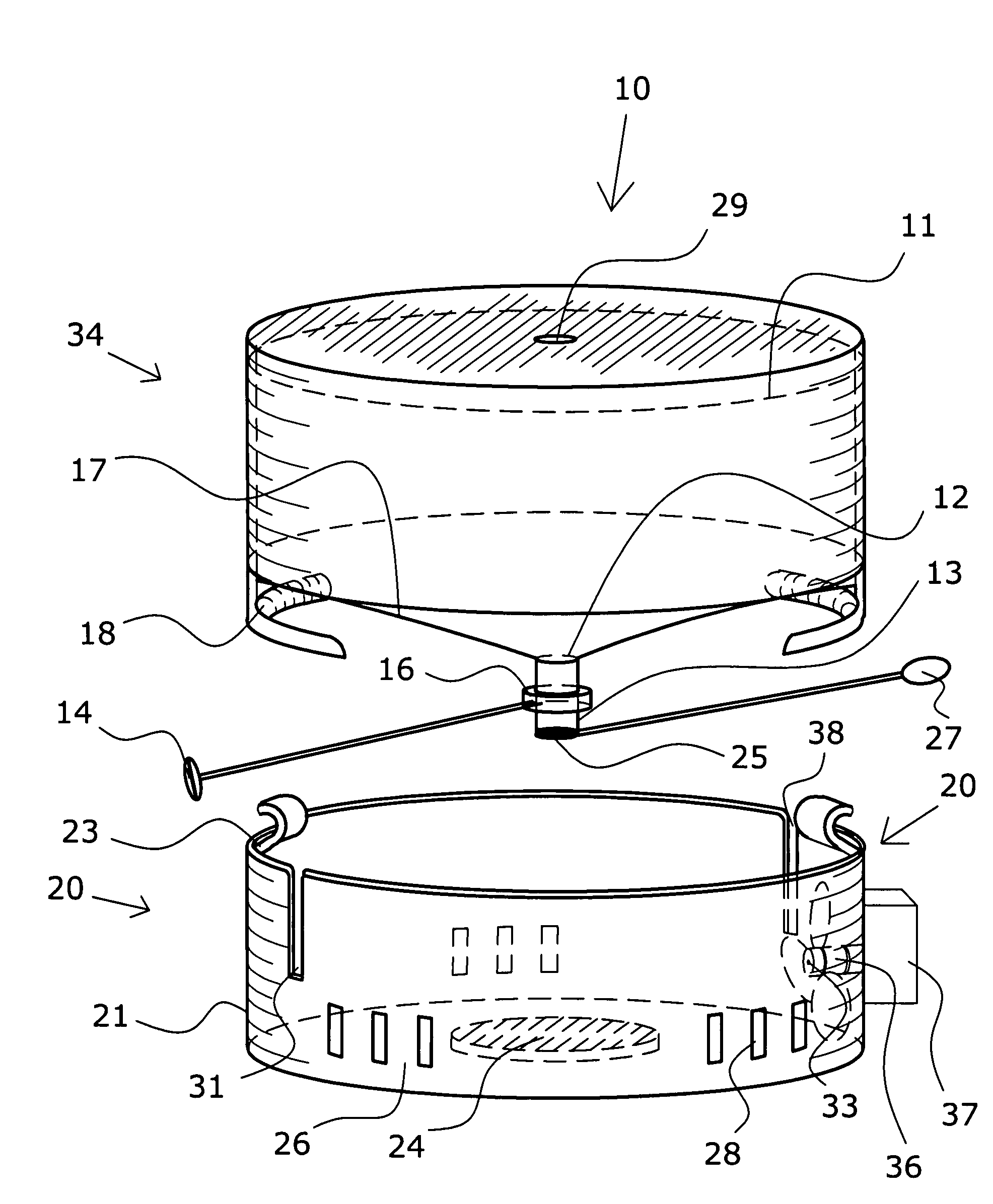

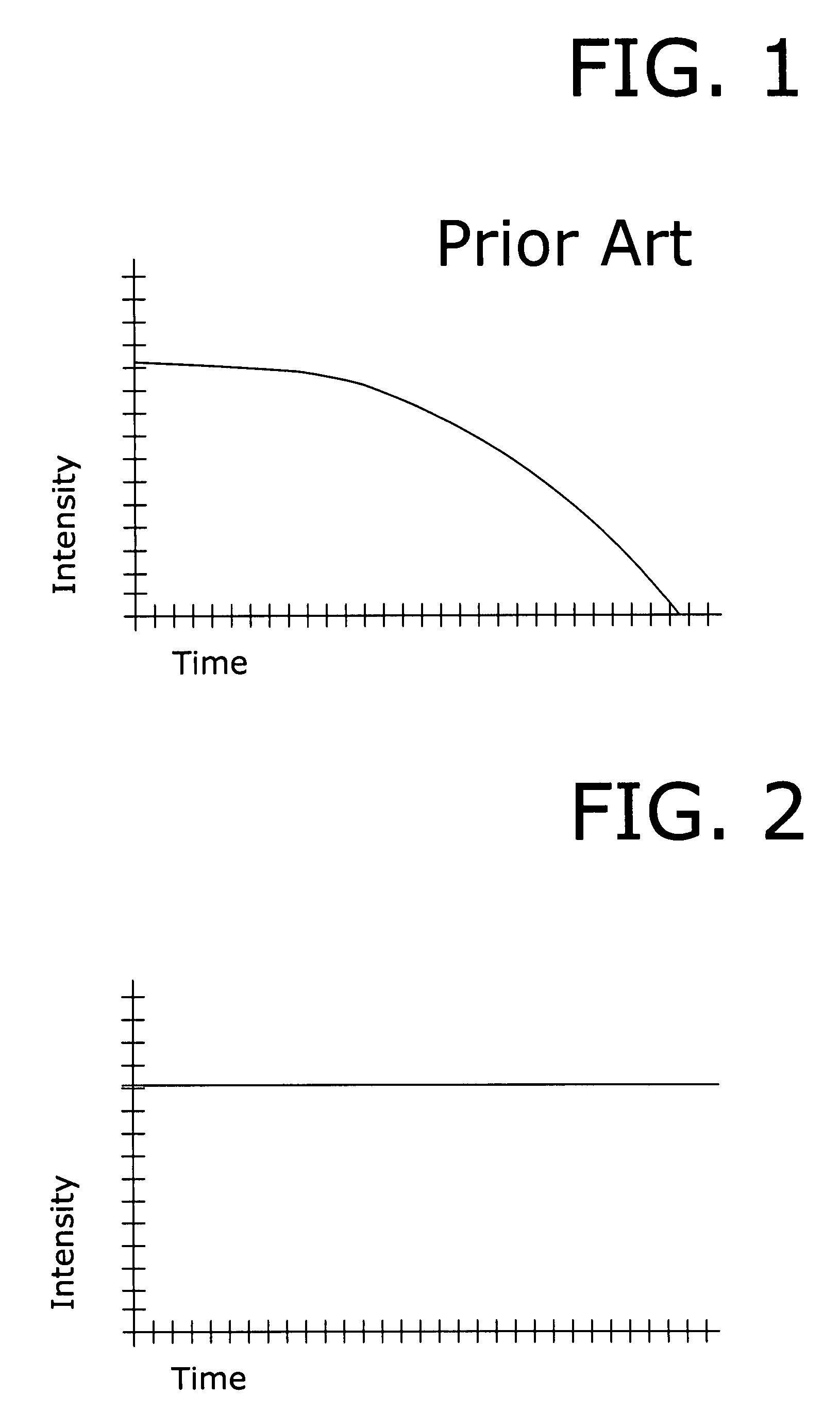

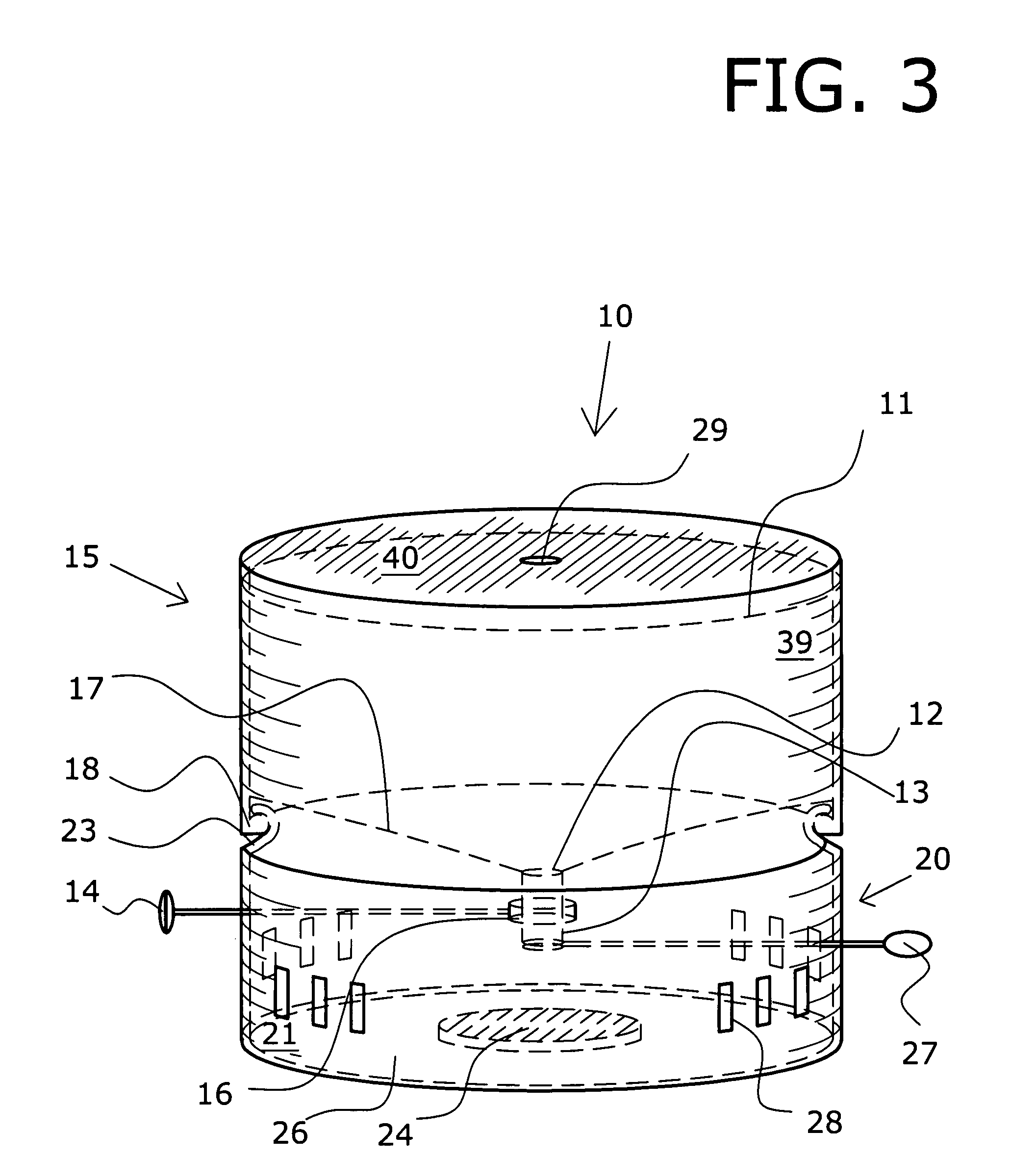

Constant-rate volatile material dispensing device

InactiveUS7597308B1Widely usedEasy to useLighting and heating apparatusMixing methodsTraffic volumeAmount of substance

A volatile material dispensing device is provided, including a reservoir containing a supply of any one of numerous volatile materials having an outlet port with attached tube through which the volatile material flows, a valve and valve adjustment mechanism to control the flow rate through the tube, a lower housing incorporating a pad to receive the volatile material, and a tear-off tab that initially seals the tube and prevents flow until removed by the consumer. Optionally, the device may include an active mechanism, such as a fan, to aid dispersal of the volatile material. The device gives the user control of the intensity of the vapor by providing the ability to adjust the flow through the valve with the valve adjustment mechanism. The device also provides constant vapor intensity over time with a time-release dispersing mechanism delivering a controlled, consistent flow, with an appropriate drip rate.

Owner:STUCKI ANDRE

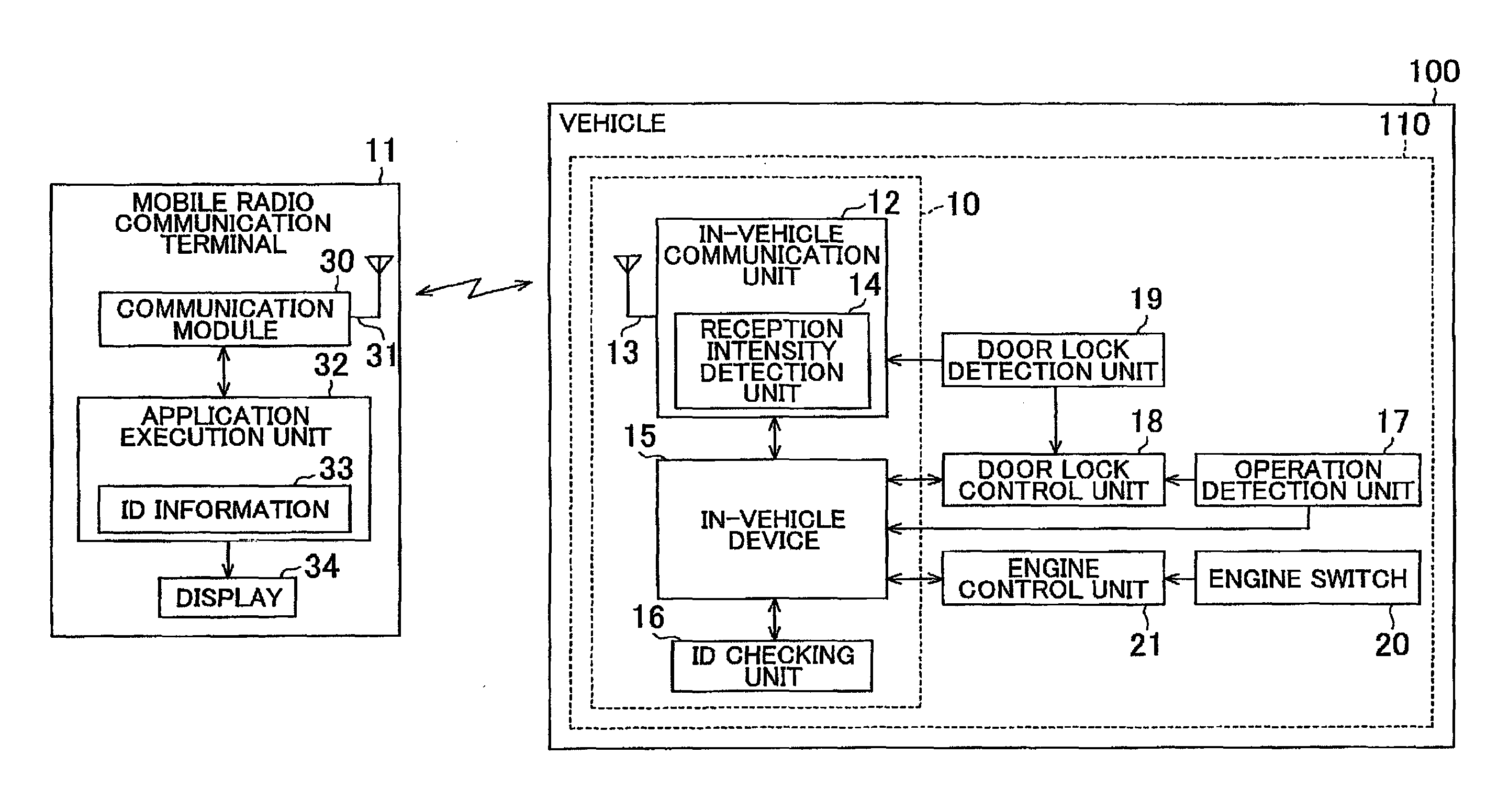

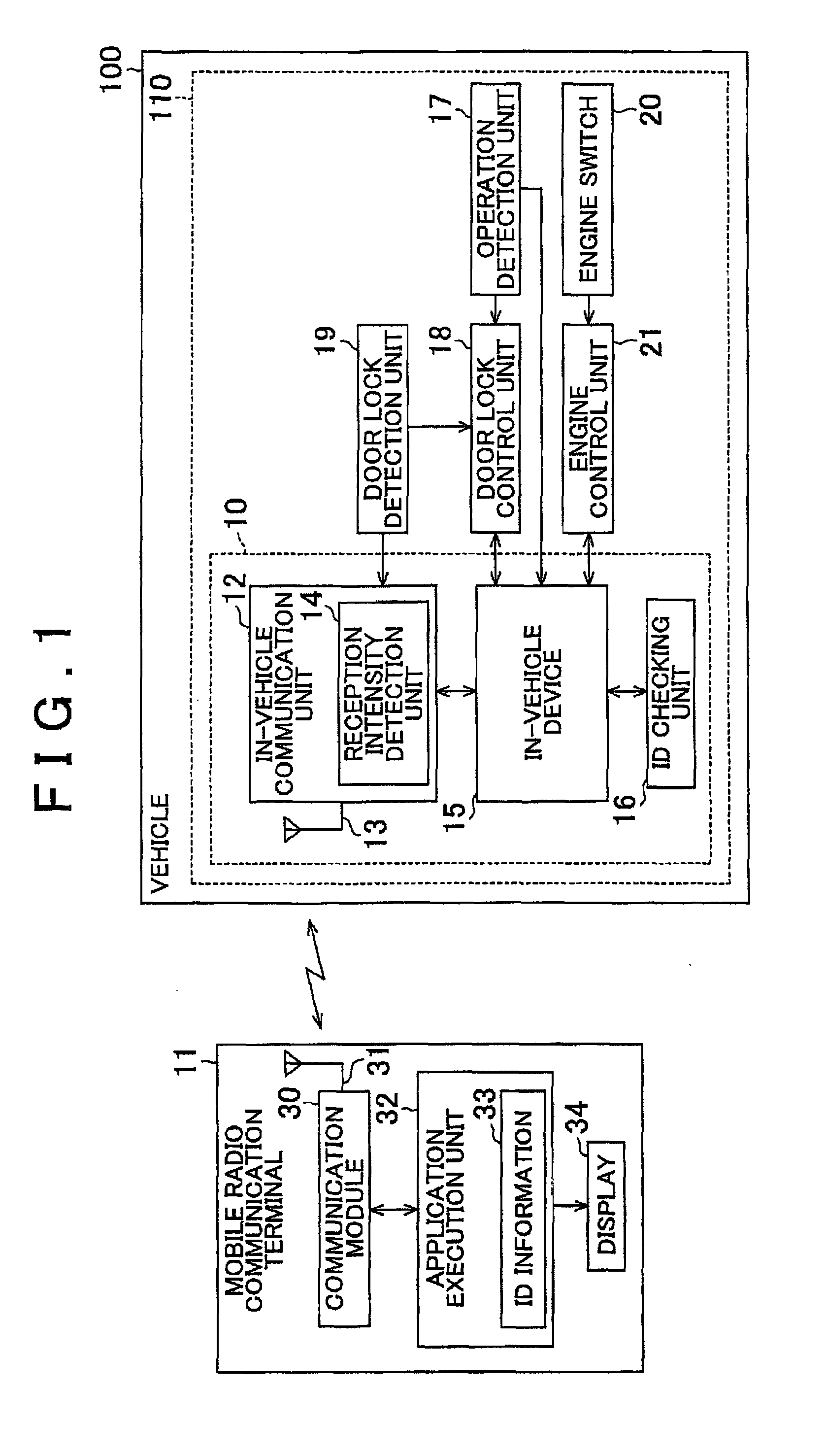

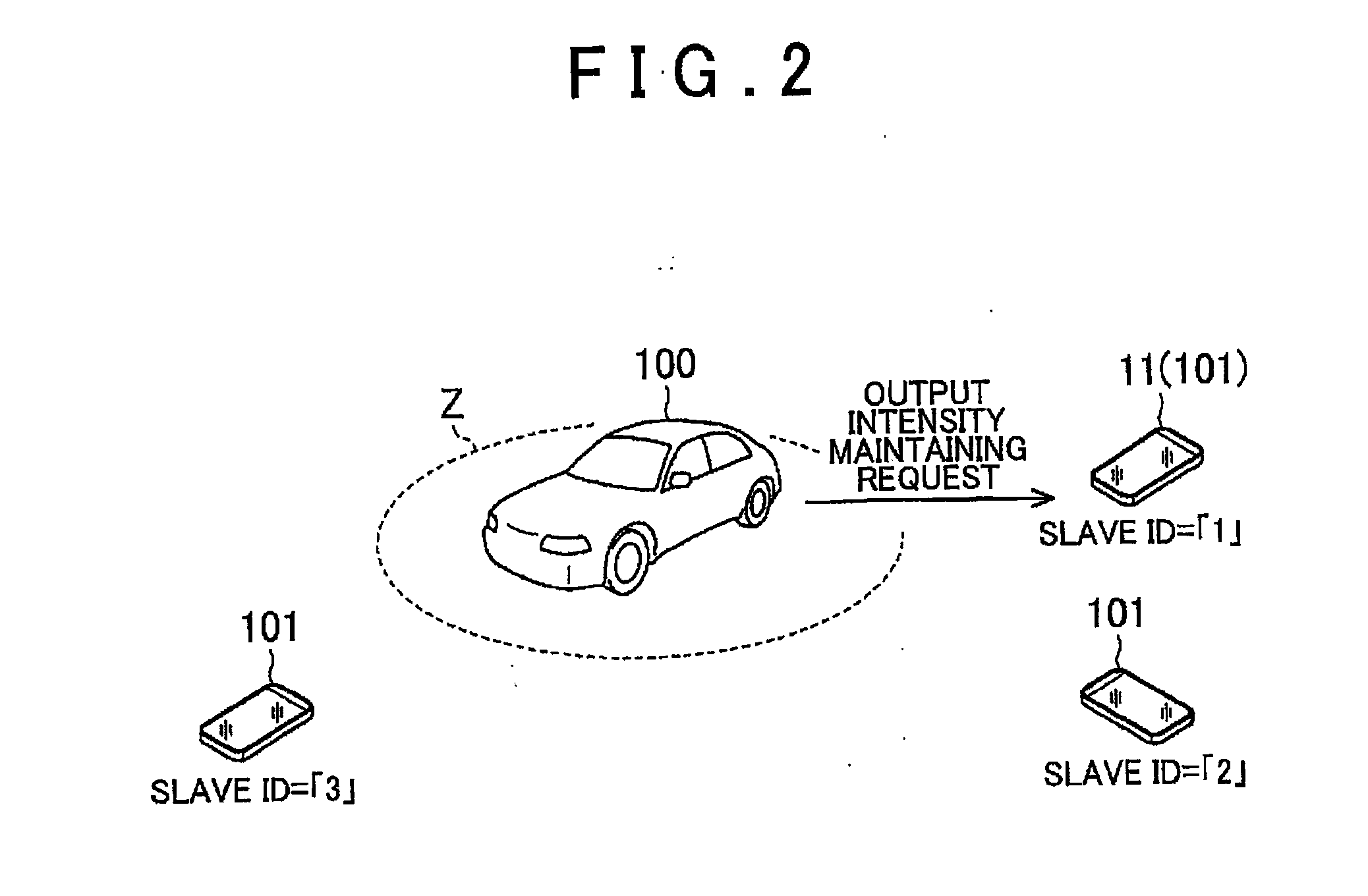

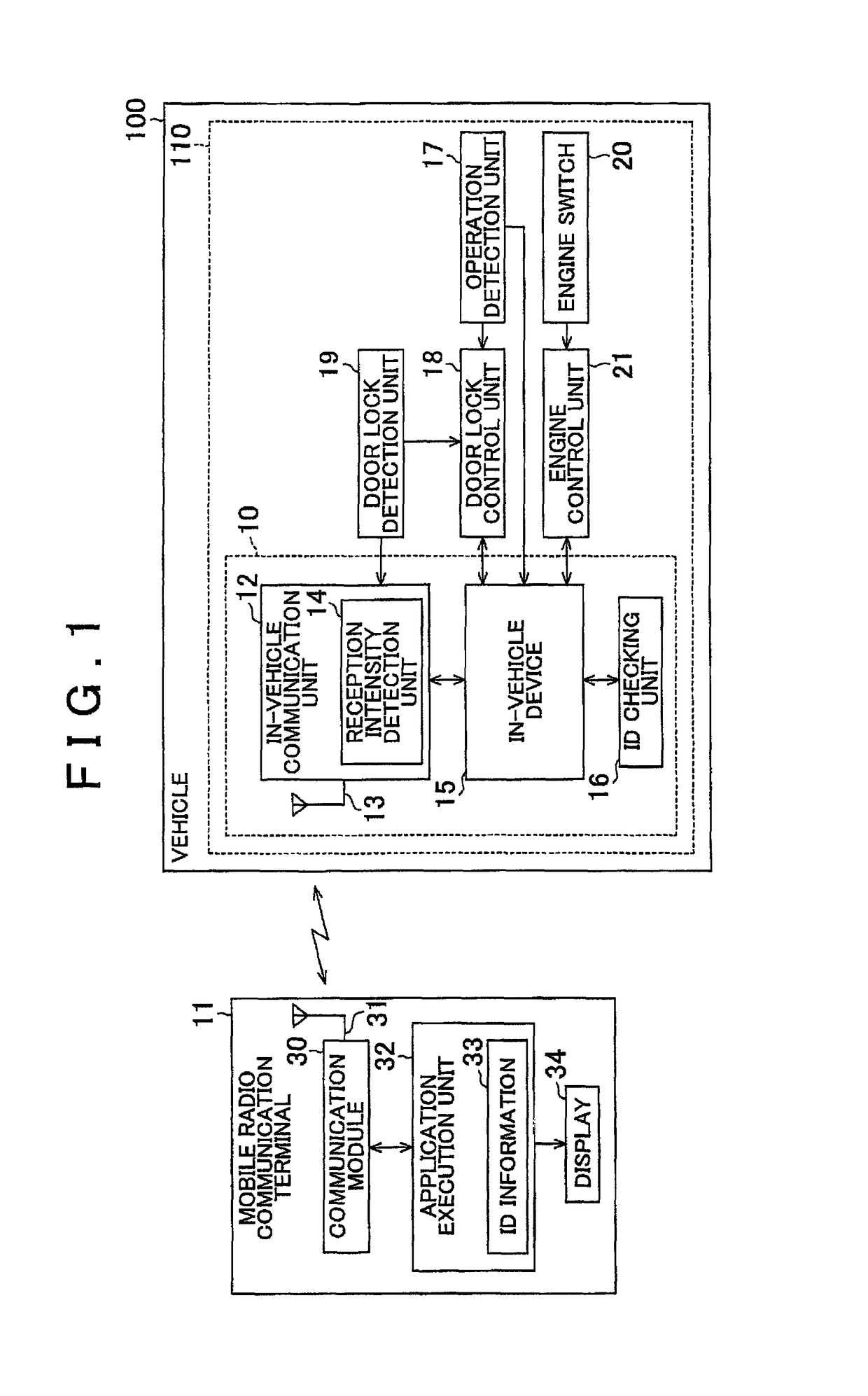

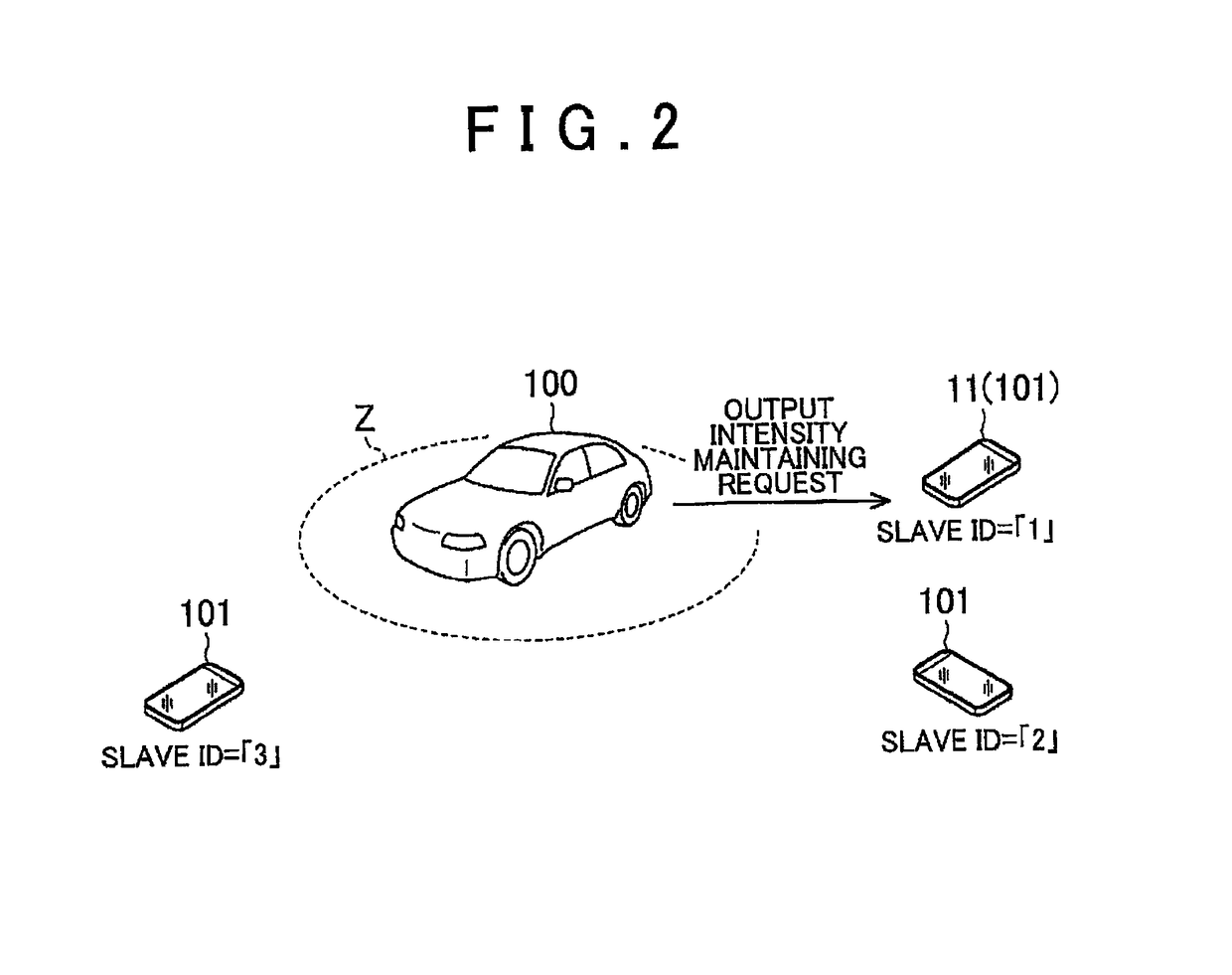

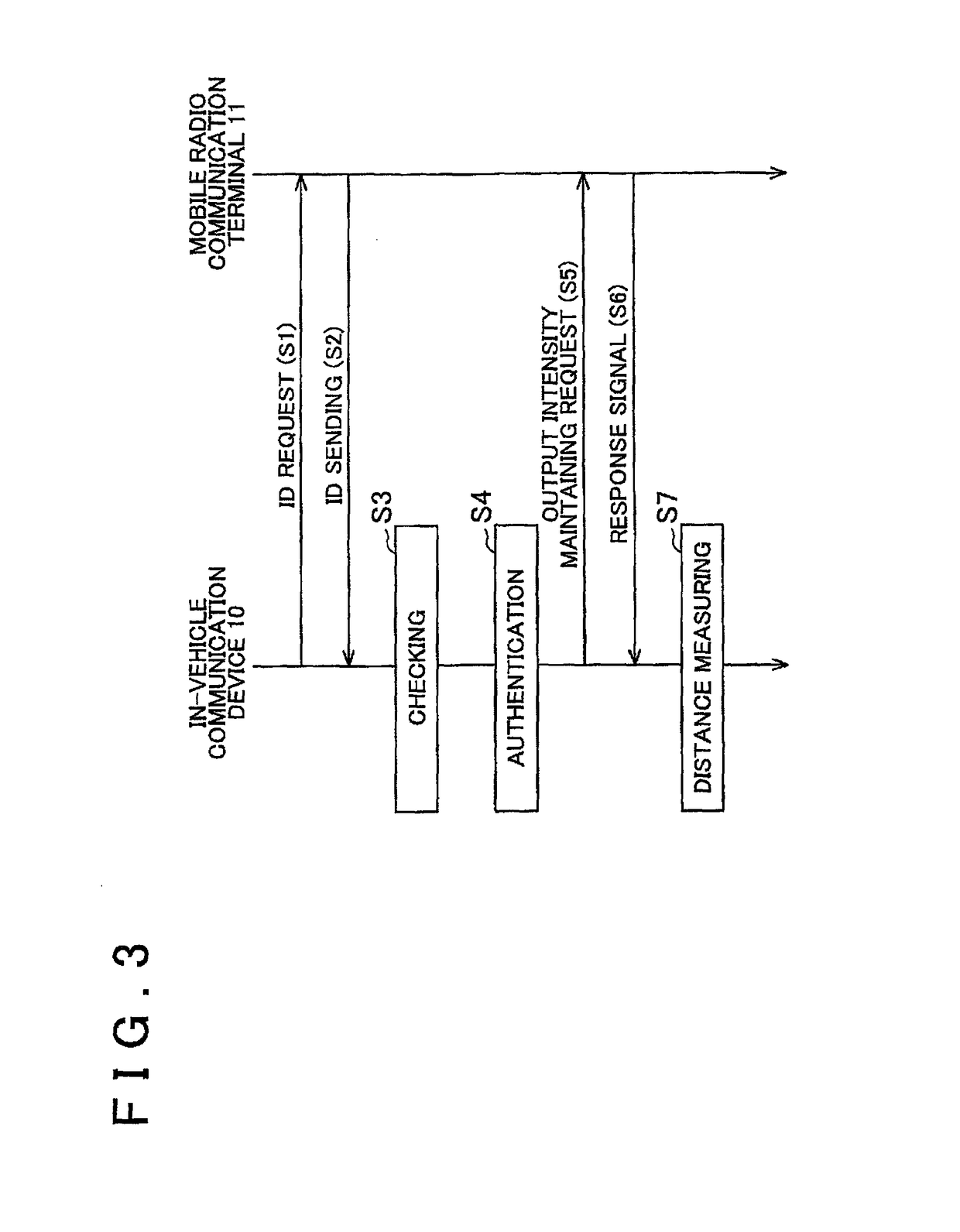

Radio communication system and distance measuring method

ActiveUS20160231421A1Constant intensityAnti-theft devicesPosition fixationCommunications systemIn vehicle

A radio communication system, in which radio communication is carried out between an in-vehicle communication device, mounted in a vehicle, and a radio communication terminal to detect a relative distance therebetween, includes an output control unit that controls a radio wave intensity of a measuring signal, which is sent from one of the in-vehicle communication device and the radio communication terminal, at a pre-set predetermined value; and a measuring unit that performs distance measuring on a vehicle side based on the radio wave intensity of the measuring signal controlled at the predetermined value or on a signal to which a value of the radio wave intensity of the measuring signal is added as information.

Owner:TOYOTA JIDOSHA KK

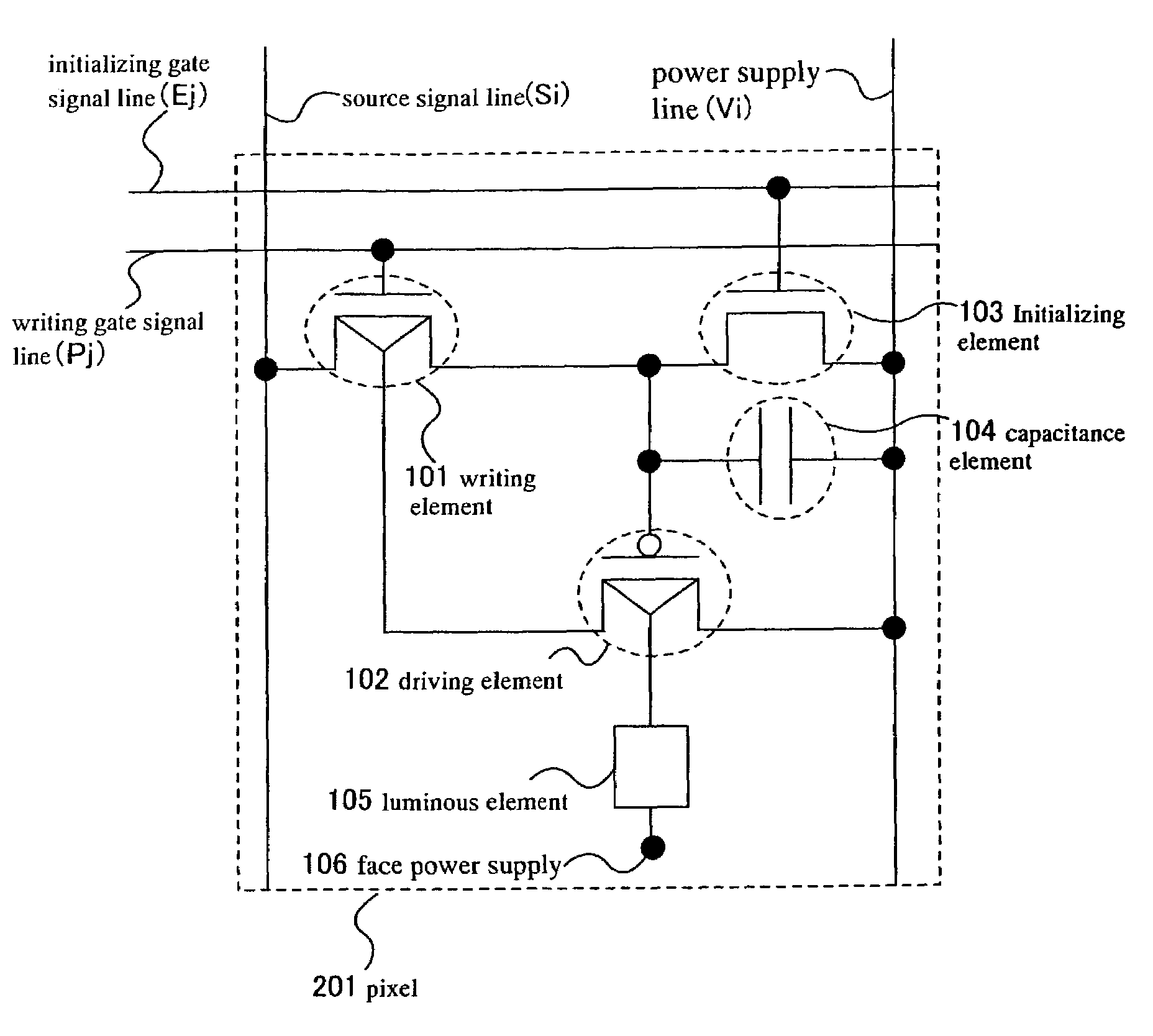

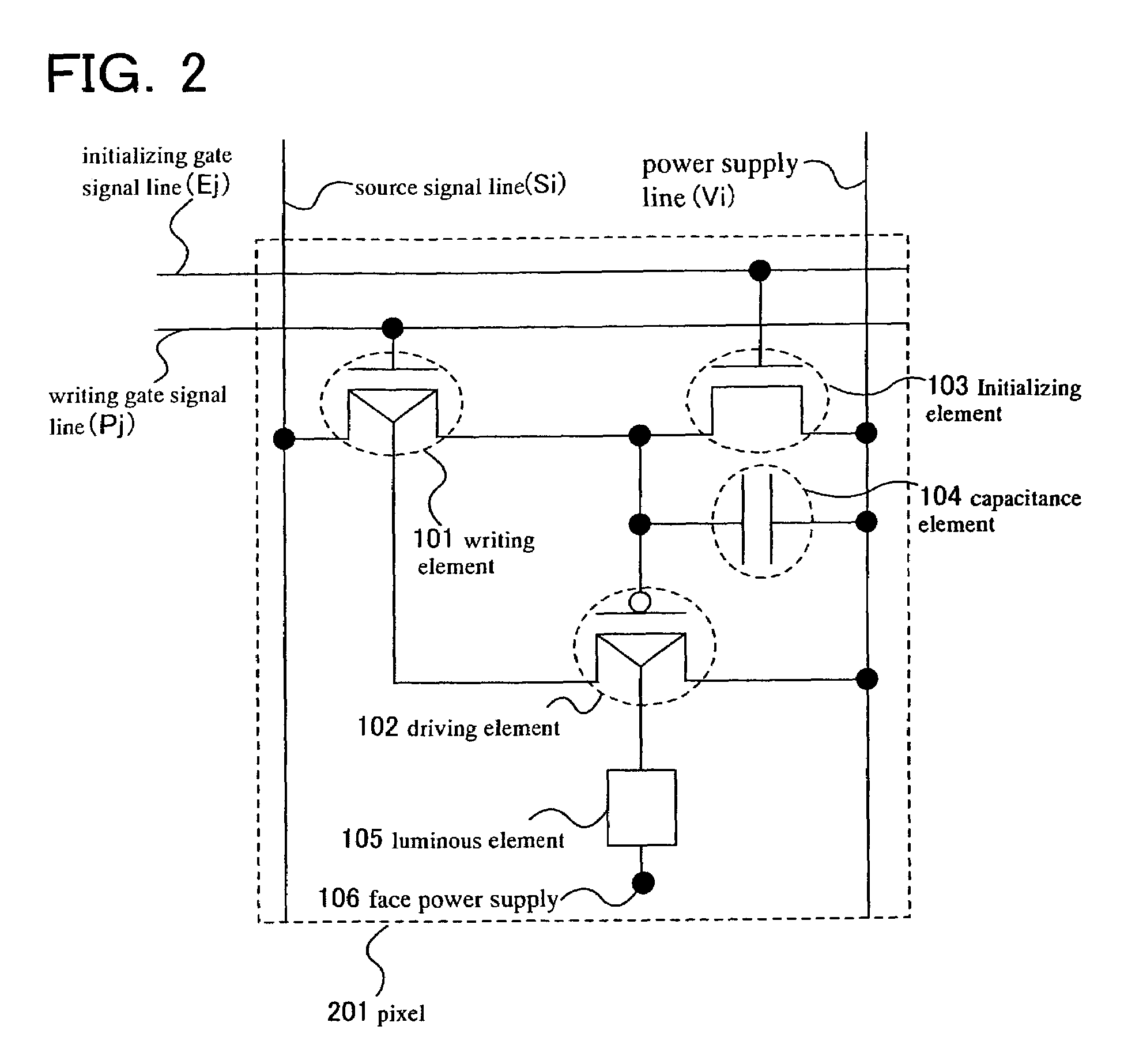

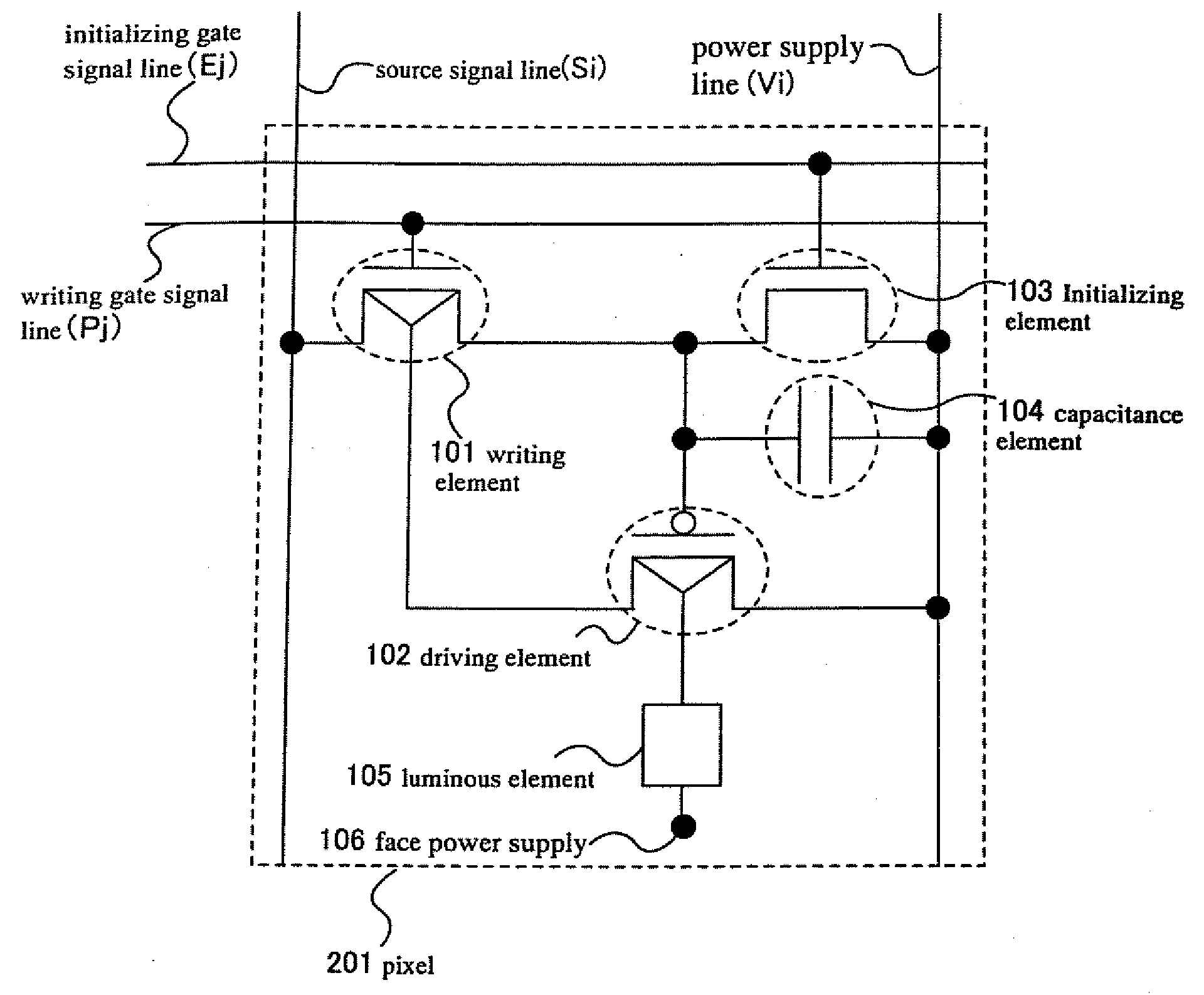

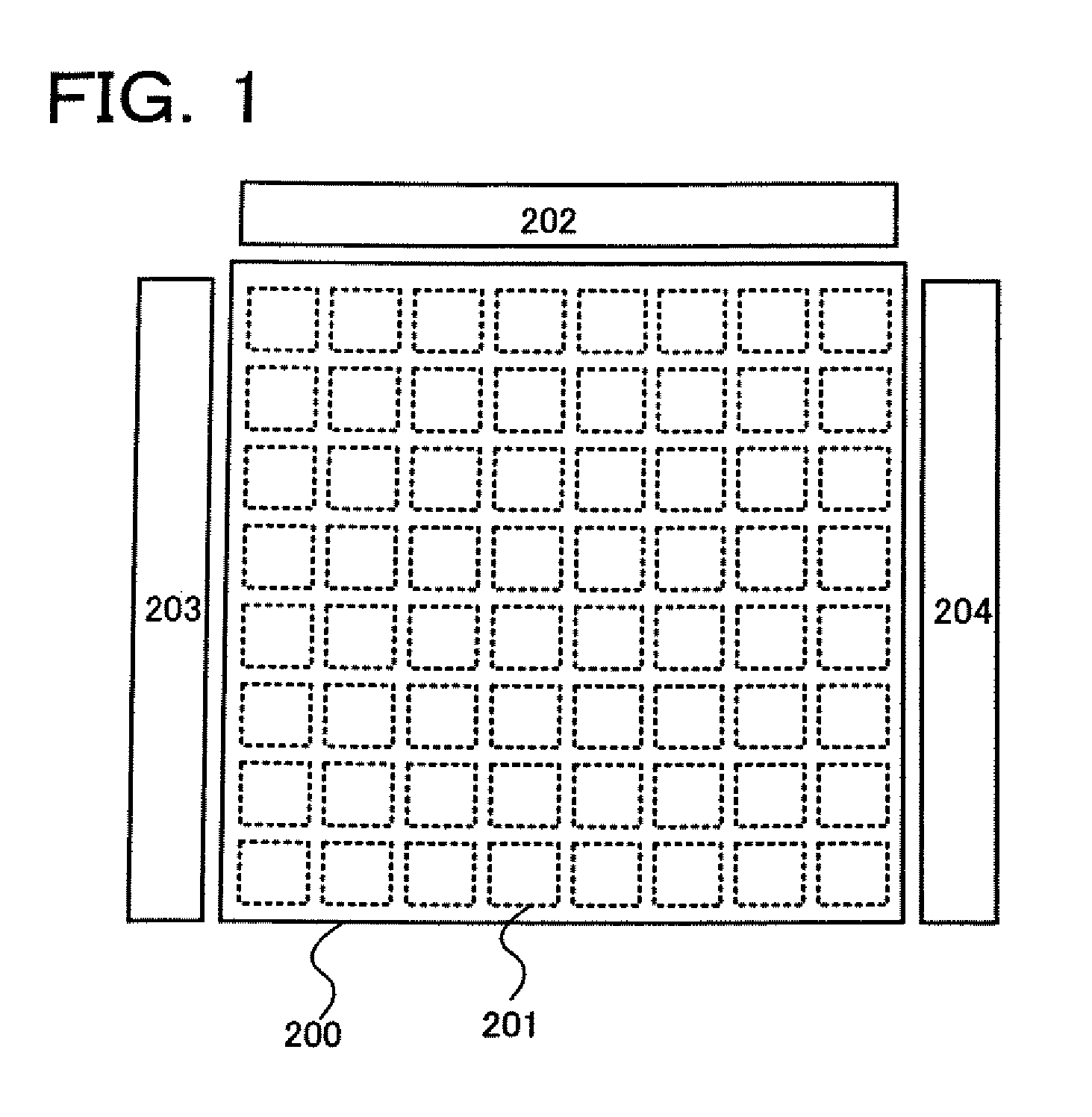

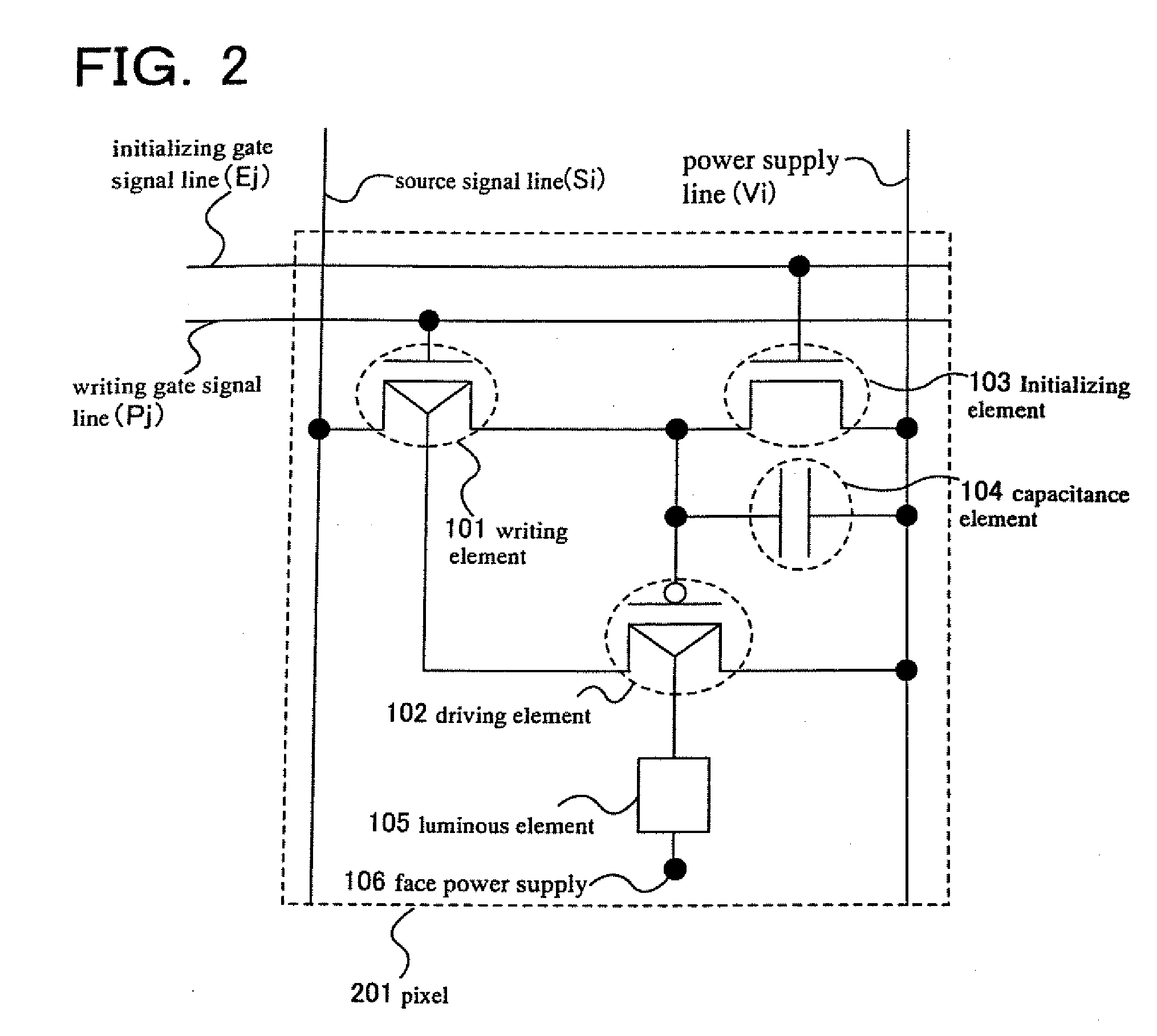

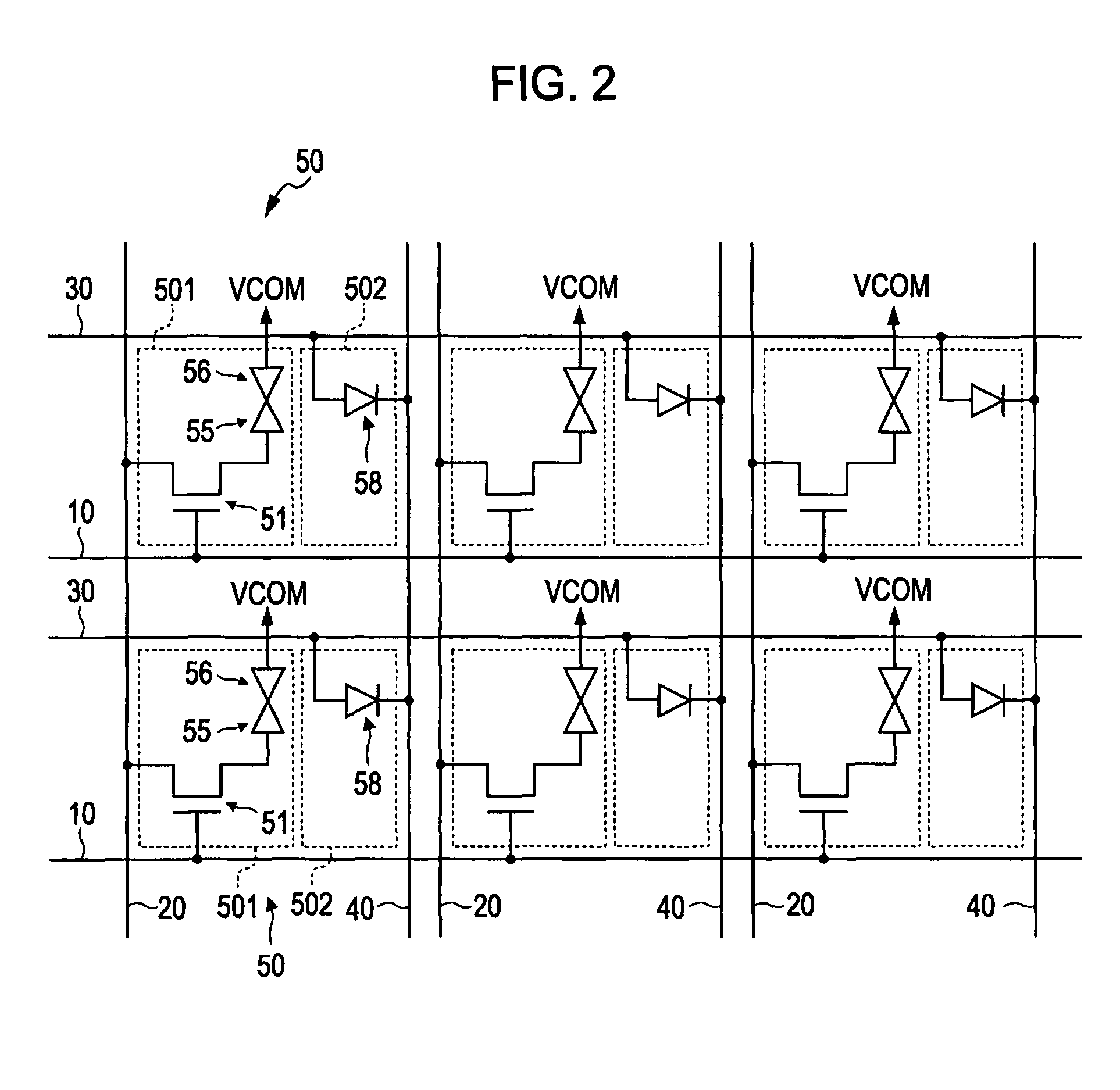

Semiconductor element, electronic device

InactiveUS7629611B2Simple structureConstant intensityTransistorTelevision system detailsDisplay deviceEngineering

A current storing circuit capable of having a small area, a simple structure with the small number of devices, a low consumption current operation and high yield in manufacturing is provided. Applying the current storing circuit to the current-driving type of display device such as an OLED display device can improve the aperture rate of pixels and reliability of the display device as well as highly functionalize the display device. The invention is characterized by using a new semiconductor element in a shape of a transistor having plural drains or sources. When the semiconductor elements is used for both of a writing element and a driving element, reading in and storing a current value and outputting the current can be performed by only the two semiconductor elements, so that the area occupied by the devices would be easily reduced significantly.

Owner:SEMICON ENERGY LAB CO LTD

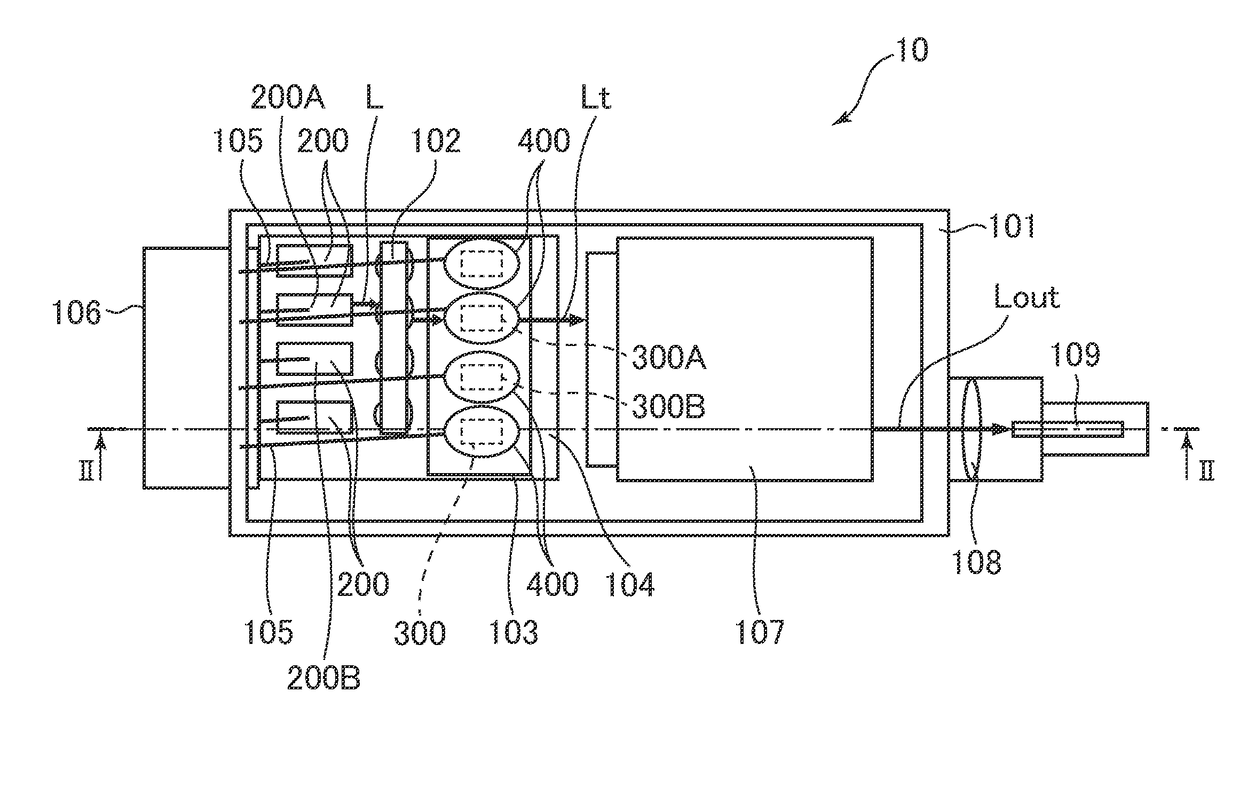

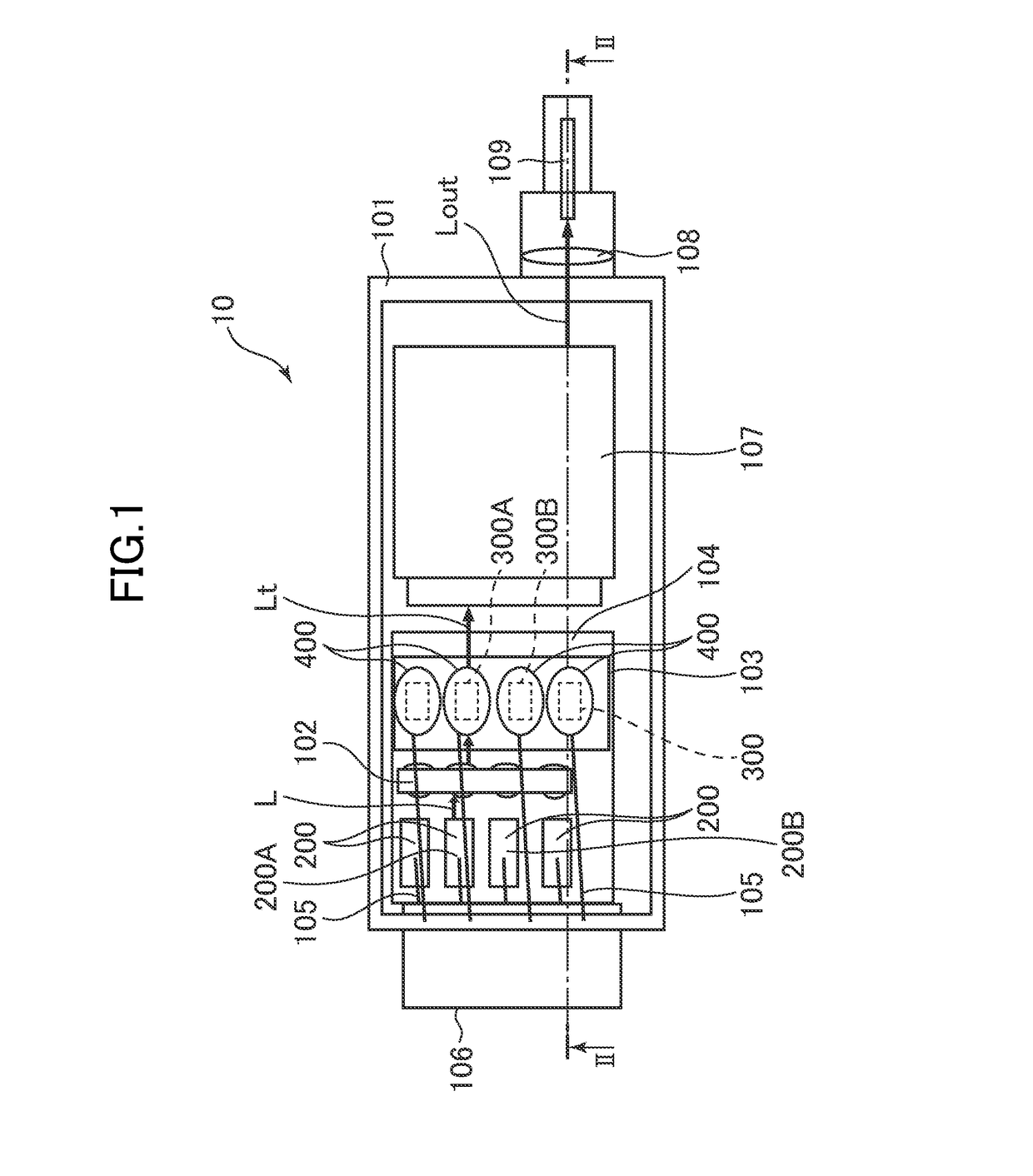

Optical transmission module

ActiveUS20160282174A1More constantAccurate monitoringPhotometryCoupling light guidesBeam splitterLight beam

An optical transmission module includes: a package; a plurality of light-emitting elements each emitting light in the interior of the package; a beam splitter splitting the light into transmitted light and split light; a plurality of light-receiving elements each including a light-receiving surface on which the split light is incident in the interior of the package, for monitoring light outputs of the plurality of light-emitting elements; and a first light-shielding film provided between the plurality of light-emitting elements and the beam splitter and including a plurality of first holes for the light to propagate to the beam splitter, wherein the plurality of light-receiving elements are disposed with the light-receiving surfaces facing the beam splitter.

Owner:LUMENTUM JAPAN INC

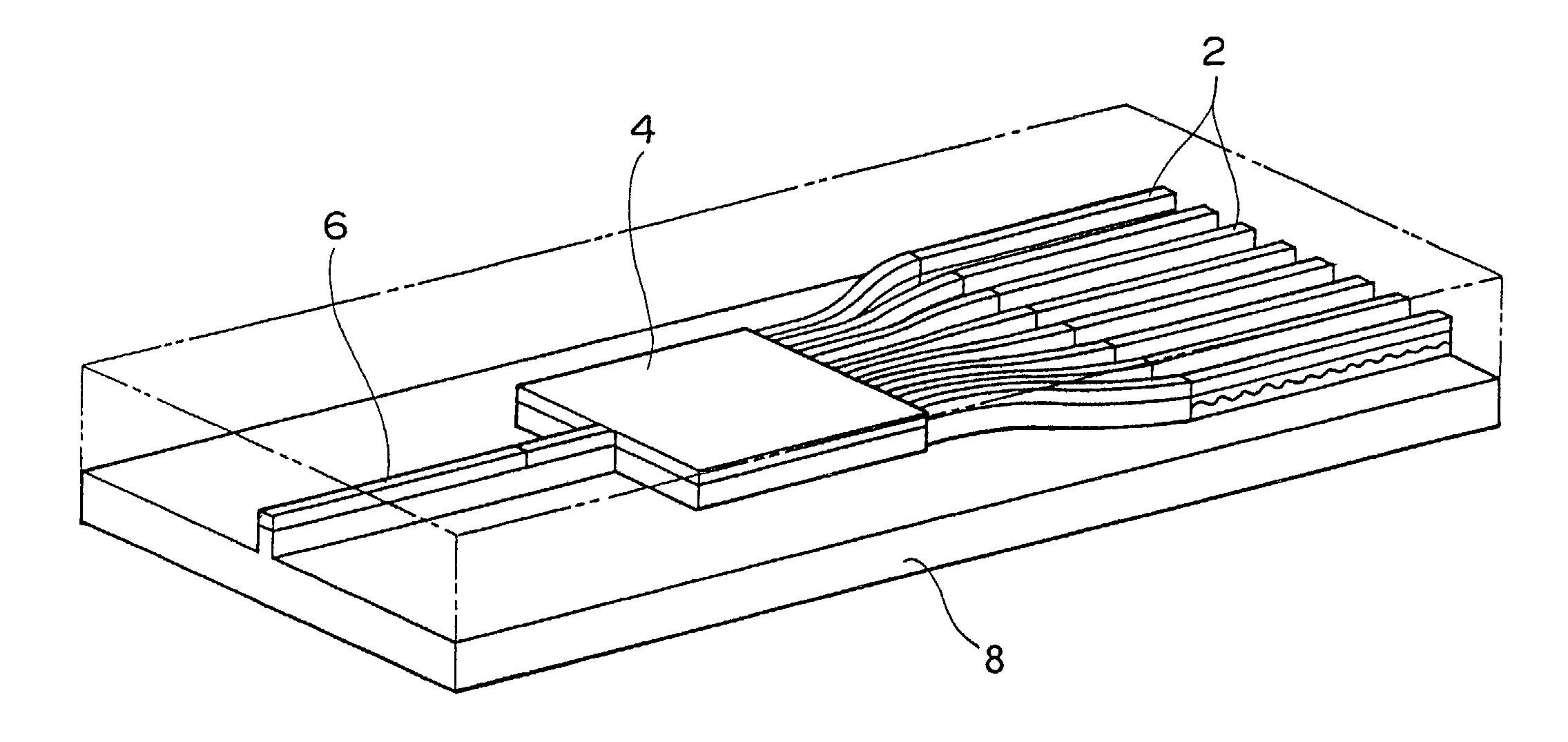

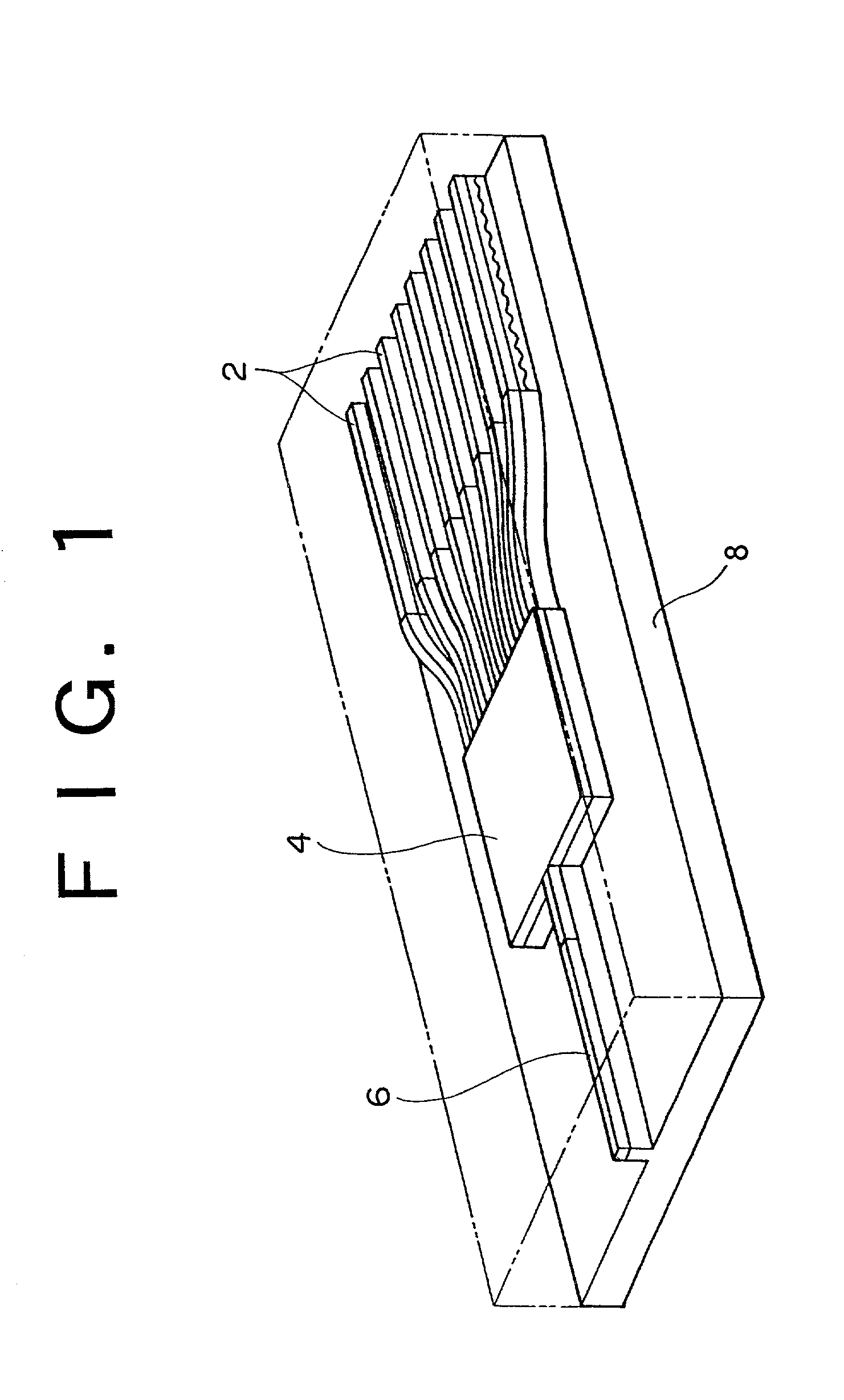

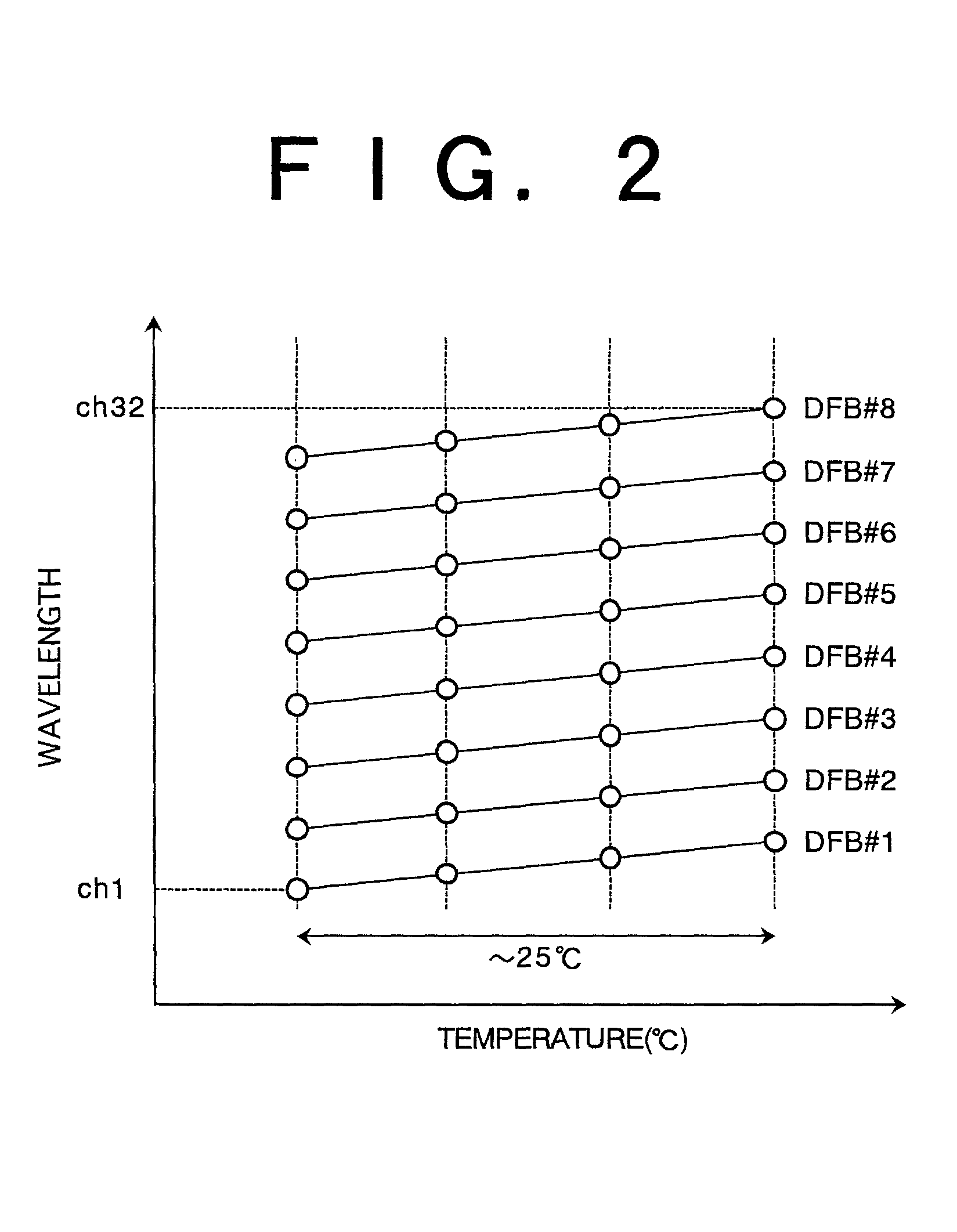

Light source device and wavelength control device therefor

InactiveUS6996142B2Wavelength control easySimple processLaser optical resonator constructionSemiconductor laser arrangementsTemperature controlLength wave

Disclosed herein is a light source device and a wavelength control device therefor. The light source device includes a plurality of laser diodes, a temperature sensor provided in the vicinity of the plurality of laser diodes, a control loop for controlling the temperatures of the plurality of laser diodes according to an output from the temperature sensor to thereby control the oscillation wavelengths of the plurality of laser diodes, and a unit for compensating temperature control conditions for the laser diodes other than a reference laser diode selected from the plurality of laser diodes, according to a change in temperature control condition for the reference laser diode. By the compensation of the temperature control conditions, the oscillation wavelength of each laser diode can be easily stabilized to each wavelength channel of WDM.

Owner:FUJITSU LTD

Semiconductor element, electric circuit, display device and light-emitting device

InactiveUS20100073352A1Simple structureConstant intensityTransistorTelevision system detailsDisplay deviceEngineering

A current storing circuit capable of having a small area, a simple structure with the small number of devices, a low consumption current operation and high yield in manufacturing is provided. Applying the current storing circuit to the current-driving type of display device such as an OLED display device can improve the aperture rate of pixels and reliability of the display device as well as highly functionalize the display device. The invention is characterized by using a new semiconductor element in a shape of a transistor having plural drains or sources. When the semiconductor elements is used for both of a writing element and a driving element, reading in and storing a current value and outputting the current can be performed by only the two semiconductor elements, so that the area occupied by the devices would be easily reduced significantly.

Owner:SEMICON ENERGY LAB CO LTD

Electro-optical device and electronic apparatus

InactiveUS8077136B2Constant intensityMeasurement accuracy of the ambient light intensity can be increasedStatic indicating devicesInput/output processes for data processingEngineeringLight intensity

An electro-optical device includes a display unit having a plurality of pixels, and the display unit is divided into a plurality of areas. The electro-optical device also includes a plurality of optical sensors that are provided for the plurality of areas, each of the optical sensors being configured to detect a light intensity, and a controller that selectively performs recognition of an operation position on the display unit or measurement of an ambient light intensity on the basis of the light intensities detected by the plurality of optical sensors.

Owner:JAPAN DISPLAY WEST

Optical modulator and optical modulation method

An optical modulator includes first and second modulation waveguides, a demultiplexer, first and second phase adjustment waveguides that changes phases of a light of the first and second modulation waveguides, a multiplexer that combines light outputs from the first and second phase adjustment waveguides, a gain controller and a modulator bias controller in which voltages of the first and second modulation signals are controlled so that a result of adding light from the first modulation waveguide to light from the second modulation waveguide where light from the first modulation waveguide has a predetermined phase is equal to a result of adding light from the first modulation waveguide to light from the second modulation waveguide where light from the second modulation waveguide has a predetermined phase. A phase-adjustment bias controller that controls phase amounts changed by the first and second phase adjustment waveguides so as to cancel phase errors.

Owner:MITSUBISHI ELECTRIC CORP

Radio communication system and distance measuring method

ActiveUS10139481B2Constant intensityDirection finders using radio wavesAnti-theft devicesCommunications systemIn vehicle

A radio communication system, in which radio communication is carried out between an in-vehicle communication device, mounted in a vehicle, and a radio communication terminal to detect a relative distance therebetween, includes an output control unit that controls a radio wave intensity of a measuring signal, which is sent from one of the in-vehicle communication device and the radio communication terminal, at a pre-set predetermined value; and a measuring unit that performs distance measuring on a vehicle side based on the radio wave intensity of the measuring signal controlled at the predetermined value or on a signal to which a value of the radio wave intensity of the measuring signal is added as information.

Owner:TOYOTA JIDOSHA KK

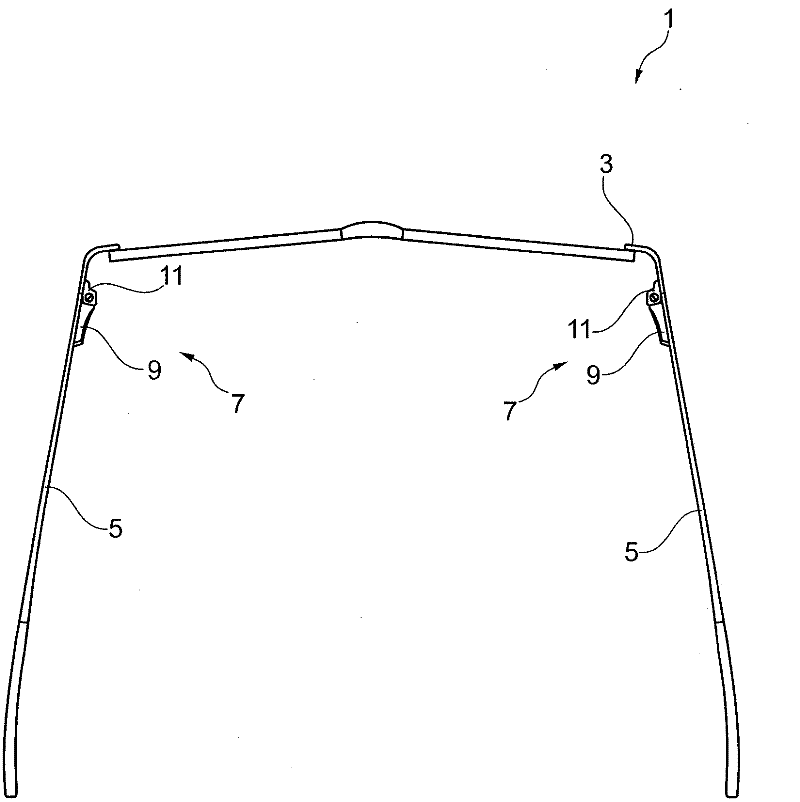

Spectacles, device having a spectacles element and a hinge part, and method for fastening a hinge part to a spectacles element

InactiveCN102648433ALow heat inputConstant powerSpectales/gogglesWelding/soldering/cutting articlesEyewearWeld seam

The invention relates to spectacles having a middle part and at least one side piece, wherein the at least one side piece is pivotably connected to the middle part by means of a hinge, and wherein the hinge comprises two hinge parts, of which a first is arranged on the at least one side piece and a second is arranged on the middle part. The spectacles are characterised in that at least one of the hinge parts is fastened to the middle part or to the side piece by laser welding, in particular seam welding, and in that a continuous weld seam, which is produced by heat-conduction welding, is formed at least on one longitudinal edge of the hinge part.

Owner:赖纳·瓦格纳

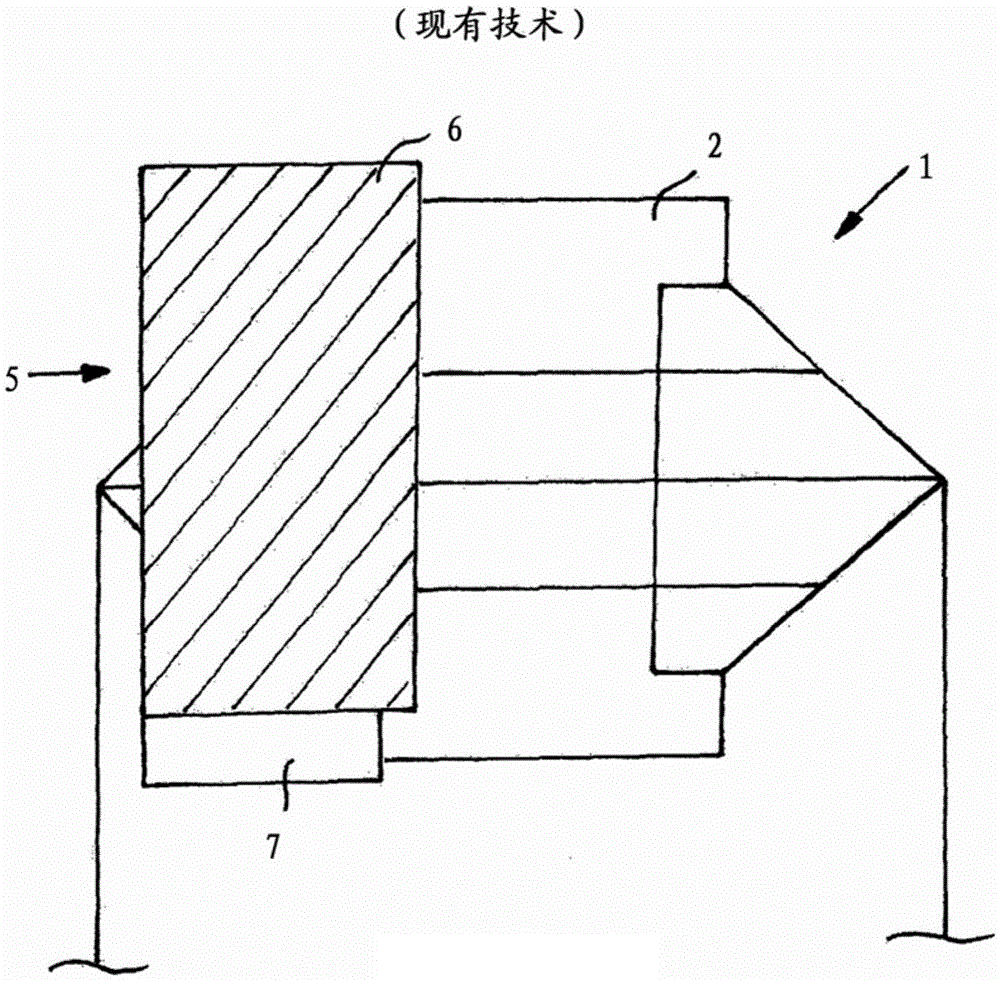

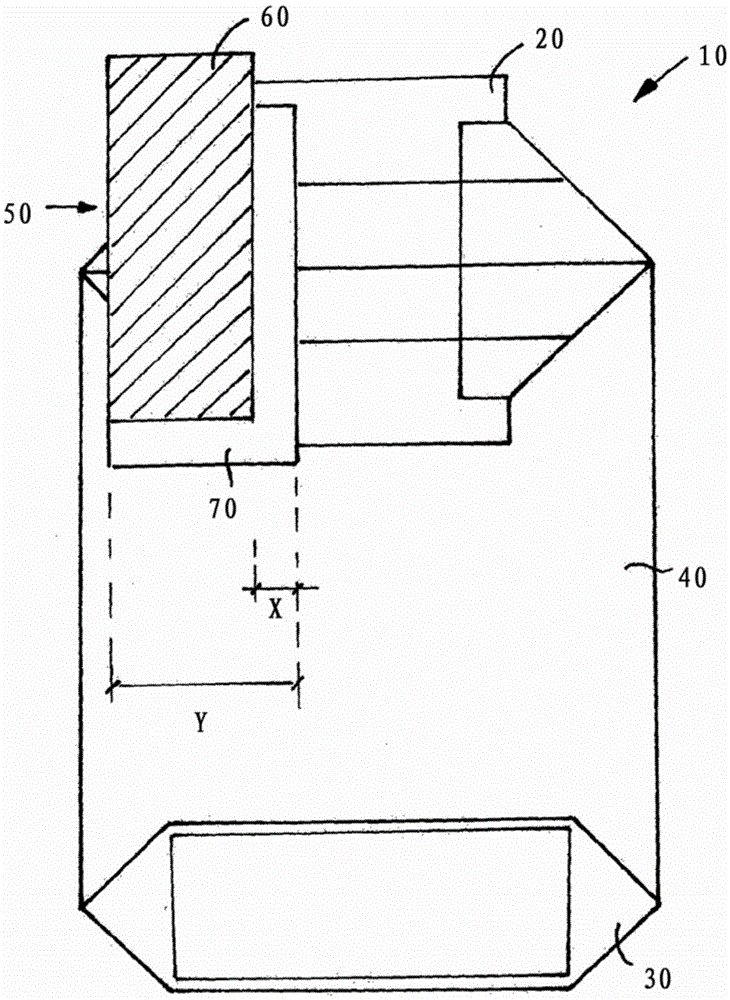

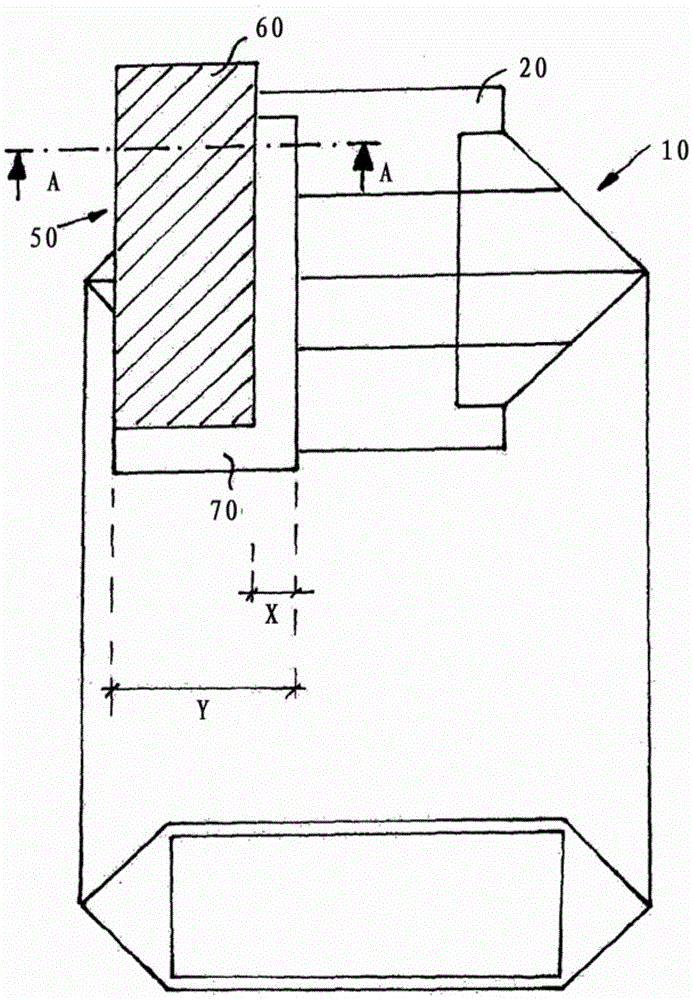

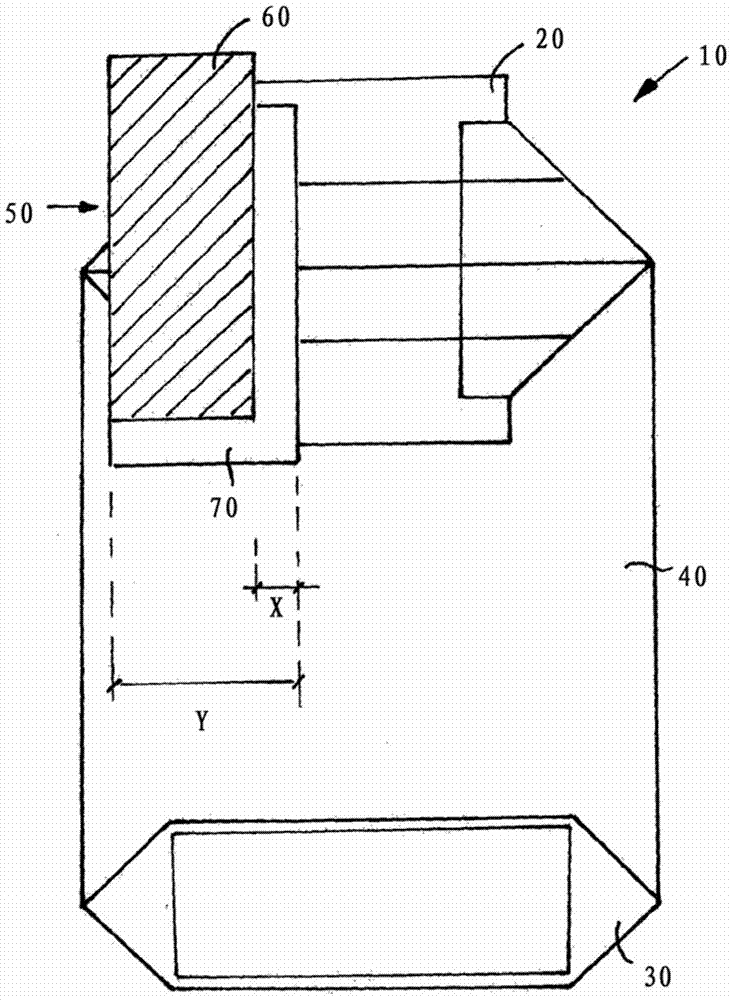

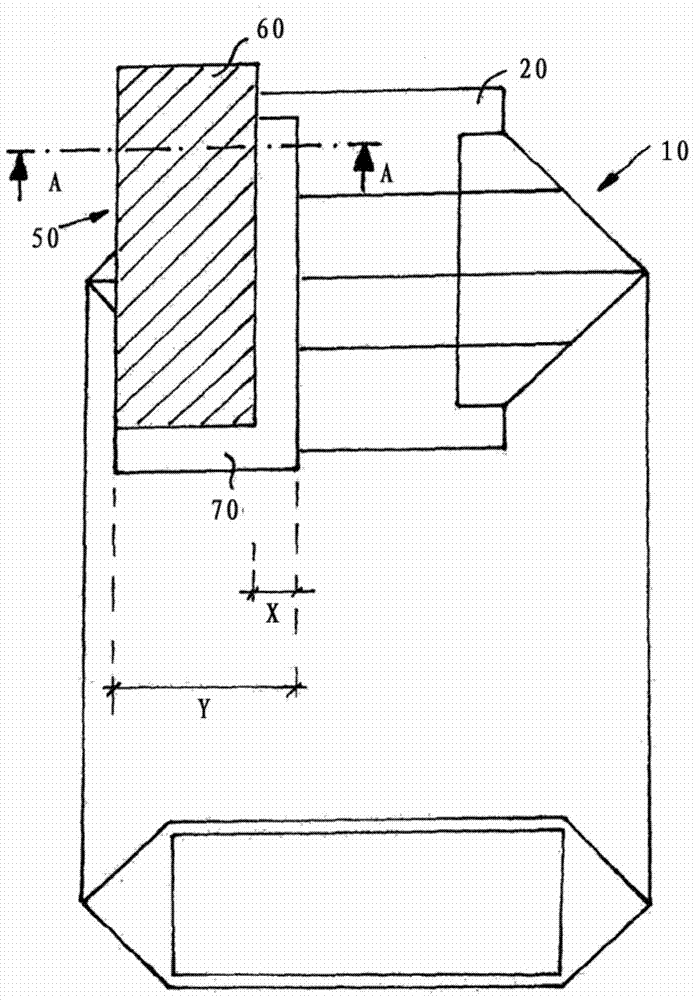

Valve bag

The invention concerns a valve bag 10 for bulk material, such as cement, gypsum, granulated material, animal feed, and the like, with a bottom, preferably a cross or block bottom, and with a valve tray which is disposed opposite the bottom and into which valve tubing 50 is inserted in order to fill the valve bag. The valve tubing is formed of a thermal material 60 and a carrier material 70 surrounding the thermal material. The areal proportion of the thermal material is smaller than the areal proportion of the carrier material.

Owner:DY PACK VERPACKUNGEN GUSTAV DYCKERHOFF

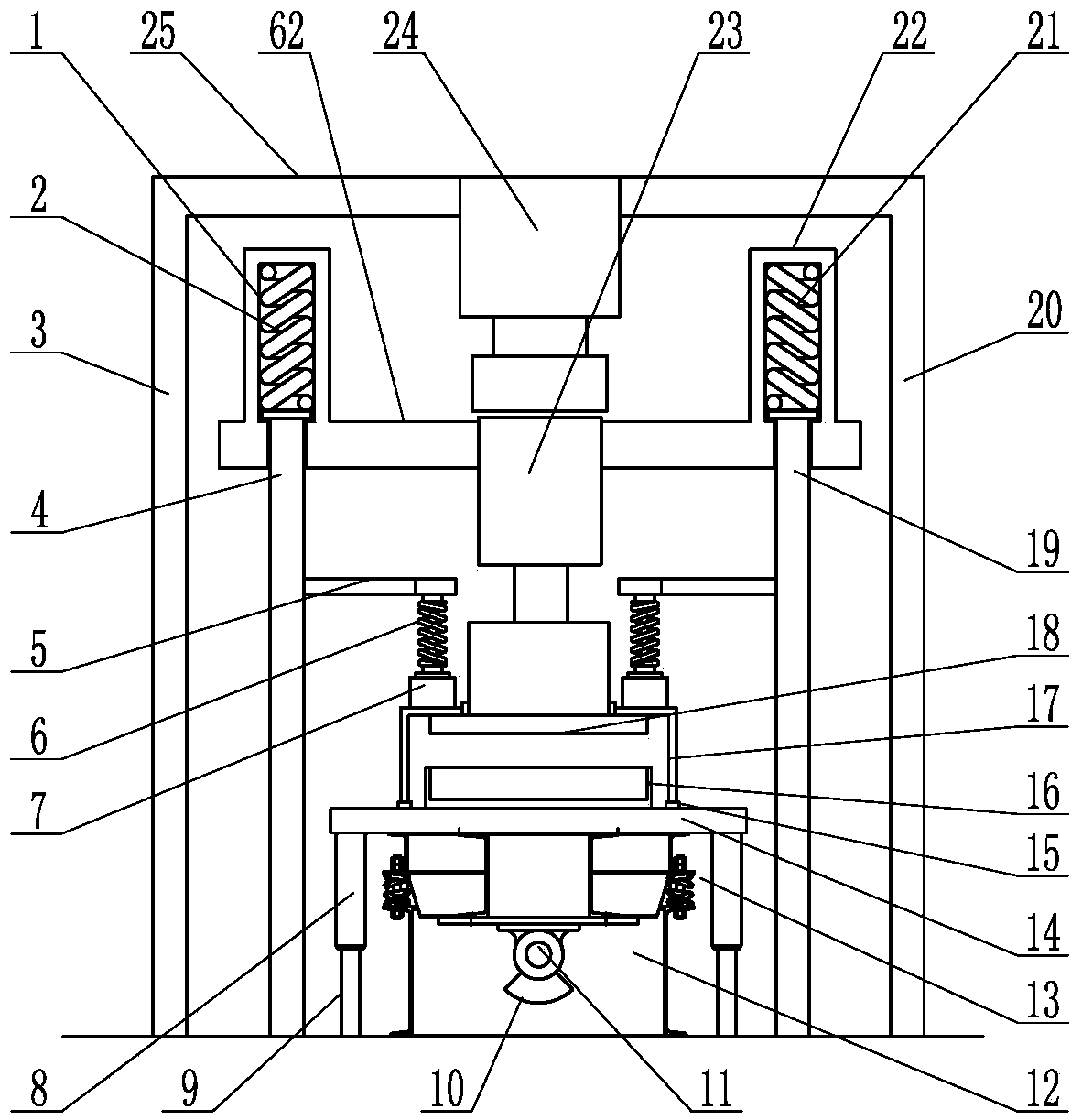

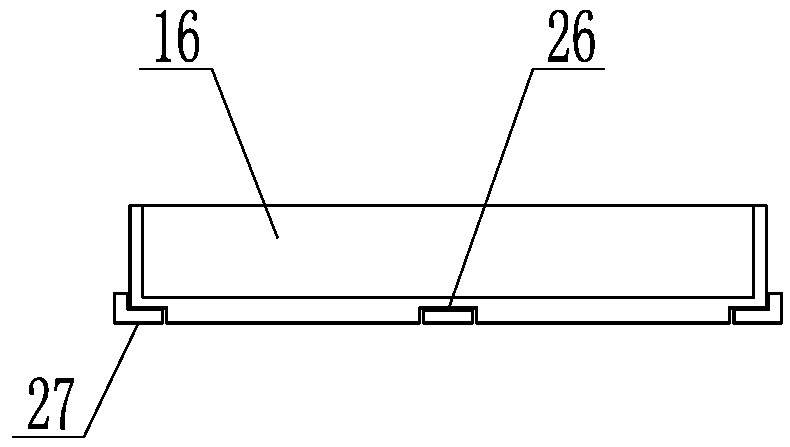

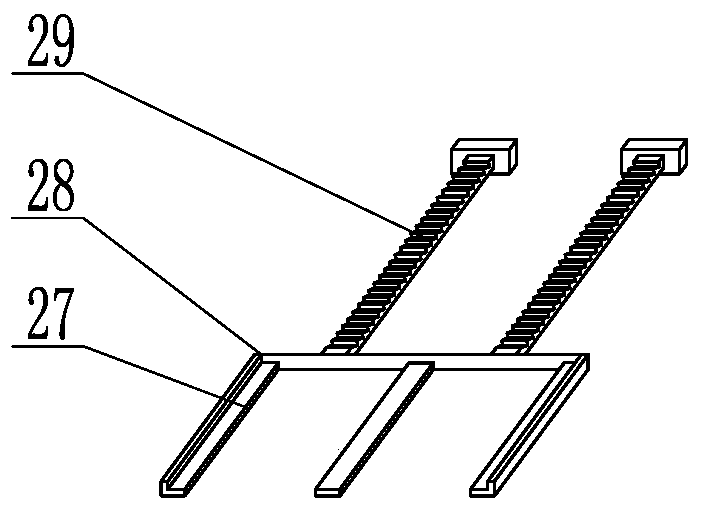

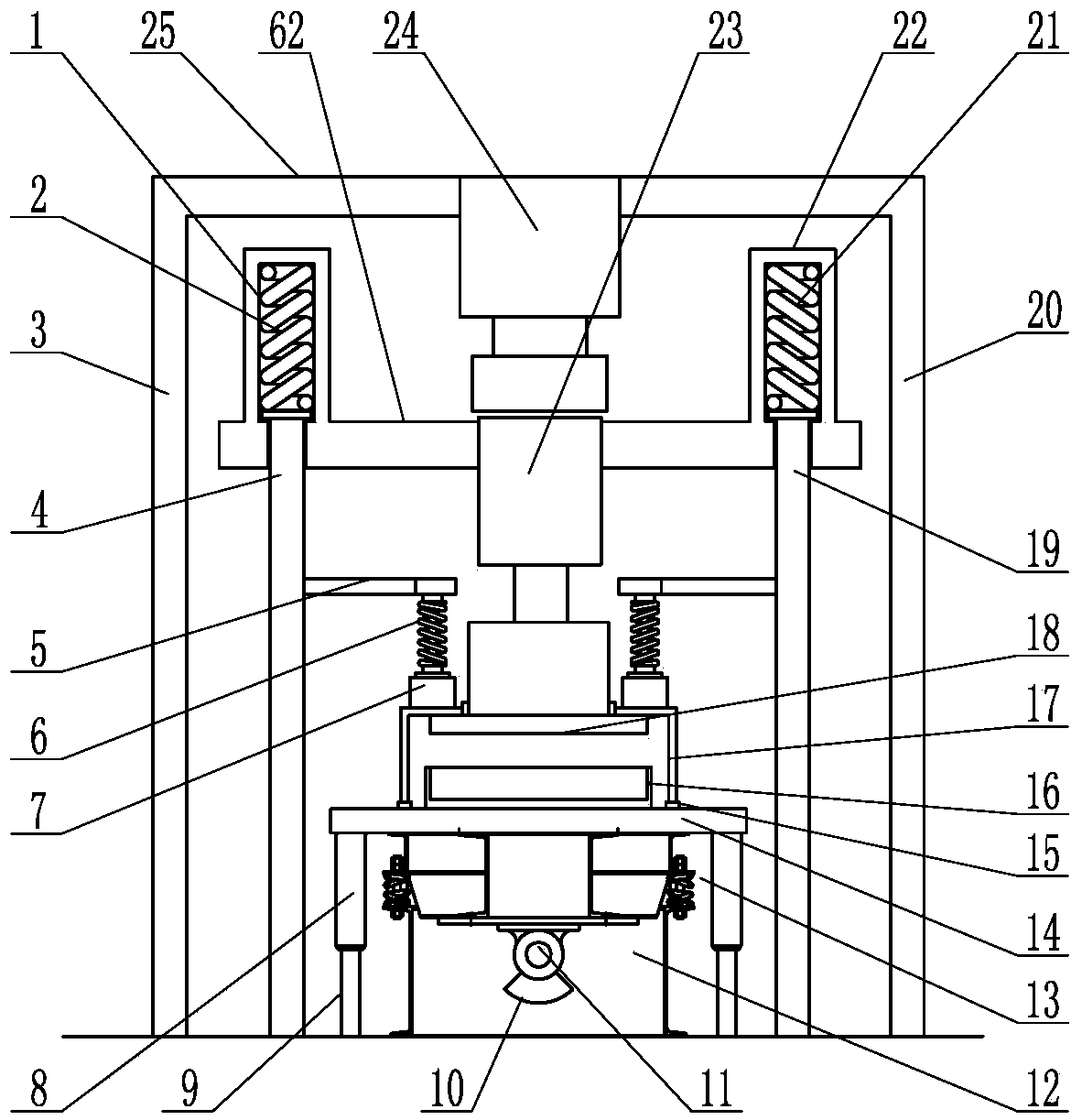

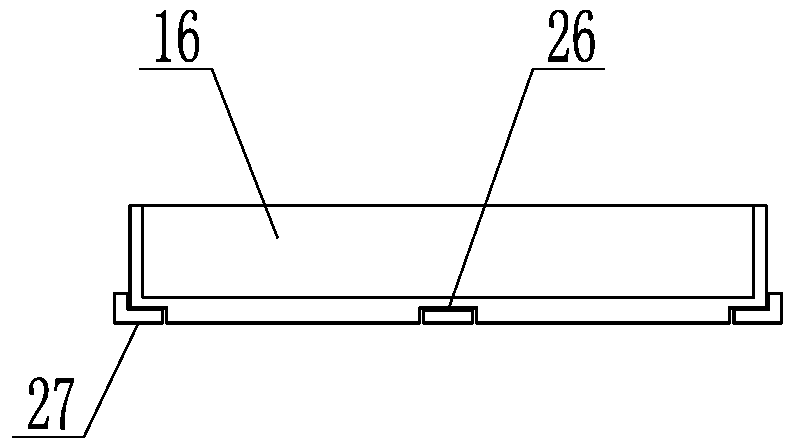

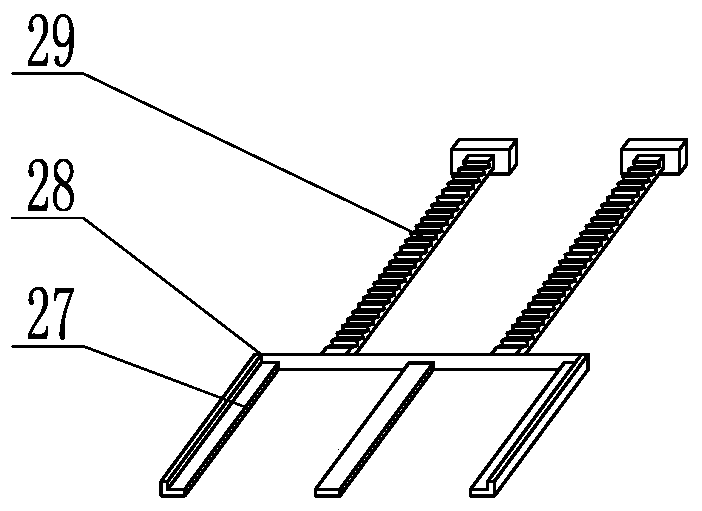

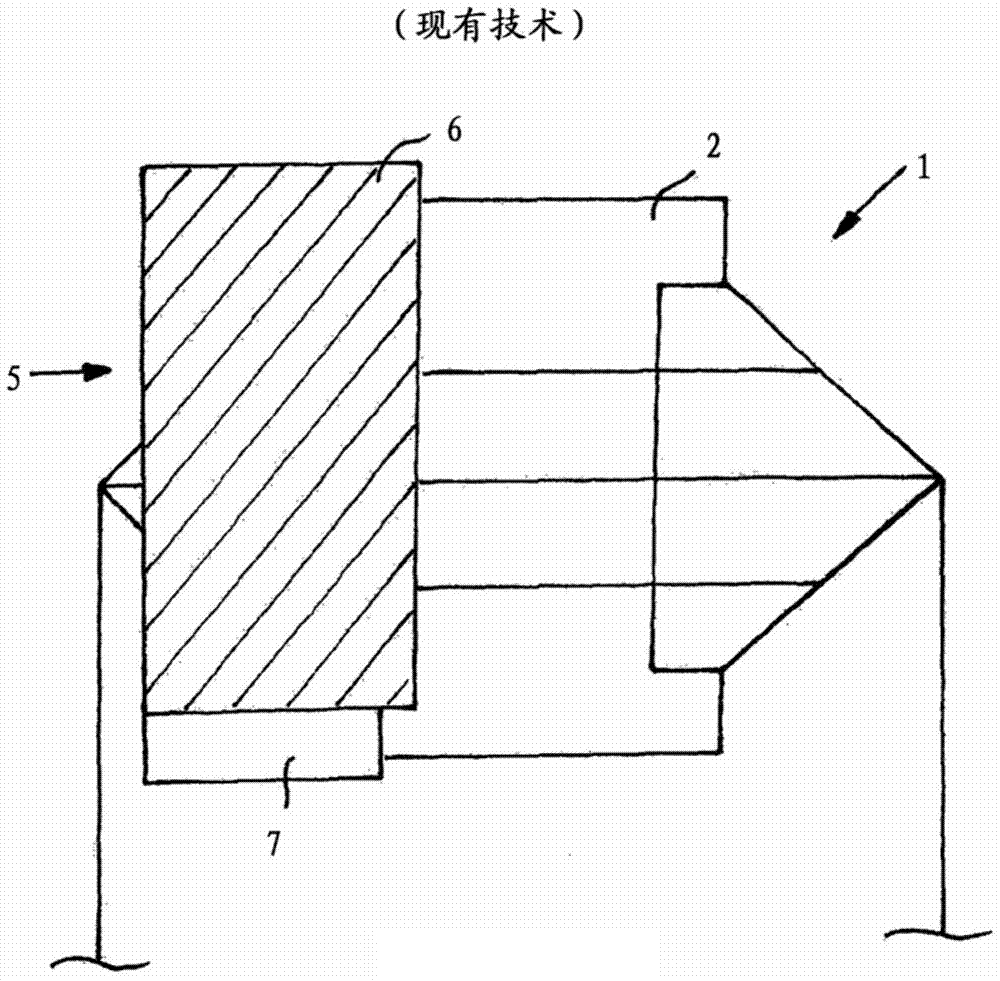

High-pressure vacuum vibration shaping machine

The invention discloses a high-pressure vacuum vibration shaping machine, and belongs to the field of building material high-density forming equipment. The high-pressure vacuum vibration shaping machine is characterized by comprising an outer rack, an inner rack, a base, a vibrator, a vibration table, a pressing mould, a pressing block, a first press machine, a second press machine and a vacuum chamber; the base, the vibrator, the vibration table, the pressing mould, the pressing block and the vacuum chamber are all arranged in the inner rack; the vibrator is connected to the vibration table;the vibration table is arranged on the base through spring devices; the pressing mould is arranged on the vibration table; a mould cavity is formed in the pressing mould; the pressing block is locatedabove the pressing mould and is connected to a telescopic arm of the first press machine; the first press machine is arranged on the top of the inner rack; the second press machine is arranged on theouter rack and is located above the first press machine; the vibrator comprises a vibration motor which is arranged on the bottom of the vibration table; and an eccentric rotation wheel is arranged on a motor shaft of the vibration motor. By adopting the high-pressure vacuum vibration shaping machine, the problem that pressure is insufficient in a pressing production process of quartz plates canbe solved, and product quality is effectively improved.

Owner:ZIBO XIANG PENG MACHINERY

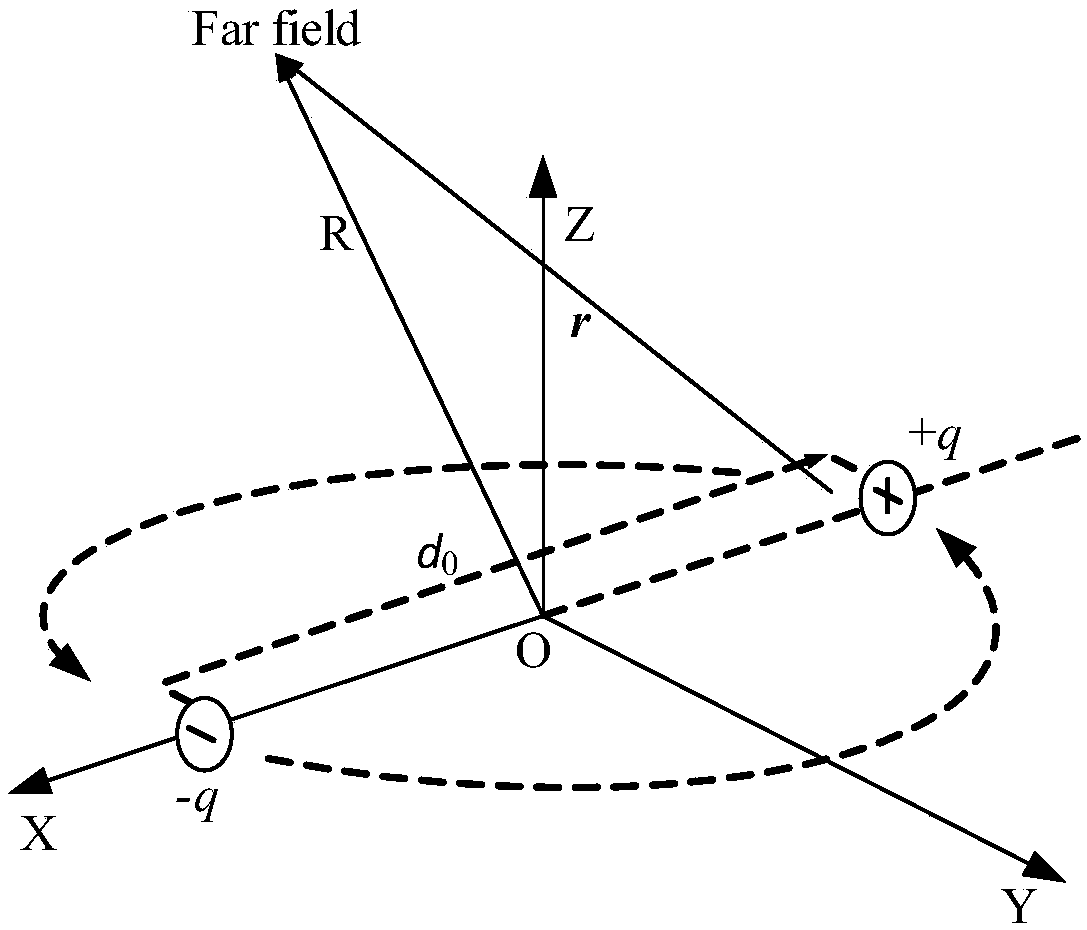

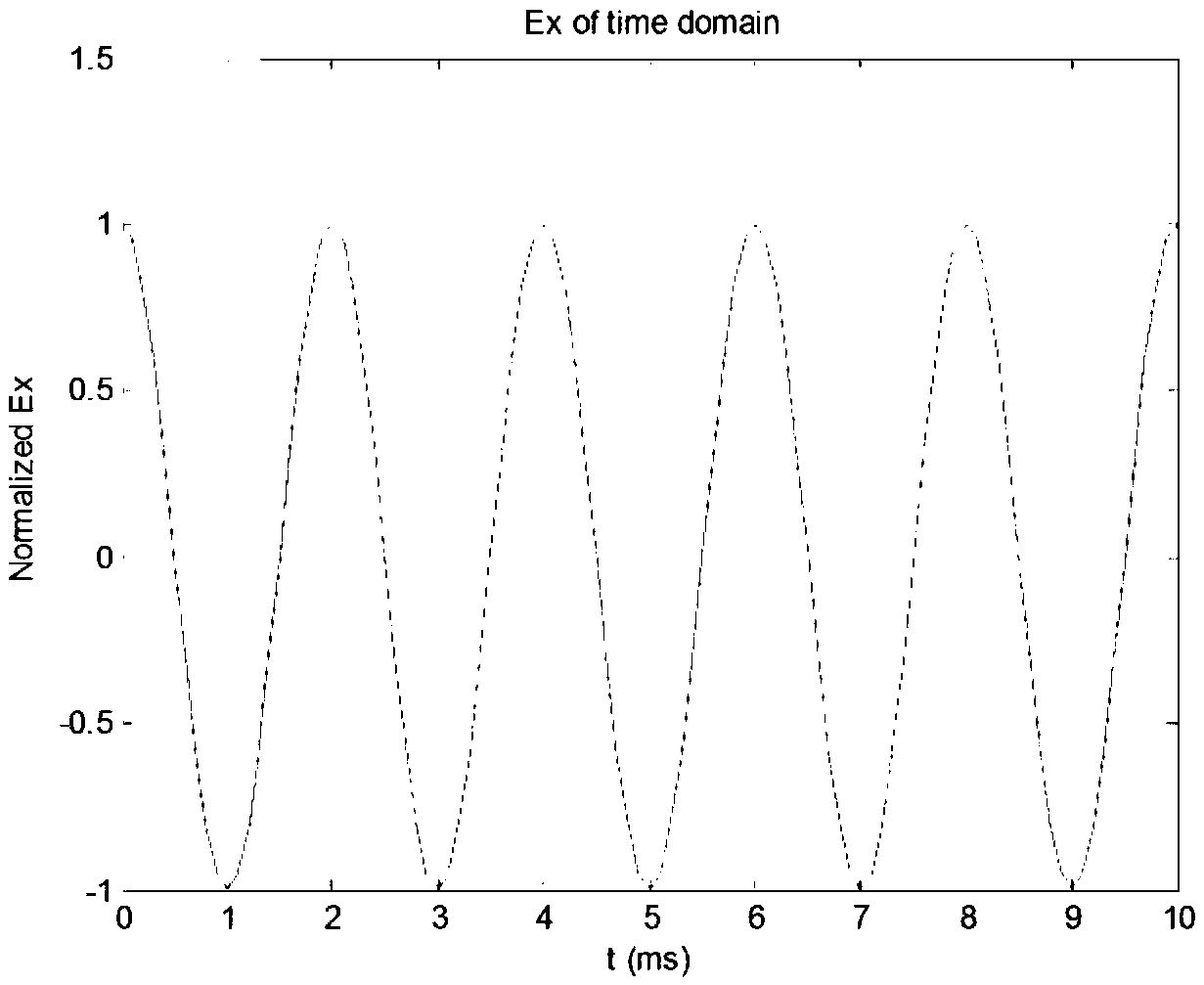

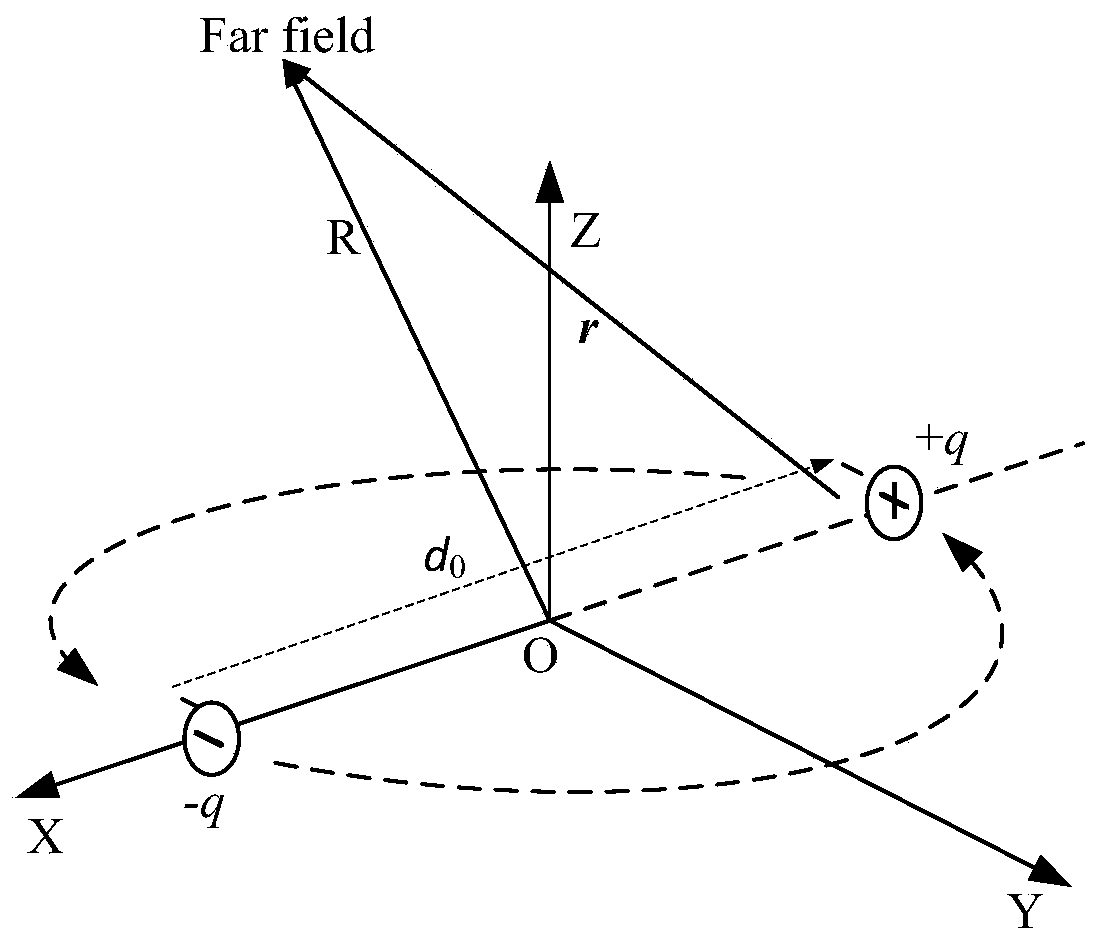

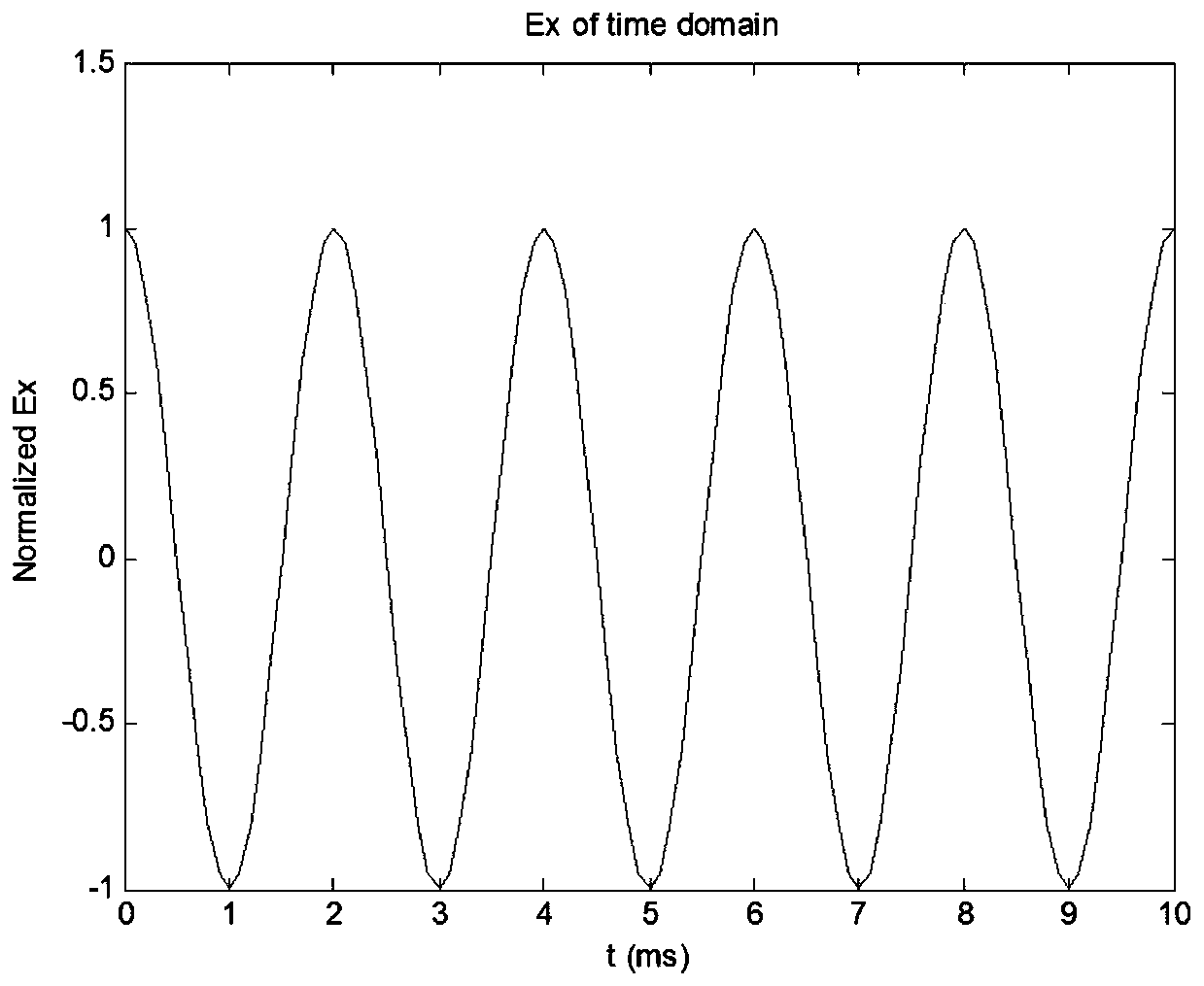

Ultra-small ULF/VLF rotating current antenna and signal amplitude-frequency modulation method

ActiveCN108736146AElectrical size reductionDoes not affect radiation efficiencyRadiating elements structural formsLoop antennasAntenna designElectricity

The invention discloses an ultra-small ULF / VLF rotating current antenna, comprising a light-emitting device and a turntable, wherein the turntable comprises a positive metal layer, a P-type semiconductor layer, an N-type semiconductor layer and a negative metal layer, which are arranged in sequence; the positive metal layer is provided with a light hole, the turntable is further provided with a conductive coil, and two ends of the conductive coil are respectively connected with the positive metal layer and the negative metal layer. The antenna designed by the invention has a very small electrical size, and may be realized in the ULF / VLF frequency band by the meter-scale volume, which is far smaller than the kilometer-scale antenna in the prior art and does not affect the radiation efficiency of the antenna.

Owner:SOUTHEAST UNIV

High-pressure vacuum vibratory forming machine

The invention provides a high-pressure vacuum vibratory forming machine and belongs to the field of building material high-density forming equipment. The high-pressure vacuum vibratory forming machineis characterized by comprising an outer rack, an inner rack, a base, a vibrator, a vibrating table, a pressing die, a pressing die, a pressing block, a first pressure machine, a second pressure machine and a vacuum chamber. The base, the vibrator, the vibrating table, the pressing die, the pressing block and the vacuum chamber are arranged in the inner rack. The vibrator is connected with the vibrating table which is installed on the base through a spring device. The pressing die is installed on the vibrating table. The pressing die is provided with a die cavity. The pressing block is locatedabove the pressing die. The pressing block is connected with a telescoping arm of a first pressure machine. The first pressure machine is installed on the top of the inner frame. A second pressure machine is installed on the outer rack and located above the first pressure machine. The vibrator comprises a vibrating motor. The vibrating motor is installed on the bottom of the vibrating table. An eccentric rotating wheel is installed on a motor shaft of the vibrating motor. The high-pressure vacuum vibratory forming machine can solve the problem that in the quartz plate pressing production process, pressure is insufficient, and the product quality can be effectively improved.

Owner:ZIBO XIANG PENG MACHINERY

Optical transmission module

ActiveUS10001590B2More constantAccurate monitoringLaser detailsSolid-state devicesComputer moduleEngineering

Owner:LUMENTUM JAPAN INC

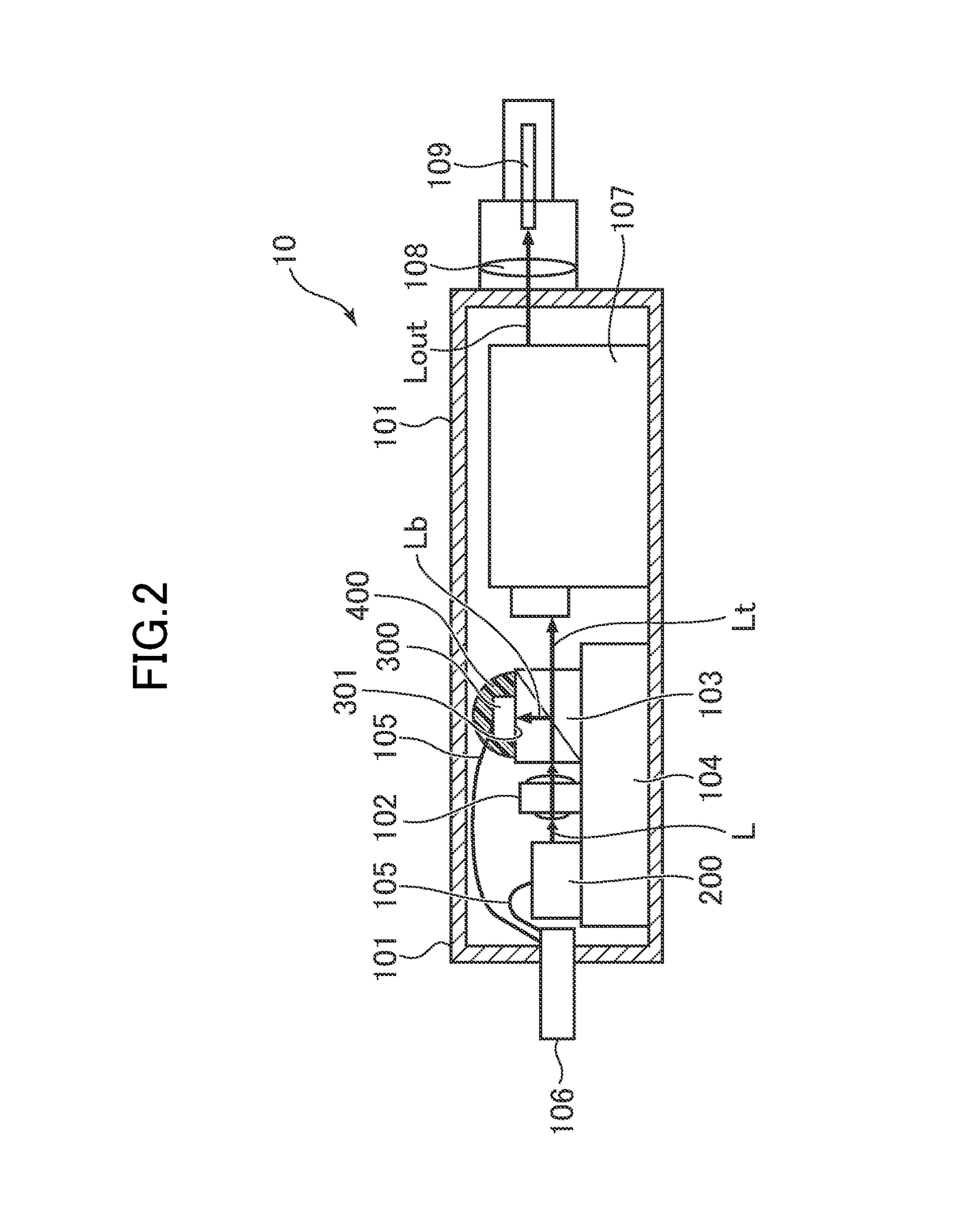

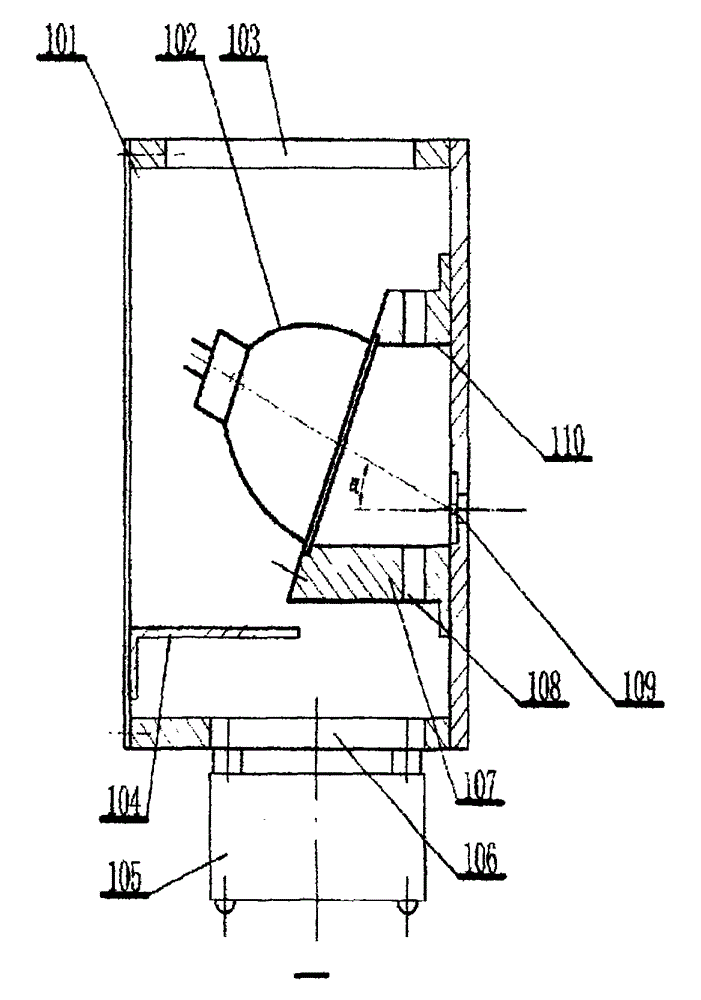

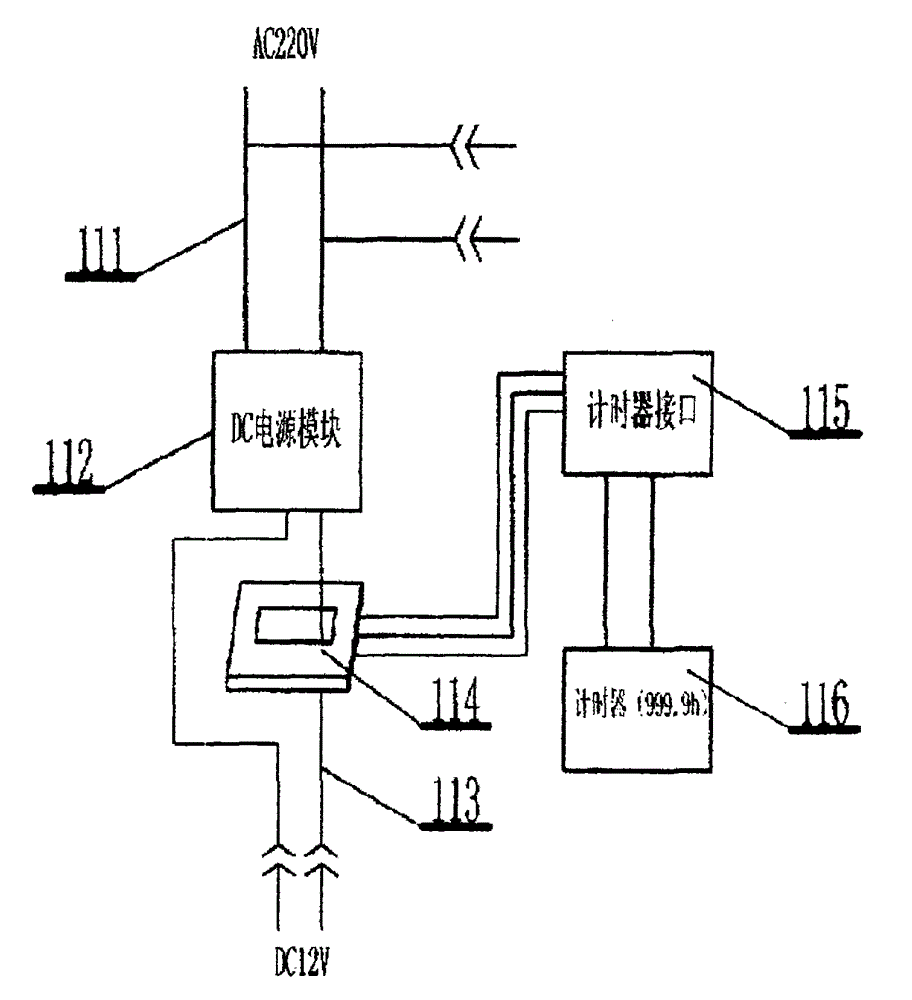

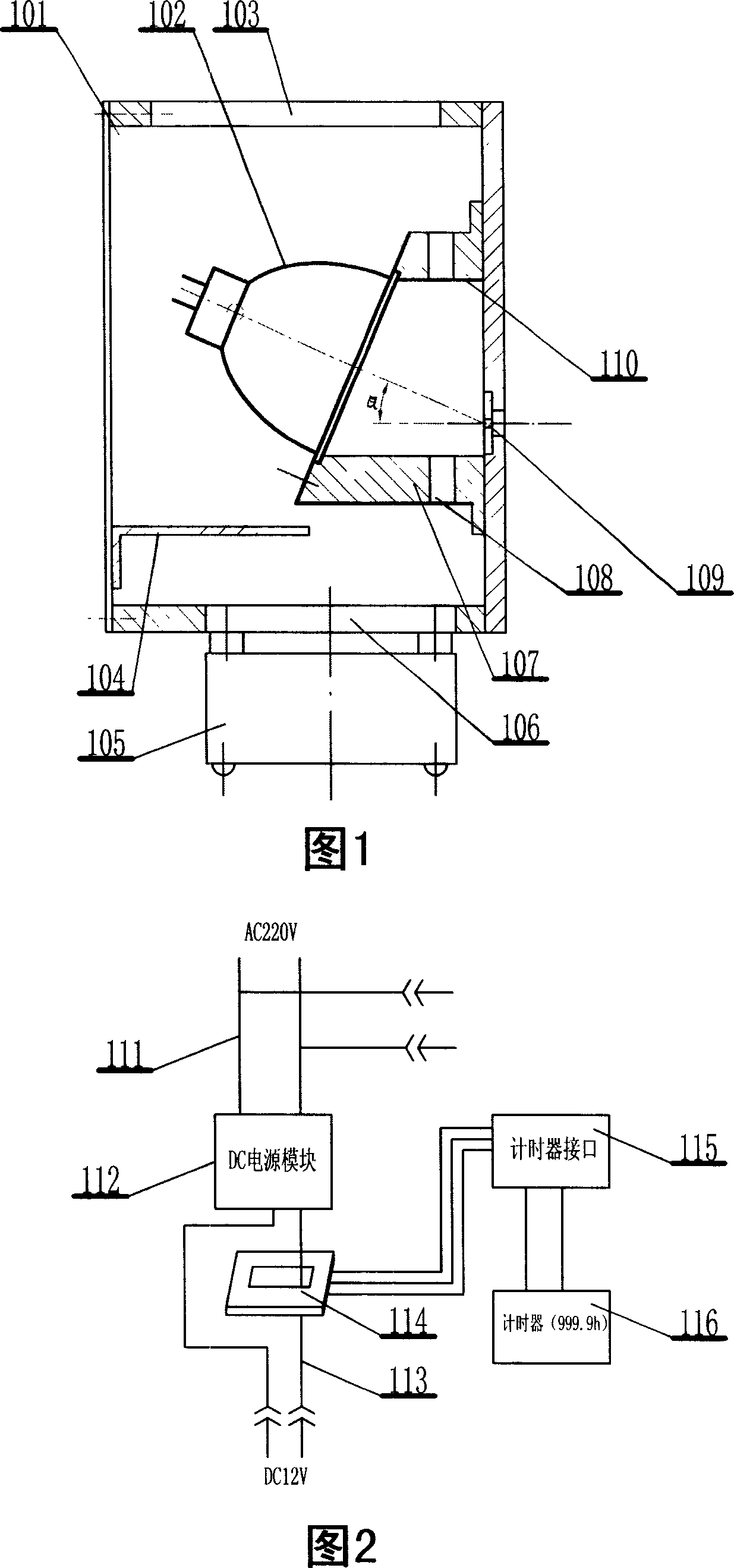

Constant light source device of high-brightness projector

InactiveCN102980100AImprove light energy utilizationReduce weightLighting applicationsElectric circuit arrangementsAutomatic controlConstant light

The invention relates to a constant light source device of a high-brightness projector, which is used for a light filming monitoring system. The constant light source device is mainly characterized in that a lamp holder with an optical channel arranged on the center is fixedly arranged in the front wall of a light source launching box body, a light source lamp with a spotlight lamp shade is arranged on the lamp holder, wherein the spotlight surface of the spotlight lamp shade faces towards the optical channel and is buckled and connected with the lamp holder, the light source lamp is respectively connected with an arranged power supply constant control module and a light source lamp working timer through wires, a light source ejecting hole is arranged in the front wall of the box body, an air inlet and a heat radiating air outlet are correspondingly arranged in the side wall of the box body, and a fan is arranged on the air inlet. The constant light source device of the high-brightness projector is capable of producing a constant high-energy intense light source; and the brightness of condensed light emitted by the light source is high and stable. Meanwhile, the using time of the light source lamp can be automatically controlled. The constant light source device has the advantages of reasonable structure design, high light energy usage, reliable work and the like.

Owner:SHANDONG YU YING OPTICAL INSTR CO LTD

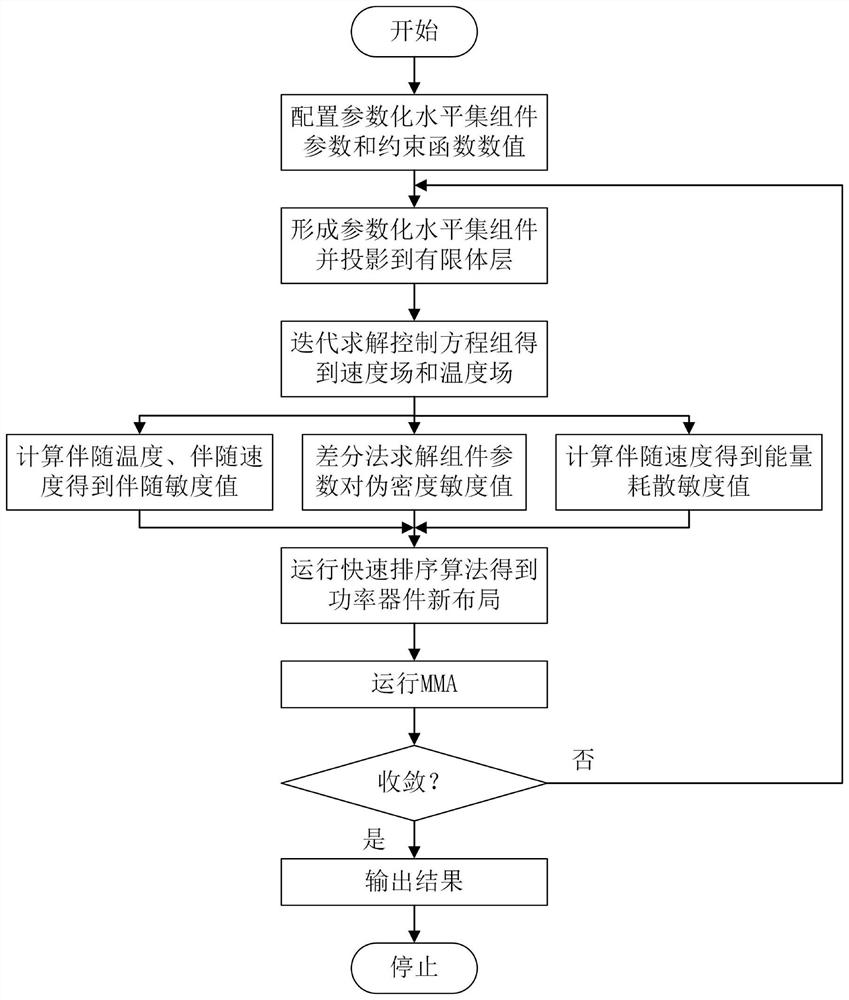

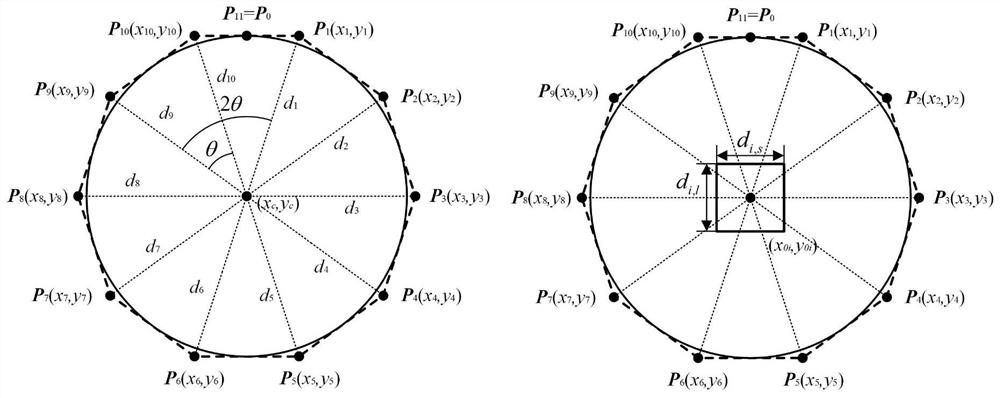

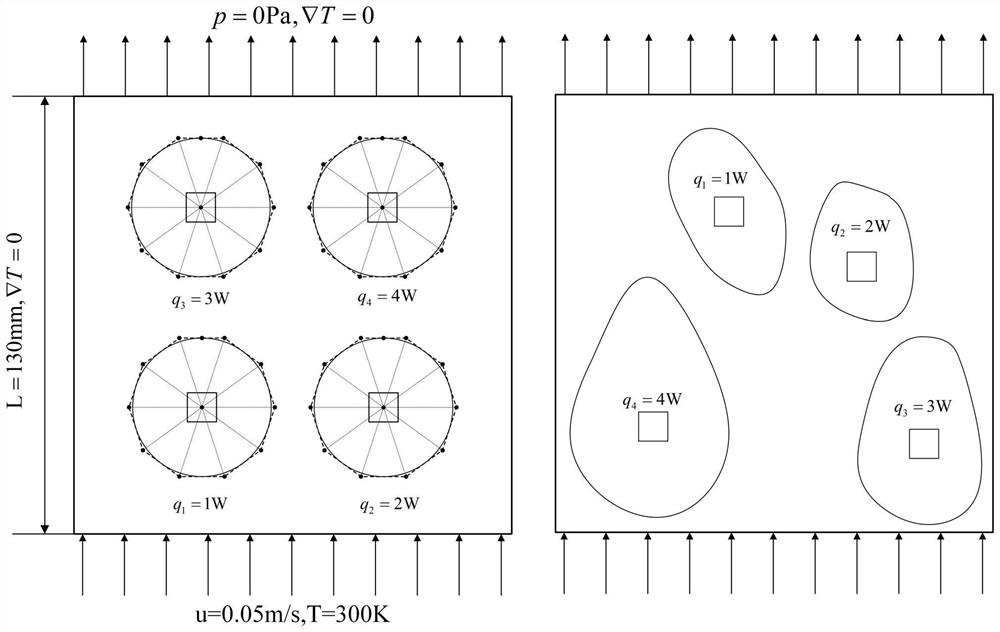

Shielding cover shape design method capable of modulating cooling airflow form in narrow space

PendingCN114595655APrecise size controlOvercoming Manufacturing ConstraintsSustainable transportationCAD circuit designEngineeringForced convection

A shielding case shape design method capable of modulating a narrow space cooling air flow form is characterized in that a parameterized level set assembly of a closed B-spline curve is utilized to describe the appearance topology of a shielding case, the shielding case is endowed with the capacity of arbitrary deformation, and the surface forced convection heat transfer performance of the shielding case is enhanced; a parameterized level set assembly of a hyperelliptic curve is used for describing a heating electronic component, and the electronic component is ensured to be always in the center of the shielding case in the optimization process through the same central position of the parameterized level set assembly and the hyperelliptic curve, so that the optimal position distribution of the electronic component on the PCB and the optimal shielding case appearance are optimized and designed at the same time; the optimization result can be directly and seamlessly connected with a CAD system, the post-processing process is greatly simplified, and meanwhile, parameterized boundary expression provides possibility for accurately controlling the structure size, overcoming manufacturing constraints and the like.

Owner:XI AN JIAOTONG UNIV

Optical transmission module

ActiveUS9880050B2More constantAccurate monitoringPhotometryCoupling light guidesBeam splitterOptoelectronics

An optical transmission module includes: a package; a plurality of light-emitting elements each emitting light in the interior of the package; a beam splitter splitting the light into transmitted light and split light; a plurality of light-receiving elements each including a light-receiving surface on which the split light is incident in the interior of the package, for monitoring light outputs of the plurality of light-emitting elements; and a first light-shielding film provided between the plurality of light-emitting elements and the beam splitter and including a plurality of first holes for the light to propagate to the beam splitter, wherein the plurality of light-receiving elements are disposed with the light-receiving surfaces facing the beam splitter.

Owner:LUMENTUM JAPAN INC

Image sensor IC

ActiveUS20120161272A1Uniform qualityUniform thicknessTelevision system detailsSolid-state devicesEngineeringPhotodiode

Owner:ABLIC INC

Constant illuminating source device of high light projector

InactiveCN101012915AImprove light energy utilizationReduce weightElectric circuit arrangementsLighting heating/cooling arrangementsAutomatic controlConstant light

The invention relates to a constant light supply of high-brightness light projector used in optical plating detector. The invention is characterized in that the front wall the injecting box of light supply is fixed with a lamp base whose center is arranged with light channel; the base is arranged with a light supply lamp with collecting lamp cover; the collecting face of the cover is toward to the light channel and connected with the lamp base; the light supply lamp via wires is respectively connected with the power constant controller and the timer of light supply lamp; the front wall of the box is arranged with the light supply outlet; the side wall is arranged with the wind inlet and radiation outlet while the wind inlet is mounted with a fan. The invention can generate constant high-brightness strong light supply with high stability. And it can automatically control the apply time of light supply lamp.

Owner:HENAN COSTAR GRP CO LTD

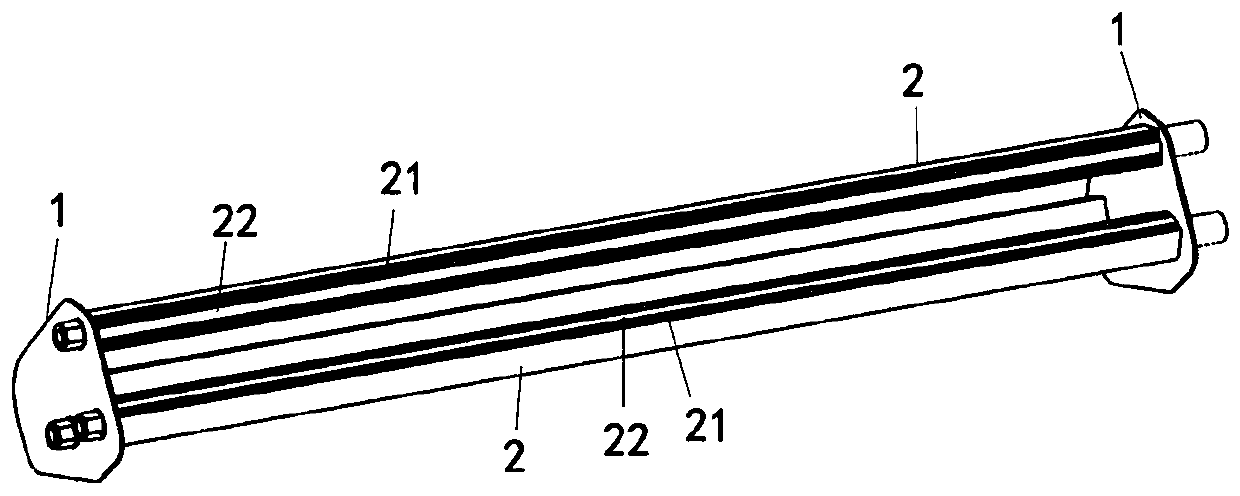

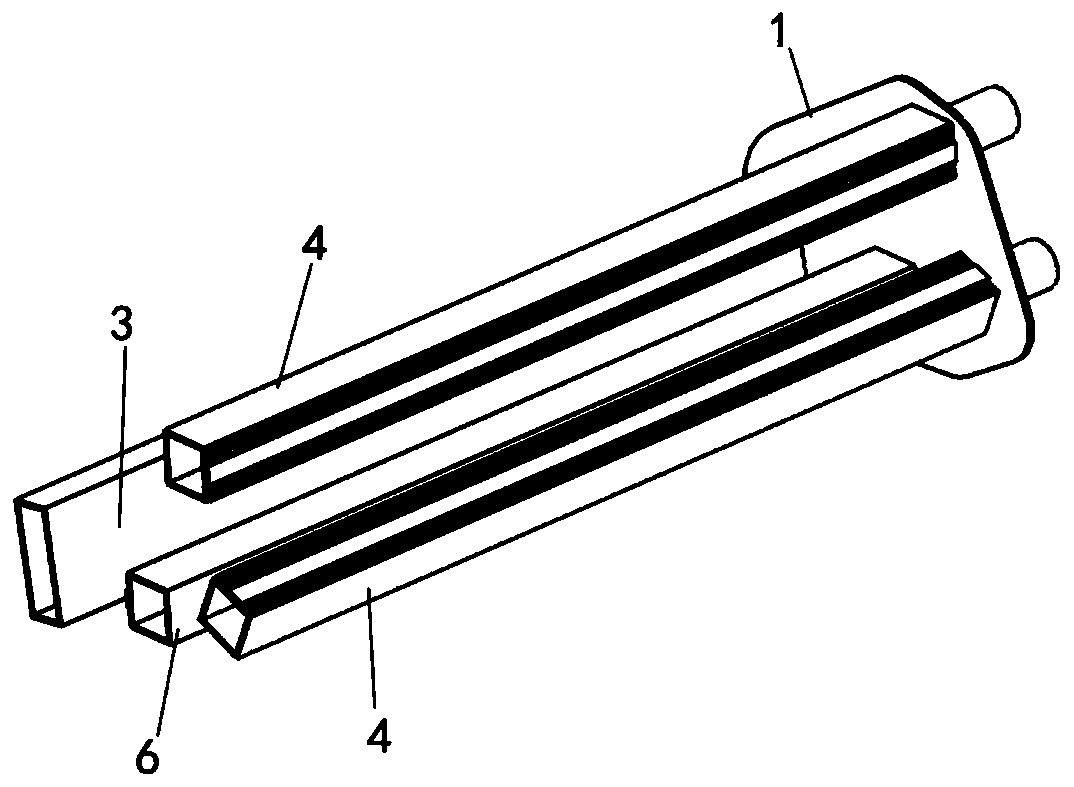

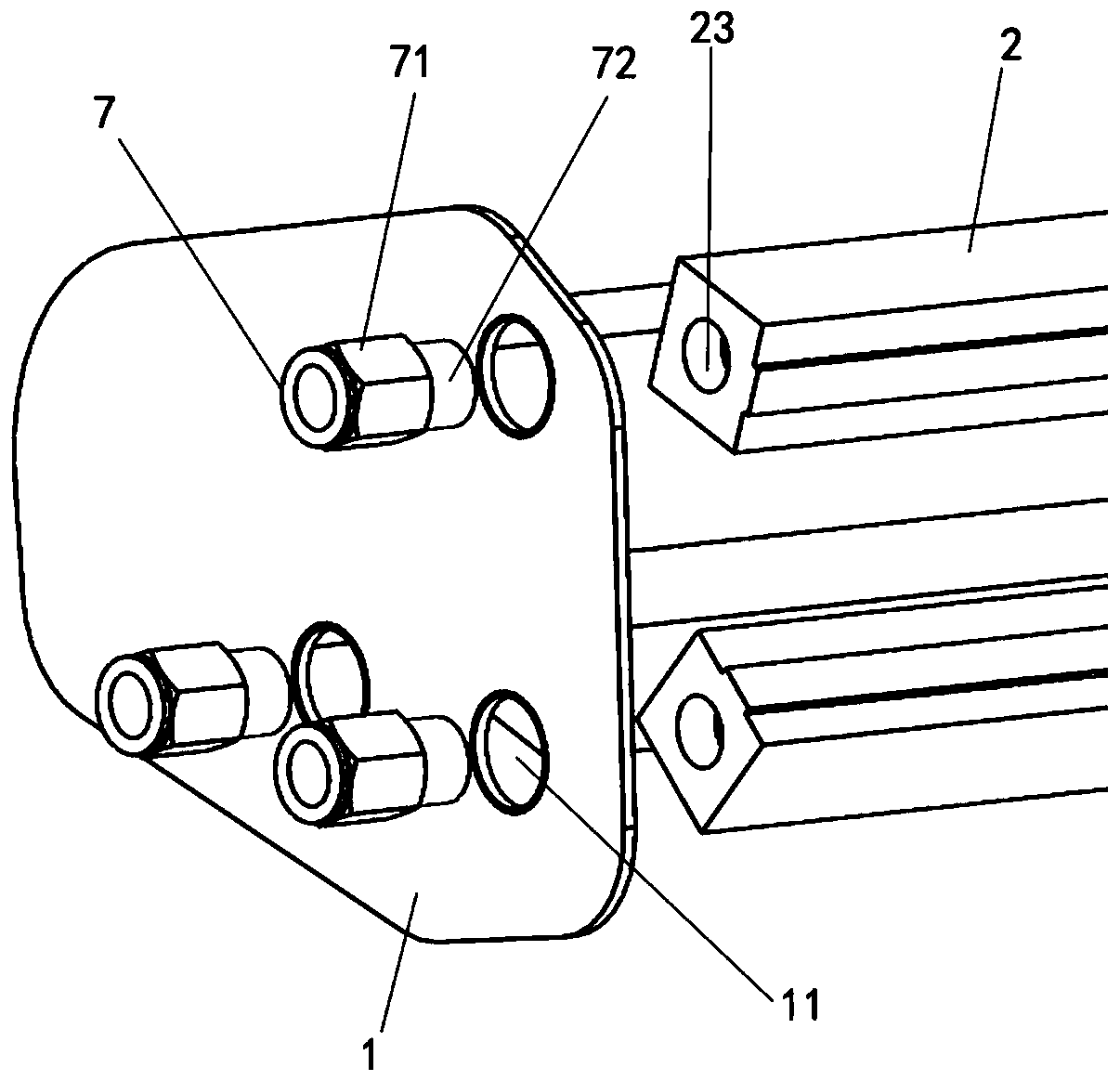

Lamp tube device used for lamp box of color selector

PendingCN109708015AReduce the temperatureIncrease temperatureLighting heating/cooling arrangementsLighting elementsAir pumpEngineering

The invention relates to a lamp tube device used for a lamp box of a color selector. The lamp tube device comprises two fixing brackets, a plurality of lamp tubes and a background plate, wherein the background plate and the plurality of lamp tubes are parallelly mounted between the two fixing brackets, a lamp panel is arranged on one side face of each lamp tube, a plurality of lamp beads are arranged on each lamp panel, the lamp tube device further comprises a plurality of air pipes and an air pump, two ends of each lamp tube communicate with each other, so that a hollow pipeline is formed, through holes are formed in the fixing brackets, the air pipes pass through the through holes, and the air pump is connected with two ends of each lamp tube through the air pipes. Compared with the prior art, the device provided by the invention has the advantages that two ends of the lamp tubes realize communicating, cooling air is delivered in, then the temperature of the lamp tubes during work isreduced, when the intensity of the light path needs to be promoted, after the power of the lamp beads is increased, the heat dissipation of the lamp beads and the lamp tubes is assisted through the flowing of the cooling air, then the temperature in a machine box is kept basically constant while the intensity of the light path is promoted, and the influences brought by high temperature are reduced.

Owner:TECHIK INSTR SHANGHAI

An ultra-small ulf/vlf rotating current antenna and signal amplitude-frequency modulation method

ActiveCN108736146BConstant intensityElectrical size reductionRadiating elements structural formsLoop antennasAntenna designFrequency modulation

The invention discloses an ultra-small ULF / VLF rotating current antenna, comprising a light-emitting device and a turntable, wherein the turntable comprises a positive metal layer, a P-type semiconductor layer, an N-type semiconductor layer and a negative metal layer, which are arranged in sequence; the positive metal layer is provided with a light hole, the turntable is further provided with a conductive coil, and two ends of the conductive coil are respectively connected with the positive metal layer and the negative metal layer. The antenna designed by the invention has a very small electrical size, and may be realized in the ULF / VLF frequency band by the meter-scale volume, which is far smaller than the kilometer-scale antenna in the prior art and does not affect the radiation efficiency of the antenna.

Owner:SOUTHEAST UNIV

Valve pocket

The present invention relates to a valve pocket 10 for bulk materials such as cement, gypsum, granular materials, animal feed, etc., having: an upright bottom, preferably a cross-shaped bottom or a square bottom; and a valve bottom opposite the upright bottom, A valve hose 50 for filling the valve pocket is inserted into the valve base, wherein the valve hose is formed from a thermal material 60 and a carrier material 70 surrounding the thermal material, wherein the thermal material has a smaller area fraction than the carrier Area share of material.

Owner:DY PACK VERPACKUNGEN GUSTAV DYCKERHOFF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com