Constant illuminating source device of high light projector

A technology of a light source device and a light projector, applied in the optical field, can solve the problems of no heat dissipation measures in the light source box, poor film thickness monitoring effect, weak light, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

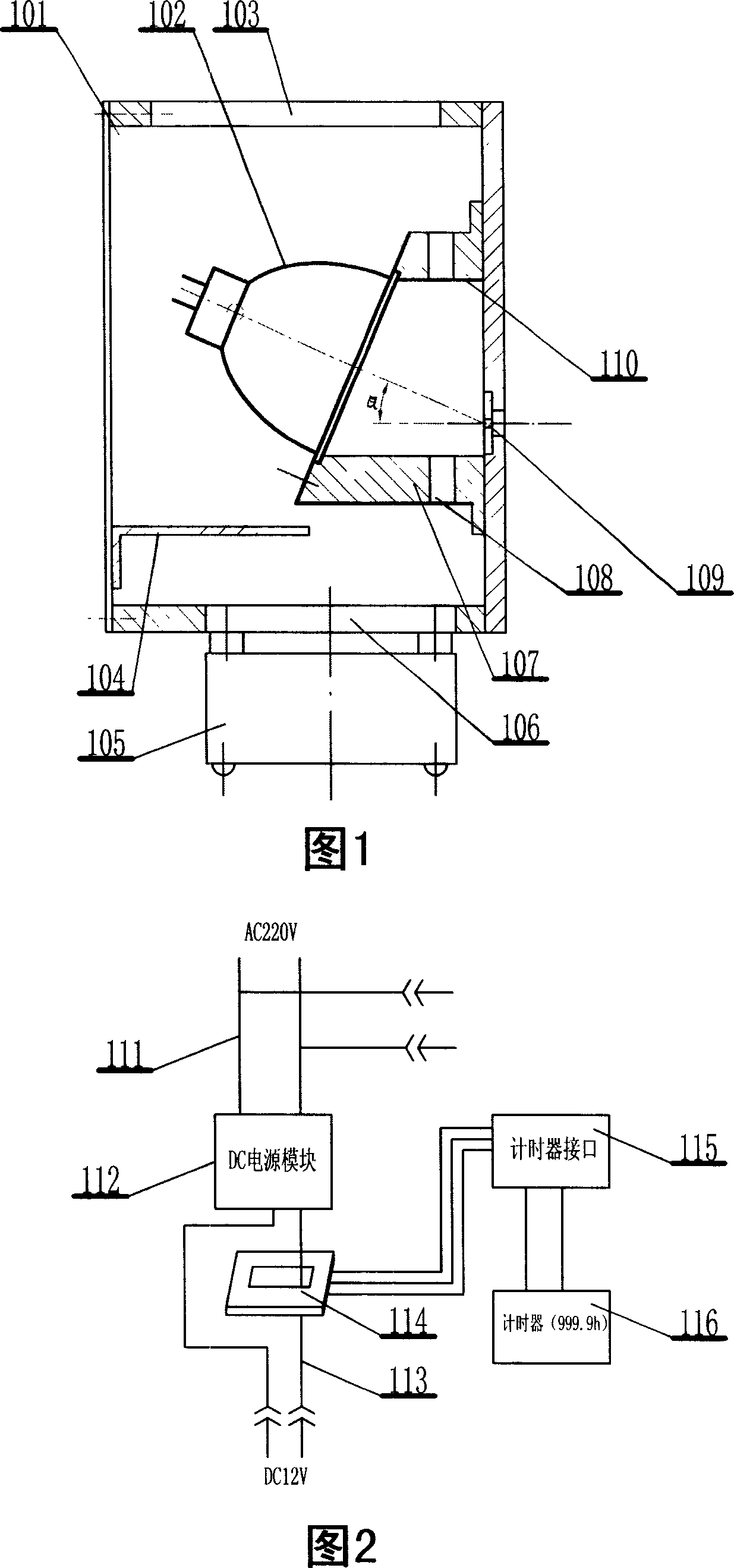

[0019] Referring to Fig. 1, the high-brightness light projector constant light source device of the present invention has a light source emitting box 101, and the front wall of the box is provided with a light source exit hole 109, and a lamp holder 107 is fixedly installed in the front wall, the lamp holder The central portion of 107 is provided with an optical channel 110 , and several cooling holes 108 communicating with the central optical channel 110 are provided on its peripheral wall. The end surface of the lamp holder 107 facing the light source is an inclined surface, the light source lamp 102 is installed obliquely on the inclined surface, and the focusing surface of the spotlight cover on it faces the light channel, and is buckled and connected with the lamp holder 107 . The light source lamp 102 adopts a halogen tungsten bulb, and the spotlight cover adopts an ellipsoidal cover. The angle α between the light axis of the light source lamp 102 and the exit light axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com