Chocolate compositions containing ethylcellulose

a technology of ethylcellulose and compositions, which is applied in the field of chocolate compositions and products, can solve the problems of high price of procedures, undesirable taste and/or texture of chocolate, and ordinary chocolate is not particularly resistant to summer temperatures or the heat of tropical countries, and achieves low saturated fat levels, reduce oil migration, and the effect of reducing the amount of saturated fa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

reference example 1

[0066]A fat substitute is prepared as follows. Ethylcellulose 22 cp or 45 cp 9% w / w (ETHOCEL®, Dow Chemical Co.) and 3% w / w SMS in a 30:70 w / w mixture of fully hydrogenated soybean oil with liquid soybean oil were heated up 140° C. to ensure full solubilization of the polymer in oil. Upon cooling of the melt, at 100° C., soybean oil heated to 100° C. was added at a 1:2 ratio (1 / 3 dilution). The final concentration of components was 6% EC, 2% SMS, 20% fully hydrogenated soybean oil and 72% soybean oil. The mixture was then allowed to cool down and set. Fully hydrogenated cottonseed oil, fully hydrogenated canola oil, beef tallow, lard, milkfat could also be added as the hardstock. This material has the functionality and texture of a fat.

reference example 2

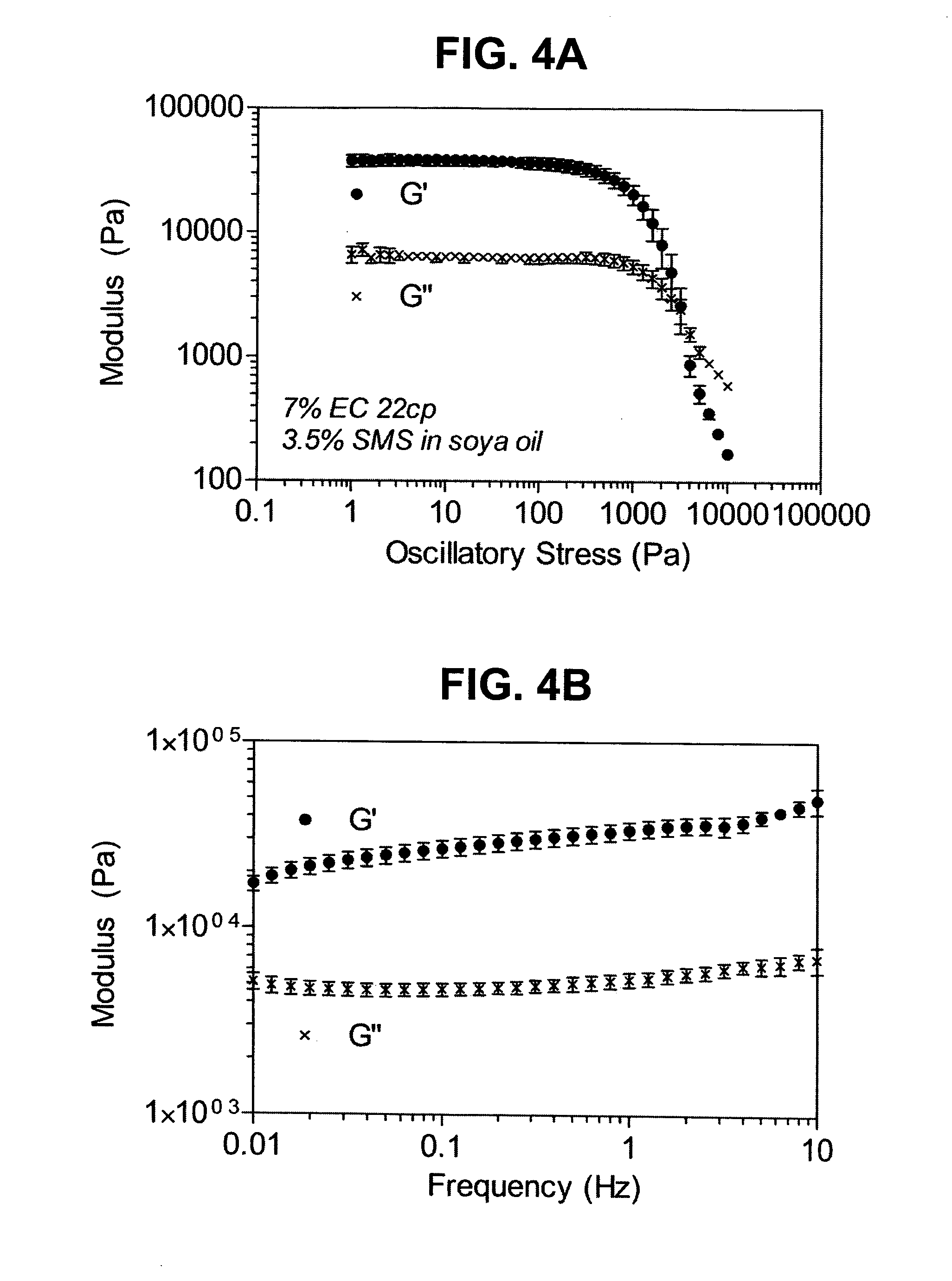

[0067]A 10% ethylcellulose 22 cps gel containing 5% sorbitan monostearate in flaxseed oil was prepared. The gel was prepared by the thermal treatment described above and allowed to set at 22° C. for one day. In order to assess the rheological properties of the gel, a controlled stress rheological test was performed. Circular 1 cm diameter by 3 mm high piece of the gel was cut out and placed on a piece of 60-grit wood sandpaper soaked in flaxseed oil. A piece of 60-grit wood sandpaper was glued to a 1 cm diameter flat stainless steel geometry. The gel sample on the oil-soaked piece of sandpaper (3×2 cm) were taped to the bottom Peltier plate of the rheometer. The sample was compressed manually to achieve a normal force of approximately 0.2N to ensure good mechanical contact and no slip. The rheometer was programmed to carry out a stress sweep from 1 to 4000 Pa at a frequency of 1 Hz. The results show that the test gel is very solid-like (firm gel), with a G′ / G″ value of about 4. The ...

reference example 3

[0068]A 6 wt. % ethylcellulose 22 cp gel containing 2 wt. % SMS in palm kernel oil (PKO) was prepared by dissolving the components at 135° C., followed by allowing the gel to set at room temperature undisturbed. The resulting gel was strong and showed no loss of free oil on standing at 55° C. for 2 hours. The gel setting temperature was determined to be 75° C., which makes it suitable for addition to chocolate compositions without excessive heating of the chocolate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com