Ambient Air Dryer with Improvements in Performance, Safety, Ease of Use and Cost of Manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

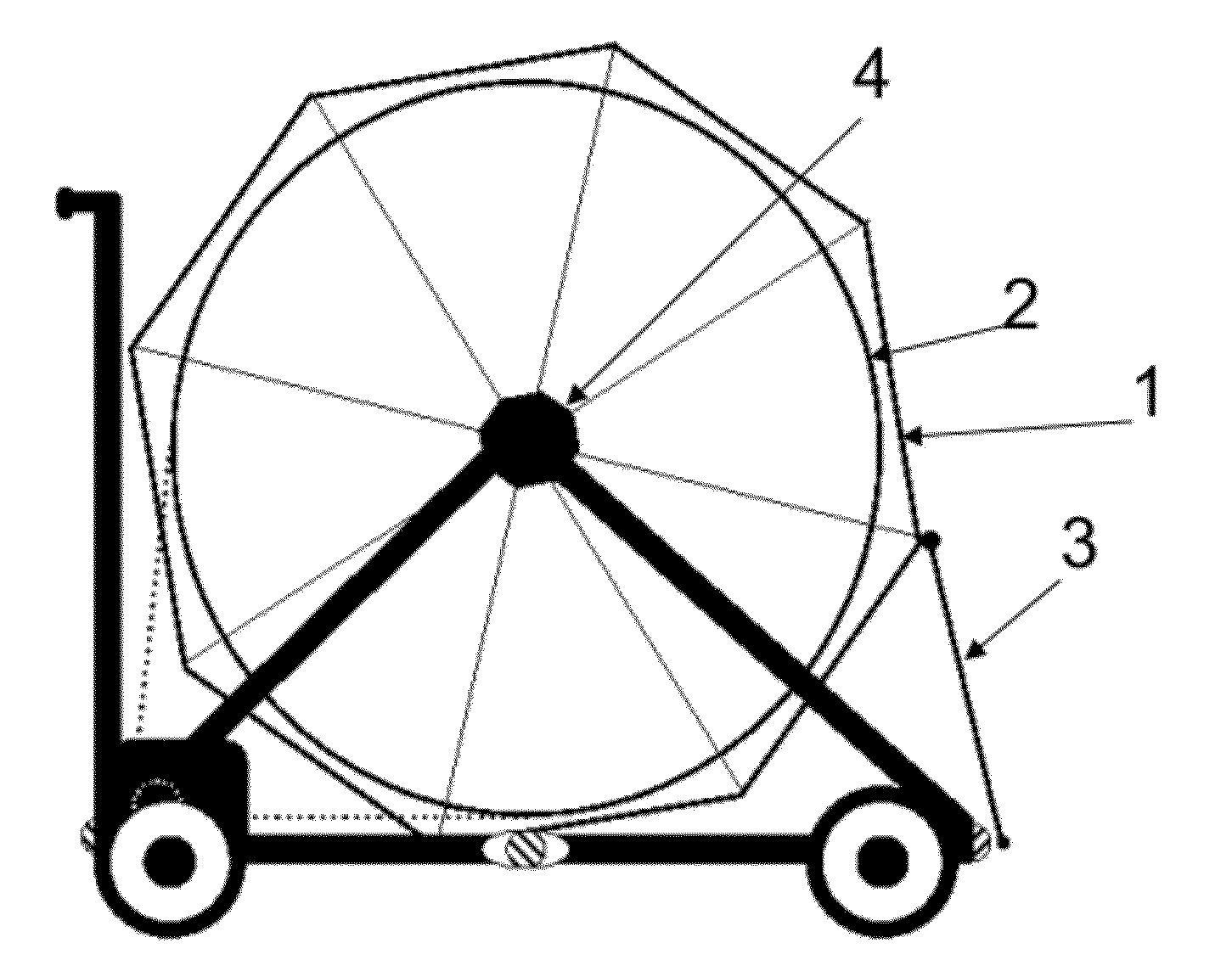

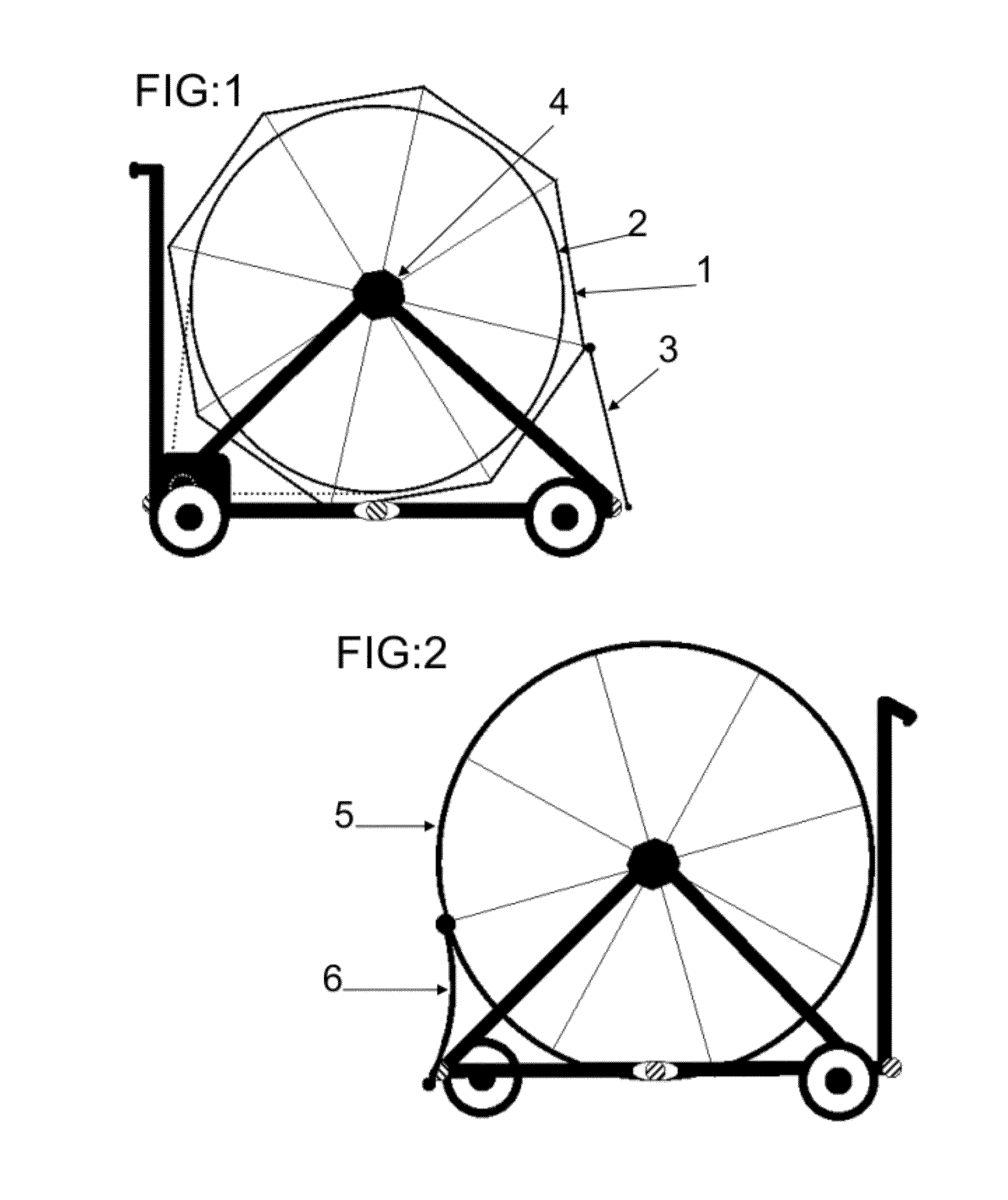

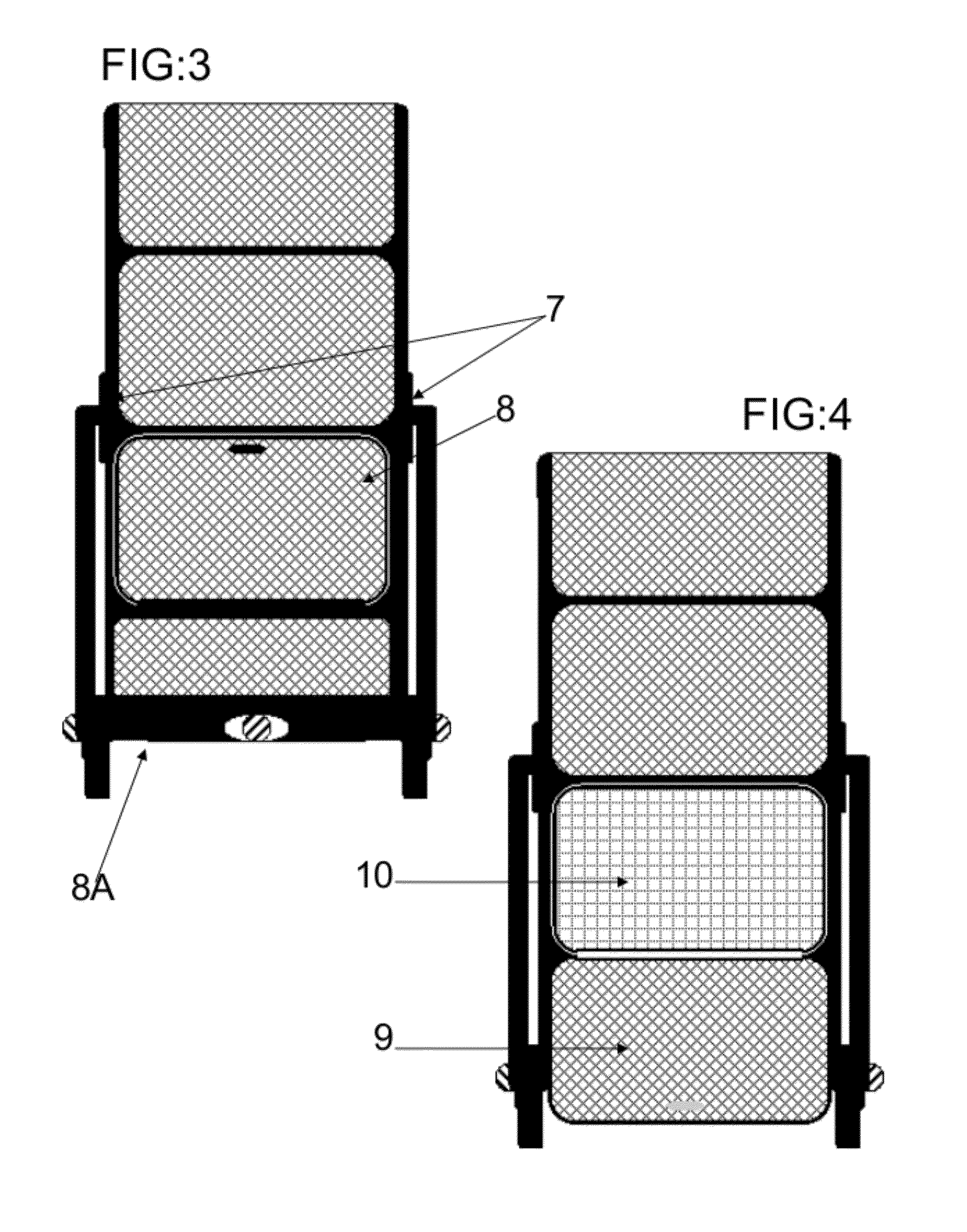

[0133]The object of the present invention is to enhance the efficiency and ease of use, increase safety, allow wider application and lower cost of the already energy saving ambient air dryer by utilizing improved manufacturing technology and present availability of materials; and providing cost effectiveness. Use of motion / heat sensors and eliminating the guard as shown in a previous patent makes the dryer lighter in weight and easier to move. In addition, the elimination of the guard makes for easier access to put items in and take items out of the dryer, increases the air flow through the dryer drum reducing drying time, and increases the visibility of items in the dryer when running. Elimination of the guard also lowers the cost of manufacture and shipping, which in turn lowers the retail price to the consumer.

[0134]Previous patents explained in detail a rotatable drum driven by a belt and a rotatable drum driven by rollers. Both of these methods function suitably. Manufacturers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com