Compression method and air separation

a technology of air separation and compression method, which is applied in the direction of machines/engines, positive displacement liquid engines, light and heating apparatus, etc., can solve the problems of loss in efficiency and likely not operating along the peak efficiency operating line, and achieve the effect of less power, less power, and more energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

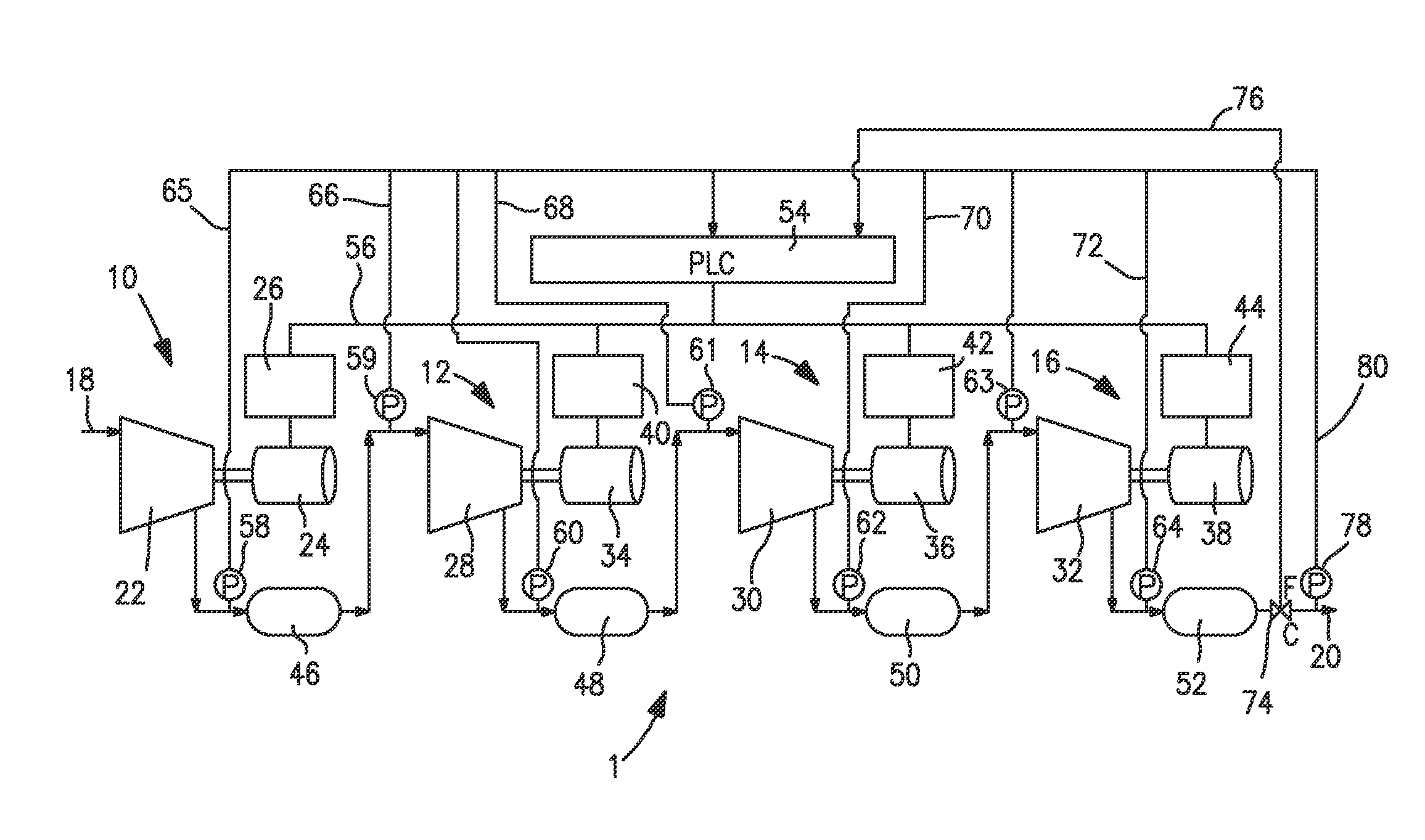

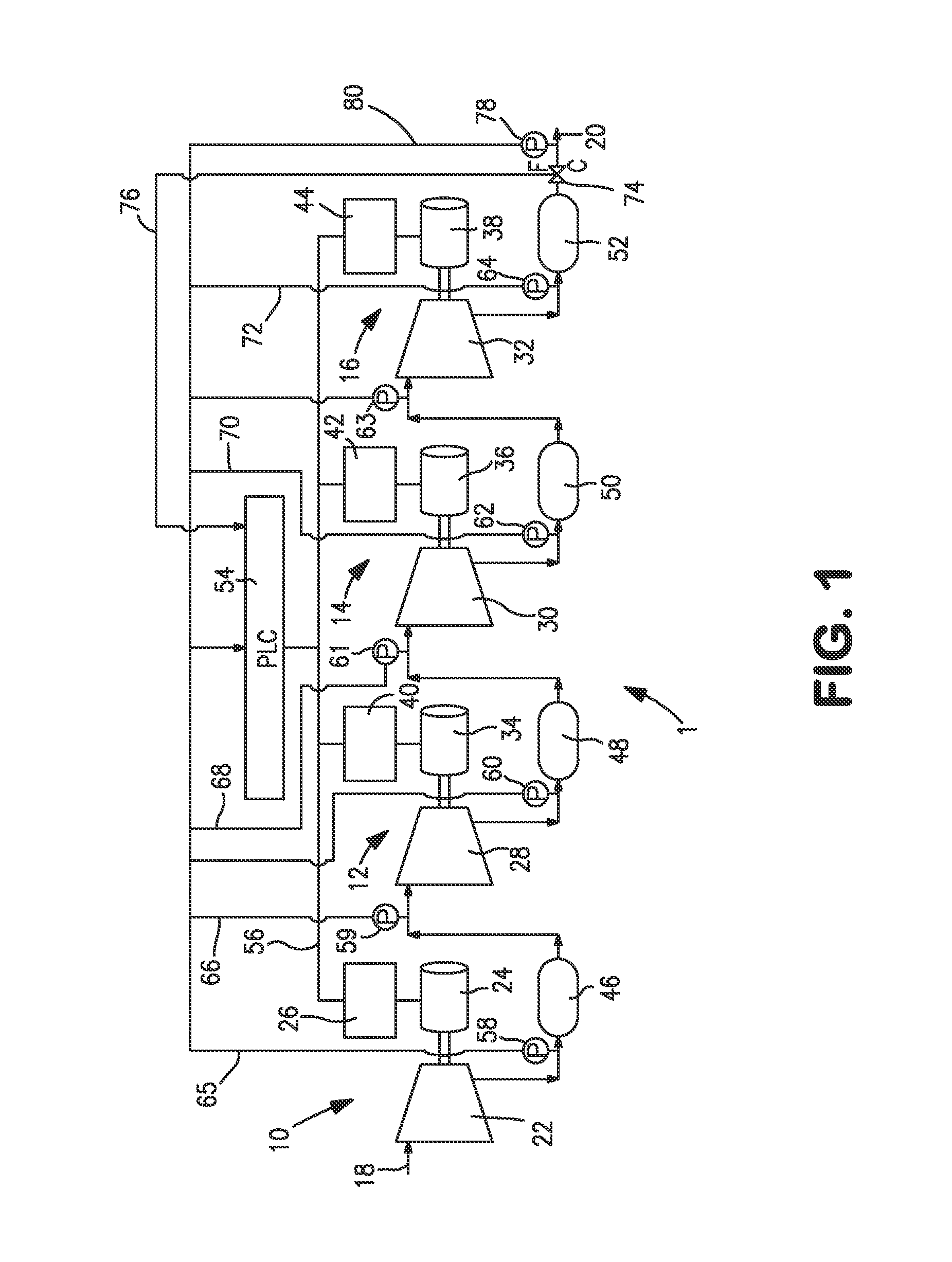

[0023]With reference to FIG. 1, a multistage compression system 1 in accordance with the present invention is illustrated. Multistage compression system 1 is a multistage compression unit having four compression stages 10, 12, 14 and 16 that is designed to compress a gas contained in a feed stream 18 from a lower pressure to a higher pressure and thereby produce a compressed gas stream 20 containing the gas at the higher pressure. It is understood that a multistage compression system in accordance with the present invention could include a greater or lesser number of stages.

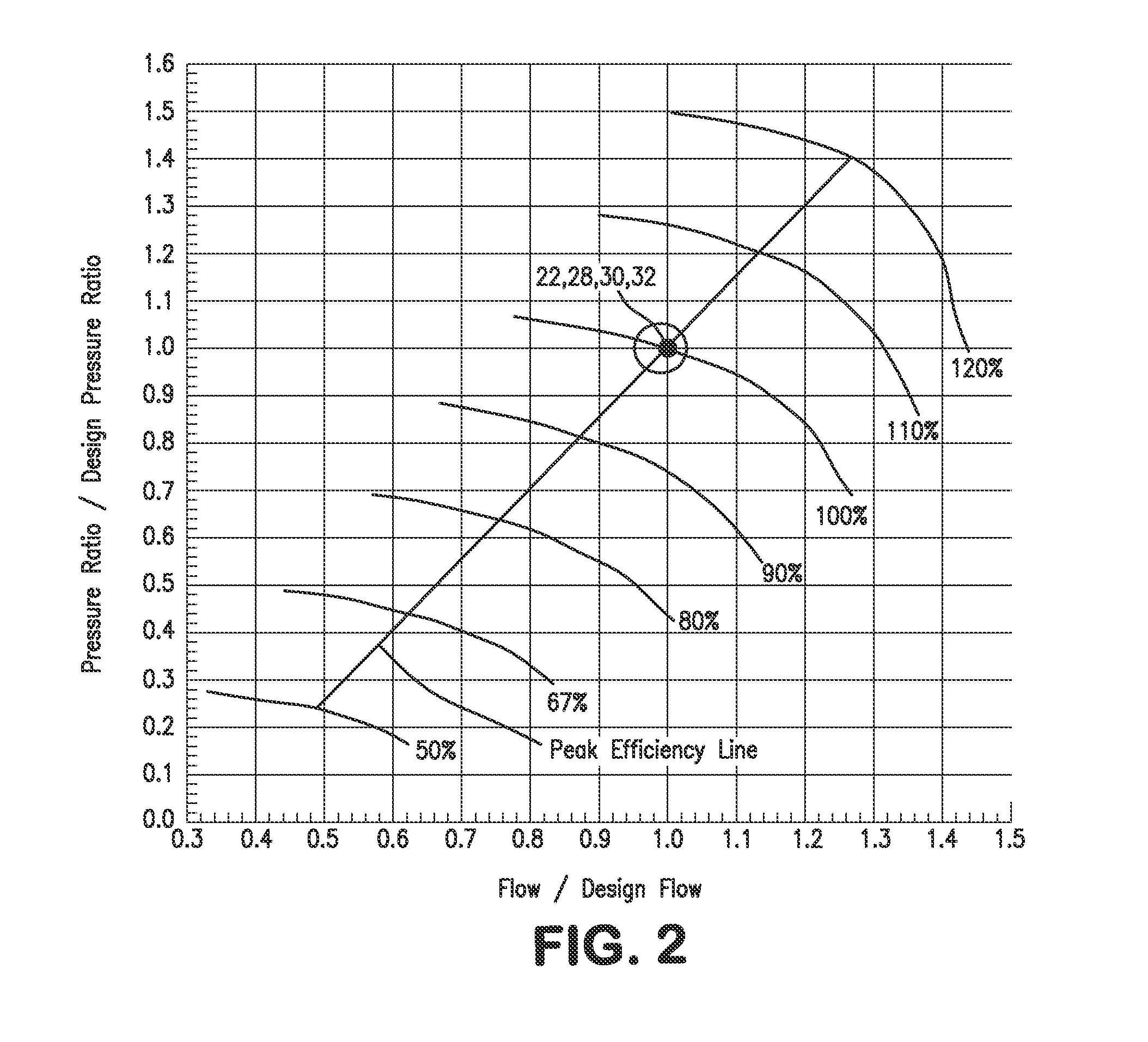

[0024]Compression stage 10 is provided with a compressor 22 that is driven by a variable speed motor 24. It is understood that the compressor 22 can be centrifugal compressor of the type described above that is driven by a variable speed electric permanent magnet motor. In compression stage 10, the variable speed motor 24 is controlled by a speed controller 26 that could be a variable frequency controller where t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com