Modular top frame

a top frame and module technology, applied in the field of palletized units, can solve the problems of reducing storage costs, reducing the strength of crush, and putting additional weight on the top frame of palletized containers, so as to increase the resistance of corner members to bending, improve strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

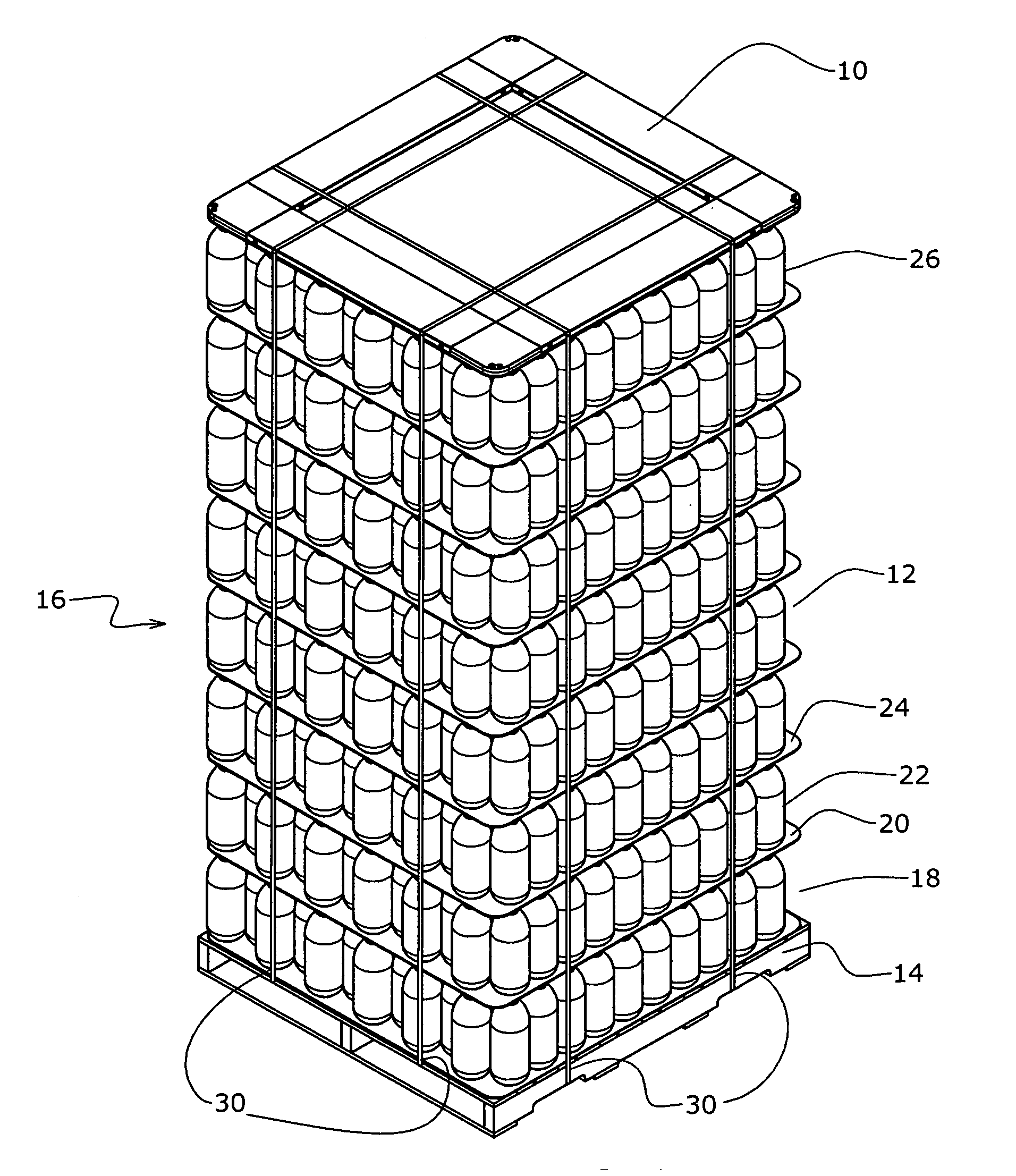

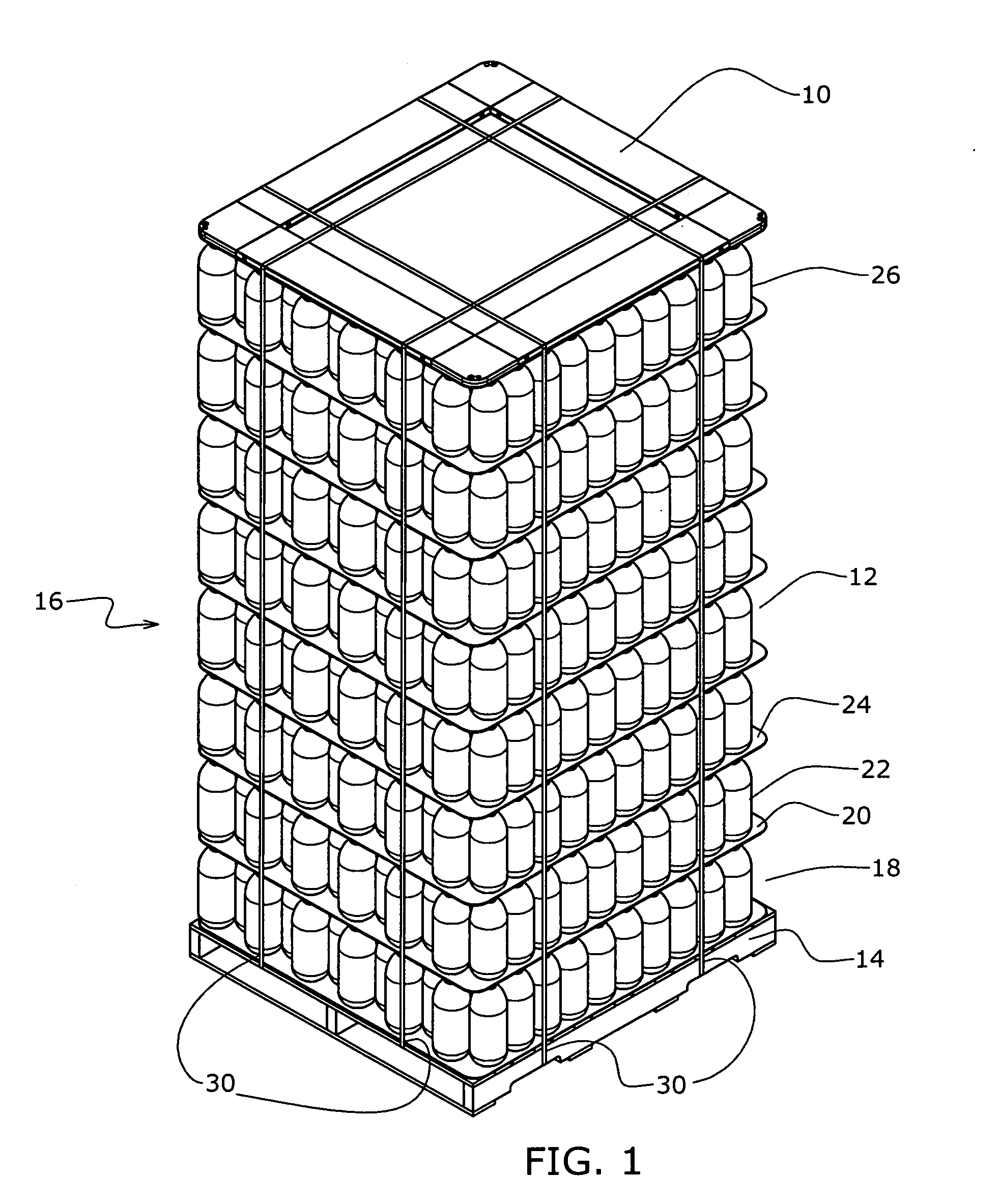

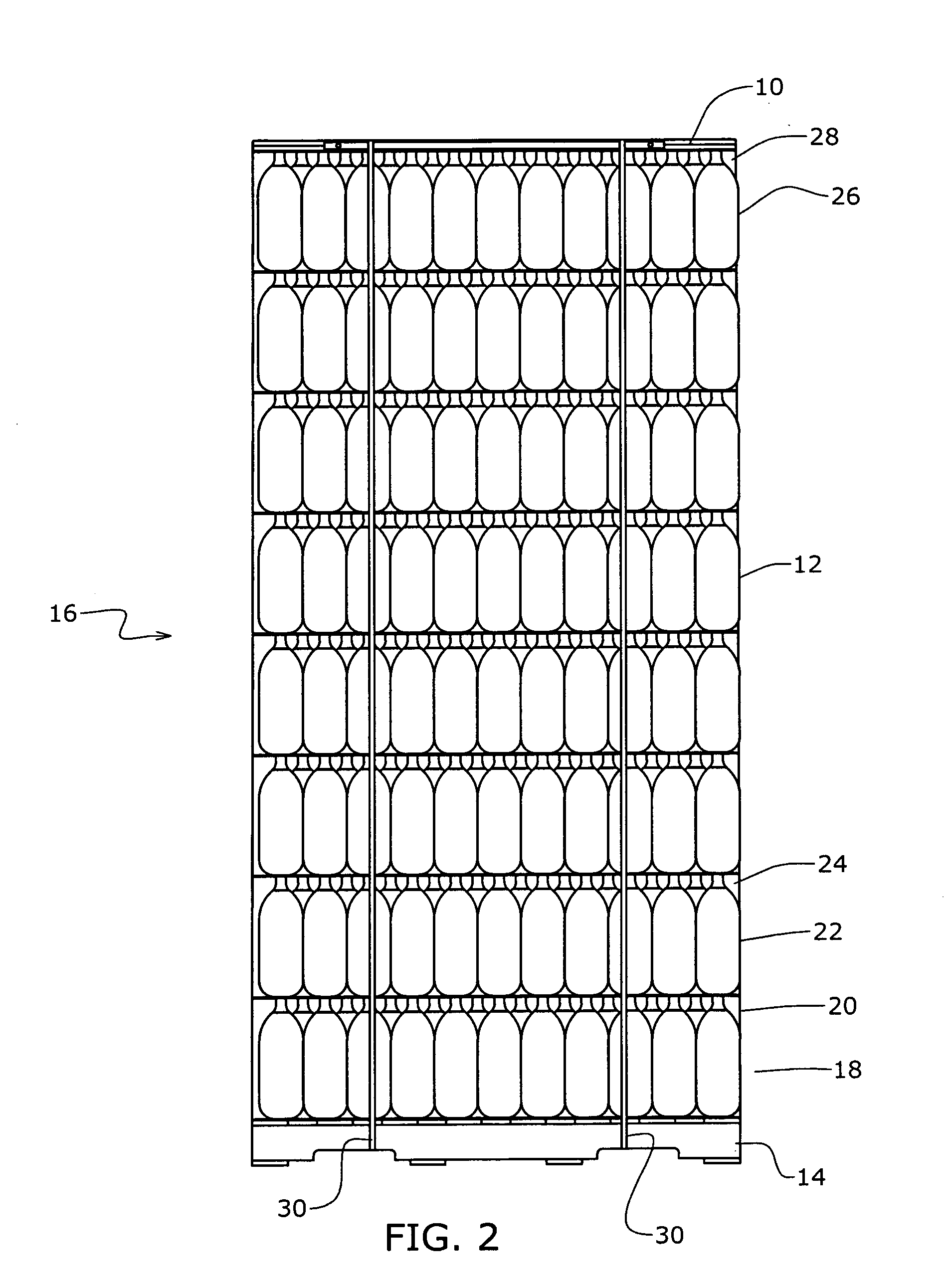

[0053]The present invention provides a modular top frame 10 with the above described desirable features that may be implemented in a variety of designs for restraining containers 12 on a pallet 14. For ease of description, the invention will be described in connection with the top frame 10 shown in FIGS. 1-15 and it should be understood that the advantageous features of the present invention may be used in connection with a variety of top frames.

[0054]The top frame 10 of the present invention is provided for use with a container palletized unit 16 as shown in FIGS. 1 and 2. Typically, in the beverage industry, empty containers 12, such as cans and plastic and glass bottles, are manufactured at one location and must be transported to another location where they can be filled and capped. To package these containers 12 for shipment, a first layer of the containers 18 are placed on a pallet 14. Typically, the pallet 14 may be made from a heavy duty plastic material or wood. Since these ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com