Method for the production of amorphous rifaximin

a technology of rifaximin and amorphous form, which is applied in the field of amorphous rifaximin production, can solve the problems of change form, unstable several forms, and serious consequences on maintaining the desired properties, and achieves the effects of increasing the solubility of amorphous forms, enhancing drug bioavailability, and increasing the solubility valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

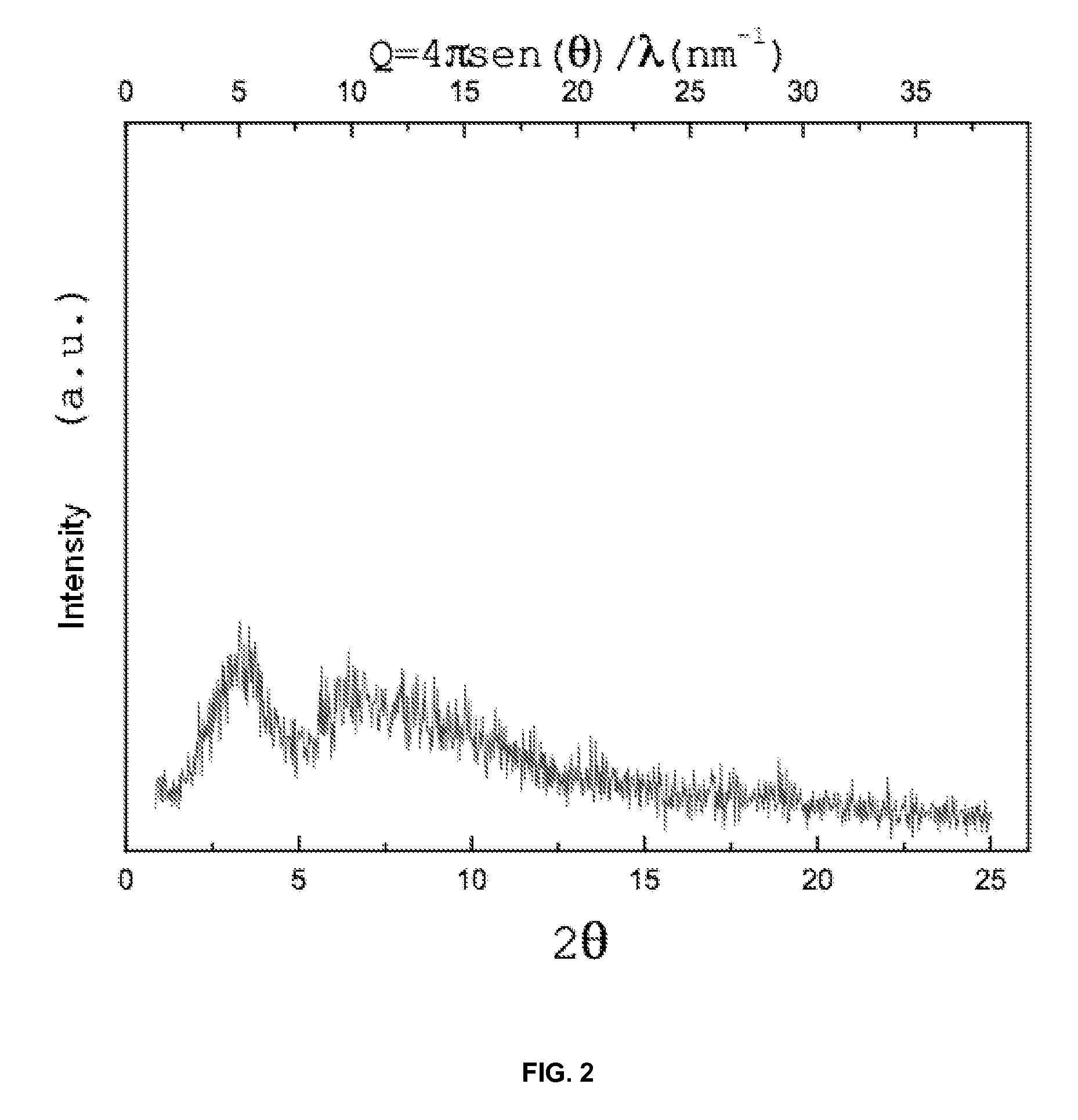

[0094]0.7 grams of rifaximin are placed in powder into a jar of the free volume of 40 cm3 and added with 2 12-mm-wide steel marbles (unitary mass 7.12 grams). The jar is closed and made integral to an apparatus of “shaker” type, actuated at about 900 revolutions / minute, equal to a frequency of impacts of about 60 impacts per second. Under optimum conditions the obtained energy transfer is in the order of 90-100 mJ per impact. The time length of the mechano-chemical action is equal to 15 minutes. The recovered material has amorphous structure and shows the XRD pattern shown in FIG. 2.

example 2

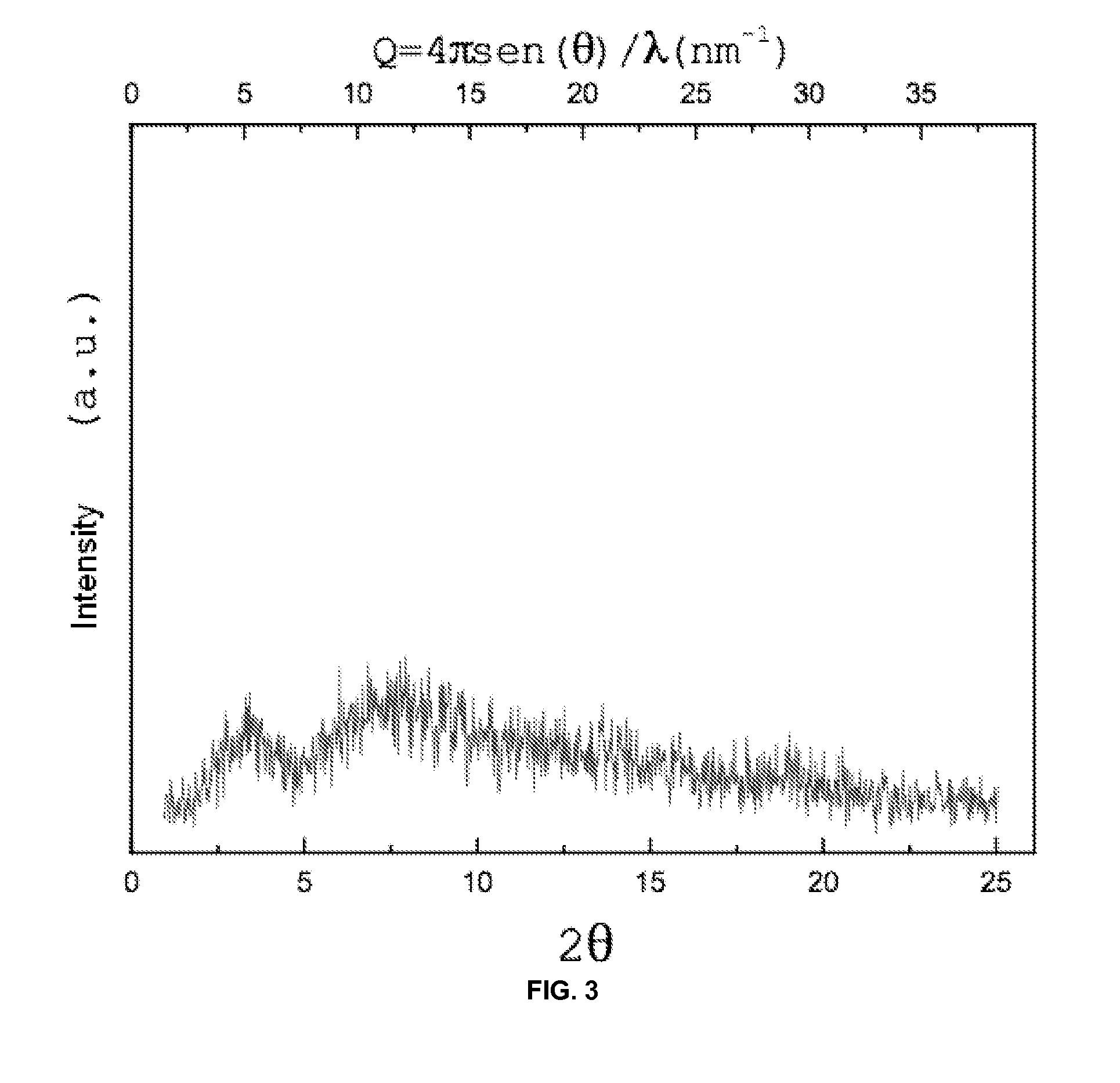

[0095]0.5 grams of rifaximin are placed in powder into a jar of the free volume of 40 cm3 and added with 4 8-mm-wide marbles of zirconium oxide (ZrO2) (unitary mass 1.63 grams). The jar is closed and made integral to an apparatus of “shaker” type, actuated at about 900 revolutions / minute, equal to an impact frequency of about 120 impacts per second. Under optimum conditions the obtained energy transfer is in the order of 20-25 mJ per impact. The time length of the mechano-chemical action is equal to 60 minutes. The recovered material has amorphous structure and shows the XRD pattern shown in FIG. 3.

example 3

[0096]1 gram of rifaximin is placed in powder into a jar of the free volume of 40 cm3 and added with 4 10-mm-wide marbles of zirconia (ZrO2) (unitary mass 3.06 grams). The jar is closed and made integral to an apparatus of “shaker” type, actuated at about 900 revolutions / minute, equal to an impact frequency of about 120 impacts per second. Under optimum conditions the obtained energy transfer is in the order of 40-50 mJ per impact. The time length of the mechano-chemical action is equal to 60 minutes. The recovered material has amorphous structure and shows the XRD pattern shown in FIG. 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| 2θ | aaaaa | aaaaa |

| 2θ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com