Contact for silicon heterojunction solar cells

a silicon heterojunction, solar cell technology, applied in the direction of semiconductor devices, electrical devices, nanotechnology, etc., can solve the problem of low doping efficiency and achieve the effect of increasing the band offset with the substrate and effectively increasing the doping level over a single material conta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

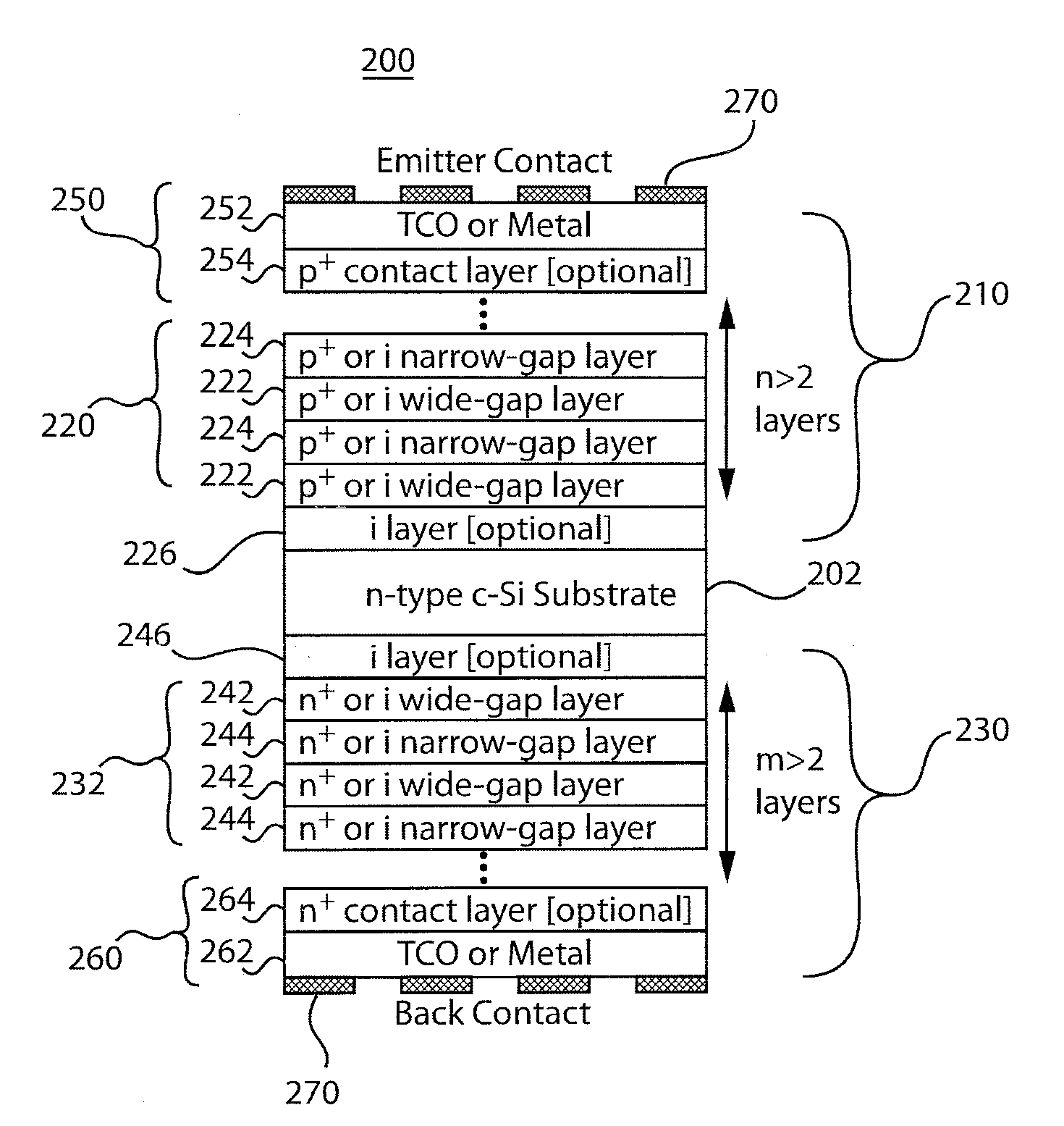

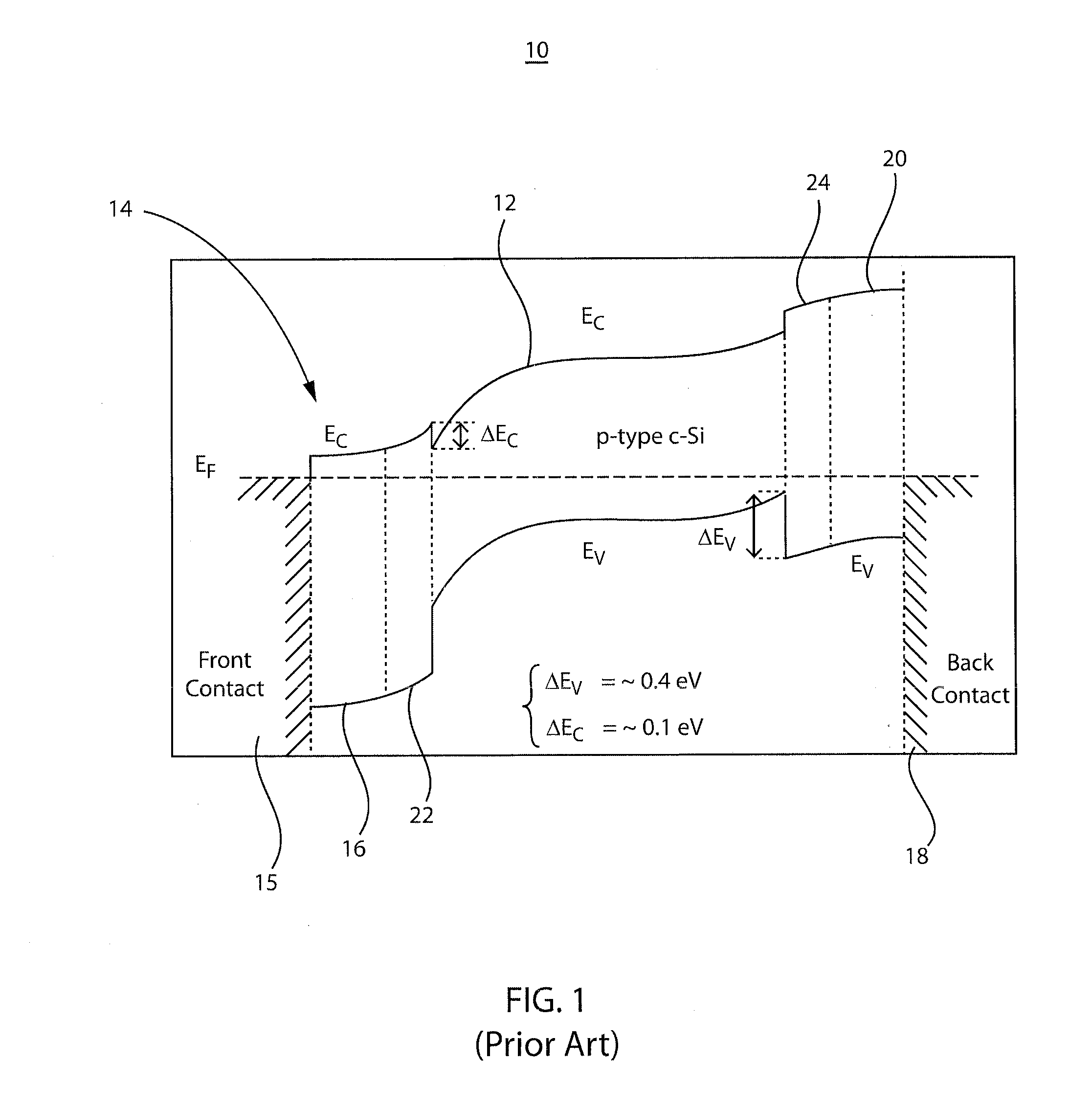

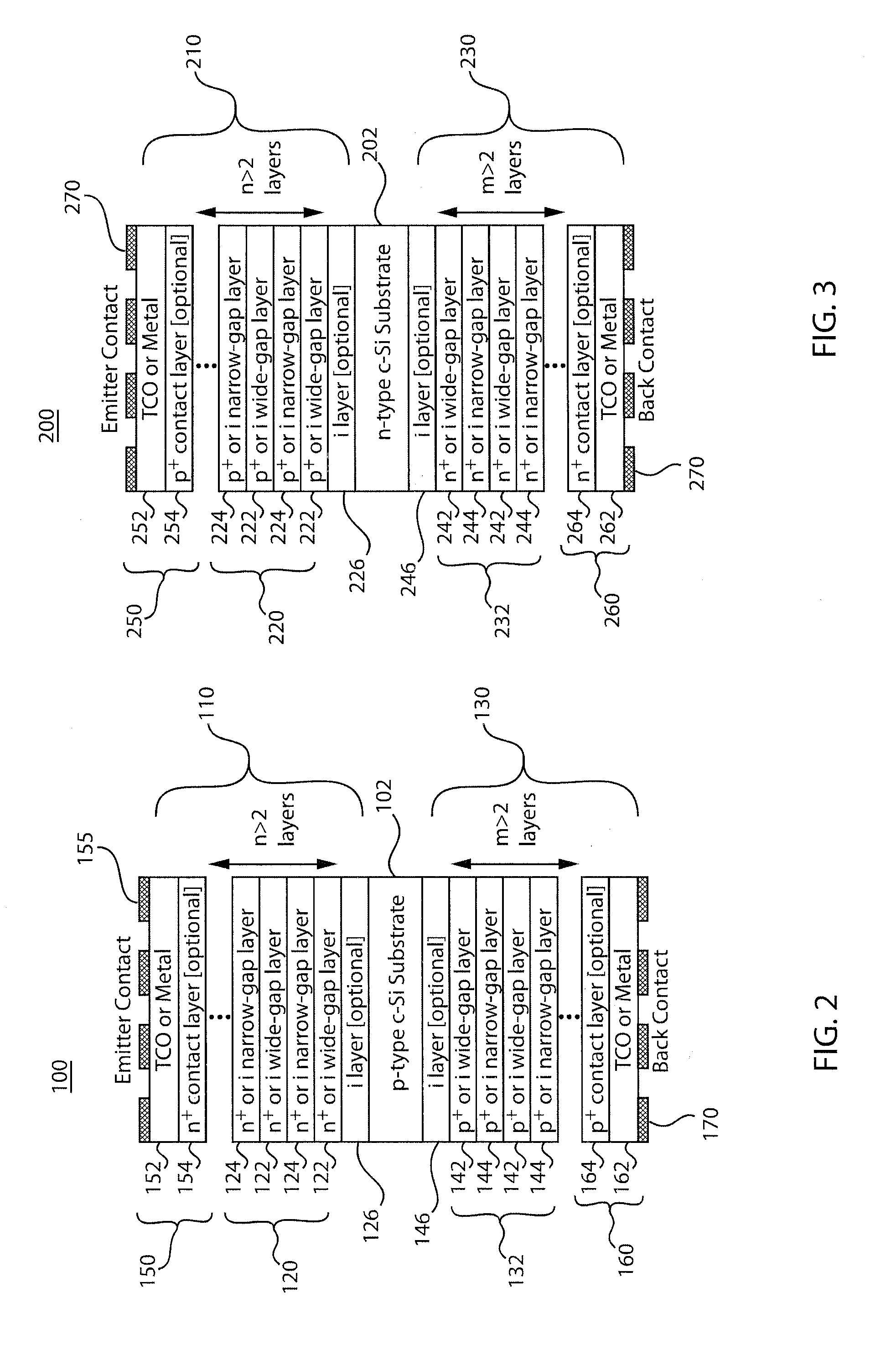

[0020]In accordance with the present principles, superlattice contact structures and methods for forming the same are provided for heterojunction solar cells. The superlattice structure improves open circuit voltage of the cell without compromising fill factor (FF). The open-circuit voltage is improved due to a larger effective band-offset of the superlattice contact and / or modulation (transfer) doping of a low band gap material in the superlattice without pinning the Fermi level. For example, n-type doping may be enhanced by the transfer of electrons from the wide bandgap material to the narrow band gap material or the transfer of holes from the narrow bandgap material to the wide band gap material. Likewise, p-type doping may be enhanced by the transfer of holes from the wide bandgap material to the narrow band gap material or the transfer of electrons from the narrow bandgap material to the wide band gap material. The fill factor is not compromised by overall reduced thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com