Pump

a rotary pump and rotary pump technology, applied in the direction of piston pumps, positive displacement liquid engines, liquid fuel engines, etc., can solve the problems of non-uniform sum of instantaneous flow rates that are pumped by the pump, non-uniform speed of fluid flow, and non-uniform flow rate of fluid that is forcibly delivered, so as to reduce the length of the route, prevent surging, and improve the structure of the power transmission system of the transmission uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

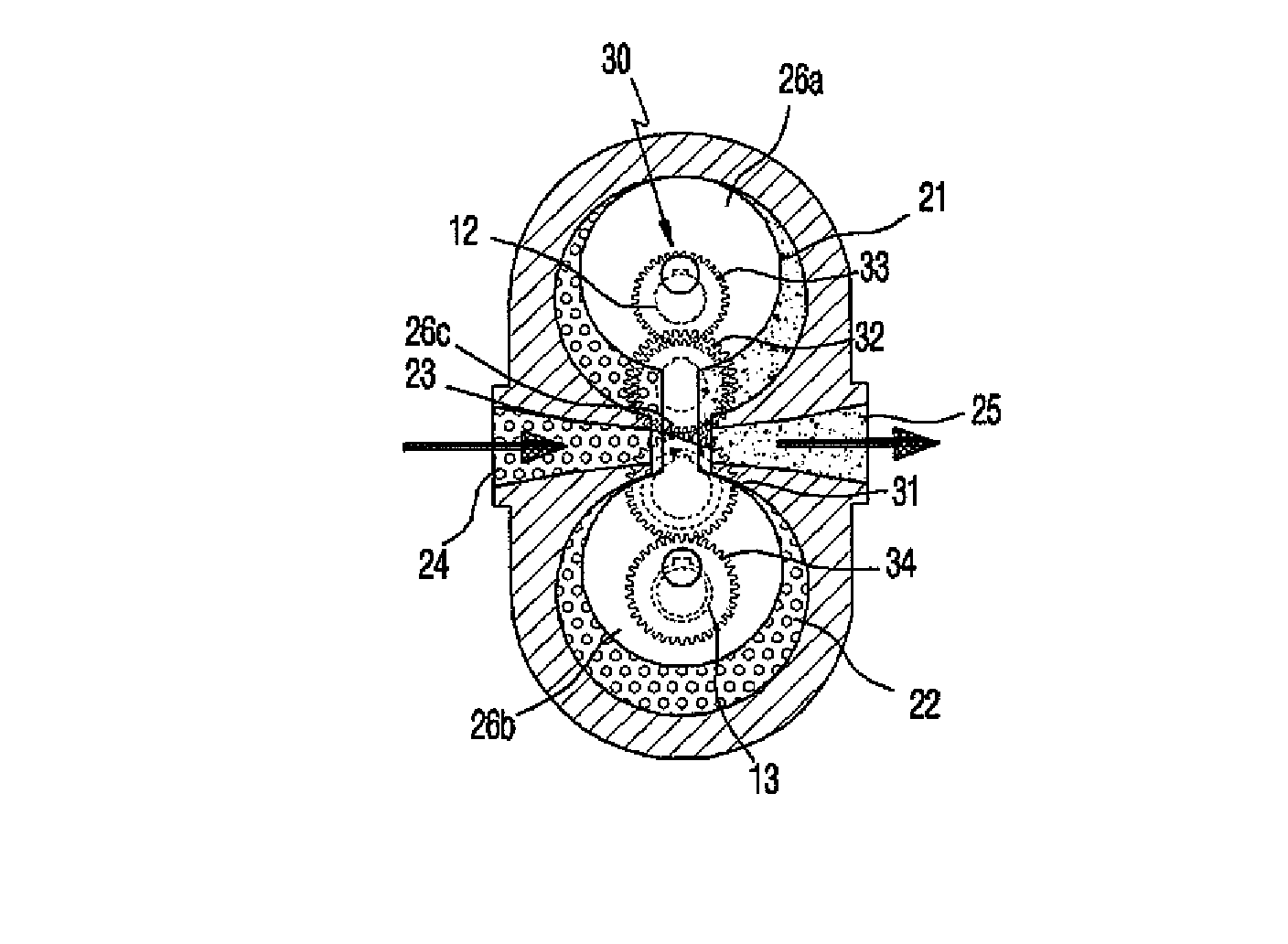

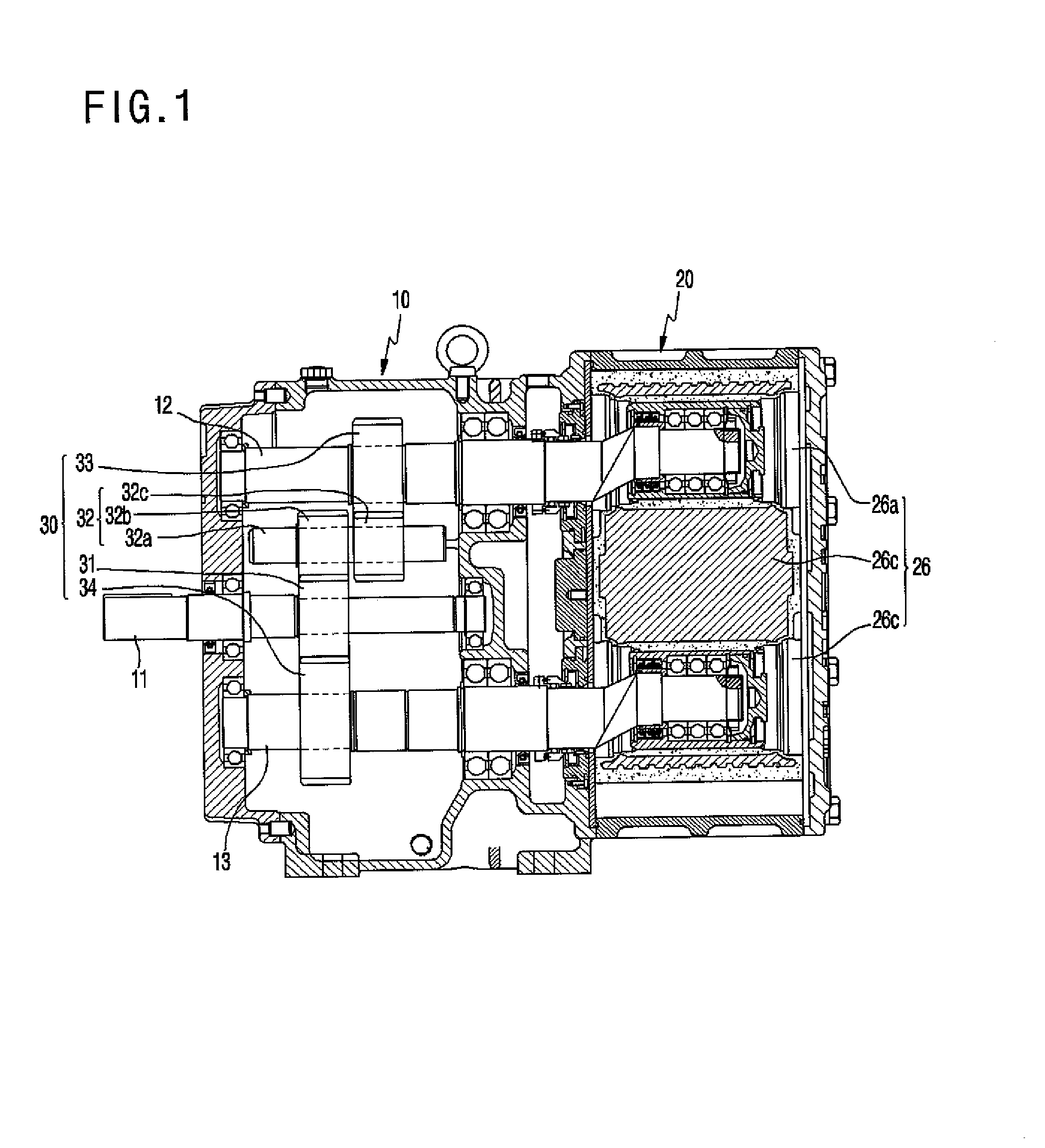

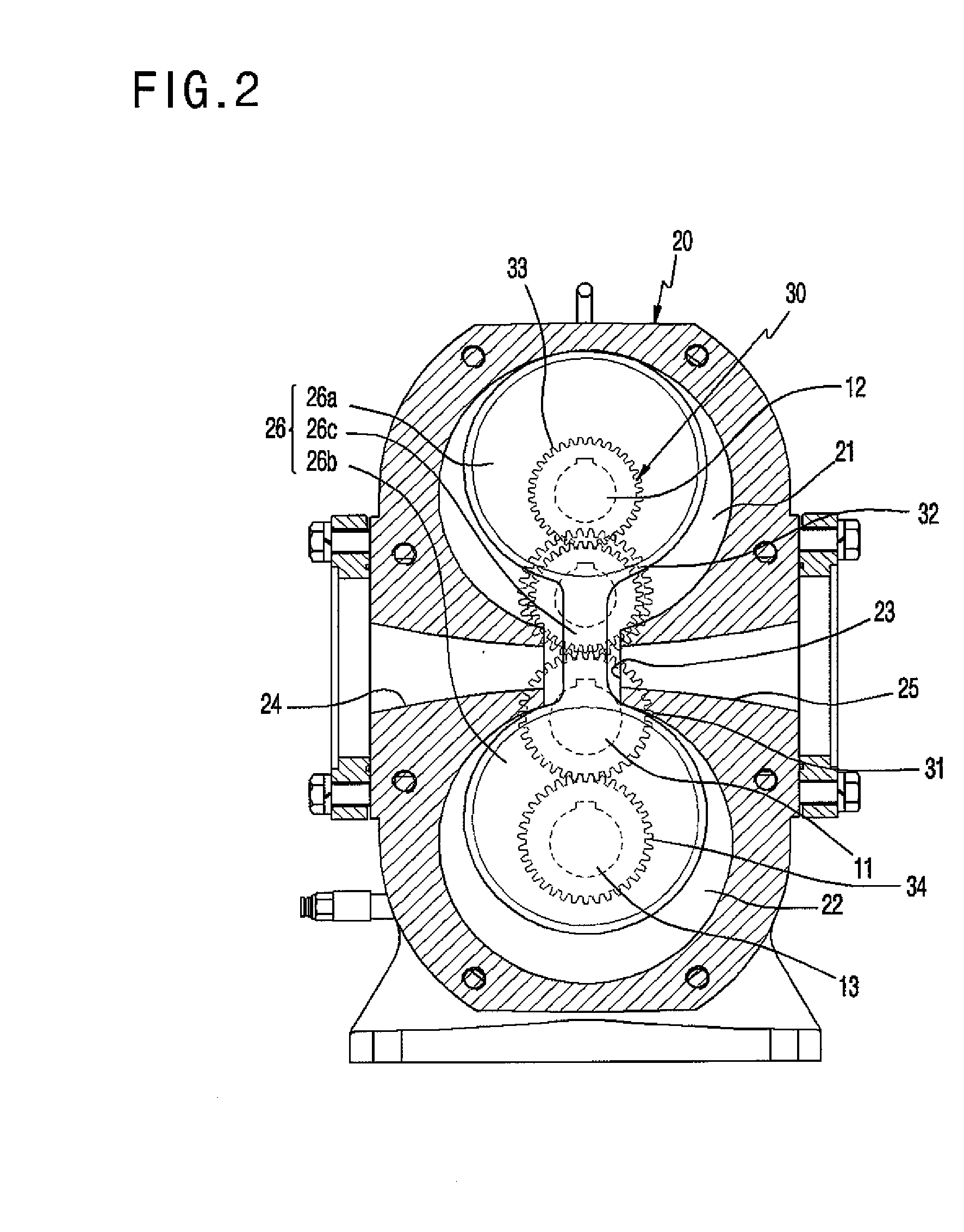

[0034]Reference will now be made in detail to various embodiments of the present invention, examples of which are illustrated in the accompanying drawings and described below. FIG. 1 and FIG. 2 show a pump according to an embodiment of the invention in detail. The invention provides a double action rotary pump, which is intended to forcibly deliver fluid such as liquid or gas.

[0035]The pump of this embodiment generally includes a transmission unit 10 and an operating unit 20, which are surrounded by respective casings such that they are isolated from each other.

[0036]First, the transmission unit 10 includes a main drive shaft 11 in the central portion of the body thereof, the main drive shaft 11 receiving driving force from a motor or the outside, a pair of crank-type first and second shafts 12 and 13, which are arranged in parallel in the upper and lower positions. The first and second shafts 12 and 13 are associated with the main drive shaft 11 and follow it via a power transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com