Metering system for releasing at least three different preparations during a washing programme of a washing machine

a technology of metering system and washing machine, which is applied in the direction of liquid transfer device, liquid handling, instruments, etc., can solve the problems of natural limits of this approach to solving the problem, and the quantity of ingredients used per washing cycle cannot be increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

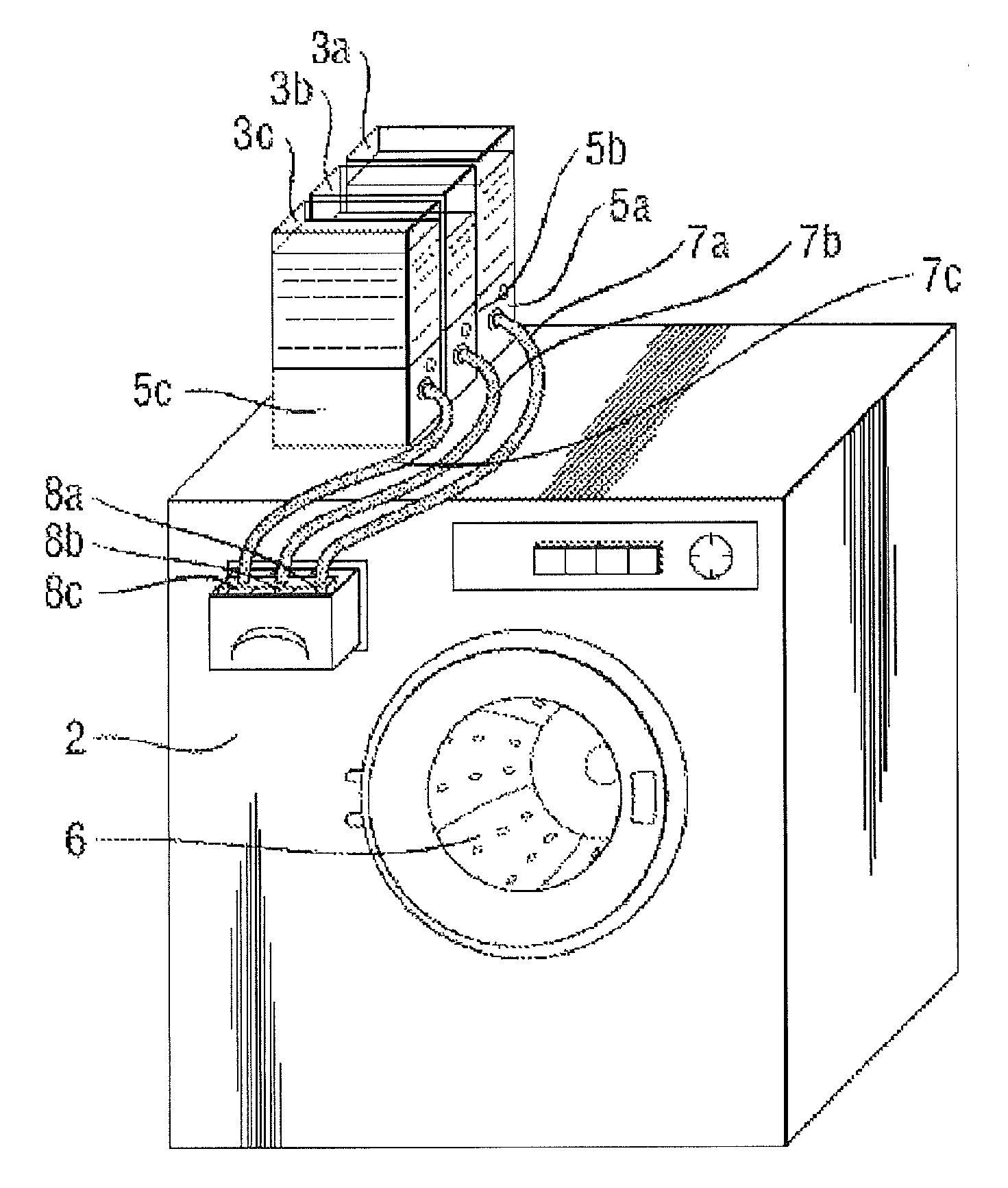

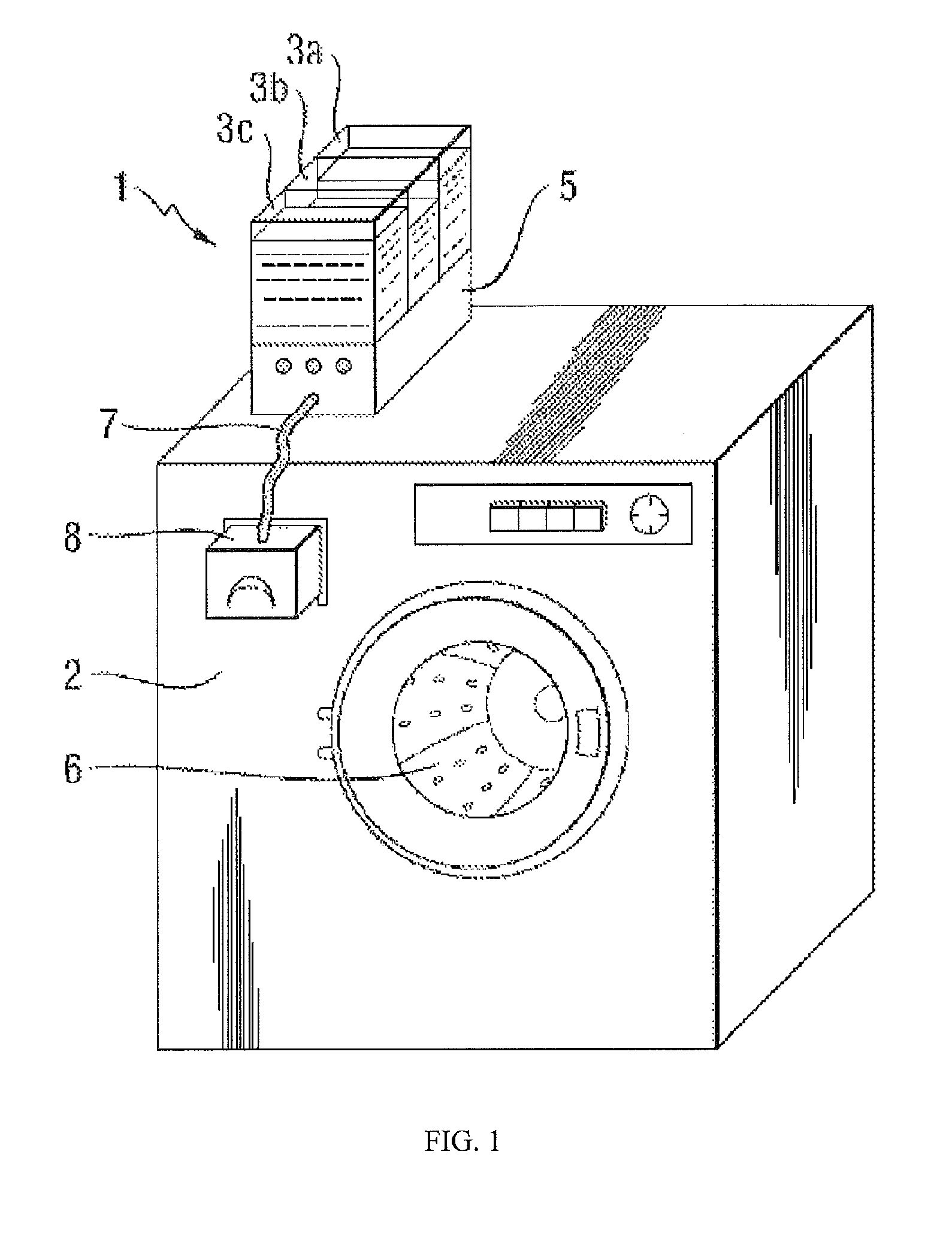

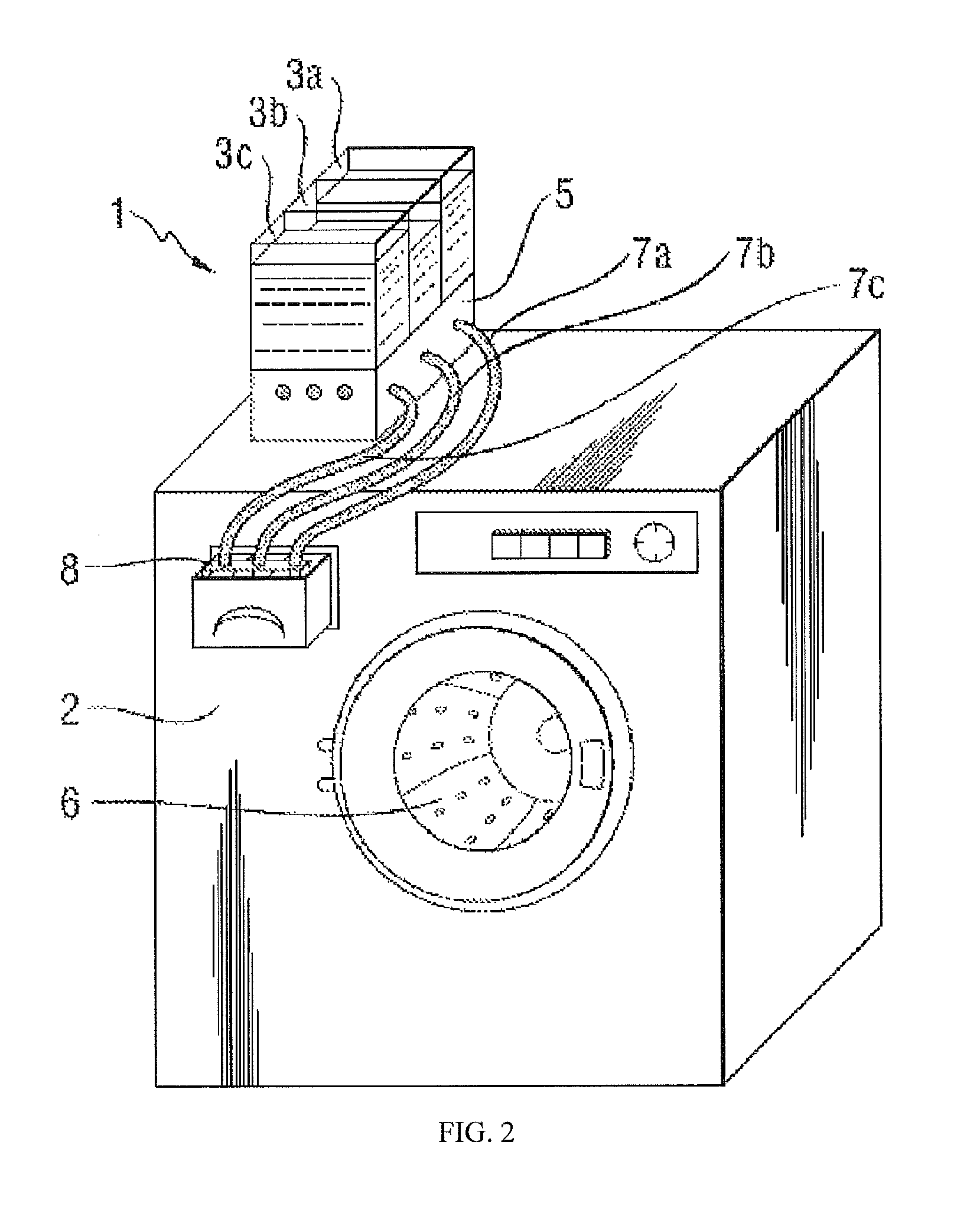

Image

Examples

example 1

[0209]Example 1 shows, in the table below, a first assignment of products to three cartridge chambers. The first chamber is here configured as the first enzyme chamber, the second chamber as the second enzyme chamber, the enzyme preparations of the first and second chambers being different from one another and the third chamber being configured as a scent chamber. It is very particularly preferable for the first chamber to store at least one enzyme, selected from the group of amylases, mannanases, cellulases, lipases and / or pectate lyases and at least one surfactant and / or complexing agent at a pH value of 6-8 and for the second chamber to store at least one protease and at least one surfactant and / or complexing agent at a pH value of 6-8.

[0210]Further components of respective chambers are stated in the following table.

[0211]Chamber 1 exhibits a substantially neutral pH value of between 6 and 8, chamber 2 preferably has a substantially neutral pH value of 6-8 while chamber 3 has an ...

example 2

[0215]Example 2 differs from Example 1 in that chamber 3 additionally contains a component for improving soft handle in the form of at least one surfactant, preferably a cationic surfactant. Suitable polymers may alternatively or additionally be used for improving soft handle.

Chamber 1Chamber 2Chamber 3EnzymeEnzyme (no protease)ProteaseEnzyme stabilizerXSurfactantXXXComplexing agentXScentXWaterXXXSolventXpH6-86-86-8Dispensing time0-15 min10-30 minAfter start ofa rinse section

example 3

[0216]Example 3 differs from Example 1 in that chamber 3 additionally contains an antimicrobial compound, for example a cationic disinfectant.

Chamber 1Chamber 2Chamber 3EnzymeEnzyme (no protease)ProteaseEnzyme stabilizerXSurfactantXXComplexing agentXScentXWaterXXXSolventXDisinfectantXpH6-86-81-3Dispensing time0-15 min10-30 minAfter start ofa rinse section

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com