Hydraulic Mining System for Tabular Orebodies Utilising Directional Drilling

a mining system and hydraulic technology, applied in the direction of borehole/well accessories, fluid removal, dislodge machines, etc., can solve the problems of roof cave in and form a goaf or gob, large amount of coal required for the production of heat and electrical energy in use today, and high cost, so as to achieve cost saving, easy movement, and short period of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

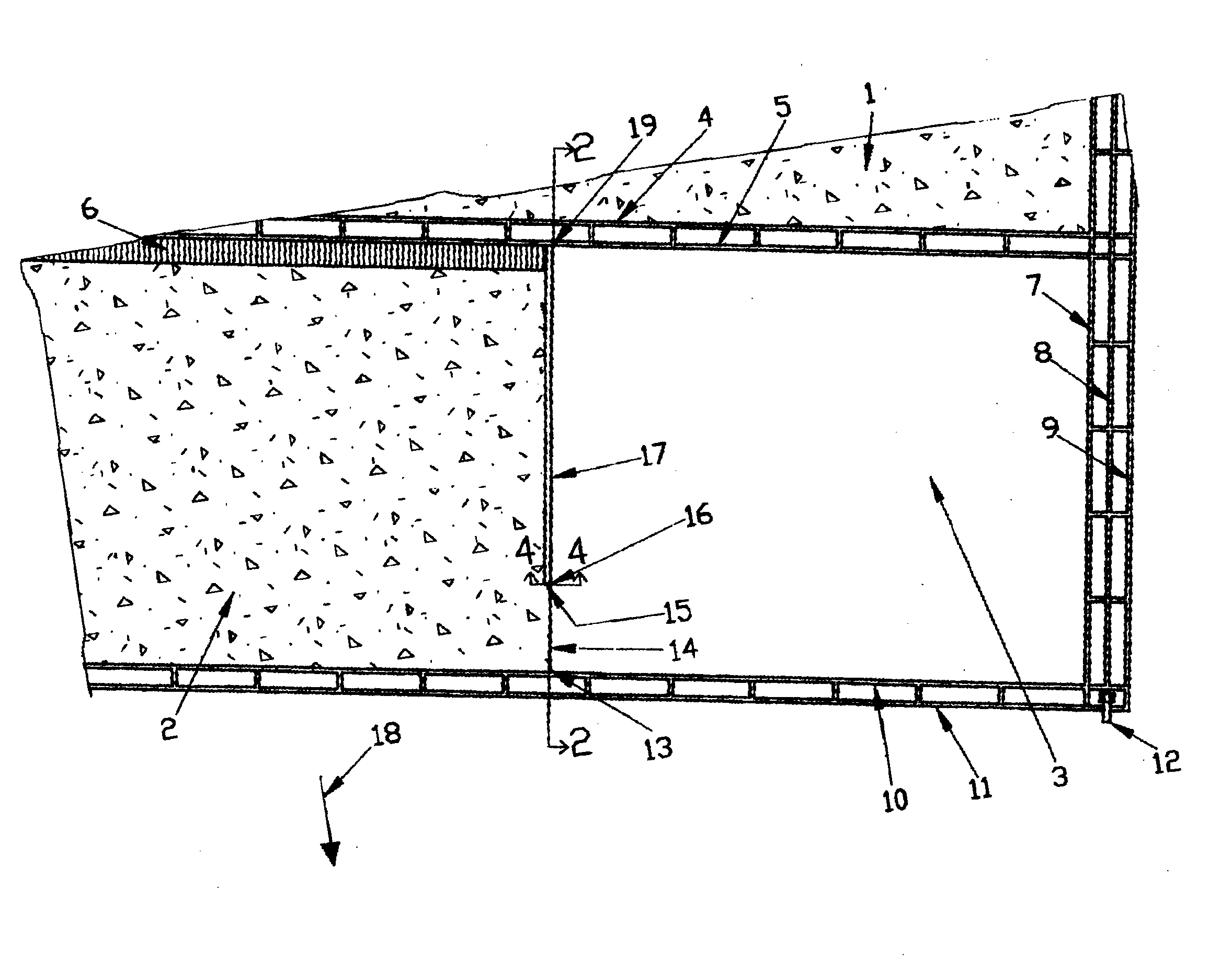

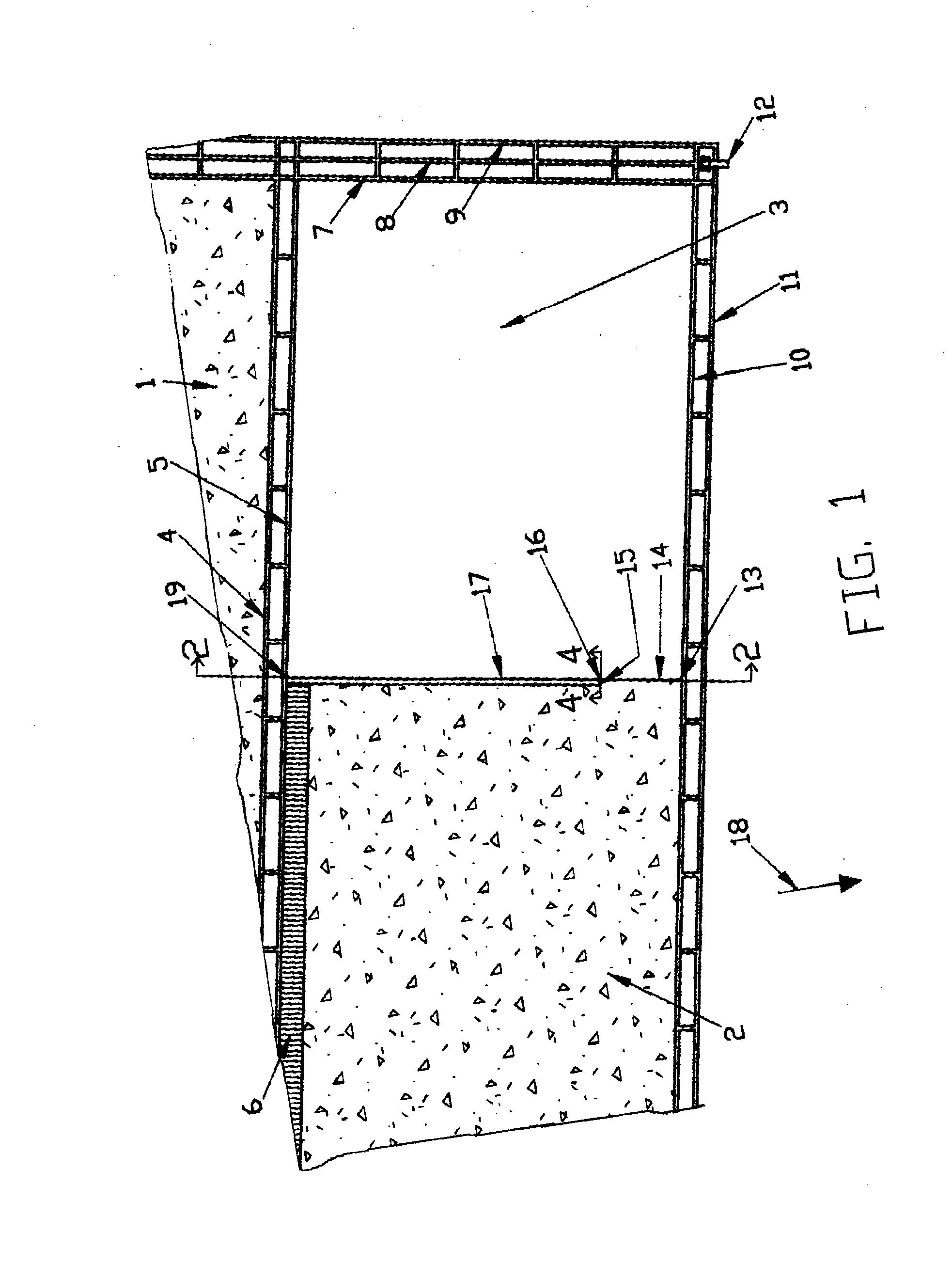

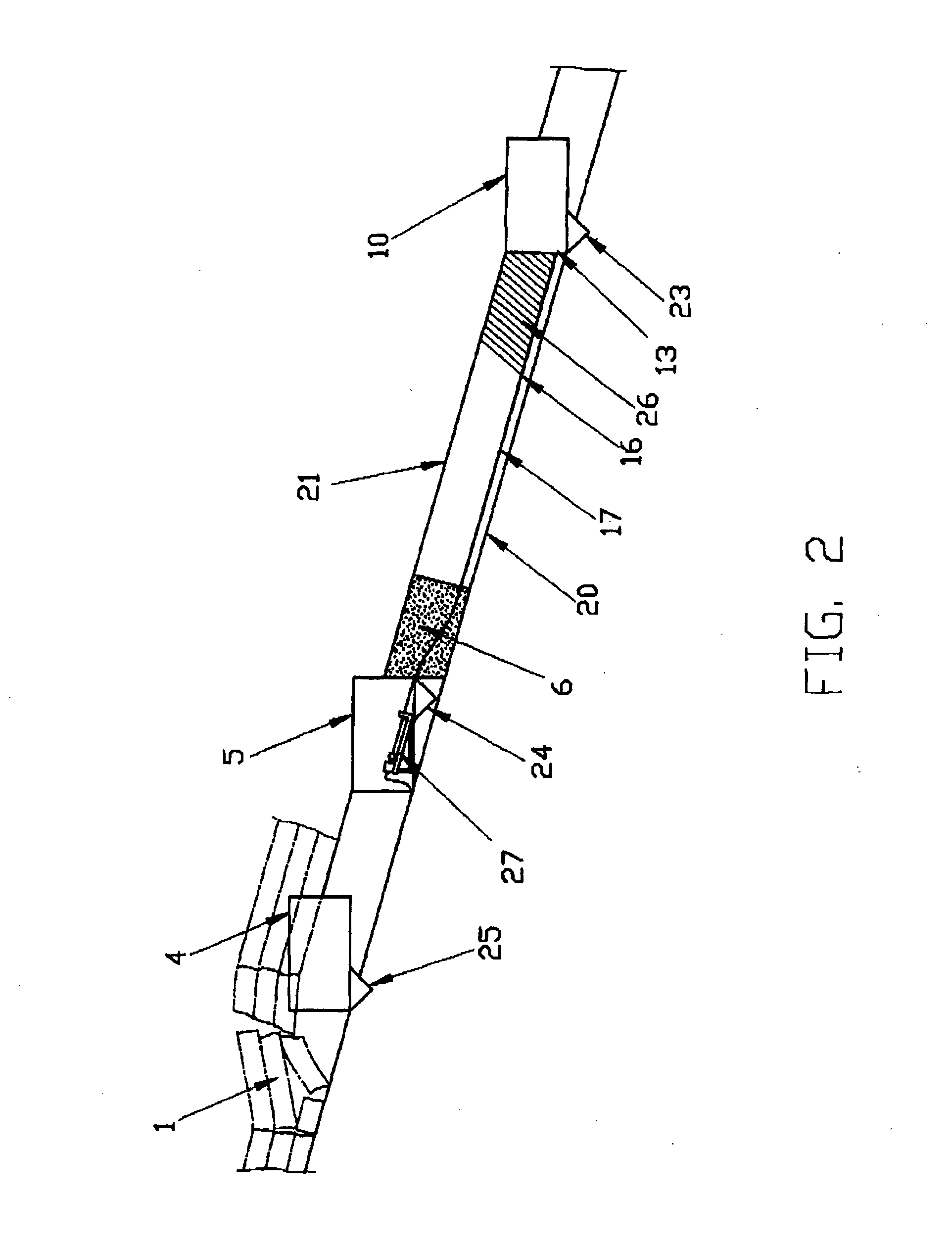

[0022]FIG. 1 illustrates a plan view of a mineral panel that is being mined by drilling down dip. The mining operation of the panel proceeds in the drawing of FIG. 1 to the right, with the goaf (2) to the left and the unmined orebody (3) to the right. The angle or dip of the panel of ore being mined is shown in FIG. 2, where the gateroad (10) is lower in elevation than the gateroad (5). The panel of ore of interest includes the solid deposit of ore (3) to be mined, as well as the goaf (2) that has been mined. The dip direction is marked by an arrow (18) in FIG. 1. illustrated also is a neighbour goaf (1) that was formed in the area of the previously mined neighbour panel. The neighbour goaf (1) is separated from the current mining panel, i.e. solid ore (3) and associated goaf (2), by gateroads (4, 5). On the lower side of the panel (2, 3) undergoing the mining operation are the lower elevation gateroads (10, 11). The gateroads (4, 5, 10, 11) slope downhill to the right of the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com