Liquid-liquid extraction unit, multistage liquid-liquid extraction apparatus using the unit, and multistage continuous extraction system for rare earth elements

a multi-stage liquid-liquid extraction and rare earth element technology, which is applied in the field of liquid-liquid extraction units, multi-stage liquid-liquid extraction apparatuses using the unit, and multi-stage continuous extraction systems for rare earth elements, can solve the problems of mixer-settler, loss of processing efficiency, and reaction cannot catch up at a high flow rate equivalent to the flow rate available, so as to achieve sufficient extraction efficiency and reduce the footprint , the effect of small siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

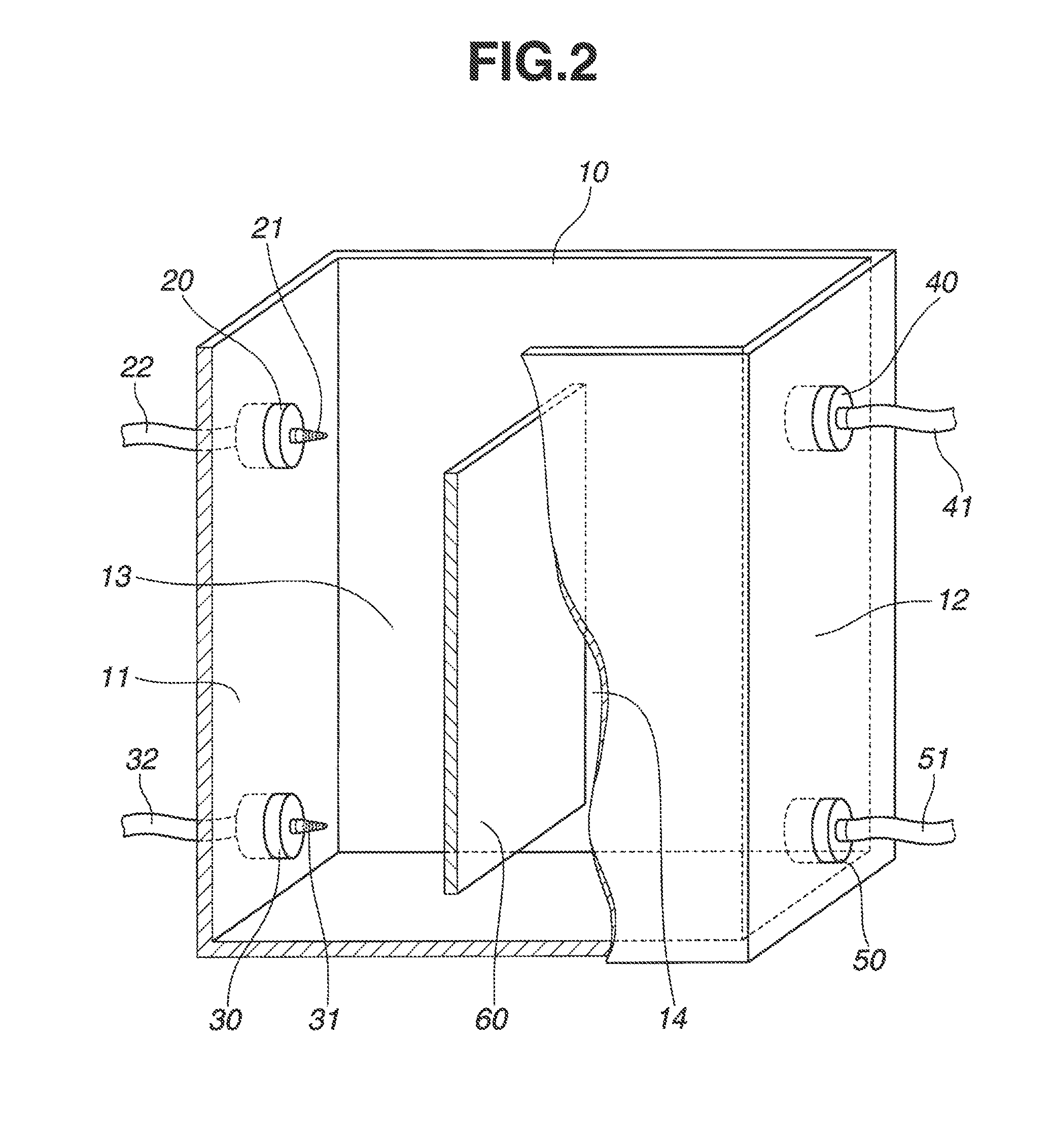

[0068]A multistage continuous extraction system was constructed as shown in FIG. 4. The system construction was the same as in FIG. 5 in Comparative Example except that extraction section A and scrubber section B were constructed using the liquid-liquid extraction units as shown in FIG. 2, and an alkali mixing section D for mixing a sodium hydroxide aqueous solution 3 with the organic phase 2 was disposed upstream of extraction section A. The back-extraction section C of 8 stages was constructed using a mixer-settler as in Comparative Example. The alkali mixing section D is a vessel dimensioned 80 mm×80 mm×200 mm and equipped with an impeller where the sodium hydroxide aqueous solution from line 3 is uniformly mixed with the organic phase 2 before the liquid is discharged or fed to extraction section A.

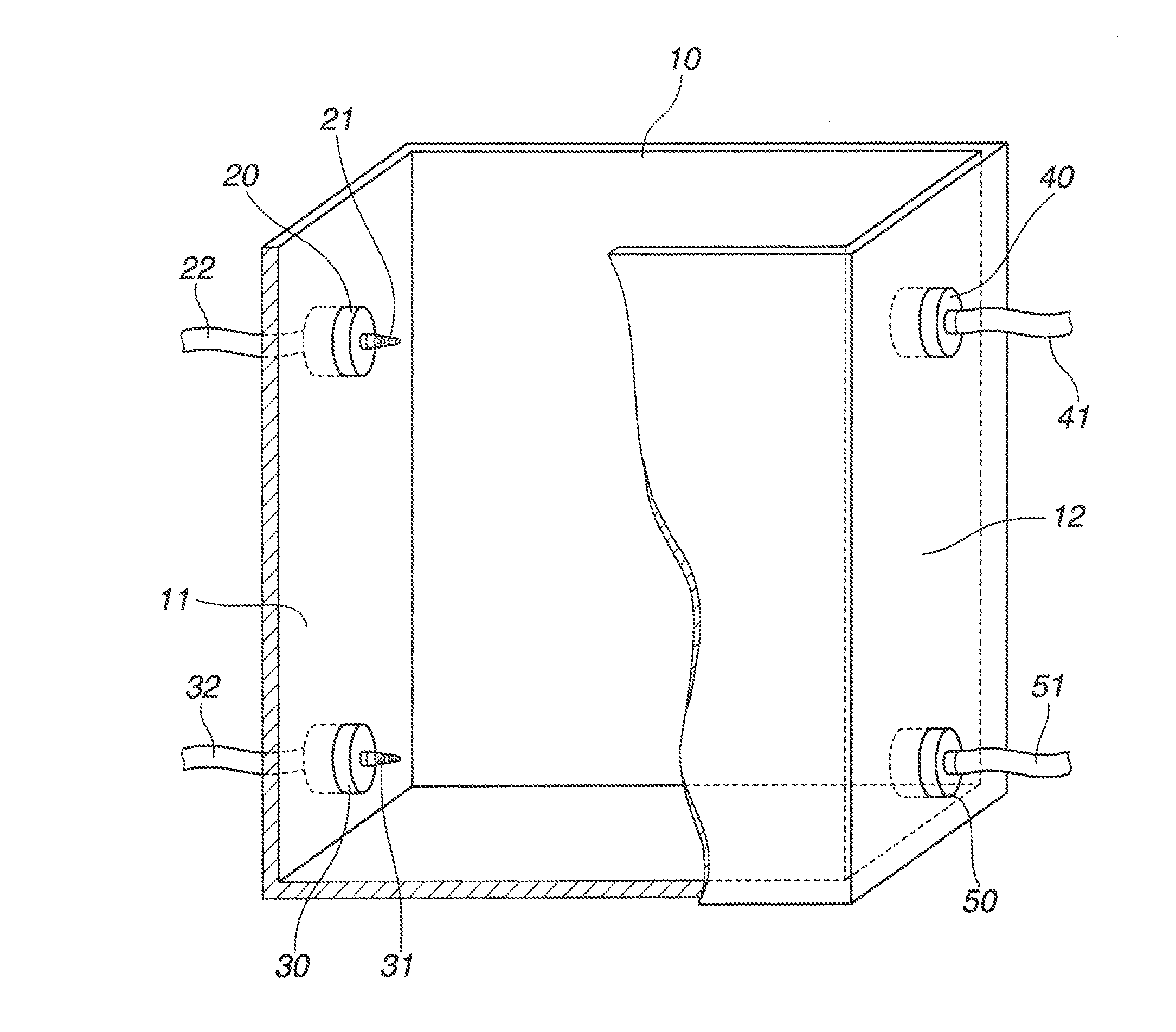

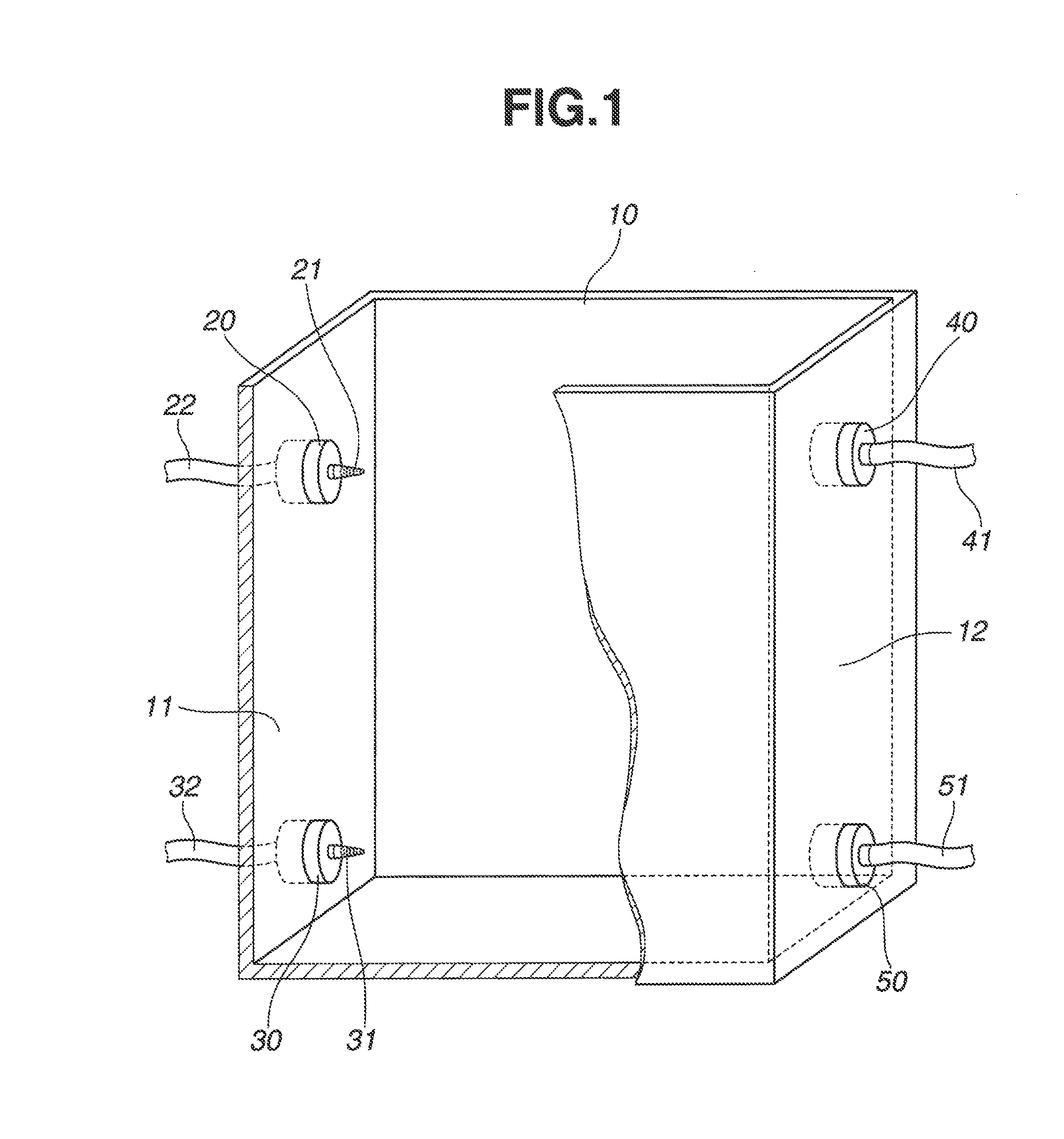

[0069]The liquid-liquid extraction unit shown in FIG. 2 is dimensioned 120 mm (W)×80 mm (D)×200 mm (H). A partition 60 of 5 mm×80 mm×170 mm (H) is disposed at a distance of 60 mm from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com