Undercoat agent and method of forming pattern of layer containing block copolymer

a technology of block copolymer and undercoat agent, which is applied in the direction of photomechanical equipment, instruments, photosensitive material processing, etc., can solve the problem of film thickness of the lower-layer film increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

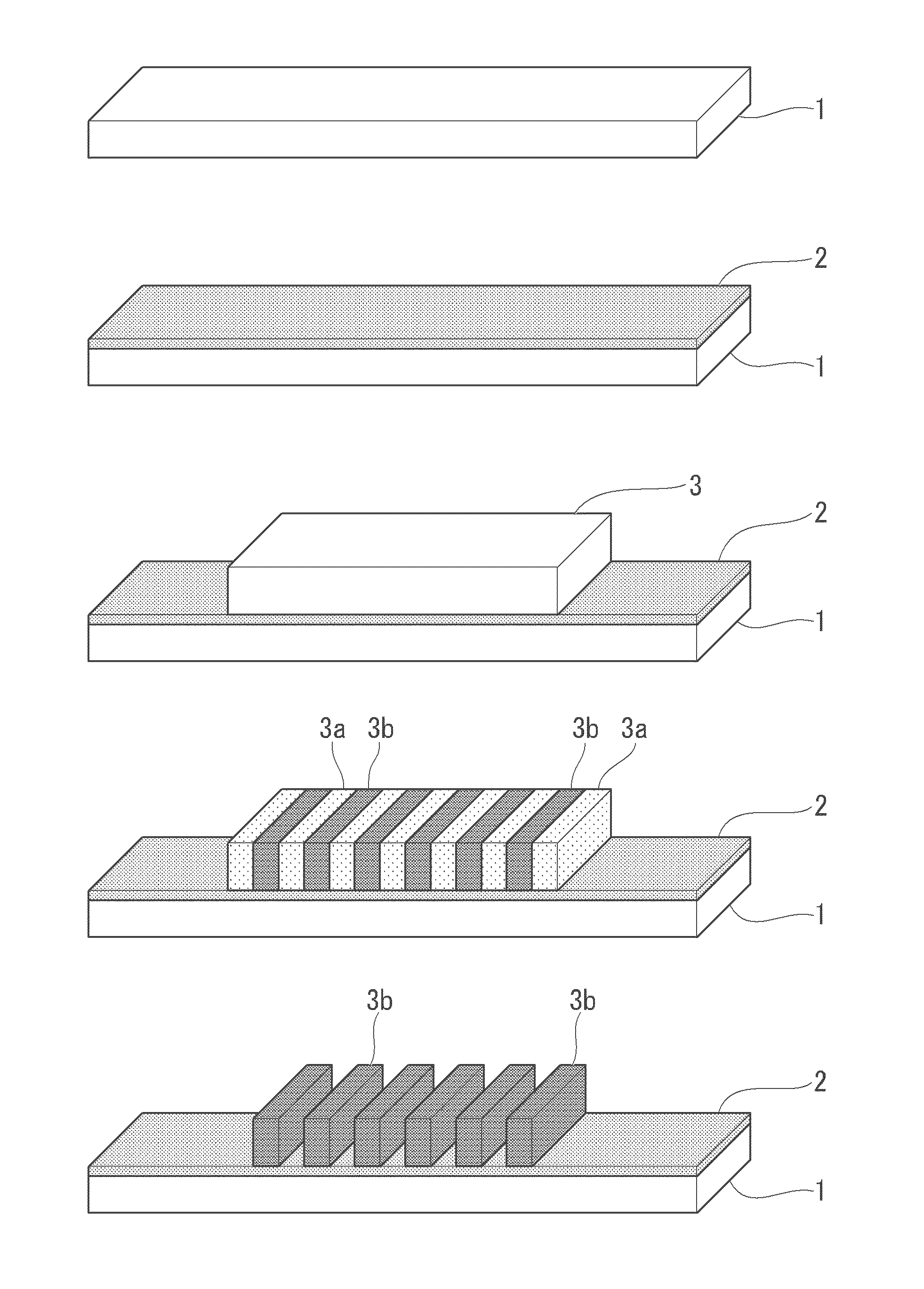

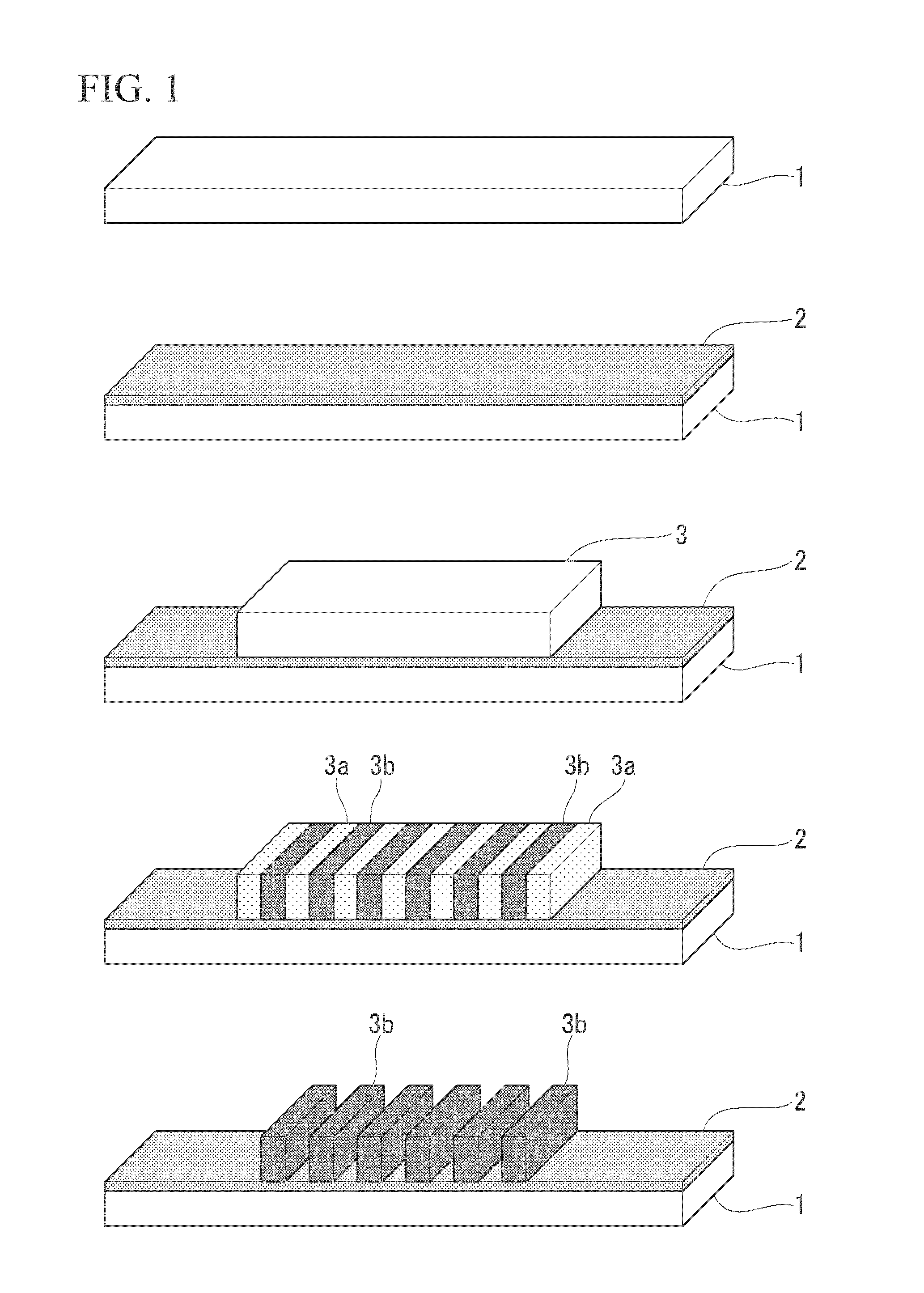

Image

Examples

examples

[0487]As follows is a description of examples of the present invention, although the scope of the present invention is in no way limited by these examples.

[0488][Production of Polymeric Compounds 1 to 9]

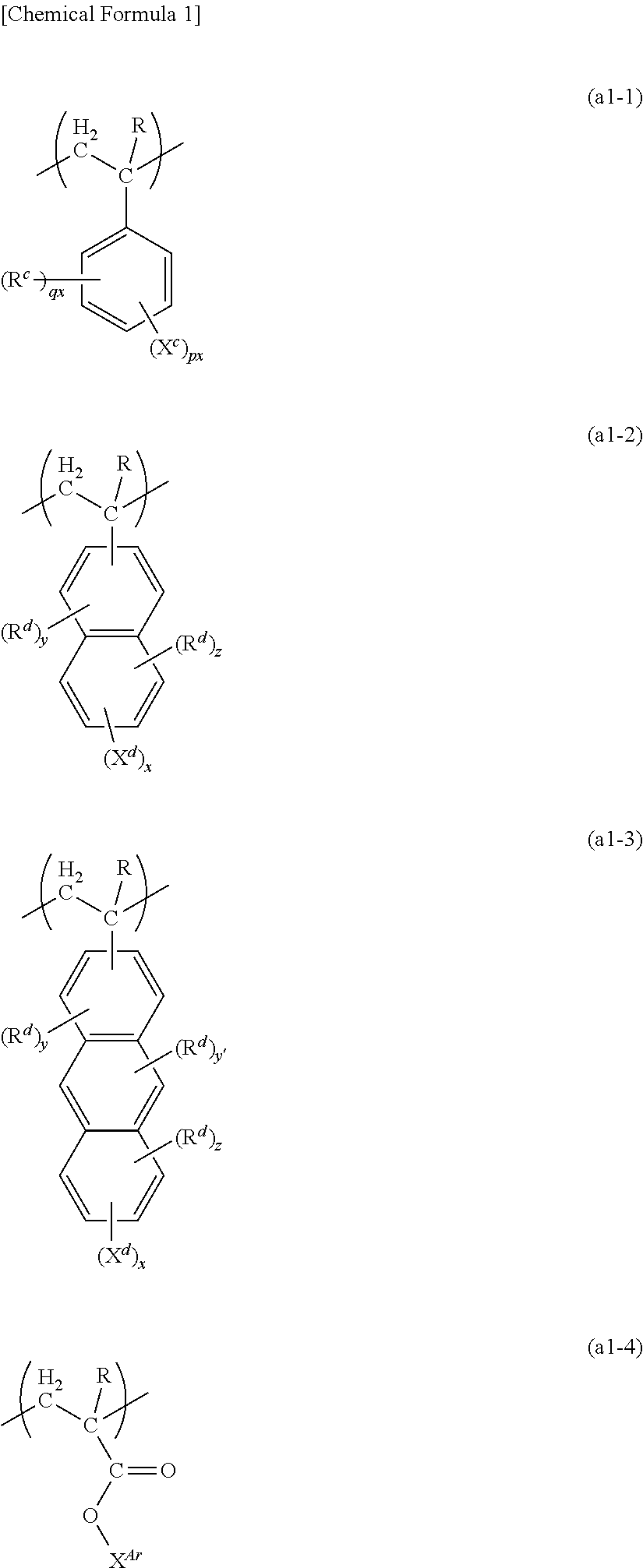

[0489]Polymeric compounds 1 to 9 were produced by a conventional method using the following monomers (1) to (8) which derived the structural units constituting each polymeric compound with a molar ratio indicated in Table 1. The molecular weight (Mw) and the molecular weight distribution (Mw / Mn) of the obtained polymeric compounds are shown in Table 1.

TABLE 1Polymeric Compound123456789Monomer(1)8585858590709292(2)70(3)2530(4)15855533(5)1575(6)10(7)5(8)5Mw4000010000400001000001000020000400005770057700Mw / Mn1.91.61.81.71.81.71.71.71.7

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pKa | aaaaa | aaaaa |

| pKa | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap