Biomass pyrolysis furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

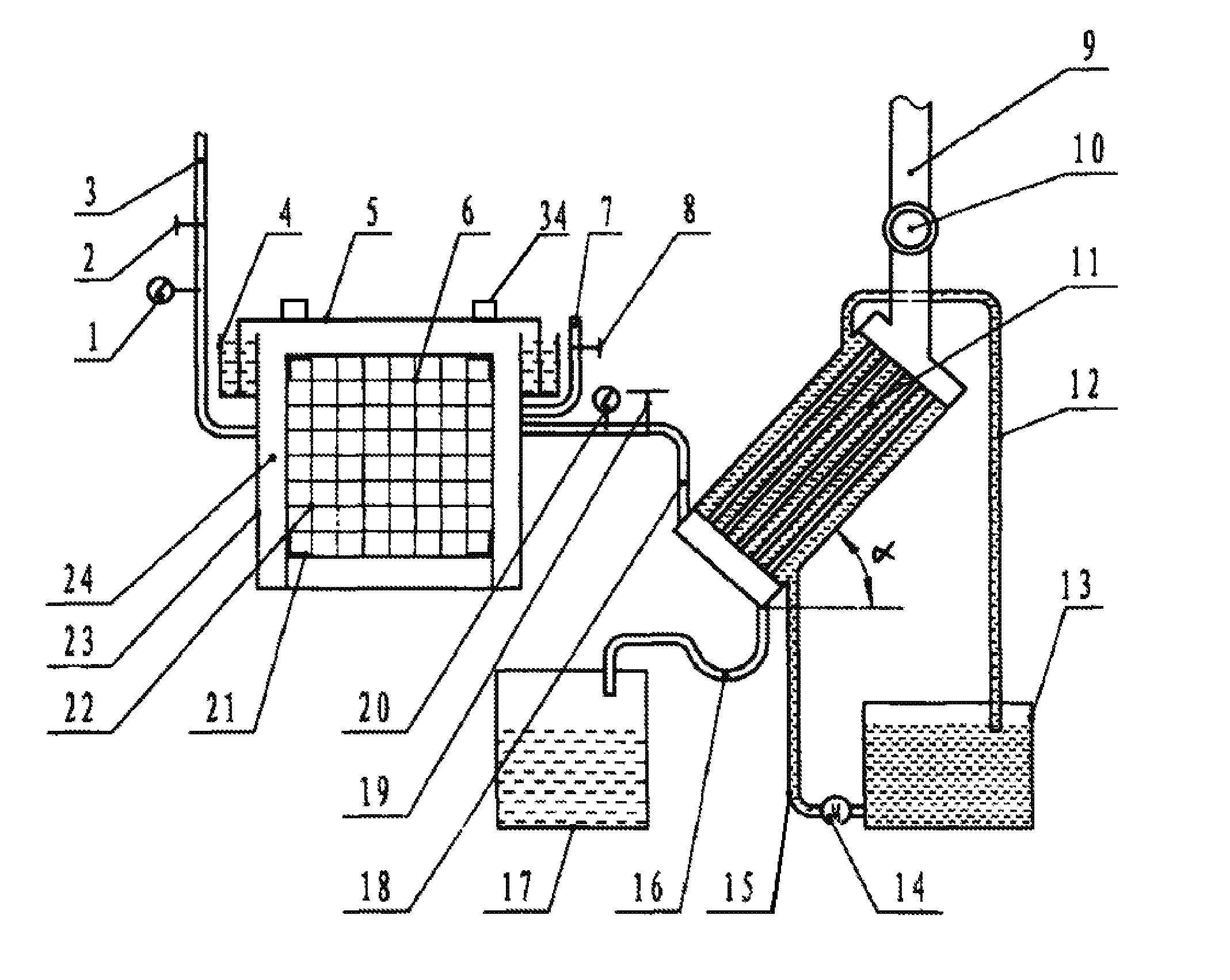

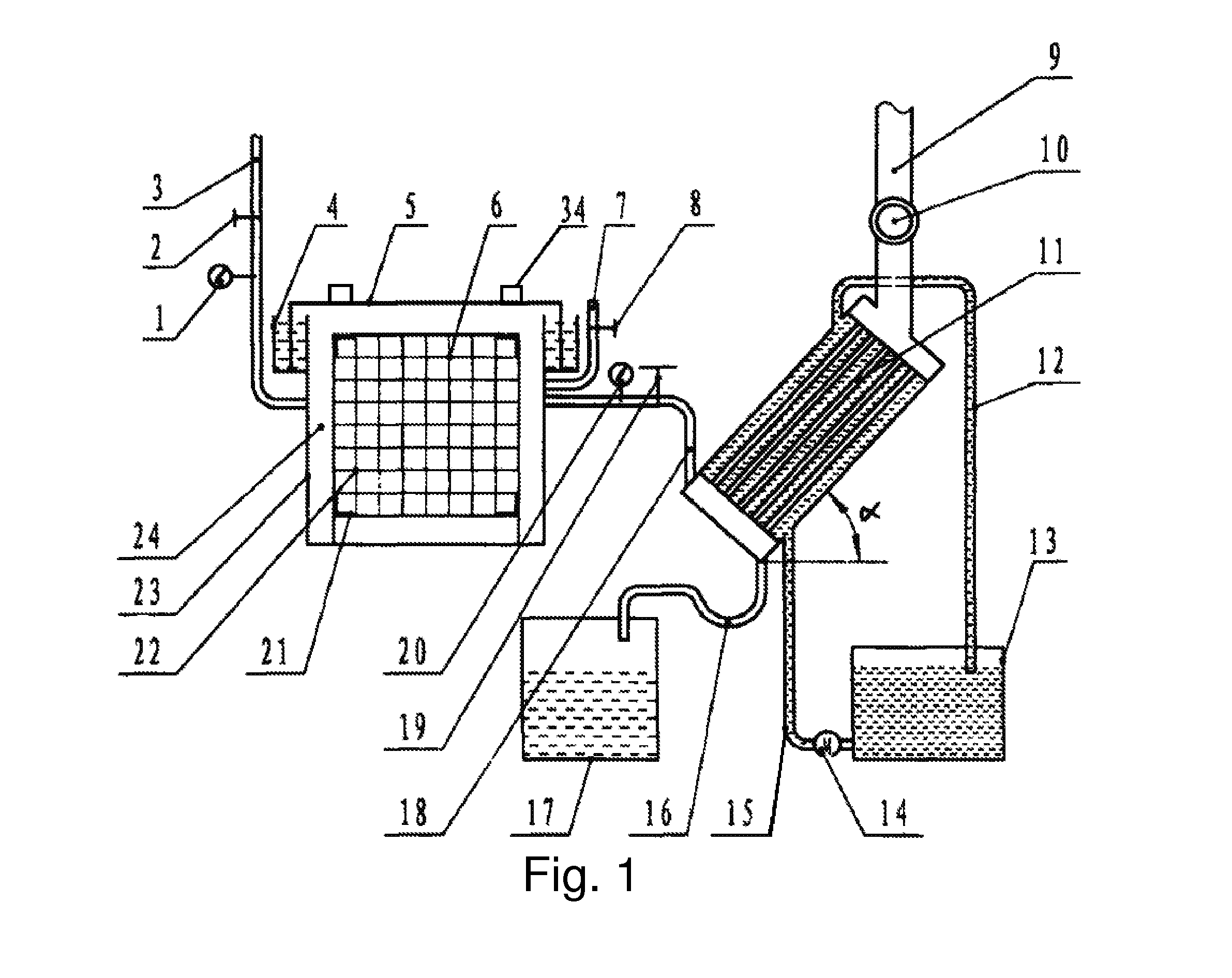

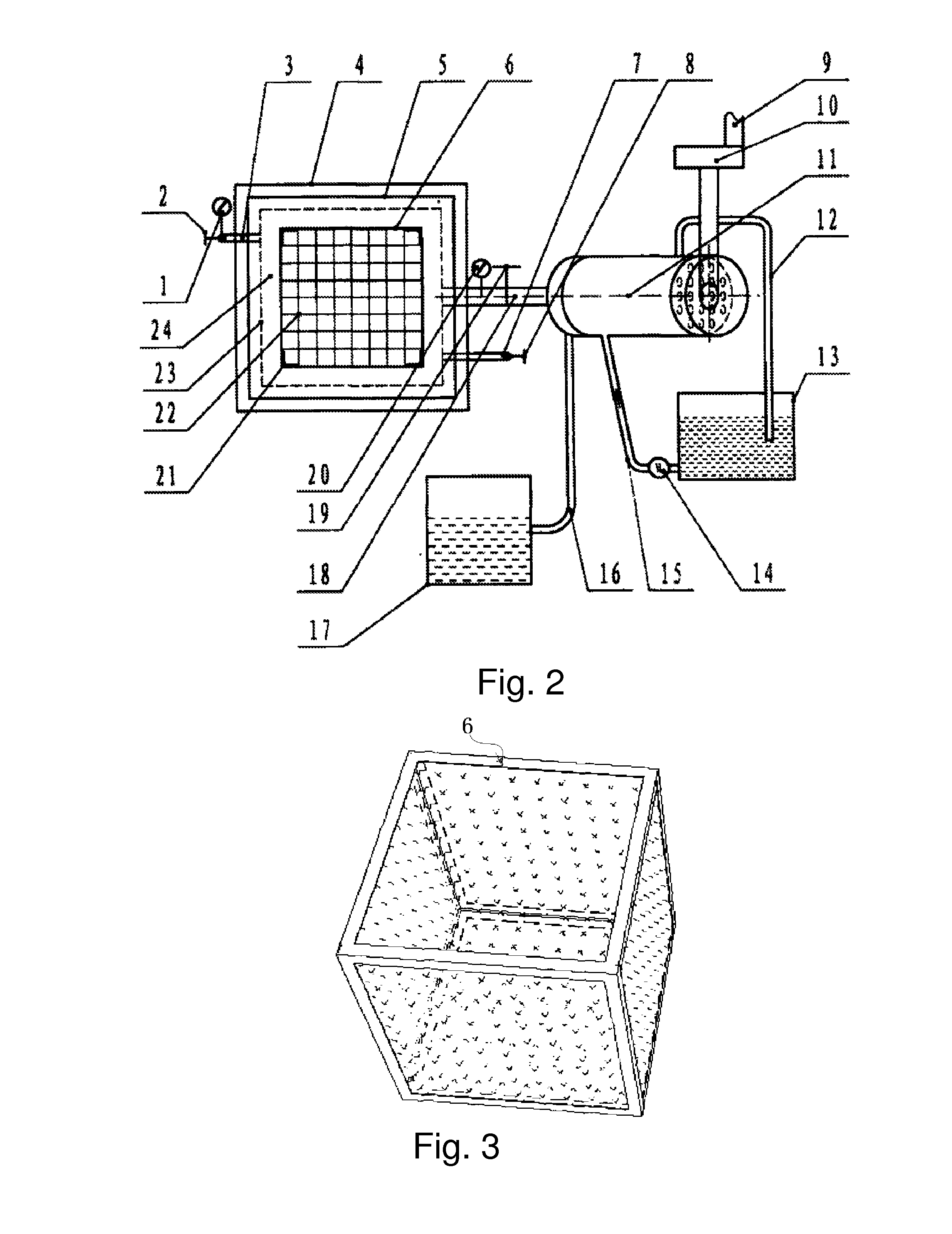

[0058]A biomass pyrolysis furnace as shown in FIG. 1 and FIG. 2, comprises a furnace shell 23, a furnace container 6, an exhaust pipe 3, an intake pipe 7, a smoke pipe 18, a recovery tower 11. The smoke pipe 18 is installed on the furnace shell 23, and the furnace container 6 is installed in the furnace shell 23. The bottom of the furnace container 6 and periphery thereof are provided with a plurality of mesh holes. An exhaust gap 24 which may be used for discharge of vapor is provided between the furnace container 6 and the inner surface of the wall of the furnace shell 23. The smoke pipe 18 is connected to the furnace shell 23 at one end thereof, and to the recovery tower 11 at the other end thereof.

[0059]The pyrolysis furnace shell 23 may be a six-side closed tank comprising a shell body and a water-seal cover 5. At its periphery, the furnace mouth of the shell body is provided with an U-shaped water-seal slot 4 which is full of water, as shown in FIGS. 7 and 8. The water-seal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com