Zero emissions pneumatic-electric engine

a technology of electric motors and pneumatics, applied in the field of engines, can solve the problems of low reluctance, weak magnetic field, and reduced engine efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

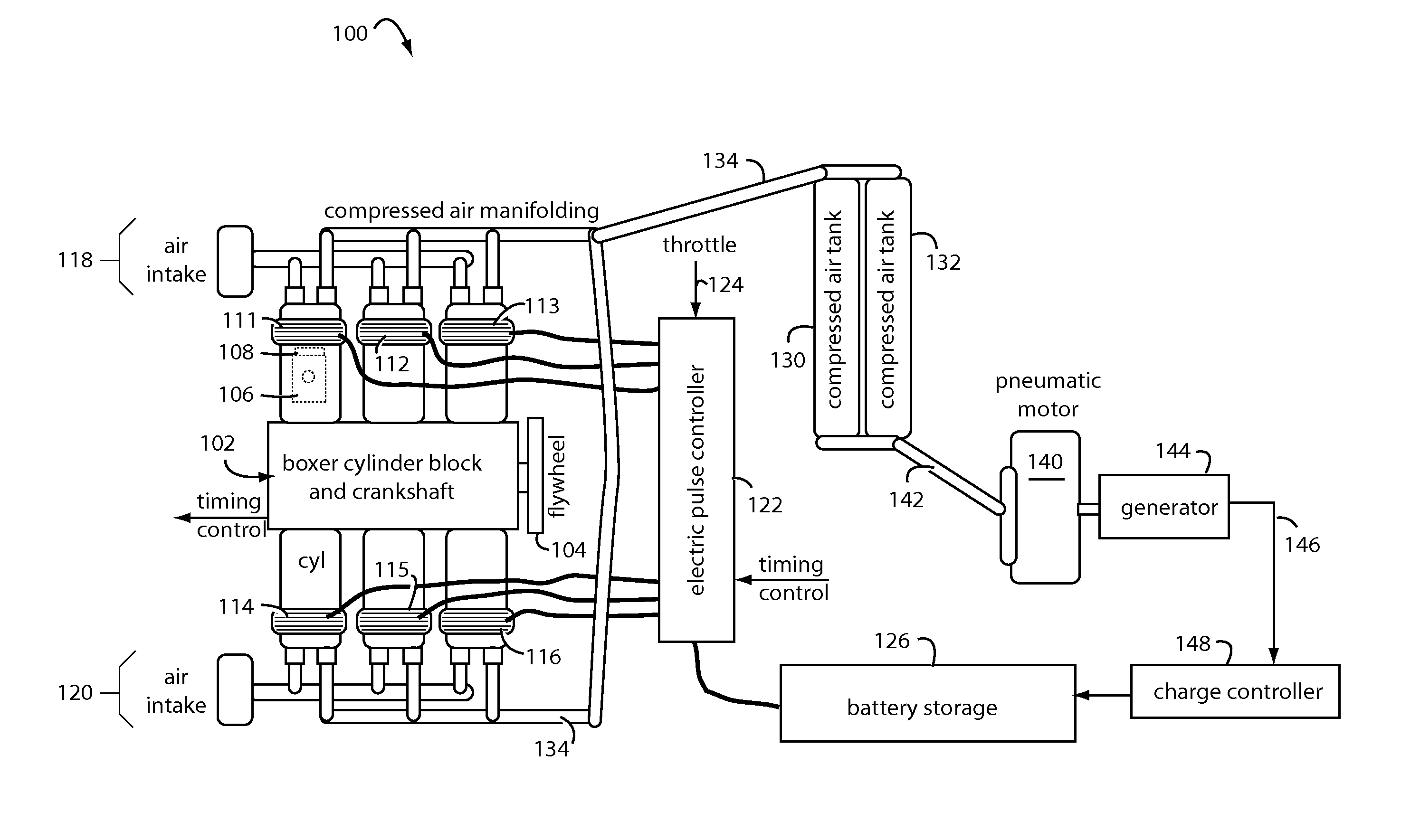

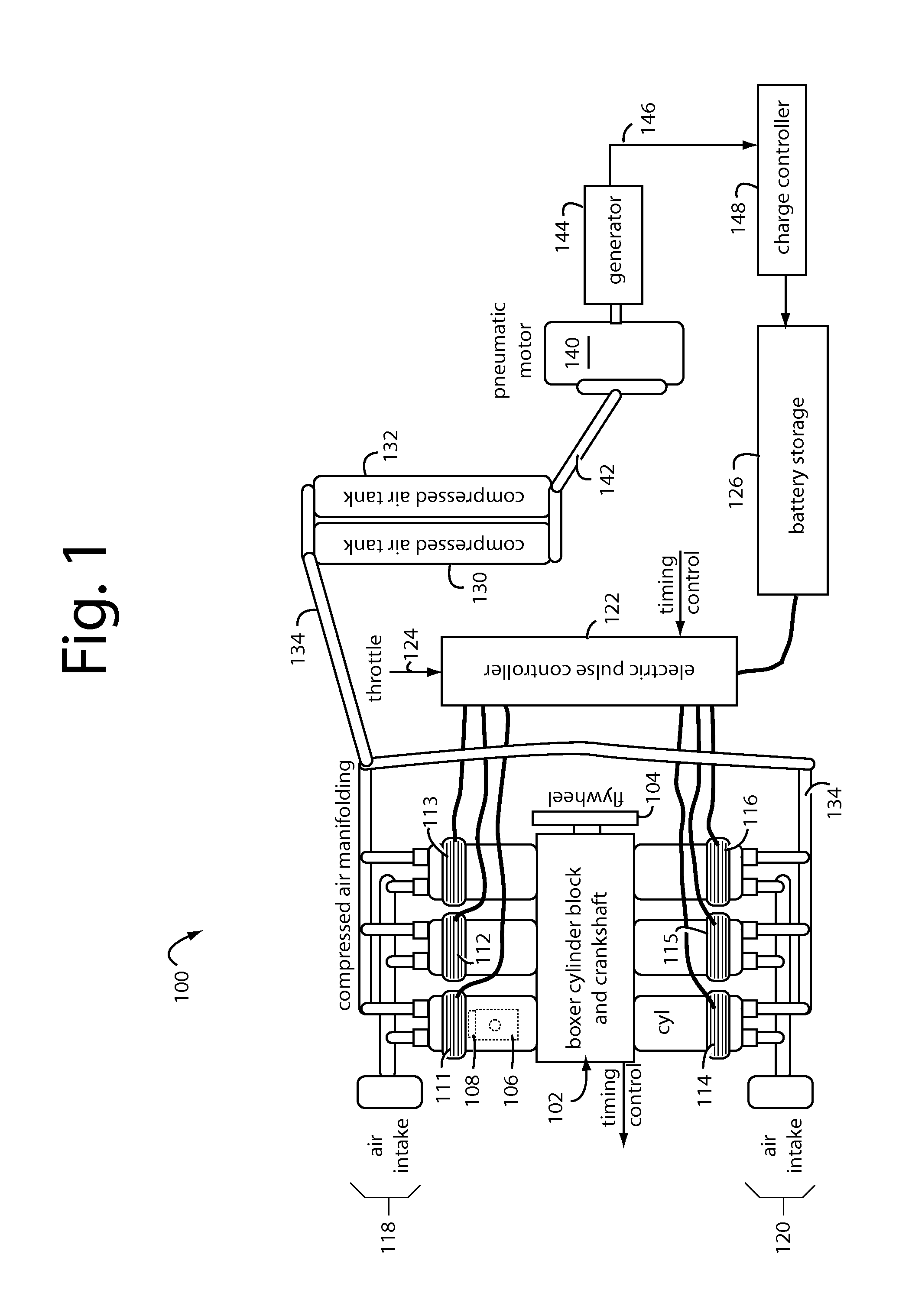

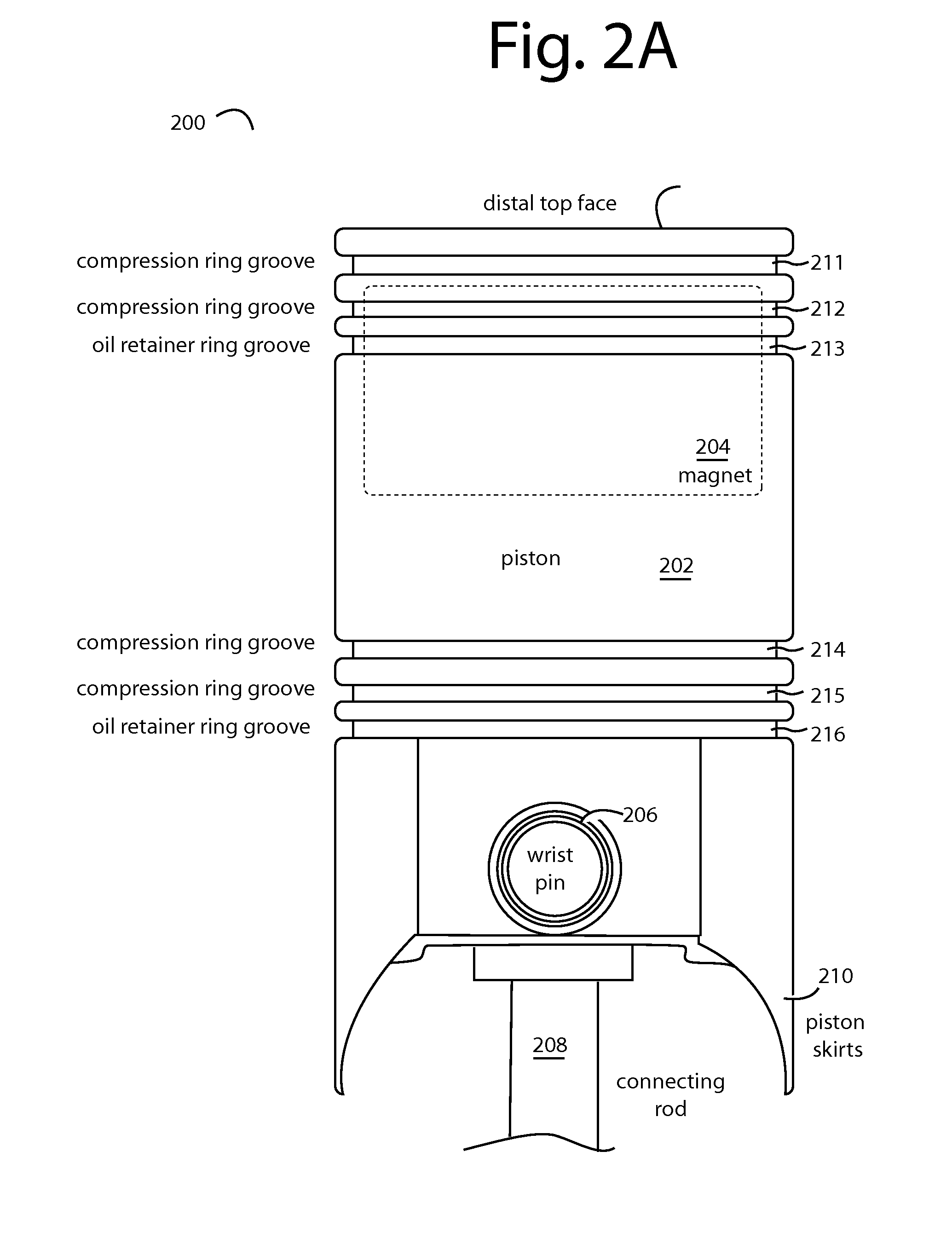

[0058]the present invention provides reciprocating electric engine with an electro-magnetic pulsed coil firing an electro-magnetic element loaded piston, where the piston face and the electro-magnetic coil face have opposing magnetic fields.

second embodiment

[0059]the present invention provides an electro-magnetic means through polarity switching that captures the magnet in a piston and acts upon it in such a manner that pushes and pulls the piston assembly. This configuration captures the piston in an electro-magnetic collapsing, energizing, and reversing manner.

third embodiment

[0060]the present invention provides an electromagnetic means to pull or attract the magnet in a piston serving to increase the reciprocating speeds capability by not reversing polarity of the magnetic field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com